设计简介

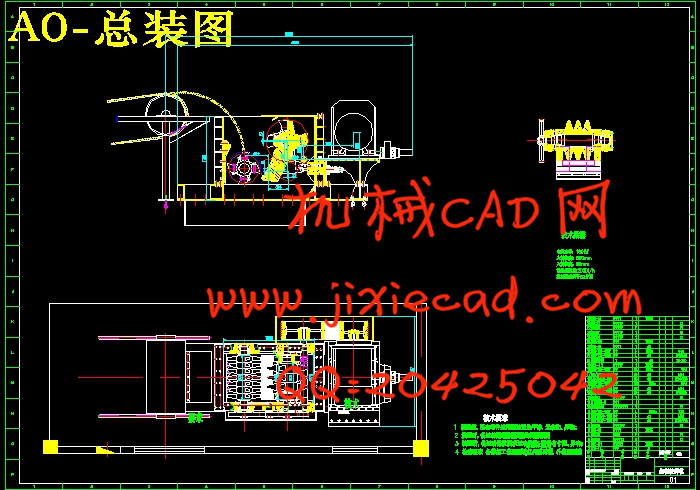

摘要:新型双齿辊破碎机由于结构紧凑,破碎物料机理合理,适应性强等突出的优点,在露天矿物料粗碎应用中很有发展前途,是较为理想的露天矿岩石破碎机。

本设计所涉及的新型的辊颚破碎机结合了颚式破碎机和齿辊破碎机的优点,使生产能力得到了很大的提高,出料粒度的均一性得到了很好的保证,使物料得到了有效的破碎,这是有生产的实践为证的。本文首先对新型双齿辊破碎机进行了电机的选择、传动机构的设计;然后对齿辊的参数进行计算,包括:输入轴、偏心轴、小齿辊轴的结构设计及校核等;最后进行键的选择及校核,包括:电机轴上、输入轴上、偏心轴上、小齿辊轴上的键。

关键词:新型双齿辊破碎机 颚式破碎机 结构设计

Abstract: Mineral sizer because the structure is compact, broken material mechanism is reasonable, strong adaptability of such prominent advantages, the original material crushing application promising, is the ideal open-pit mine rock crusher.

The design of the new type of roller involved jaw crusher combines jaw crusher and the advantages of the teeth roll crusher, make the production capacity were greatly increased, the grain-size homogeneity of got a very good guarantee, make the material effectively of broken, it is the practice of production for the card. This paper first to mineral sizer the choice of the motor, a transmission mechanism design; And then the teeth roll the parameters of the computation, including: input shaft, eccentric shaft, small teeth of the roller structure design and check; The last key selection and checking, including: motor shaft, input shaft, eccentric shaft on small teeth, the key on the roller.

