设计简介

摘 要

烟花鞭炮的传统生产工艺大多系手工操作,工艺烦琐。不仅劳动强度大、功效低、产品质量难以保证,研发花炮筒扇形排布穿引机,是提高生产效率,确保安全生产和稳定产品质量的必然趋势。

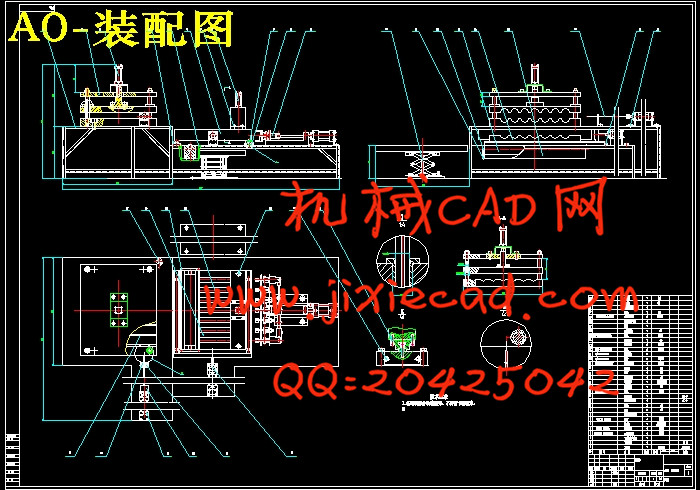

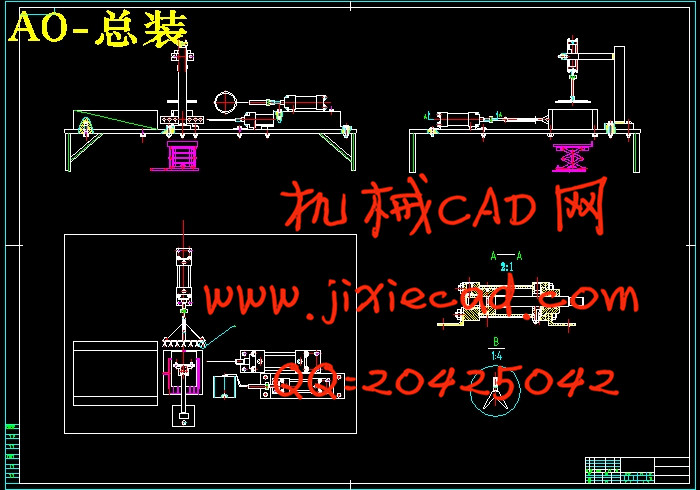

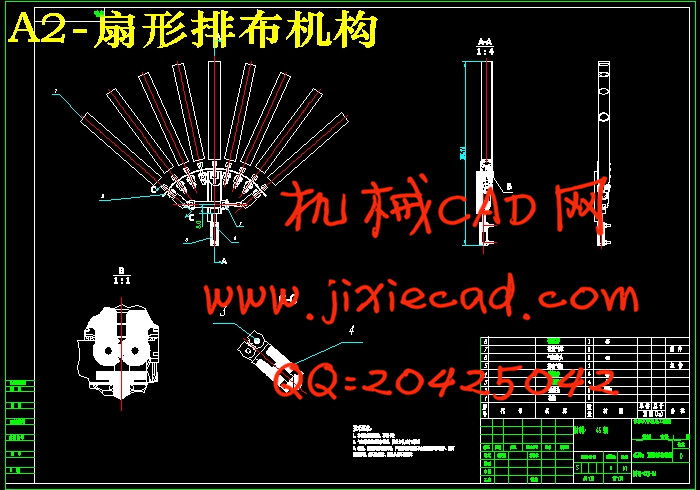

