设计简介

前 言

核桃,是人们常见的食物。它营养丰富,具有健脑、补肾、美容、降血脂四大功效。核桃和核桃仁还是我国传统的出口商品。但是,由于核桃壳坚硬,手工剥核极其不便而且费时费力。因此,提高核桃取仁的机械化程度,是生产过程中急需解决的问题。鉴于此,本设计根据以往的研究与资料,提出了弧板—滚筒式核桃破壳原理,研制了核桃破壳机。本机能完美的解决核桃难剥核和人工剥核不能保证仁的完全性难题,且又有较高的生产率和较高的高路仁率。

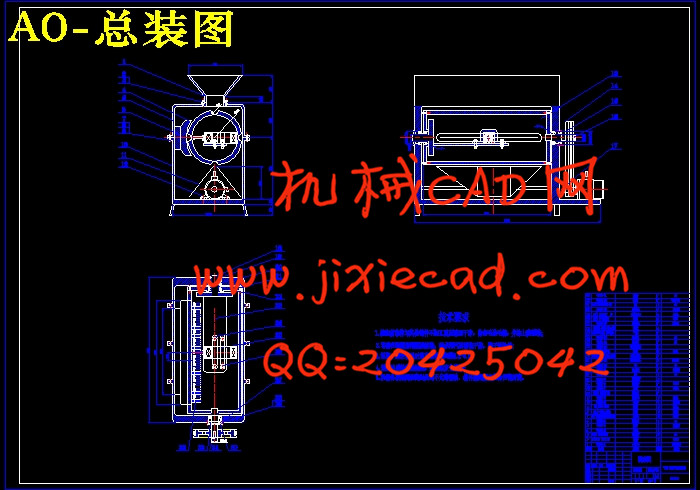

本次设计采用常见的电机作动力源,利用V带传递功率。利用轴旋转带动滚筒的转动,利用气缸实现破壳,从而使机器能够连续的工作,大大提高了生产率。

目录

1在国内(外)研究现状及分析·······································1

1.1坚果类破壳机现状··············································1

1.1.1坚果类破壳机常见的机械脱壳方法 ································1

1.1.2新型核桃脱壳方法·············································1

1.1.3几种典型的坚果类破壳机·······································2

1.2对坚果类破壳机械未来展望分析···································2

2破壳机设计的目的、意义···········································3

3弧板-滚筒式破壳机工作原理········································3

3.1破壳机的总体装配思路··········································4

4气动装置的选取···················································4

5弧板-滚筒式核桃破壳机的设计·····································5

5.1电动机的选择·················································5

6带及设计··················································5

6.1传动带的设计·············································6

6.1.1确定计算功率················································6

6.1.2选择V带的型号·············································6

6.1.3确定带轮的基准直径···········································6

6.1.4确定传动中心距和带长·········································6

6.1.5验算主动轮上的包角···········································7

6.1.6确定V带的根数·············································7

6.1.7确定带的初拉力···············································7

6.1.8求V带传动作用在轴上的压力····································8

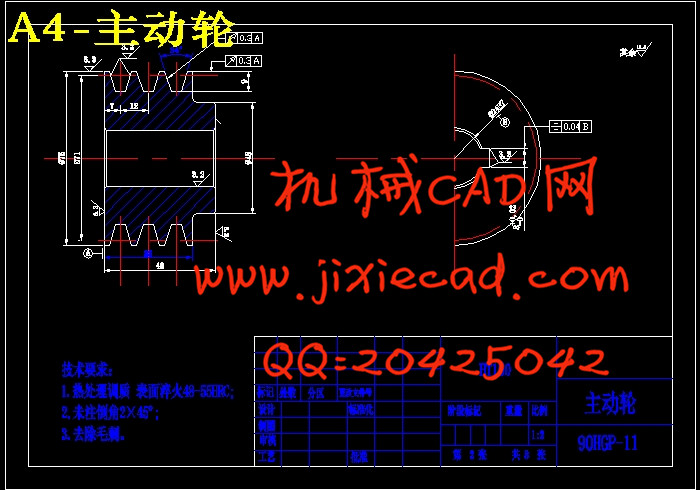

7V带带轮的设计····················································8

7.1带轮的材料选择···············································8

7.2结构设计·····················································8

