设计简介

摘要

超声波清洗是属于物理力清洗,并且其本身是绿色清洗,如在清洗液中添加适宜的清洗剂,则属于组合清洗,更具明显的清洗效果。超声波清洗是功率超声中应用最为广泛的一种,超声波清洗作为现代一种重要的清洗方式,与现代科技发展及先进制造工艺密切相关。超声波清洗在各种化学、物理及机械的清洗中是高效的的一种清洗方法,随着科学技术的高速发展,超声波清洗技术已被广泛应用于机械、光学、电子、纺织、轻工、化工、船舶、航空航天、原子能以及医疗医药各领域。超声波可以对工件施加非常大的能量,对有些表面形状复杂的精密零部件来说,提高零部件清洁水平不仅可以降低设备的振动和噪声,还可以提高使用寿命和可靠性。此次设计的超声波清洗机主要应用于精密零件的清洗,例如中小齿轮、轴承的清洗。利用高能量的超声波可以穿透固体物质而使整个清洗介质振动并产生空化气泡,该清洗方式对待清洗件不存在清洗不到的死角,不仅如此,且清洗洁净度非常高。

关键词:超声波;换能器;清洗机

Abstract

Belongs to physical cleaning, ultrasonic cleaning and cleaning itself is green, such as the appropriate cleaning agent is added in the cleaning fluid, belong to combination cleaning, cleaning effect is more obvious. Ultrasonic cleaning is one of the most widely used in ultrasonic power, ultrasonic cleaning, as a kind of important modern cleaning method, is closely related to the development of modern science and technology and advanced manufacturing technology. Ultrasonic cleaning in all kinds of chemical, physical and mechanical cleaning is one of the efficient cleaning method, with the rapid development of science and technology, ultrasonic cleaning technology has been widely used in machinery, optics, electronics, textile, light industry, chemical industry, shipbuilding, aerospace, atomic energy, and medical treatment in various fields. Ultrasound can apply for very big energy, for some complex shape surface precision components, and improve the level of parts cleaning can not only reduce the vibration and noise of device, also can improve the service life and reliability. The design of the ultrasonic cleaning machine is mainly used in precision parts cleaning, such as small gears, bearings cleaning. Using high-energy ultrasound can penetrate solid matter and make the overall vibration and cavitation bubble cleaning media, the cleaning method to clean corner, there is no cleaning not only that, and washing cleanliness is very high.

Keywords:ultrasonic;transducer;Cleaner

目录

第1章 绪论 1超声波清洗是属于物理力清洗,并且其本身是绿色清洗,如在清洗液中添加适宜的清洗剂,则属于组合清洗,更具明显的清洗效果。超声波清洗是功率超声中应用最为广泛的一种,超声波清洗作为现代一种重要的清洗方式,与现代科技发展及先进制造工艺密切相关。超声波清洗在各种化学、物理及机械的清洗中是高效的的一种清洗方法,随着科学技术的高速发展,超声波清洗技术已被广泛应用于机械、光学、电子、纺织、轻工、化工、船舶、航空航天、原子能以及医疗医药各领域。超声波可以对工件施加非常大的能量,对有些表面形状复杂的精密零部件来说,提高零部件清洁水平不仅可以降低设备的振动和噪声,还可以提高使用寿命和可靠性。此次设计的超声波清洗机主要应用于精密零件的清洗,例如中小齿轮、轴承的清洗。利用高能量的超声波可以穿透固体物质而使整个清洗介质振动并产生空化气泡,该清洗方式对待清洗件不存在清洗不到的死角,不仅如此,且清洗洁净度非常高。

关键词:超声波;换能器;清洗机

Abstract

Belongs to physical cleaning, ultrasonic cleaning and cleaning itself is green, such as the appropriate cleaning agent is added in the cleaning fluid, belong to combination cleaning, cleaning effect is more obvious. Ultrasonic cleaning is one of the most widely used in ultrasonic power, ultrasonic cleaning, as a kind of important modern cleaning method, is closely related to the development of modern science and technology and advanced manufacturing technology. Ultrasonic cleaning in all kinds of chemical, physical and mechanical cleaning is one of the efficient cleaning method, with the rapid development of science and technology, ultrasonic cleaning technology has been widely used in machinery, optics, electronics, textile, light industry, chemical industry, shipbuilding, aerospace, atomic energy, and medical treatment in various fields. Ultrasound can apply for very big energy, for some complex shape surface precision components, and improve the level of parts cleaning can not only reduce the vibration and noise of device, also can improve the service life and reliability. The design of the ultrasonic cleaning machine is mainly used in precision parts cleaning, such as small gears, bearings cleaning. Using high-energy ultrasound can penetrate solid matter and make the overall vibration and cavitation bubble cleaning media, the cleaning method to clean corner, there is no cleaning not only that, and washing cleanliness is very high.