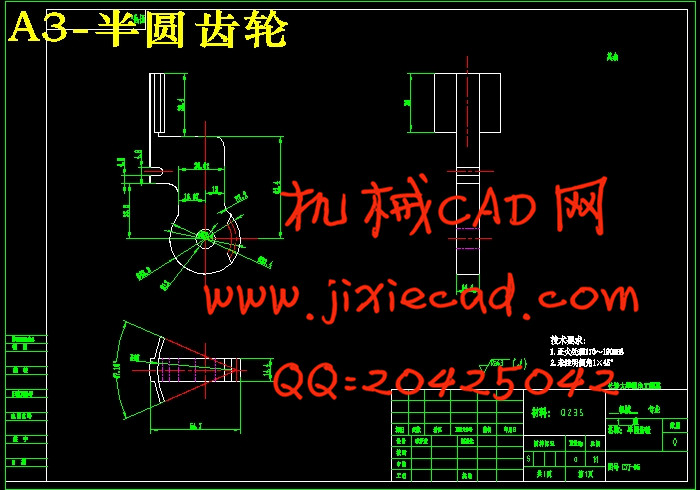

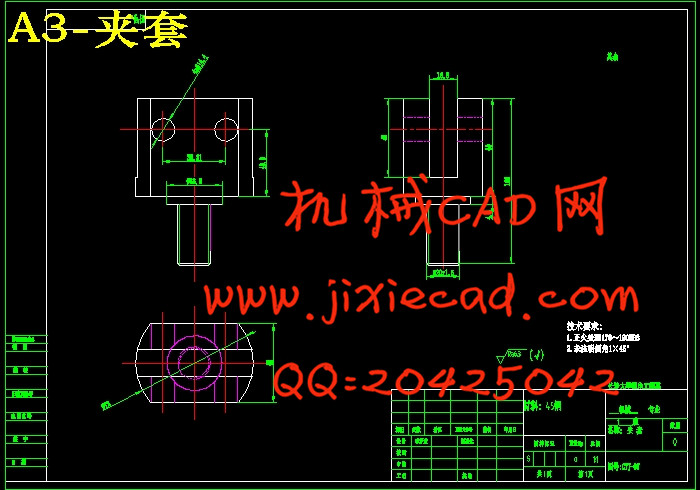

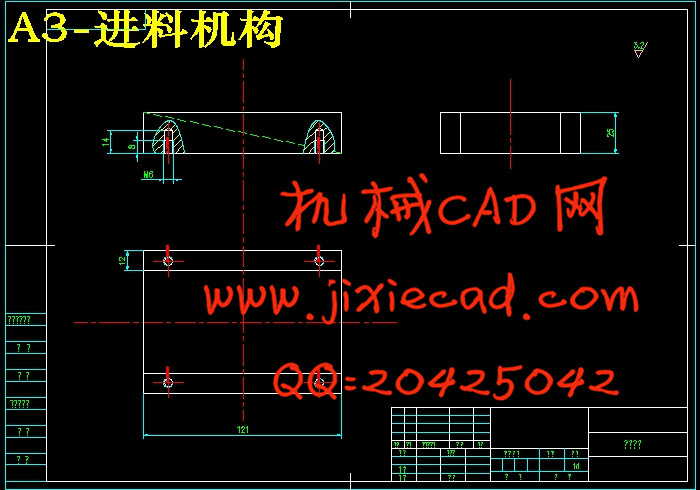

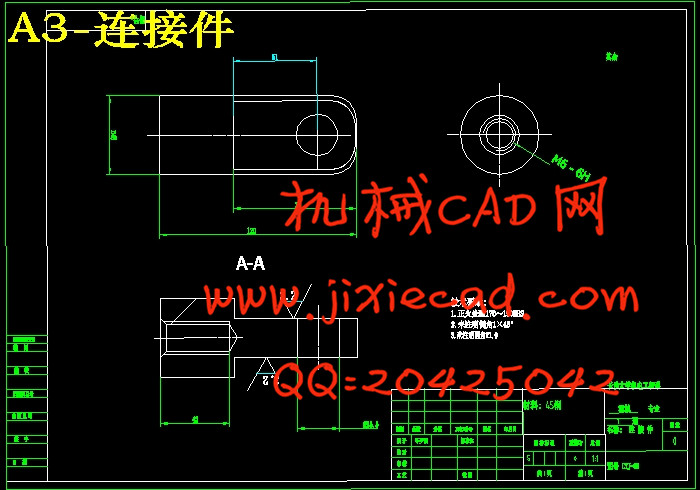

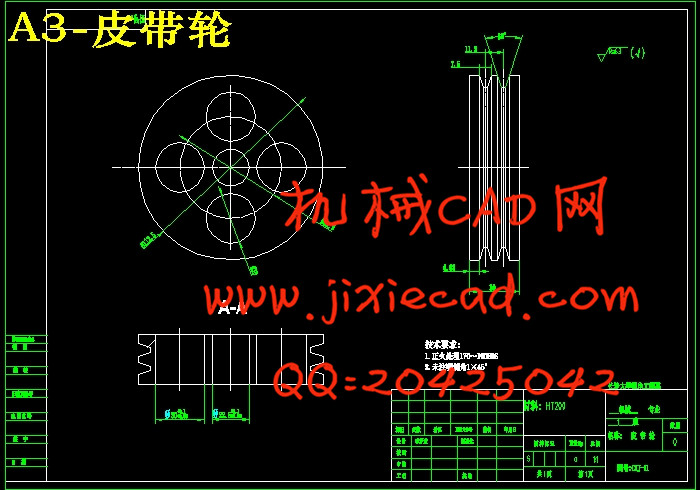

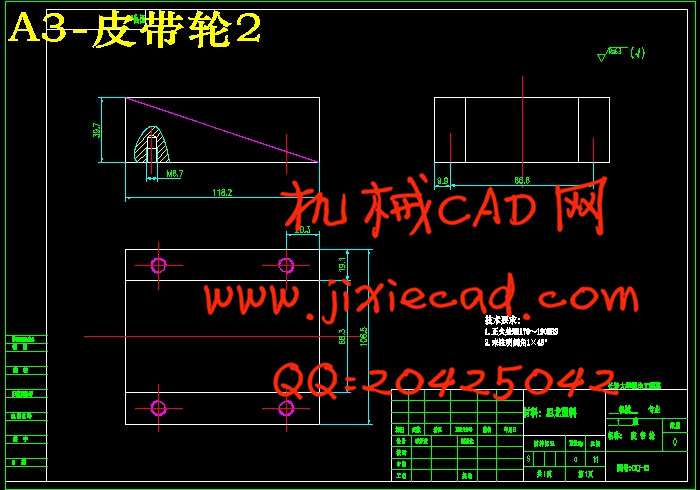

