设计简介

摘 要:红薯具有很高的营养价值和很好的味道,很多人们喜欢吃。随着人们的生活水平越来越高,对红薯的食用要求也越来越高。例如在食用红薯的时候要将其切成丝或片,因而切片机应运而生。本文设计的切片机主要针对中小型场合,例如加工作坊、食堂、家庭等。本设计针对红薯茎块的形状而设计的。本文分别对带、轴、刀片、刀盘等进行设计计算,对轴承、键等元件进行了选择。本设计的切片机有较高的效率,能对红薯茎块等进行工作。

关键词:红薯;切片;切片机;刀片

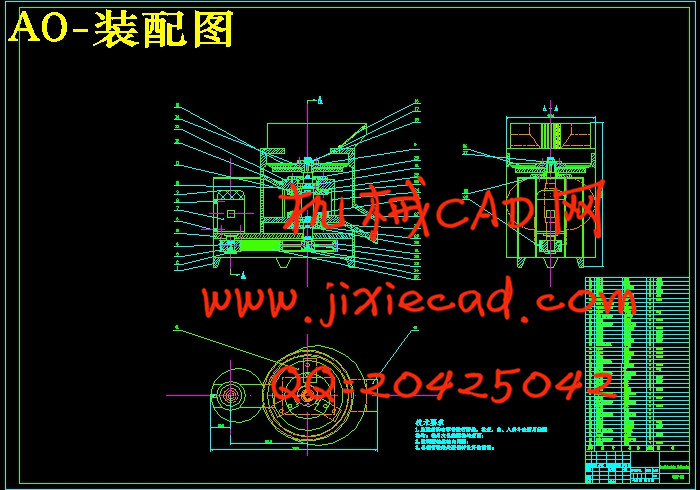

Abstract: The sweet potato has a high nutritional value and taste good ,a lot of people like to eat. With the development of economy, the standard of sweet potato for people is getting higher and higher. For example,people cut the sweet potatoes into pieces when they want to eat it. so the slicing machine born. the slicing machine designed in this paper uses at some small and medium-sized places, such as the workshop、canteen and household. The slicing machine is designed based on the tuber crops of sweet potatoes . In this paper,the tape、axis、blade and cutter disk are designed and calculated and the components of axle bearing and bond are selected. The design of the slice machine has a high efficiency when it works on the sweet potato tubers.