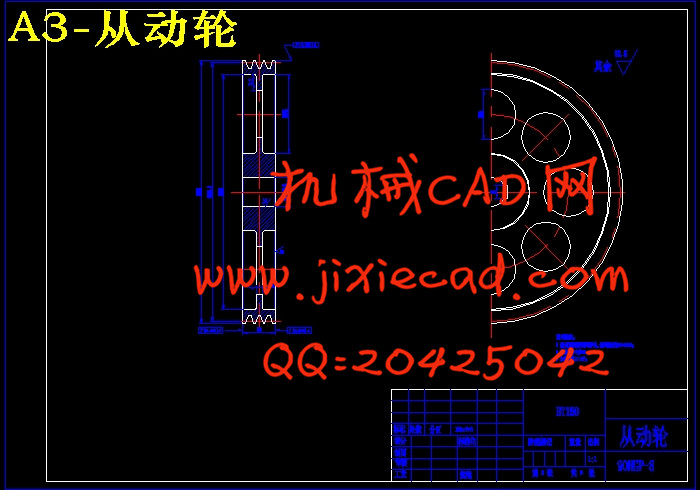

7.3 从动带轮的设计················································9

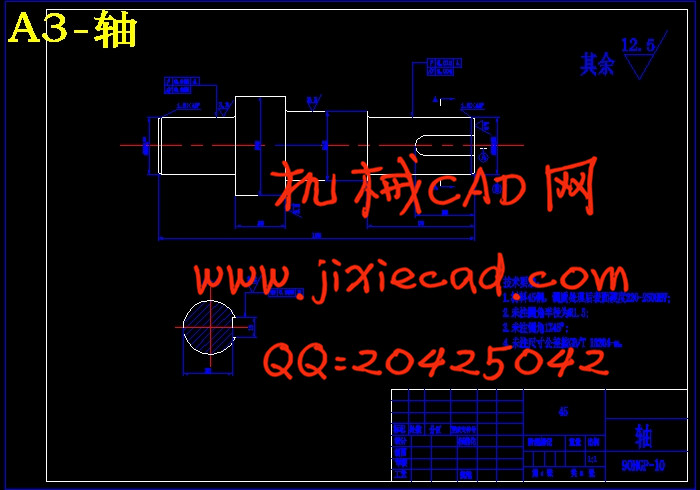

8传动轴的设计·····················································9

8.1根据轴向定位的要求确定轴的各段直径和长度·························10

8.2初步选择输出轴系··············································10

8.3确定输出轴上的圆角半径······································10

8.4 按弯扭合成条件校核轴的强度·····································11

8.4.1求输出轴上的所受作用力的大小··································11

8.4.2求滚筒上所受的的合力·········································11

8.4.3轴上水平面内所受支反力如图···································11

8.4.4轴在垂直面内所受的支反力·····································11

8.4.5作弯矩图···················································12

8.4.6轴的载荷分析················································12

8.4.7当量弯矩计算················································12

8.5 校核轴的强度·················································13

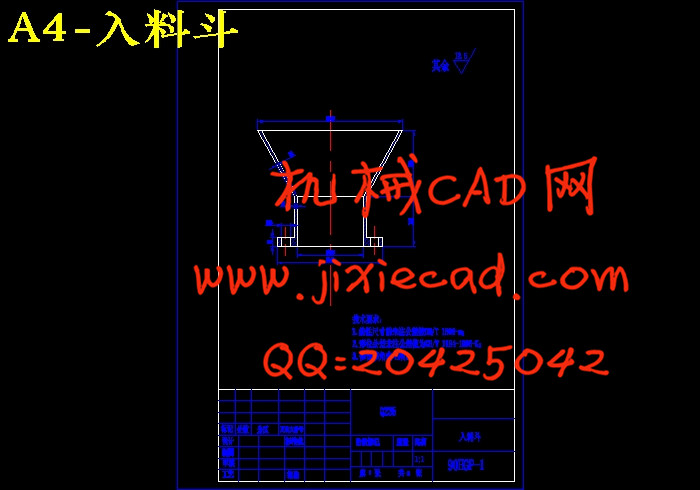

9入料斗的结构设计···············································13

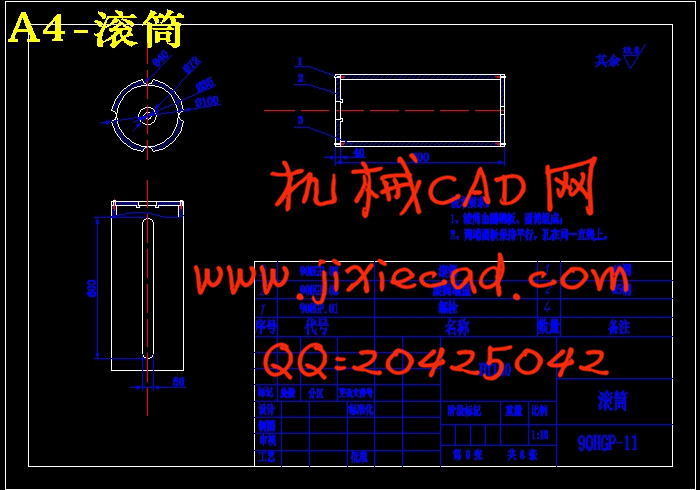

10滚筒的设计····················································13

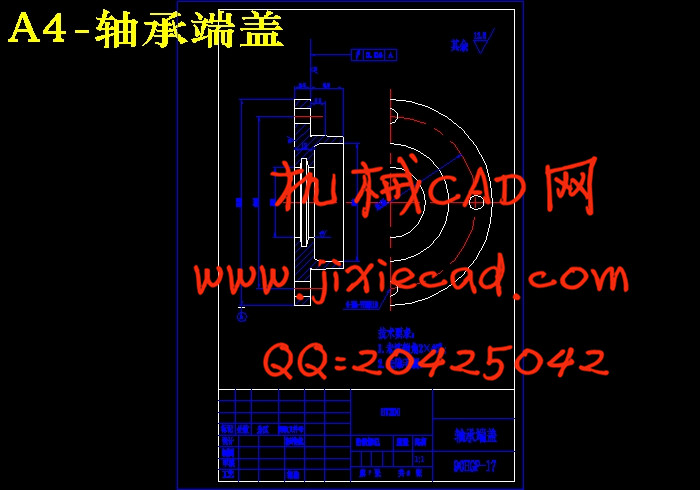

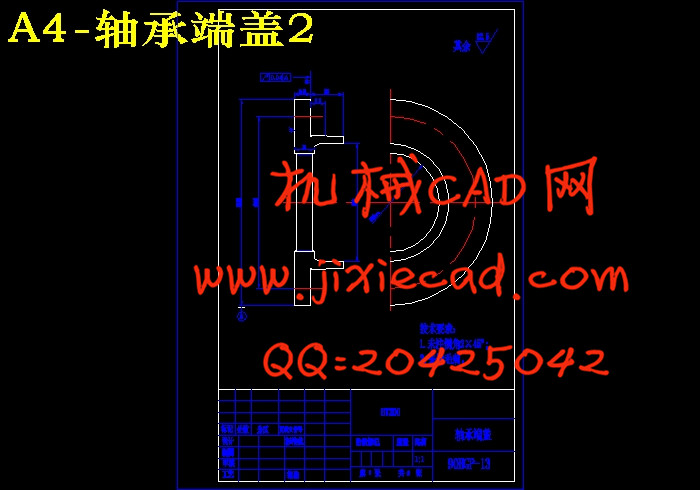

11轴承端盖······················································14

12气缸撞击装置················································14

13影响核桃破壳的因素··········································14

13.1核桃的性质···············································14

13.1.2核桃饱满程度和均匀度····································14

13.1.3核桃的湿度要适中········································15

13.1.4破壳板的硬度···········································15

13.2 喂料速度对破壳效果的影响··································15

14结论························································16

14.1本课题所完成的工作········································16

14.2需要重点研究的、关键的问题及解决的思路·······················16

