设计简介

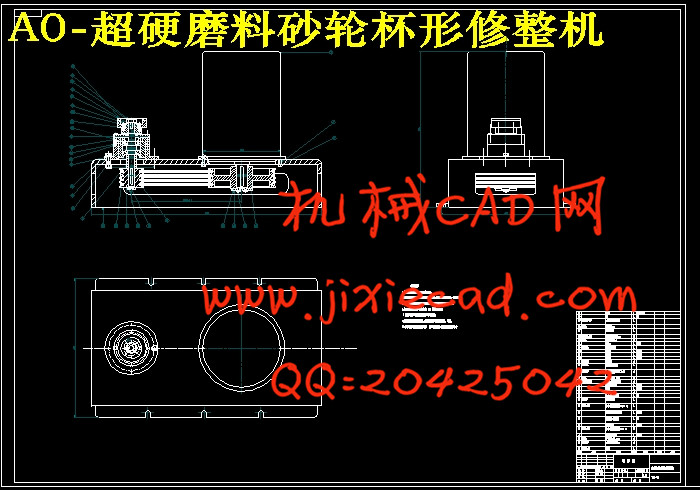

超硬磨料砂轮杯形修整器

摘要:本文主要阐述了超硬磨料砂轮杯形修整器的设计结构原理,为了满足生产的需要,设计制作了砂轮修整器,安装在磨床上进行修整砂轮,完成工件加工。砂轮修整器具有结构简单,轻巧,使用方便等特点,可对普通和超硬型砂轮进行整修。该修整器采用SiC 磨料杯形砂轮作为修整工具可以对超硬磨料砂轮完成修形和修锐工作,并利用变频器实现修整时的无级调速以达到最佳修整效果。杯形砂轮修整技术可以获得较好的砂轮磨削性能以及修整效率。

关键词:修整器设计;杯形砂轮;超硬磨料砂轮;修整;磨削力

Dresser of Cup Superabrasives Wheel Finisher Designs

Abstract :The article mainly elaborated the dresser of cup superabrasives wheel finisher design structure principle, in order to satisfy the production the need, the design has manufactured the grinding wheel finisher, installs carries on the truing of grinding wheel on the grinder, completes the work piece processing. The grinding wheel finisher has the structure to be simple, dexterous, characteristics and so on easy to operate, may carry on the renovation to ordinary and the ultra hard grinding wheel. The dresser of cup superabrasives wheel which is used for truing and dressing the grinding wheel by SiC cup wheel. Through a frequency converter , the dresser can adjust the rotating speed of cup wheel to achieve the best grinding parameters in dressing process. The cup truing technology is often adopted to obtain fine grinding performance and truing efficiency.

Keywords:design of dresser; cup wheel; superabrasives wheel; truing and dressing; grinding force

