设计简介

摘 要

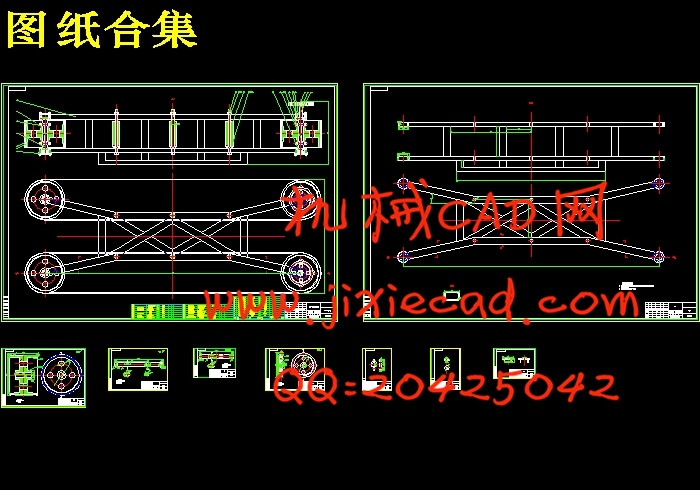

随着新的农业生产模式和新技术的发展与应用,农业机器人将成为农业生产的主力军。该文在分析大白菜收获机工作特点的基础上,从大白菜的采摘、转运、打包等方面进行分析。其中主要对提升运输部分做了详细的设计说明。该大白菜收获机适用于中小规模收割大白菜,结构简单、制造成本低。

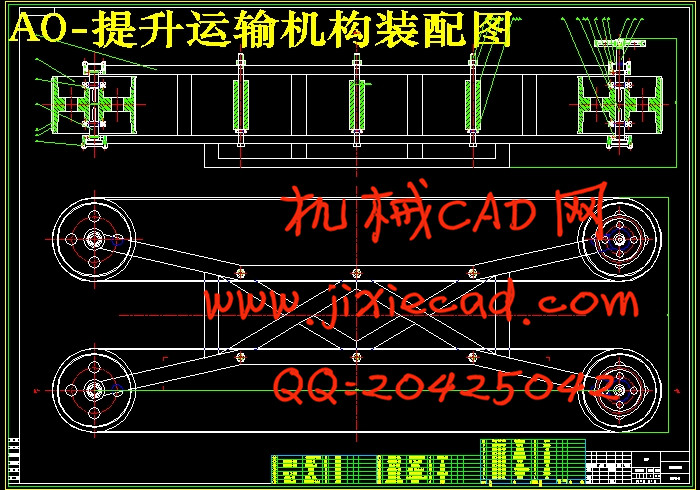

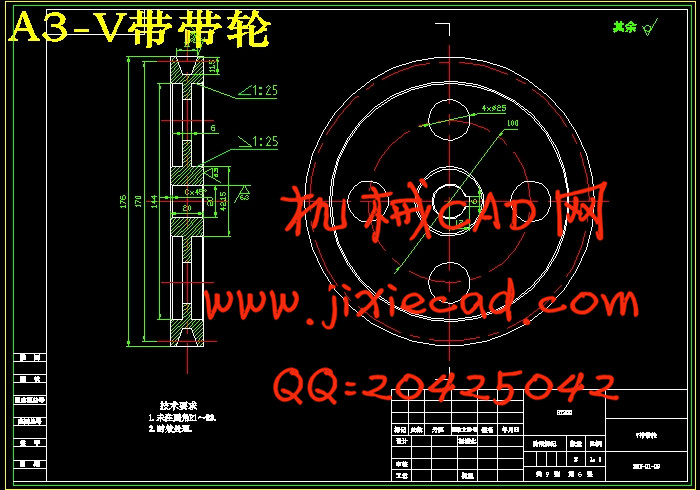

该大白菜收获机的提升运输部分采用带式输送,而张紧装置作为带式输送机构中不可缺少的重要组成部分,对带式输送机的稳定运行有着至关重要的作用。本文内容包括机架设计方案,平带带轮和平带的选择,轴的校核,以及张紧装置的作用、类型,且设计了张紧装置的总体方案,对其主要零部件的设计和选型进行了说明。所设计的张紧装置使用螺杆作为张紧执行元件,具有张紧力可调、结构简单、适应性强、控制方便、安全性能好等特点。

关键词:大白菜、收获机、带式提升输送装置、张紧装置、螺杆

Designing Of Hoisting And Transporting Mechanism

For Cabbage Harvest Machinery

Abstract

Farm machinery is to become the capital ship of the agriculture.This paper introduced gathering ,transporting and packing cabbage,on the basis of the working peculiarity of the cabbage harvest machinery,and it mainly introduced its transporting mechanism. The cabbage harvest machinery is suitable to gather in the cabbage for family expenses.

