设计简介

摘 要

本文在对工业机械手总体构思和结构分析的基础上,结合通用机械手的给定要求

和功能,对机械手结构进行了系统的分析、设计和计算,并拟定了整体驱动系统和控制系统。

采用机电一体化设计思想,充分考虑机、电、软、硬件各自特点进行互补优化,对机械手整体结构、传动系统、驱动装置和控制系统进行了分析和设计。

在结构设计的过程中结合以往机械设计的经验确定了机械手的详细尺寸。在标准件的应用中,充分考虑实际情况和标准件的应用准则进行了选用。由于该机械手采用液压驱动,在油路的布置和规划中结合机械制造的基础,不但使油路符合制造的可行性,而且将油路布置成空间结构,是机械手的结构更加简洁和紧凑。

在传动系统和驱动装置的设计中,结合各个液压缸的动作,对液压油的流量和压力进行了分析,结合液压原理中各种常用回路的功能和各液压元件的选用原则,制定出了一套完整的液压系统。

在控制系统的设计过程中,采用PLC可编程控制器作为控制主机,行程开关的开合作为中间动作信号,在加上PLC内部延时继电器的使用对该机械手进行了编程,提出了一份有不同功能模块的梯形图。

通过以上各部分的工作,得出了实用化、高可靠性通用机械手的设计方案,对其他类型的数控系统的设计也有一定的借鉴价值。

关键词:通用机械手、结构设计、驱动系统、PLC

Abstract

This paper in the overall industrial manipulator design and structural analysis on the basis of Combining manipulator to establish requirements and functions of the manipulator structure of the system analysis, design and calculation and the preparation of the overall drive system and control system .

Electrical and Mechanical design integration, and give full consideration to, electronic hardware and software characteristics of their respective complementary optimization, manipulator of the overall structure, transmission, drive and control system for the analysis and design .

The structural design of the course with previous experience in mechanical design of the manipulator to determine the detailed size .In the application of standard parts, and give full consideration to the actual situation and the standard parts of the selection criteria .

As the hydraulic manipulator drivers in the asphalt layout and planning with machinery manufacturing base not only with asphalt manufacturing feasibility and layout of asphalt into space structure, Manipulator is the structure more simple and compact .

Drivers in the transmission system and equipment design,the integration of the various hydraulic cylinder moves the hydraulic oil flow and pressure analysis hydraulic principles used various circuit functions and the use of hydraulic components, draw up a complete set of hydraulic systems .

In the control system design process, using PLC as the control host, Switching trip to the Middle cooperating moves signal In addition PLC internal delay relays on the use of manipulator of programming, presented a different function module ladder .

Through the above, the part of the process come to practical use, high reliability General manipulator design, for other types of CNC system design has some reference value .

Keywords :Definitive manipulator、structural design、drive system、PLC

目录

本文在对工业机械手总体构思和结构分析的基础上,结合通用机械手的给定要求

和功能,对机械手结构进行了系统的分析、设计和计算,并拟定了整体驱动系统和控制系统。

采用机电一体化设计思想,充分考虑机、电、软、硬件各自特点进行互补优化,对机械手整体结构、传动系统、驱动装置和控制系统进行了分析和设计。

在结构设计的过程中结合以往机械设计的经验确定了机械手的详细尺寸。在标准件的应用中,充分考虑实际情况和标准件的应用准则进行了选用。由于该机械手采用液压驱动,在油路的布置和规划中结合机械制造的基础,不但使油路符合制造的可行性,而且将油路布置成空间结构,是机械手的结构更加简洁和紧凑。

在传动系统和驱动装置的设计中,结合各个液压缸的动作,对液压油的流量和压力进行了分析,结合液压原理中各种常用回路的功能和各液压元件的选用原则,制定出了一套完整的液压系统。

在控制系统的设计过程中,采用PLC可编程控制器作为控制主机,行程开关的开合作为中间动作信号,在加上PLC内部延时继电器的使用对该机械手进行了编程,提出了一份有不同功能模块的梯形图。

通过以上各部分的工作,得出了实用化、高可靠性通用机械手的设计方案,对其他类型的数控系统的设计也有一定的借鉴价值。

关键词:通用机械手、结构设计、驱动系统、PLC

Abstract

This paper in the overall industrial manipulator design and structural analysis on the basis of Combining manipulator to establish requirements and functions of the manipulator structure of the system analysis, design and calculation and the preparation of the overall drive system and control system .