目 录

第一章 绪论

1.1超硬磨料砂轮的概述……………………………………………………………1

1.1.1 超硬磨料的性能……………………………………………………………1

1.1.2 超硬磨料砂轮的种类………………………………………………………2

1.1.3 超硬磨料砂轮特性及其磨削加工特点……………………………………4

1.2超硬磨料砂轮的应用现状和发展趋势……………………………………………5

1.2.1超硬磨料砂轮的应用现状…………………………………………………5

1.2.2 超硬磨料砂轮的发展趋势…………………………………………………8

1.3 超硬磨料砂轮杯形修整器的设计意义……………………………………………9

1.4 超硬磨料砂轮杯形修整器的国内研究现状……………………………………11

第二章 总体设计方案……………………………………………………………16

2.1设计的主要内容………………………………………………………………16

2.2设计要求………………………………………………………………………17

2.3设计的主要参数………………………………………………………………17

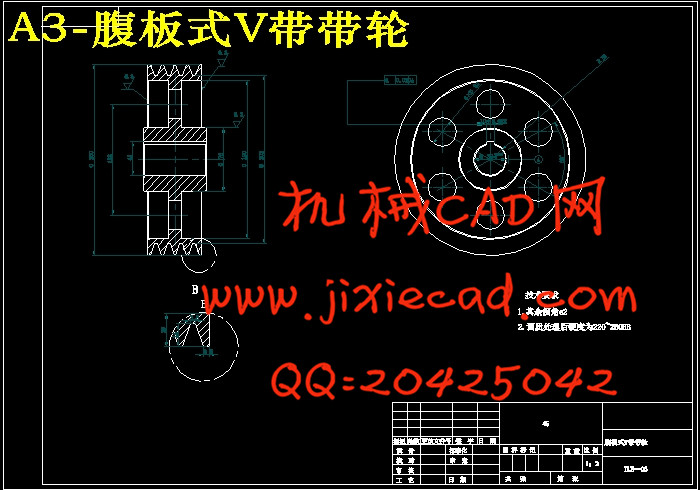

2.4传动方案的设计………………………………………………………………17

2.5电机的选择……………………………………………………………………21

2.6变频电机原理简介及其选择…………………………………………………21

第三章 机械部分设计及其计算………………………………………………26

3.1传动系统简图…………………………………………………………………26

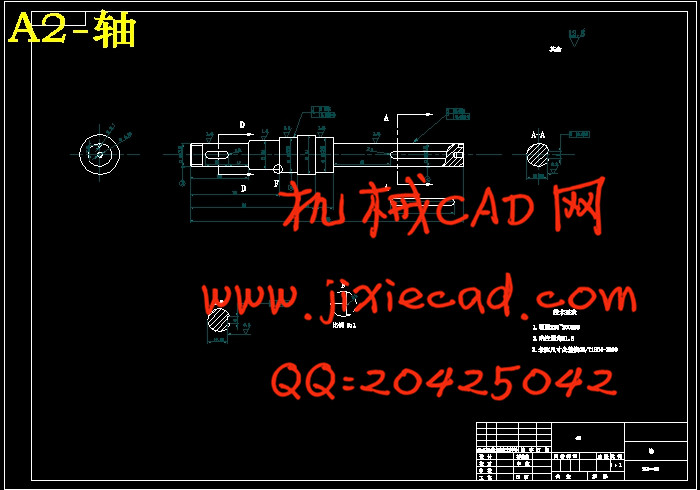

3.2 超硬磨料砂轮杯形修整器结构设计的相关计算…………………………26

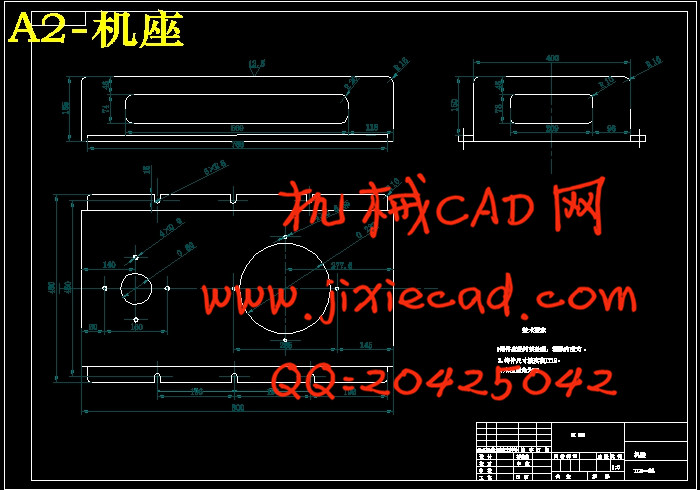

3.3 砂轮修整器的结构设计……………………………………………………29

结论……………………………………………………………………………………32

参考文献………………………………………………………………………………33

致谢……………………………………………………………………………………34

摘要:本文主要阐述了超硬磨料砂轮杯形修整器的设计结构原理,为了满足生产的需要,设计制作了砂轮修整器,安装在磨床上进行修整砂轮,完成工件加工。砂轮修整器具有结构简单,轻巧,使用方便等特点,可对普通和超硬型砂轮进行整修。该修整器采用SiC 磨料杯形砂轮作为修整工具可以对超硬磨料砂轮完成修形和修锐工作,并利用变频器实现修整时的无级调速以达到最佳修整效果。杯形砂轮修整技术可以获得较好的砂轮磨削性能以及修整效率。

