设计简介

摘要

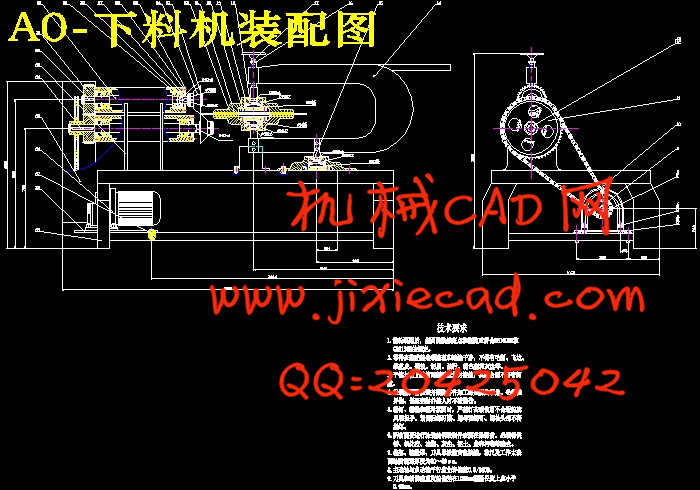

大直径圆片下料机是一种小型的集经济性、实用性于一体的机器。

该机床是在前人的设计基础上进行了一些改进和优化,主要包含了以下几个方面。

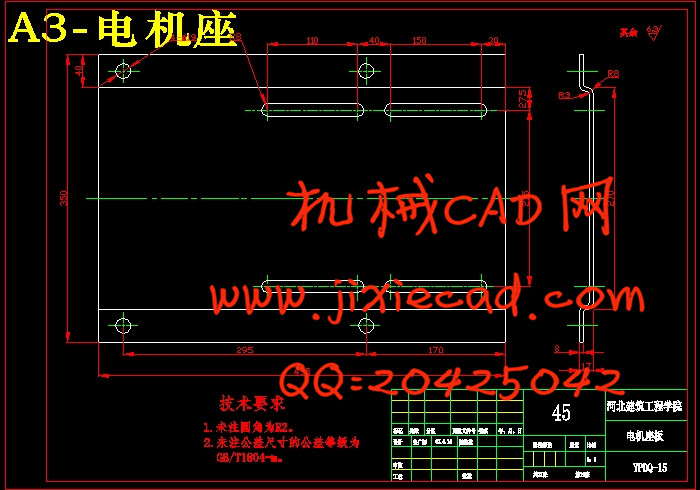

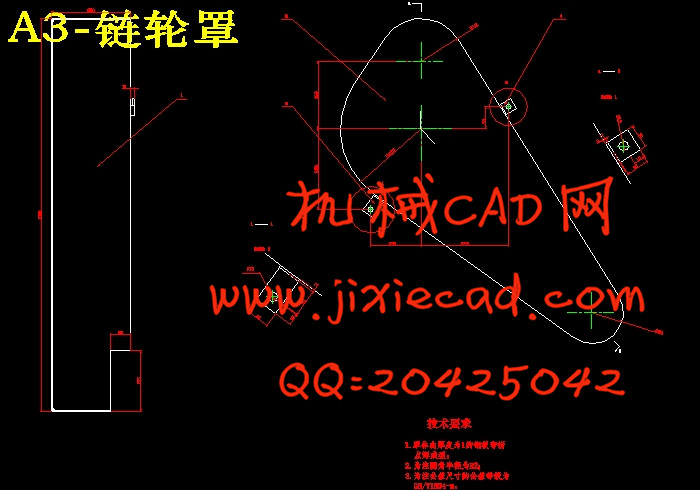

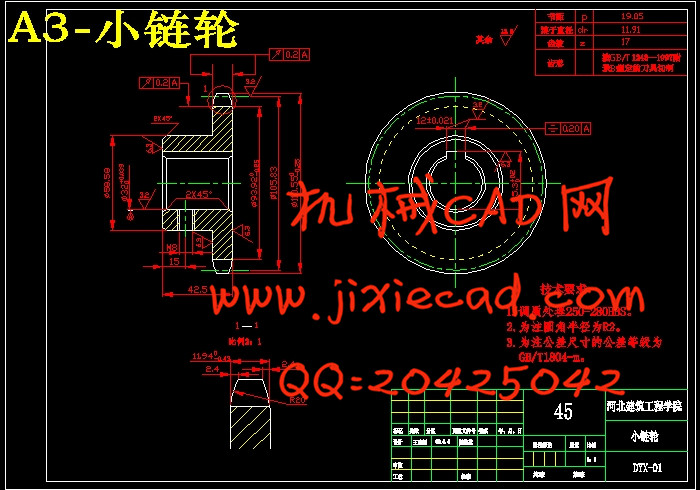

选用减速电动机作动力,简化了传动系统,用链传动代替以前的带传动,在调整了剪切进给速度的同时满足了传递低速大扭矩动力的要求,优化了机床的传动系统,此为创新点之一。

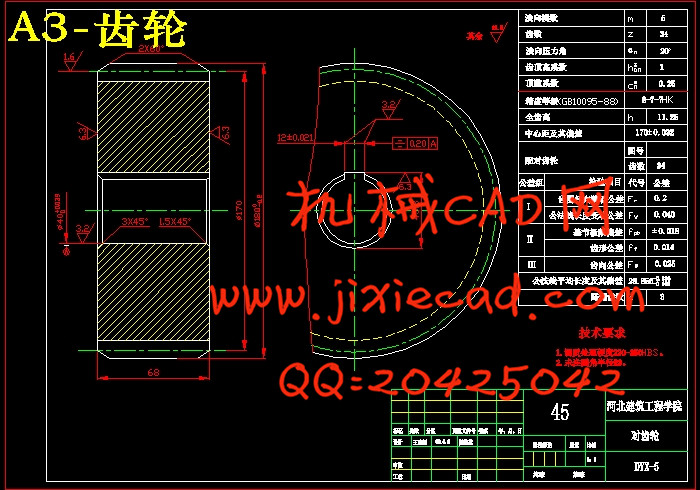

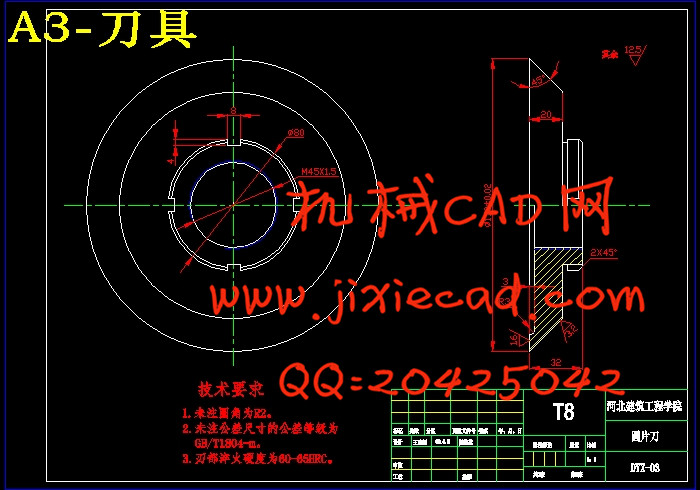

在该装置中应用了对齿轮传动,圆刀剪切,夹持装置的设计尤为重要,大直径圆片下料机的一个鲜明特点就是大直径,它主要生产的是大直径的铝板,所以加紧装置必须要可靠,以防出现在剪切过程中出现铝板偏移的现象。另外,刀具在剪切的过程中要承受一定的力,所以连接刀片的支架要有足够的强度来承受该力。

关键词:圆刀 、夹持装置、减速电动机、对齿轮、大直径。

ABSTRACT

The big dia wafer blank device is one kind of small collection efficiency, the usability in a body machine.

This engine bed has made some improvements and the optimization in the predecessor round thin-bladed knife bar cutter foundation, mainly has contained following three innovation spot:

Selects decelerates the electric motor to make the power, simplified the transmission system, replaces beforehand belt transmission with the chain drive, while adjusted cutting feed rate to satisfy the transmission low speed great torque power request, optimized the engine bed transmission system, this first of for innovation.

It apply the duet gear transmission and the grooving tool cut in this apparatus .The design of the holding device is very important,A rarely peculiarity of the big dia wafer blank device is big dia,it mainly product the aluminium plate of the big dia,so holding device must be reliable,be prepared arise the aluminium plate departure in cut process .In addition the cutters bearing a little of force in cut process,so the backing that concatenation cutters should have enough density that concatenation cutters to bearing strength .