14.2.1目前核桃破壳取仁机械存在的主要问题························16

15致谢························································17

16参考文献····················································

核桃,是人们常见的食物。它营养丰富,具有健脑、补肾、美容、降血脂四大功效。核桃和核桃仁还是我国传统的出口商品。但是,由于核桃壳坚硬,手工剥核极其不便而且费时费力。因此,提高核桃取仁的机械化程度,是生产过程中急需解决的问题。鉴于此,本设计根据以往的研究与资料,提出了弧板—滚筒式核桃破壳原理,研制了核桃破壳机。本机能完美的解决核桃难剥核和人工剥核不能保证仁的完全性难题,且又有较高的生产率和较高的高路仁率。

本次设计采用常见的电机作动力源,利用V带传递功率。利用轴旋转带动滚筒的转动,利用气缸实现破壳,从而使机器能够连续的工作,大大提高了生产率。

目录

1在国内(外)研究现状及分析·······································1

1.1坚果类破壳机现状··············································1

1.1.1坚果类破壳机常见的机械脱壳方法 ································1

1.1.2新型核桃脱壳方法·············································1

1.1.3几种典型的坚果类破壳机·······································2

1.2对坚果类破壳机械未来展望分析···································2

2破壳机设计的目的、意义···········································3

3弧板-滚筒式破壳机工作原理········································3

3.1破壳机的总体装配思路··········································4

4气动装置的选取···················································4

5弧板-滚筒式核桃破壳机的设计·····································5

5.1电动机的选择·················································5

6带及设计··················································5

6.1传动带的设计·············································6

6.1.1确定计算功率················································6

6.1.2选择V带的型号·············································6

6.1.3确定带轮的基准直径···········································6

6.1.4确定传动中心距和带长·········································6

6.1.5验算主动轮上的包角···········································7

6.1.6确定V带的根数·············································7

6.1.7确定带的初拉力···············································7

6.1.8求V带传动作用在轴上的压力····································8

7V带带轮的设计····················································8

7.1带轮的材料选择···············································8