keywords: mineral sizer jaw crusher structure design

目 录

1 前言···························································2

2 齿辊破碎机的电机选择及传动机构设计······················4

2.1 产品的技术参数·················································4

2.2 电机选型·······················································4

2.2.1 电机功率计算···············································4

2.2.2 电机选择···················································4

2.3 传动机构的设计及计算···········································5

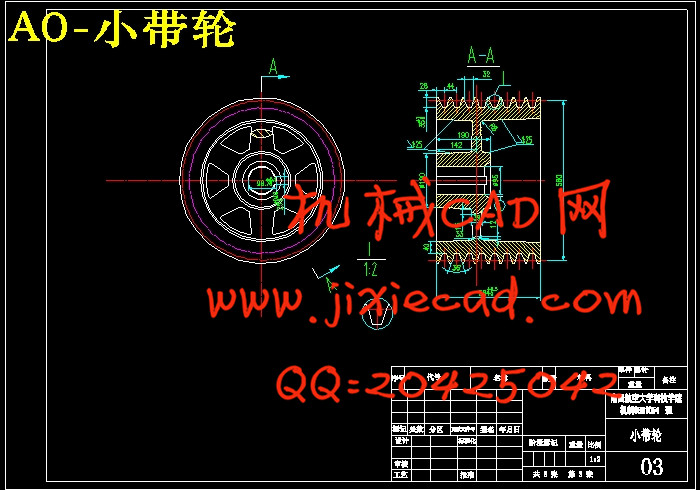

2.3.1 带传动的设计计算···········································5

2.3.2 齿轮传动设计计算···········································7

3 齿辊参数计算·················································7

3.1 传统的颚式破碎机和辊式破碎机··································12

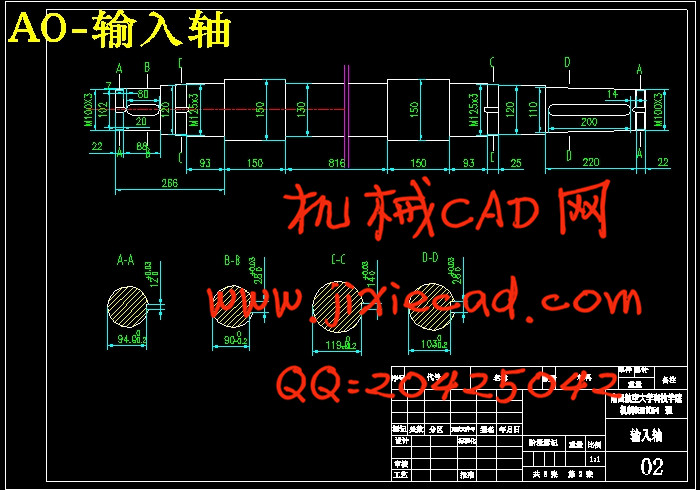

3.2 输入轴的结构设计及校核·······································24

3.3 偏心轴的结构设计及校核·······································30

3.4 小齿辊轴的结构设计及校核·····································35

3.5 新型齿辊破碎机的设计·········································40

4 键的选择及其校核···········································41

4.1 电机轴上键的选择及校核········································41

4.2 输入轴上键的选择及校核········································41

4.3 偏心轴上键的选择及校核········································42

4.4 小齿辊轴上键的选择及校核······································43

5 结论··························································45

参考文献·························································46

致谢······························································47

本设计所涉及的新型的辊颚破碎机结合了颚式破碎机和齿辊破碎机的优点,使生产能力得到了很大的提高,出料粒度的均一性得到了很好的保证,使物料得到了有效的破碎,这是有生产的实践为证的。本文首先对新型双齿辊破碎机进行了电机的选择、传动机构的设计;然后对齿辊的参数进行计算,包括:输入轴、偏心轴、小齿辊轴的结构设计及校核等;最后进行键的选择及校核,包括:电机轴上、输入轴上、偏心轴上、小齿辊轴上的键。

关键词:新型双齿辊破碎机 颚式破碎机 结构设计

Abstract: Mineral sizer because the structure is compact, broken material mechanism is reasonable, strong adaptability of such prominent advantages, the original material crushing application promising, is the ideal open-pit mine rock crusher.

The design of the new type of roller involved jaw crusher combines jaw crusher and the advantages of the teeth roll crusher, make the production capacity were greatly increased, the grain-size homogeneity of got a very good guarantee, make the material effectively of broken, it is the practice of production for the card. This paper first to mineral sizer the choice of the motor, a transmission mechanism design; And then the teeth roll the parameters of the computation, including: input shaft, eccentric shaft, small teeth of the roller structure design and check; The last key selection and checking, including: motor shaft, input shaft, eccentric shaft on small teeth, the key on the roller.

keywords: mineral sizer jaw crusher structure design

目 录

1 前言···························································2

2 齿辊破碎机的电机选择及传动机构设计······················4

2.1 产品的技术参数·················································4

2.2 电机选型·······················································4

2.2.1 电机功率计算···············································4

2.2.2 电机选择···················································4

2.3 传动机构的设计及计算···········································5

2.3.1 带传动的设计计算···········································5

2.3.2 齿轮传动设计计算···········································7

3 齿辊参数计算·················································7

3.1 传统的颚式破碎机和辊式破碎机··································12

3.2 输入轴的结构设计及校核·······································24

3.3 偏心轴的结构设计及校核·······································30

3.4 小齿辊轴的结构设计及校核·····································35

3.5 新型齿辊破碎机的设计·········································40

4 键的选择及其校核···········································41

4.1 电机轴上键的选择及校核········································41

4.2 输入轴上键的选择及校核········································41

4.3 偏心轴上键的选择及校核········································42

4.4 小齿辊轴上键的选择及校核······································43

5 结论··························································45

参考文献·························································46

致谢······························································47