Electrical and Mechanical design integration, and give full consideration to, electronic hardware and software characteristics of their respective complementary optimization, manipulator of the overall structure, transmission, drive and control system for the analysis and design .

The structural design of the course with previous experience in mechanical design of the manipulator to determine the detailed size .In the application of standard parts, and give full consideration to the actual situation and the standard parts of the selection criteria .

As the hydraulic manipulator drivers in the asphalt layout and planning with machinery manufacturing base not only with asphalt manufacturing feasibility and layout of asphalt into space structure, Manipulator is the structure more simple and compact .

Drivers in the transmission system and equipment design,the integration of the various hydraulic cylinder moves the hydraulic oil flow and pressure analysis hydraulic principles used various circuit functions and the use of hydraulic components, draw up a complete set of hydraulic systems .

In the control system design process, using PLC as the control host, Switching trip to the Middle cooperating moves signal In addition PLC internal delay relays on the use of manipulator of programming, presented a different function module ladder .

Through the above, the part of the process come to practical use, high reliability General manipulator design, for other types of CNC system design has some reference value .

Keywords :Definitive manipulator、structural design、drive system、PLC

目录

第一章 绪论…................. ..... .................................................................................................1

1.1 研究背景及发展现状 ........................................................................................................1

1.2 本课题研究目的及意义........................................................................................................2

1.3 本课题的研究内容................................................................................................................2

第二章 机械手的总体计..........................................................................................3

2.1 总体方案的比较与选定........................................................................................................3

2.1.1 各种坐标形式机械手的比较.............................................................................................3

2.1.2选定的两个机械手方案的概述及比较...............................................................................4

2.2 机械手的组成及各部分关系概述........................................................................................7

2.2.1 执行机构.............................................................................................................................8

2.2.2 驱动机构.............................................................................................................................8

2.3 机械手的主要参数................................................................................................................9

2.3.1 机械手的主要技术参数.....................................................................................................9

2.3.2 机械手的主要规格参数.....................................................................................................9

第三章 机械手机械系统的设计..............................................................................9

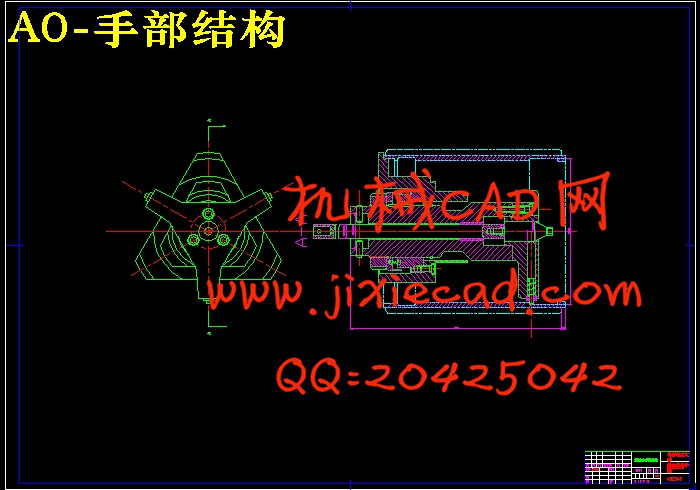

3.1 手部的设计.............................................................................................................................9

3.1.1 手部结构的设计..................................................................................................................9

3.1.2 手部的计算与分析.............................................................................................................10

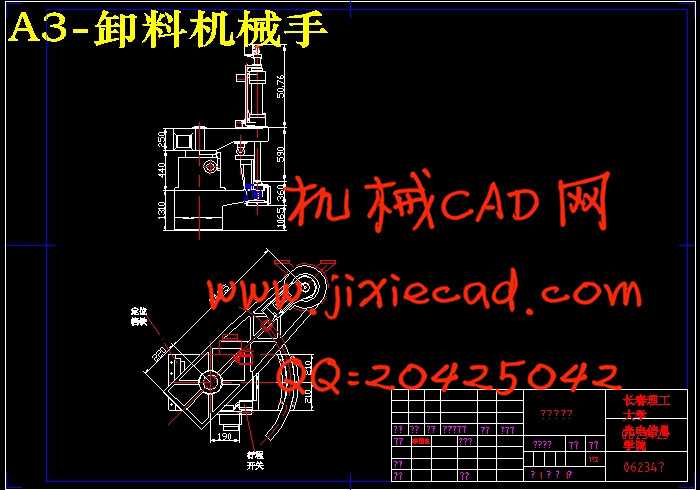

3.2 臂部........................................................................................................................................13