Key words: Sweet potato; Slice; Cut machine; Razor blade

目 录

摘要…………………………………………………………………………………………1

关键词………………………………………………………………………………………1

1 前言…………………………………………………………………………………… 1

2 切片机现状…………………………………………………………………………… 2

2.1 国外发展情况………………………………………………………………… 2

2.2 国内切片机技术的发展概况………………………………………………… 2

3 红薯切片机总体方案的确定………………………………………………………… 3

3.1 结构特点和工作原理………………………………………………………… 3

3.1.1 结构特点……………………………………………………………… 3

3.1.2 工作原理及工作条件………………………………………………… 4

3.2 机构的组成部分及特点……………………………………………………… 4

3.2.1 电动机………………………………………………………………… 4

3.2.2 皮带传送装置………………………………………………………… 4

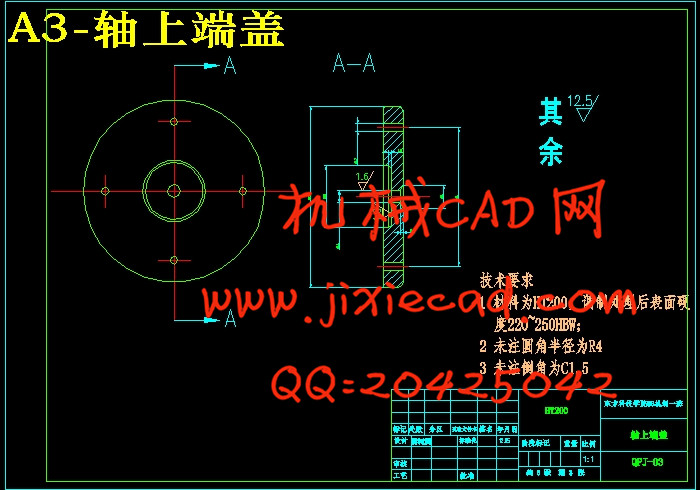

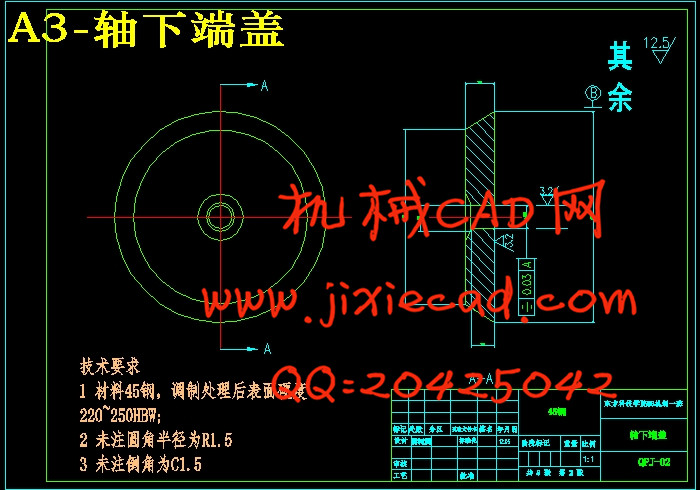

3.2.3 轴……………………………………………………………………… 4

4 电机的选择…………………………………………………………………………… 4

5 V带传动的设计计算………………………………………………………………… 5

5.1 求计算功率PC………………………………………………………………… 5

5.2 选V带的型号……………………………………………………………………5

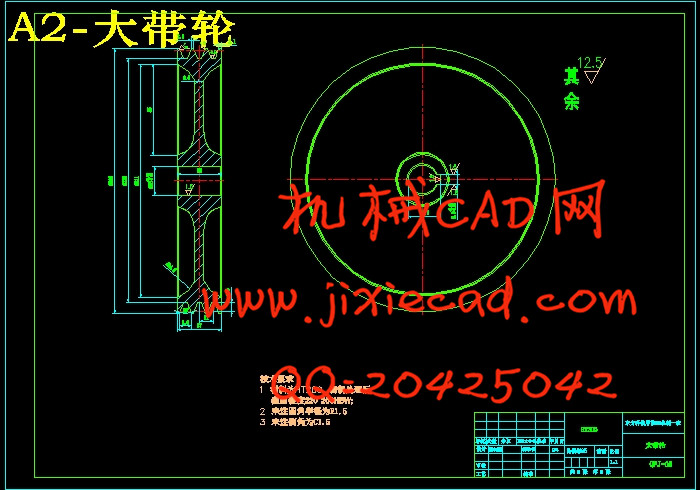

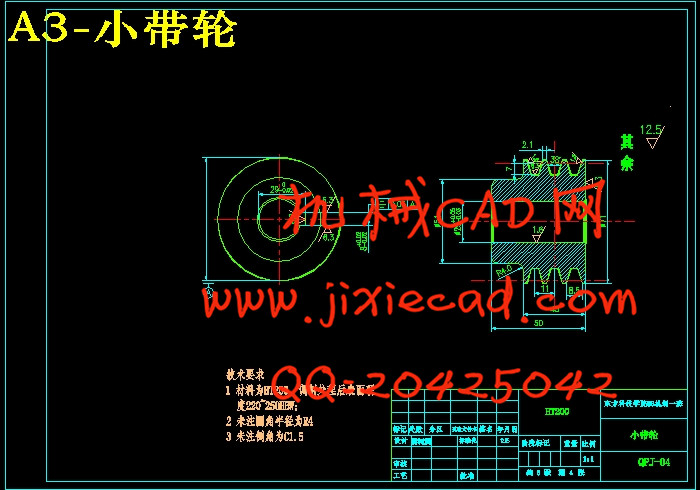

5.3 求大小带轮d2、 d1基准直径…………………………………………………5

5.4 验算带速V………………………………………………………………………5

5.5 计算V带的基准长度Ld和中心距a……………………………………………5

5.6 验算小带轮包角α1………………………………………………………… 6

5.7 求V带的根数………………………………………………………………… 6

5.8 求作用在带轮轴上的压力FQ……………………………………………………6

6 V带轮的设计……………………………………………………………………………7

6.1 V带轮的要求……………………………………………………………………7

6.2 带轮的结构尺寸的设计……………………………………………………… 7

6.2.1 带轮结构形式的设计………………………………………………… 7

6.2.2 带轮尺寸的设计…………………………………………7

7 轴的选择……………………………………………………………………………… 9

7.1 计算轴的最小直径…………………………………………………………… 9

7.2 轴的结构尺寸确定…………………………………………………………… 9

7.3 轴的校核……………………………………………………………………… 10

7.4 按弯扭合成应力校核轴的强度……………………………………………… 11

8 轴承的选择及校核……………………………………………………………11

8.1 轴承的选择…………………………………………………………………… 11

8.2 轴承的校核…………………………………………………………………… 12

9 键的选择与校核……………………………………………………………………… 13