关键词:修整器设计;杯形砂轮;超硬磨料砂轮;修整;磨削力

Dresser of Cup Superabrasives Wheel Finisher Designs

Abstract :The article mainly elaborated the dresser of cup superabrasives wheel finisher design structure principle, in order to satisfy the production the need, the design has manufactured the grinding wheel finisher, installs carries on the truing of grinding wheel on the grinder, completes the work piece processing. The grinding wheel finisher has the structure to be simple, dexterous, characteristics and so on easy to operate, may carry on the renovation to ordinary and the ultra hard grinding wheel. The dresser of cup superabrasives wheel which is used for truing and dressing the grinding wheel by SiC cup wheel. Through a frequency converter , the dresser can adjust the rotating speed of cup wheel to achieve the best grinding parameters in dressing process. The cup truing technology is often adopted to obtain fine grinding performance and truing efficiency.

Keywords:design of dresser; cup wheel; superabrasives wheel; truing and dressing; grinding force

| 技 术 参 数: | ||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

目 录

第一章 绪论

1.1超硬磨料砂轮的概述……………………………………………………………1

1.1.1 超硬磨料的性能……………………………………………………………1

1.1.2 超硬磨料砂轮的种类………………………………………………………2

1.1.3 超硬磨料砂轮特性及其磨削加工特点……………………………………4

1.2超硬磨料砂轮的应用现状和发展趋势……………………………………………5

1.2.1超硬磨料砂轮的应用现状…………………………………………………5

1.2.2 超硬磨料砂轮的发展趋势…………………………………………………8

1.3 超硬磨料砂轮杯形修整器的设计意义……………………………………………9

1.4 超硬磨料砂轮杯形修整器的国内研究现状……………………………………11

第二章 总体设计方案……………………………………………………………16

2.1设计的主要内容………………………………………………………………16

2.2设计要求………………………………………………………………………17

2.3设计的主要参数………………………………………………………………17

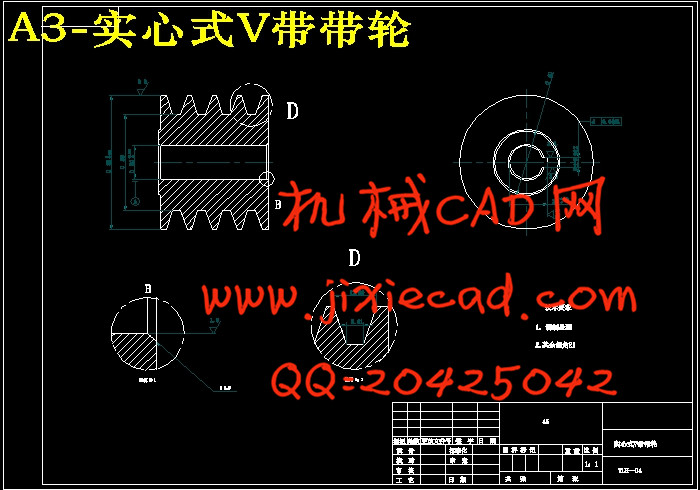

2.4传动方案的设计………………………………………………………………17

2.5电机的选择……………………………………………………………………21

2.6变频电机原理简介及其选择…………………………………………………21

第三章 机械部分设计及其计算………………………………………………26

3.1传动系统简图…………………………………………………………………26

3.2 超硬磨料砂轮杯形修整器结构设计的相关计算…………………………26

3.3 砂轮修整器的结构设计……………………………………………………29

结论……………………………………………………………………………………32

参考文献………………………………………………………………………………33

致谢……………………………………………………………………………………34