Keywords:ultrasonic;transducer;Cleaner

目录

1.1 超声波及超声波清洗的认识 1

1.2 超声波清洗的应用与发展 1

1.3 本次设计的创新 1

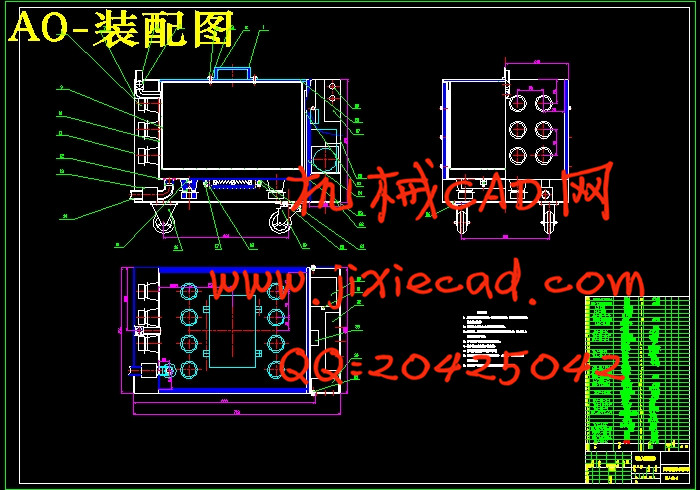

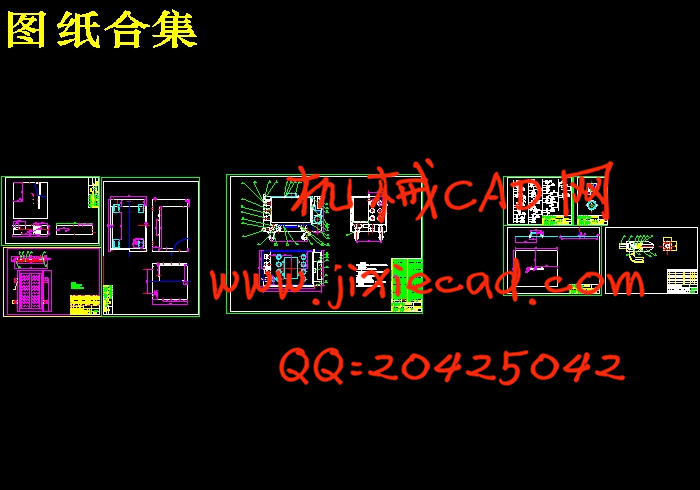

第2章 超声波清洗机原理与结构 2

2.1 超声波清洗机的原理与特点 2

2.2 超声波清洗机的结构和参数设定 5

2.2.1 超声波清洗机结构设计 5

2.2.2 超声波清洗机参数设定 5

第3章 超声波发生器的设计 6

3.1超声波发生器的选择 6

3.2超声波发生器的设计 6

3.2.1超声波振荡器的设计 6

3.2.2 超声波放大器的设计 9

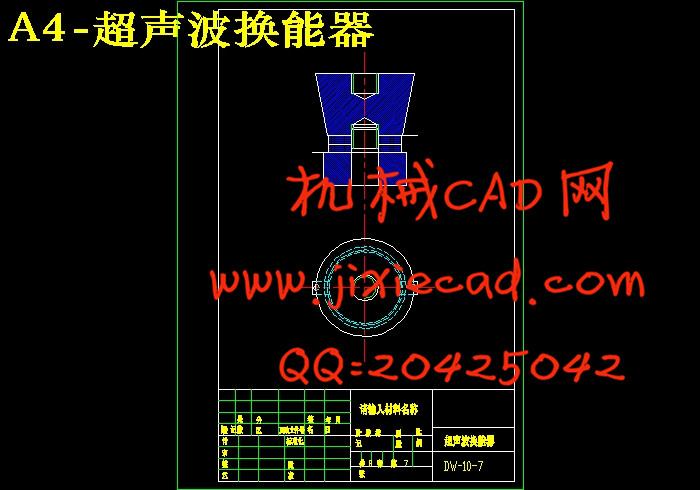

第4章 超声换能器的设计 13