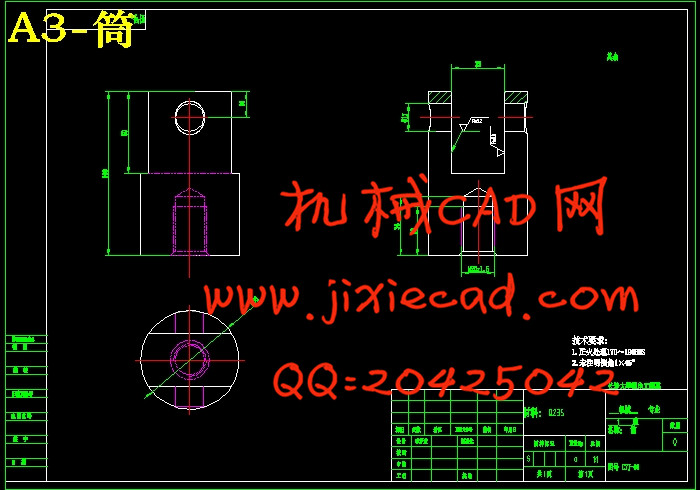

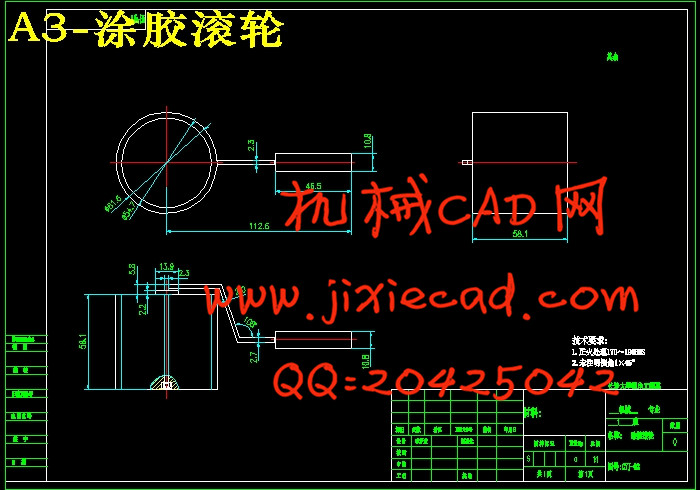

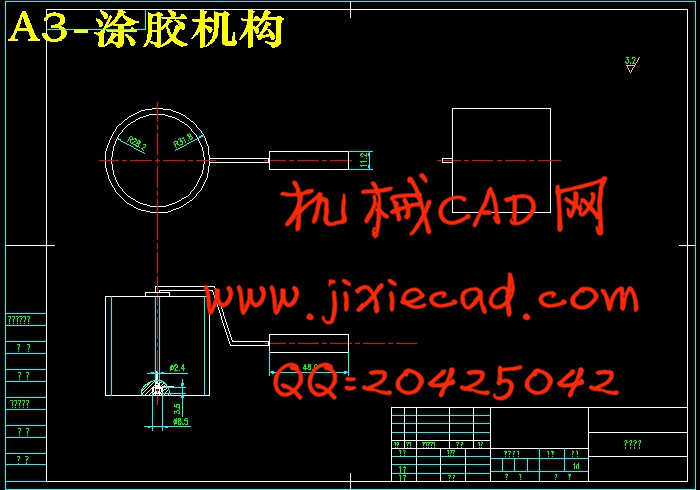

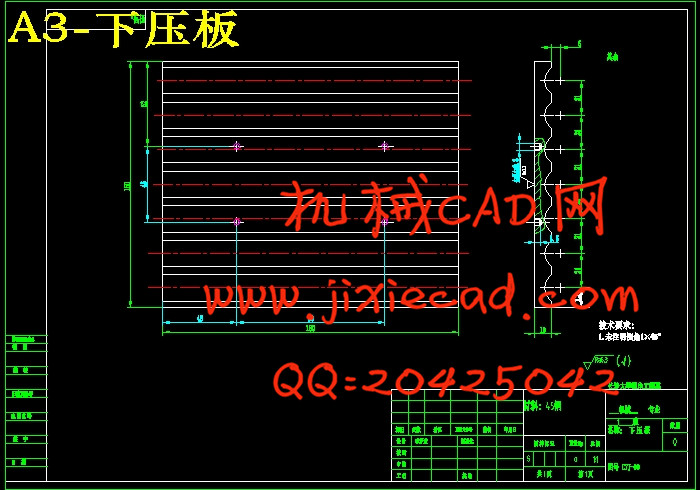

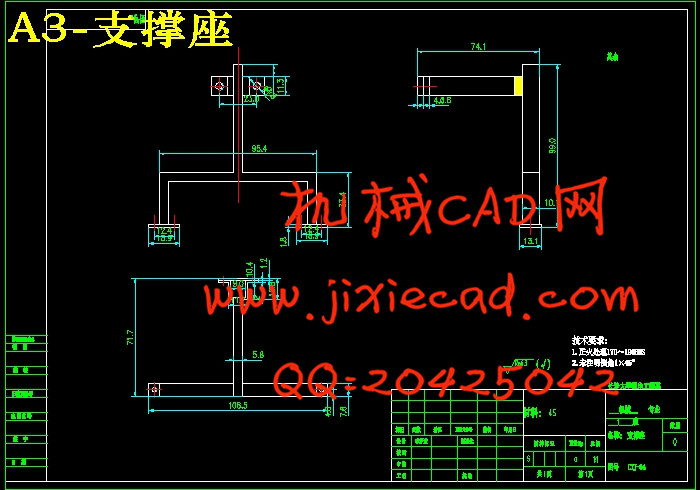

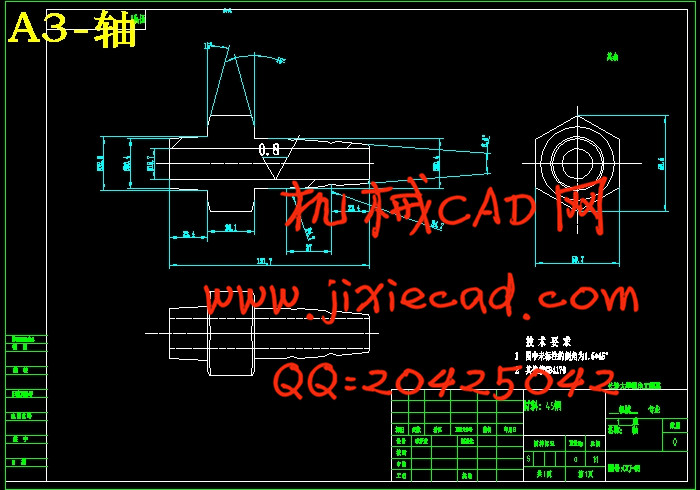

花炮筒扇形排布穿引机可实现花炮筒的扇形排布、涂胶、穿引等工序,其主要由四部分组成:扇形排布机构、打孔穿引机构、涂胶机构、堆砌机构。扇形排布机构部分是实现花跑筒固定并且呈扇形排布的机构,主要通过弹性元件变形实现均匀扇形;打孔穿引机构是通过气缸实现在花炮筒底端打孔,同时将引线勾入炮筒的机构;涂胶机构是采用胶箱、涂胶滚筒实现在花炮筒筒体涂胶的机构;堆砌机构是将已排的扇形花炮筒堆砌,形成扇形筒堆。为传统烟花鞭炮生产提供了一种可用的自动扇形排布穿引机。