9.1 键的选择……………………………………………………………………… 13

9.2 键的校核……………………………………………………………………… 13

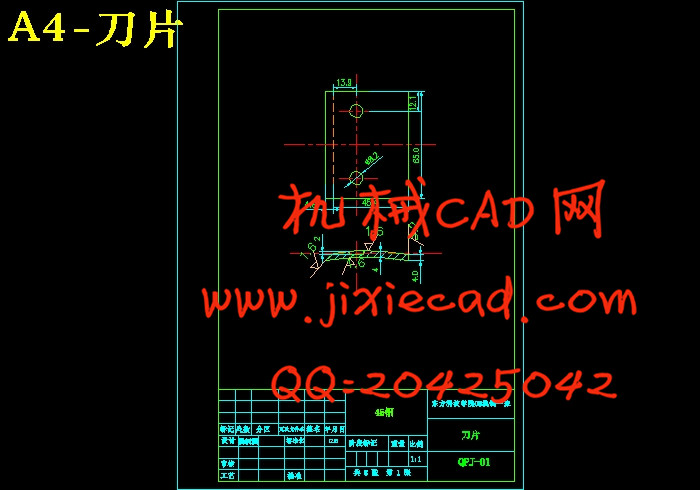

10 刀片的设计……………………………………………………………………………13

10.1 万片类型的选择………………………………………………………………13

10.2 万片形位及尺寸的设计………………………………………………………15

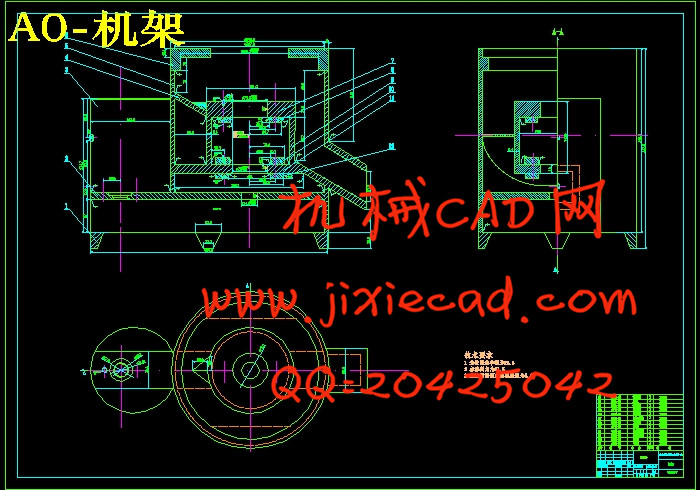

11 机架的设计………………………………………………………………………… 15

11.1 机架设计要求…………………………………………………………………15

11.2 机架材料的选用及壁厚选择…………………………………………………16

11.3 机架整体设计…………………………………………………………………17

12 机体结构的设计………………………………………………………………………17

13 结论……………………………………………………………………………………17

参考文献……………………………………………………………………………………18

致谢…………………………………………………………………………………………19

关键词:红薯;切片;切片机;刀片

Abstract: The sweet potato has a high nutritional value and taste good ,a lot of people like to eat. With the development of economy, the standard of sweet potato for people is getting higher and higher. For example,people cut the sweet potatoes into pieces when they want to eat it. so the slicing machine born. the slicing machine designed in this paper uses at some small and medium-sized places, such as the workshop、canteen and household. The slicing machine is designed based on the tuber crops of sweet potatoes . In this paper,the tape、axis、blade and cutter disk are designed and calculated and the components of axle bearing and bond are selected. The design of the slice machine has a high efficiency when it works on the sweet potato tubers.

Key words: Sweet potato; Slice; Cut machine; Razor blade

目 录

摘要…………………………………………………………………………………………1

关键词………………………………………………………………………………………1

1 前言…………………………………………………………………………………… 1

2 切片机现状…………………………………………………………………………… 2

2.1 国外发展情况………………………………………………………………… 2

2.2 国内切片机技术的发展概况………………………………………………… 2

3 红薯切片机总体方案的确定………………………………………………………… 3

