设计简介

摘要

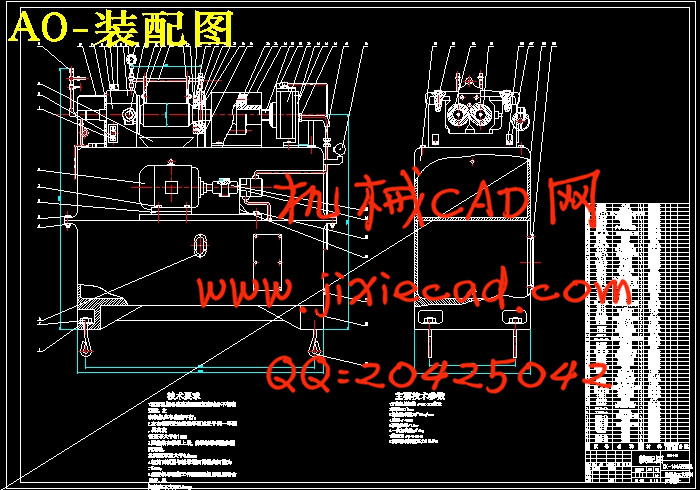

开炼机全名又叫做开放式炼胶机,它是橡胶工业中最基本最不可缺少的设备,同时也是三大炼胶设备之一,它是一种使用最早的,结构简单的最基本的橡胶机械,并且很早就应用到了橡胶工业中。开炼机主要作用有:生胶塑炼、胶料混炼、混合胶热炼、供胶,胶料压片,清除胶料中杂志:生胶的破碎、洗涤;再生胶破碎、混炼、压片;生橡胶的压片制作等。结合生产生活实际与学校要求,本论文研究了XK-160液压马达开炼机的基本设计与主要参数的计算,主要用于实验室橡胶的混炼,本论文通过经验公式计算传动功率,确定横压力,采用液压装置,通过装在辊筒上的液压马达,使开炼机驱动部分及其简单,这样使开炼机的占地面积得到了很大的减小,并使开炼机具有传动性能好、制动性能号、噪音低、可变速和传动柔性好等优点。对辊筒、机架及横梁单独设计,进行压力分析,并计算其强度。滚筒轴承使用双列向心球面滚子轴承,摩擦损失小、节能;采用手动调节装置,调距方便快捷;使用液压安全装置,免除安全垫片破损后停机更换的不方便;采用冷却水冷却,防止温度过高塑料变性。

本论文设计的开炼机具有以下特点:

(1)结构简单,占地面积小。开炼机的动力装置为液压电机,电机直接将扭矩传递给前辊筒与后辊筒,使动力传送链减短,减少了传送过程中的损耗,减小了开炼机的体积,使占地空间大幅减少,使用户的厂房排布更加方便、节省资金。

(2)安装调整方便、快捷。液压传动开炼机结构小巧,安装时只需调整机体和辊筒部分的精度就可以实现开炼机的正常运转。

(3)维护保养容易。由于本次设计的开炼机结构简单,没有太多复杂、精密的零件,所以液压传动开炼机很容易进行维护保养,及时没有很专业的机械设备原理知识的普通工人再进行一段时间的学习后也能对开炼机进行维护保养,并且液压电机的安装和拆卸都非常简单,有一两个人就可以完成开炼机的维护保养,可以节省大量的时间和雇佣专业人员的支出,为用户节省大量的资金和精力,使用户把更多精力放在产品质量上。

(4)安全性能极好。开炼机的动力源为液压电机,这种电机缓冲性能好,可以实现辊筒的快速制动,并且有一定的缓冲时间,便于辊筒在很小的转动角度内实现制动,而且不会对设备造成大的冲击,对设备的损害降到最低,不但延长了设备的使用寿命,而且还最大限度的保护人员安全,使工人安心的进行生产操作。

关键词:液压系统、辊筒、轴承、调距装置、安全装置

Abstract

Open smelting machine full name is also called open rubber mixing machine, it is the rubber industry in the most basic most indispensable equipment, and it is also one of the three mixing equipment, it is using the first, simple structure of the most basic rubber machinery and very early in the application to the rubber industry. Open smelting machine main functions: rubber plastic refining, rubber mixing, mixed hot glue mixing, glue, rubber sheeting, remove rubber magazine: Rubber crushing, washing; regenerated rubber crushing, mixing, tabletting; raw rubber sheeting production etc..

Combined with the actual production and living and school requirements, this paper studied xk-160 hydraulic motor to open the basic design of the mixer and the main parameter calculation, mainly for laboratory rubber mixing, this paper through the empirical formula calculation power transmission and determine the horizontal pressure, hydraulic device is used, by installing the hydraulic motor on the roller, open smelting machine driving part and simple, so that open smelting machine area has been reduced greatly, and the open smelting machine has good transmission performance, braking performance, and low noise, transmission and transmission flexible etc. advantages. Separate design of roller, frame and beam, stress analysis, and calculate its strength. Roller bearing using double row radial spherical roller bearing, friction loss, save energy, adopts the manual adjusting device, distance adjustment is convenient and quick; hydraulic safety device, exempt from safety gasket damaged after shutdown replacement of inconvenient; cooling water is used for cooling to prevent high temperature plastic degeneration.

The design of the paper mill has the following features:

(1) the structure is simple, and the area of land is small. Use hydraulic motor as the power device of the mixer, directly to the torque transmitted to the two roller, greatly reduced the power transmission process, the floor space is greatly reduced, users of the plant row not more convenient and save money.