关键词:扇形花炮, 扇形排布, 打孔穿引, 涂胶

ABSTRACT

The fireworks and firecrackers in the traditional production process are mostly manual operation, process cumbersome. Not only has large labor intensity, low efficiency, difficult to guarantee the quality of products, R & D fireworks barrel threading machine platoon, raises the production efficiency, ensure the safety of production and product quality and stability of the inevitable trend.

Fireworks and firecrackers barrel threading machine can realize fan-shaped arrangement flower barrels platoon, glue, threading and other processes, which mainly consists of four parts: a fan-shaped arrangement mechanism, drilling threading mechanism, a glue spreading mechanism, stacking mechanism. Fan arrangement mechanism part is spent achieving run cylinder fixed and fan-shaped arrangement of institutions, mainly through the elastic element deformation to achieve uniform sector; drilling threading mechanism is through the cylinder to achieve the fireworks barrel bottom end punch, while the wire hook into the barrel body; the adhesive mechanism adopts plastic boxes, spreading roller in fireworks cylinder cylinder coating mechanism; stack mechanism is the row of scalloped flower barrel together, forming a fan cylinder pile. As the traditional fireworks and firecrackers production provided an available automatic platoon threading machine.

Keywords: The fan-shaped fireworks, platoon, drilling threading, glue

目 录

摘 要 I

ABSTRACT II

第1章 绪论 1

1.1花炮的历史及其发展 1

1.1.1花炮的由来 1

1.1.2花炮的发展 1

1.2扇形彩烟的生产现状和发展趋势 2

1.2.1 扇形彩烟的生产现状 2

1.3扇形彩烟的传统生产方式 3

1.3.1扇形彩烟的简单介绍 3

1.3.2 扇形彩烟的应用及前景 5

第2章 花炮筒扇形排布穿引机整体设计 7

2.1花炮筒扇形排布穿引机简介 7

2.2设计目的 7

2.3.1 扇形排布机构原理分析 7

2.3.2 打孔穿引机构原理分析 10

(1)打孔穿引概述 10

(2)打孔穿引原理 10

2.6.1打孔穿引机构气缸的计算 14

(6)气缸筒的壁厚的确定 16

(7)气缸进排气口直径d0 16

(8)活塞杆的校核 17

2.6.2下压机构气缸的计算 18

2.7机构设计 19

2.8关键部位的强度校核 20

2.7.1固胶机构气缸的横杆的校核 20

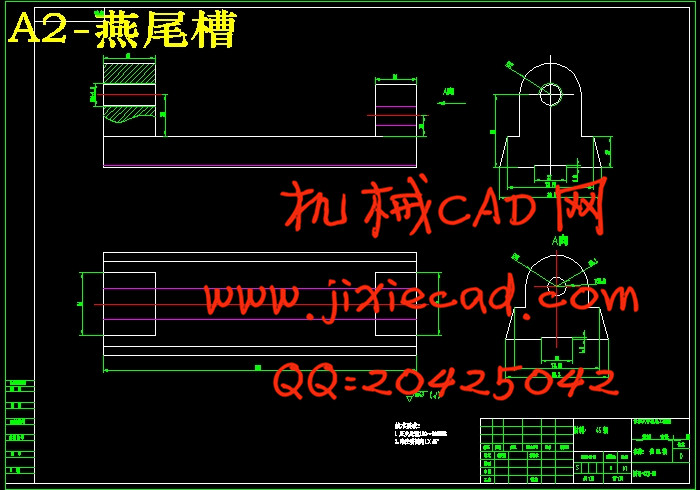

2.7.2排布气缸与燕尾槽的螺栓连接 21

2.7.3 下压气缸与支撑座的连接杆 22

第3章 标准件的选取 23

3.1气缸的选择 23

3.2导轨的选择 29

3.3 联轴器的选择 30

第4章 设计成果 32

结 论 34

参考文献 35

附 录 36

气缸的设计计算与校核 36

气缸内径的确定 36

致 谢 37