7.2结构设计·····················································8

7.3 从动带轮的设计················································9

8传动轴的设计·····················································9

8.1根据轴向定位的要求确定轴的各段直径和长度·························10

8.2初步选择输出轴系··············································10

8.3确定输出轴上的圆角半径······································10

8.4 按弯扭合成条件校核轴的强度·····································11

8.4.1求输出轴上的所受作用力的大小··································11

8.4.2求滚筒上所受的的合力·········································11

8.4.3轴上水平面内所受支反力如图···································11

8.4.4轴在垂直面内所受的支反力·····································11

8.4.5作弯矩图···················································12

8.4.6轴的载荷分析················································12

8.4.7当量弯矩计算················································12

8.5 校核轴的强度·················································13

9入料斗的结构设计···············································13

10滚筒的设计····················································13

11轴承端盖······················································14

12气缸撞击装置················································14

13影响核桃破壳的因素··········································14

13.1核桃的性质···············································14

13.1.2核桃饱满程度和均匀度····································14

13.1.3核桃的湿度要适中········································15

13.1.4破壳板的硬度···········································15

13.2 喂料速度对破壳效果的影响··································15

14结论························································16

14.1本课题所完成的工作········································16

14.2需要重点研究的、关键的问题及解决的思路·······················16

14.2.1目前核桃破壳取仁机械存在的主要问题························16

15致谢························································17

16参考文献····················································