(2) the installation adjustment is convenient and fast. Hydraulic transmission open smelting machine structure is compact, installation just adjustment body and roller part accuracy can be achieved on the normal operation of the mill.

(3) maintenance easy. Due to the design of open smelting machine has the advantages of simple structure, so hydraulic transmission open smelting machine maintenance is very easy and the installation and the disassembly of hydraulic motor are very simple, can save a lot of maintenance time, for the user to save a lot of money and energy.

(4) the safety performance is excellent. Open smelting machine power source for the hydraulic motor, can achieve a roller rapid braking, the roller in very small rotation angle realize brake and not of the equipment caused by shock and arrogant limit protection equipment and personnel safety.

Keywords: hydraulic system, roller, bearing, distance adjusting device, safety device

目 录

第一章概述 1

第二章主要参数确定 3

2.1辊筒直径与辊距 3

2.2辊筒回转速度与速比 3

2.3横压力 3

2.3.1滚筒受力分析 3

2.3.2横压力计算 3

2.3.3单位横压力 4

2.4传动功率 4

第三章传动系统 6

3.1传动型式 6

3.2速比齿轮的参数确定 7

3.3电机的选择 9

3.4液压元件的选择 9

3.5油箱容积的确定 11

第四章主要零部件设计 12

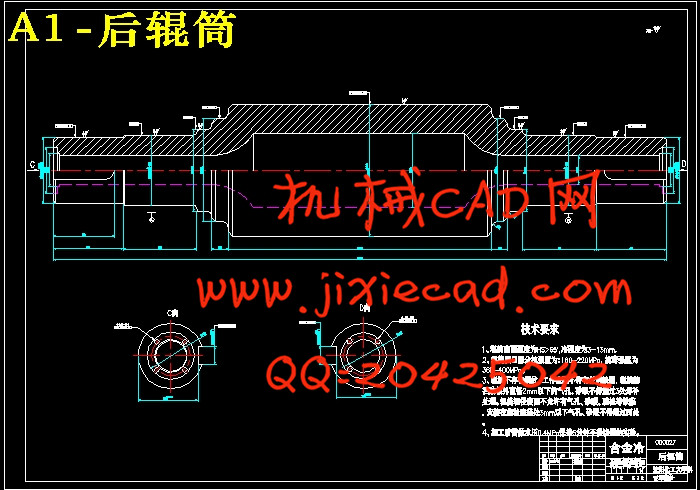

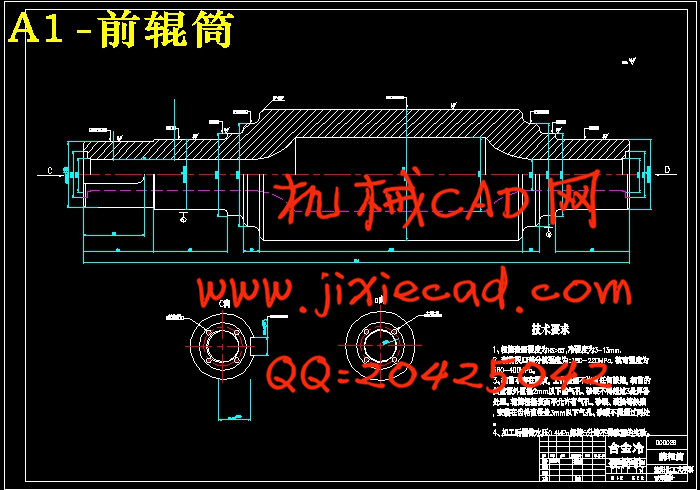

4.1辊筒 12

4.1.1辊筒的材料 12

4.1.2结构形状与各部尺寸 12

4.1.3辊筒受力分析 13

4.1.4辊筒强度计算 15

4.1.5考虑温度对其强度的影响 17

4.2辊筒轴承 17

4.2.1轴承类型及材料 17

4.2.2滚动轴承结构尺寸滑动机构 17

4.2.3轴承强度计算 19

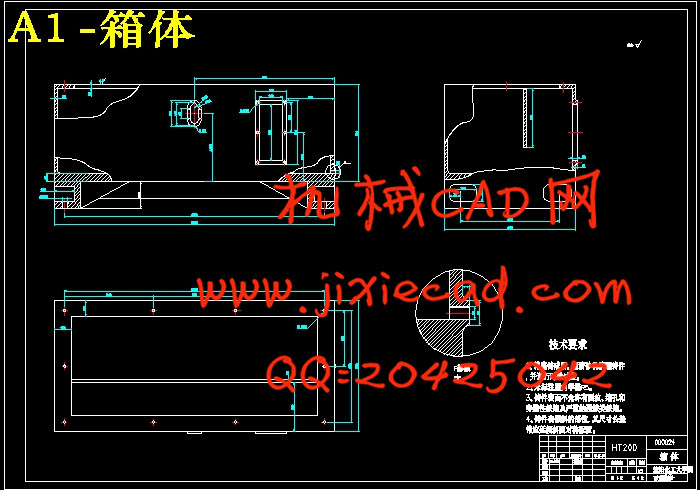

4.3机架和横梁强度计算 19

4.3.1机架强度计算 19

4.3.2压盖的强度计算 24

4.4调距装置 26

4.5辊温调节装置 28

参考文献 30

致谢 31