3.1 结构特点和工作原理………………………………………………………… 3

3.1.1 结构特点……………………………………………………………… 3

3.1.2 工作原理及工作条件………………………………………………… 4

3.2 机构的组成部分及特点……………………………………………………… 4

3.2.1 电动机………………………………………………………………… 4

3.2.2 皮带传送装置………………………………………………………… 4

3.2.3 轴……………………………………………………………………… 4

4 电机的选择…………………………………………………………………………… 4

5 V带传动的设计计算………………………………………………………………… 5

5.1 求计算功率PC………………………………………………………………… 5

5.2 选V带的型号……………………………………………………………………5

5.3 求大小带轮d2、 d1基准直径…………………………………………………5

5.4 验算带速V………………………………………………………………………5

5.5 计算V带的基准长度Ld和中心距a……………………………………………5

5.6 验算小带轮包角α1………………………………………………………… 6

5.7 求V带的根数………………………………………………………………… 6

5.8 求作用在带轮轴上的压力FQ……………………………………………………6

6 V带轮的设计……………………………………………………………………………7

6.1 V带轮的要求……………………………………………………………………7

6.2 带轮的结构尺寸的设计……………………………………………………… 7

6.2.1 带轮结构形式的设计………………………………………………… 7

6.2.2 带轮尺寸的设计…………………………………………7

7 轴的选择……………………………………………………………………………… 9

7.1 计算轴的最小直径…………………………………………………………… 9

7.2 轴的结构尺寸确定…………………………………………………………… 9

7.3 轴的校核……………………………………………………………………… 10

7.4 按弯扭合成应力校核轴的强度……………………………………………… 11

8 轴承的选择及校核……………………………………………………………11

8.1 轴承的选择…………………………………………………………………… 11

8.2 轴承的校核…………………………………………………………………… 12

9 键的选择与校核……………………………………………………………………… 13

9.1 键的选择……………………………………………………………………… 13

9.2 键的校核……………………………………………………………………… 13

10 刀片的设计……………………………………………………………………………13

10.1 万片类型的选择………………………………………………………………13

10.2 万片形位及尺寸的设计………………………………………………………15

11 机架的设计………………………………………………………………………… 15

11.1 机架设计要求…………………………………………………………………15

11.2 机架材料的选用及壁厚选择…………………………………………………16

11.3 机架整体设计…………………………………………………………………17

12 机体结构的设计………………………………………………………………………17

13 结论……………………………………………………………………………………17

参考文献……………………………………………………………………………………18

致谢…………………………………………………………………………………………19