Key word: Circle cuts, Holding device, decelerates the electric motor, duet gear transmission, big dia

目录

第1章 前言··········································································1

第2章 总体设计····································································5

2.1 概述············································································5

2.2确定总体设计方案····························································5

第3章 各部分的设计····························································8

3.1确定选用电机的型号·························································8

3.2传动系统设计·································································10

第4章 参数的确定·······························································21

4.1键的校核·······································································21

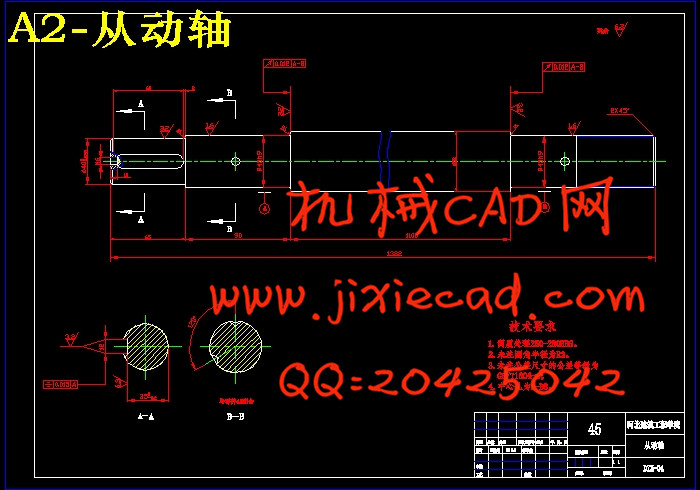

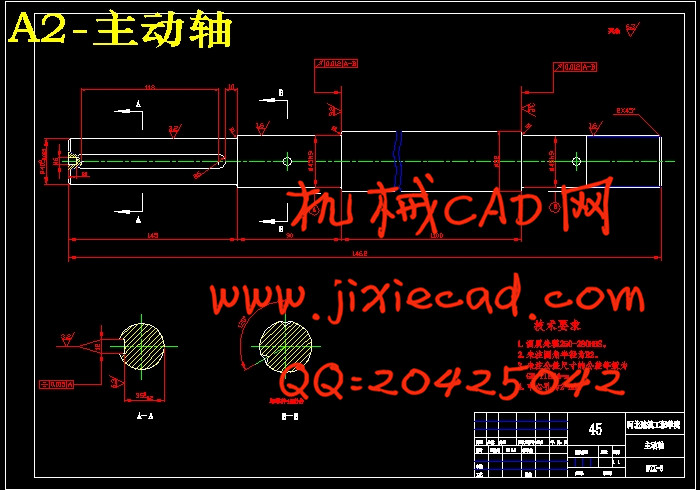

4.2工作轴的校核·································································23

设计小结············································································41

参考文献············································································44

大直径圆片下料机是一种小型的集经济性、实用性于一体的机器。

该机床是在前人的设计基础上进行了一些改进和优化,主要包含了以下几个方面。

选用减速电动机作动力,简化了传动系统,用链传动代替以前的带传动,在调整了剪切进给速度的同时满足了传递低速大扭矩动力的要求,优化了机床的传动系统,此为创新点之一。

在该装置中应用了对齿轮传动,圆刀剪切,夹持装置的设计尤为重要,大直径圆片下料机的一个鲜明特点就是大直径,它主要生产的是大直径的铝板,所以加紧装置必须要可靠,以防出现在剪切过程中出现铝板偏移的现象。另外,刀具在剪切的过程中要承受一定的力,所以连接刀片的支架要有足够的强度来承受该力。

关键词:圆刀 、夹持装置、减速电动机、对齿轮、大直径。

ABSTRACT

The big dia wafer blank device is one kind of small collection efficiency, the usability in a body machine.

This engine bed has made some improvements and the optimization in the predecessor round thin-bladed knife bar cutter foundation, mainly has contained following three innovation spot:

Selects decelerates the electric motor to make the power, simplified the transmission system, replaces beforehand belt transmission with the chain drive, while adjusted cutting feed rate to satisfy the transmission low speed great torque power request, optimized the engine bed transmission system, this first of for innovation.

It apply the duet gear transmission and the grooving tool cut in this apparatus .The design of the holding device is very important,A rarely peculiarity of the big dia wafer blank device is big dia,it mainly product the aluminium plate of the big dia,so holding device must be reliable,be prepared arise the aluminium plate departure in cut process .In addition the cutters bearing a little of force in cut process,so the backing that concatenation cutters should have enough density that concatenation cutters to bearing strength .

Key word: Circle cuts, Holding device, decelerates the electric motor, duet gear transmission, big dia

目录

第1章 前言··········································································1

第2章 总体设计····································································5

2.1 概述············································································5

2.2确定总体设计方案····························································5

第3章 各部分的设计····························································8

3.1确定选用电机的型号·························································8

3.2传动系统设计·································································10

第4章 参数的确定·······························································21

4.1键的校核·······································································21

4.2工作轴的校核·································································23

设计小结············································································41

参考文献············································································44