3.2.1 手臂不自锁条件................................................................................................................ 14

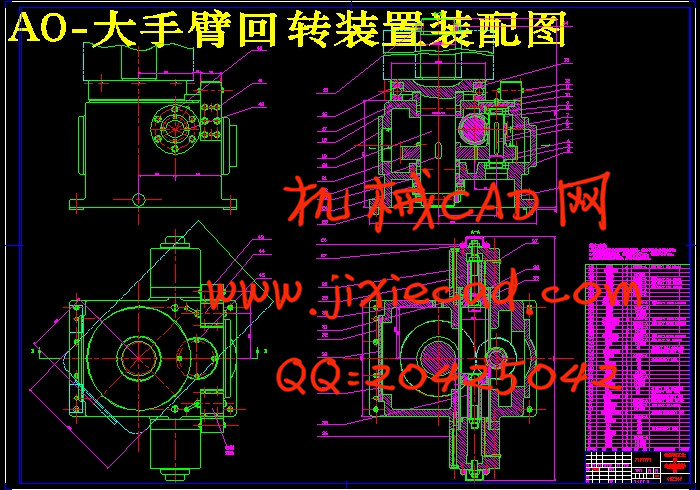

3.2.2 手臂回转缸结构设计.........................................................................................................14

3.2.3 大手臂相关参数计算.........................................................................................................15

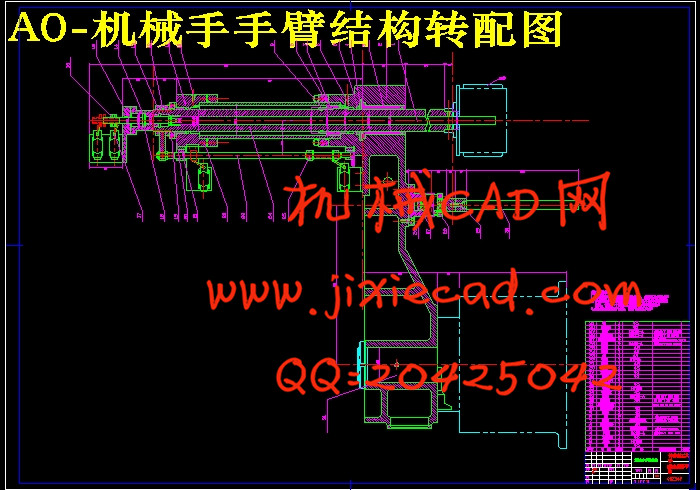

3.2.4 手臂伸缩缸的结构设计 ...............................................................................................23

3.2.5 手臂伸缩缸的设计计算.....................................................................................................24

致 谢..................................................................................................... ...............................30

参考文献 ...................................................................................................................31

总 结....................................................................................................................32

1.1 研究背景及发展现状 ........................................................................................................1

1.2 本课题研究目的及意义........................................................................................................2

1.3 本课题的研究内容................................................................................................................2

第二章 机械手的总体计..........................................................................................3

2.1 总体方案的比较与选定........................................................................................................3

2.1.1 各种坐标形式机械手的比较.............................................................................................3

2.1.2选定的两个机械手方案的概述及比较...............................................................................4

2.2 机械手的组成及各部分关系概述........................................................................................7

2.2.1 执行机构.............................................................................................................................8

2.2.2 驱动机构.............................................................................................................................8

2.3 机械手的主要参数................................................................................................................9

2.3.1 机械手的主要技术参数.....................................................................................................9

2.3.2 机械手的主要规格参数.....................................................................................................9

第三章 机械手机械系统的设计..............................................................................9

3.1 手部的设计.............................................................................................................................9

3.1.1 手部结构的设计..................................................................................................................9

3.1.2 手部的计算与分析.............................................................................................................10

3.2 臂部........................................................................................................................................13

3.2.1 手臂不自锁条件................................................................................................................ 14

3.2.2 手臂回转缸结构设计.........................................................................................................14

3.2.3 大手臂相关参数计算.........................................................................................................15

3.2.4 手臂伸缩缸的结构设计 ...............................................................................................23

3.2.5 手臂伸缩缸的设计计算.....................................................................................................24

致 谢..................................................................................................... ...............................30

参考文献 ...................................................................................................................31

总 结....................................................................................................................32