4.1 超声换能器的选择 13

4.2 超声换能器的设计 13

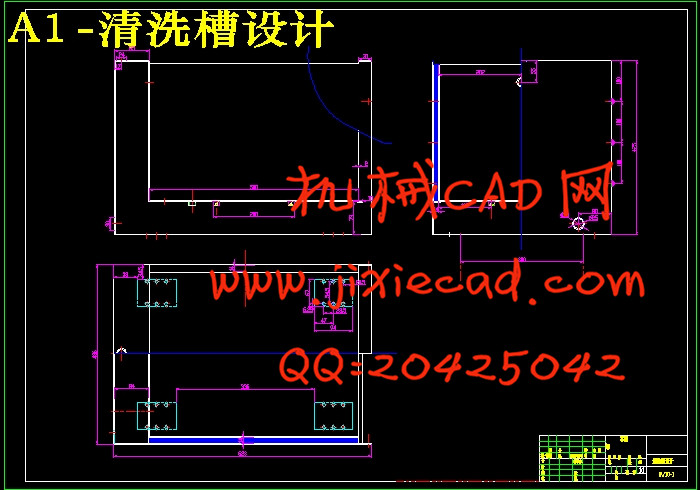

第5章 箱体的设计 14

5.1 清洗槽的设计 14

5.2 附加箱的设计 14

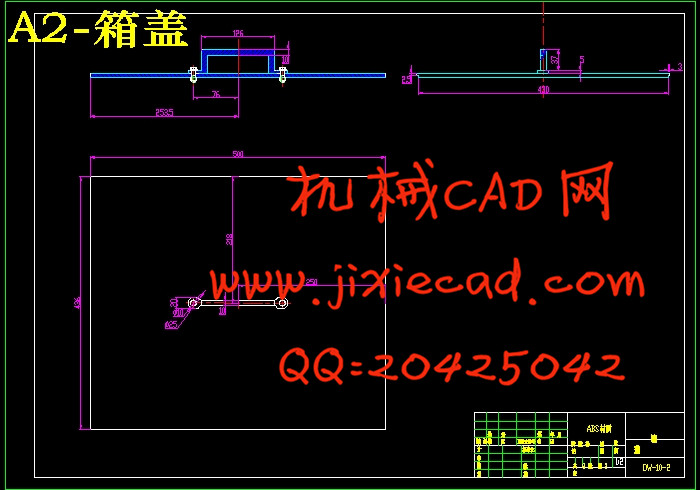

5.3 箱盖的设计 14

5.4 脚轮的设计 15

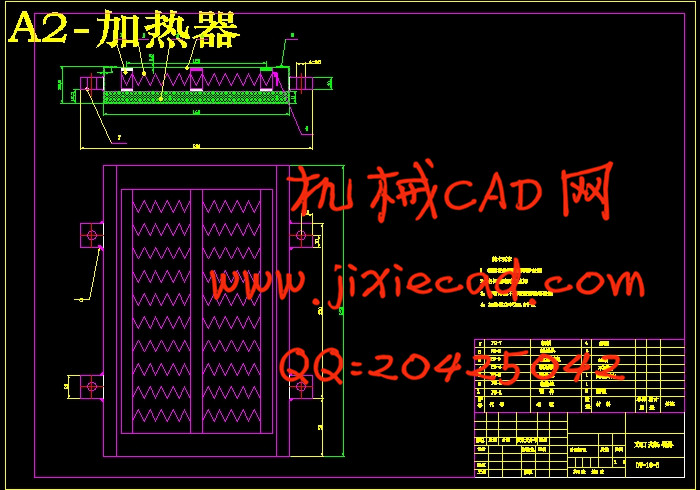

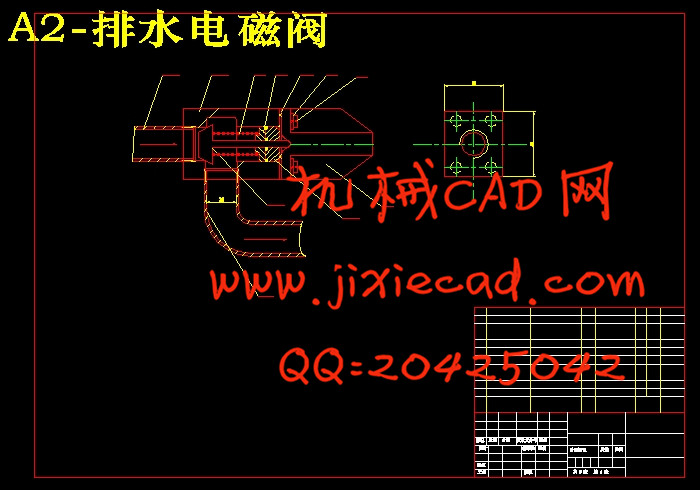

第6章 附加部件的选择 16

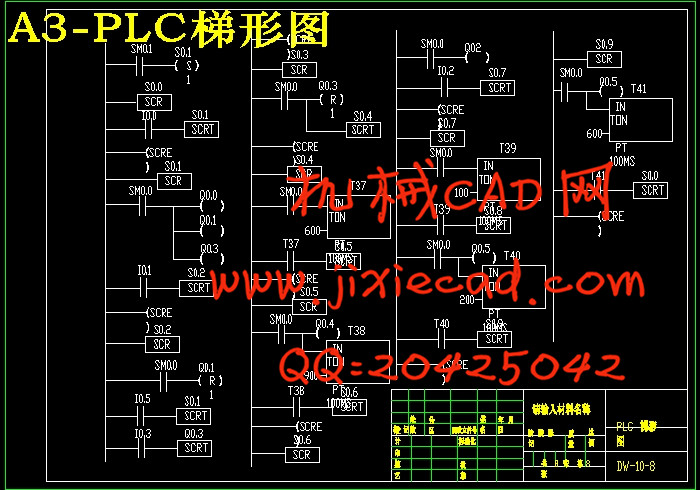

第7章 中央控制系统设计 17

7.1 系统工艺流程设计 17

7.2 主控制器的设计 17

7.3 软件设计 18

第8章 总结 20

致谢 21

参考文献 22