The cabbage harvest machinery use belt conveyors as its transporting mechanism,while Tensioning device, as an important and indispensable component of the belt conveyor, has a vital role to the stable operation of the belt conveyor . This paper introduces the role of the tensioning device,type,installation layout principles, and its development profile.And then raised the tension of the belt conveyor to the tension and take-up device requirements, on the basis the analysis of the principle of the transmission belt conveyor. In this paper, the main device design programme of the automatically tensioning device have been introduced, and descripte its main components for the design and selection of the note.The tensioning device use the screwstaff as the take-up of the implementation component.,with adjustable tension, simple, strong adaptability and control convenience, performance and safety and so on.

Keywords:Cabbage harvest; machinery; Belt hoisting and transporting mechanism; tensioning;Screwstaff

目 录

1 绪论 1

2 大白菜收获机总体和主要部件简介2

2.1. 大白菜收获机工作原理和结构简介2

2.2 收获机提升运输装置简介 2

2.3 其他装置简介3

2.3.1 收获机输送部分简介3

2.3.2 锁紧装置简介4

3 提升运输装置主要零部件的设计 7

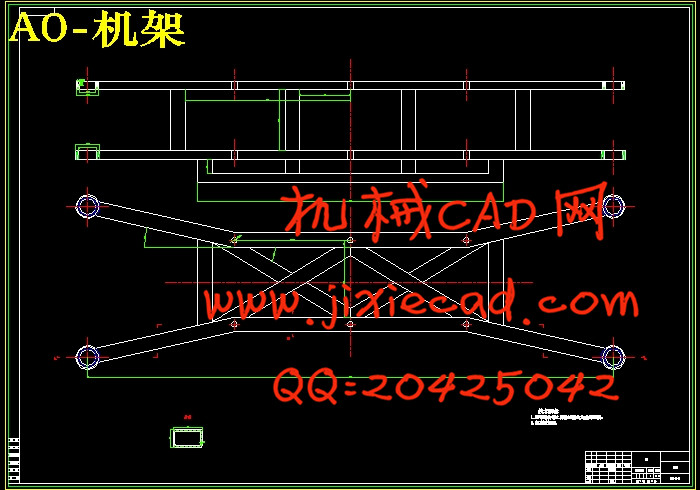

3.1 机架的设计 7

3.1.1 机架外形7

3.1.2 计算部分8

3.1.3 机架结构的确定8

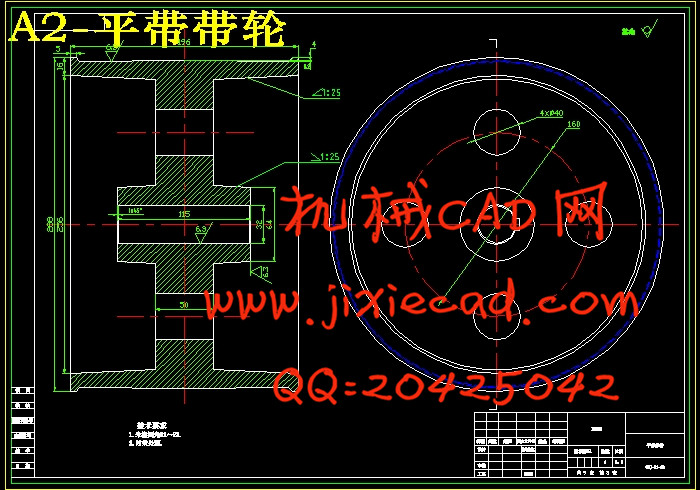

3.2平带带轮的设计 9

3.3平带的选择 10

3.4平带带轮轴的设计 11

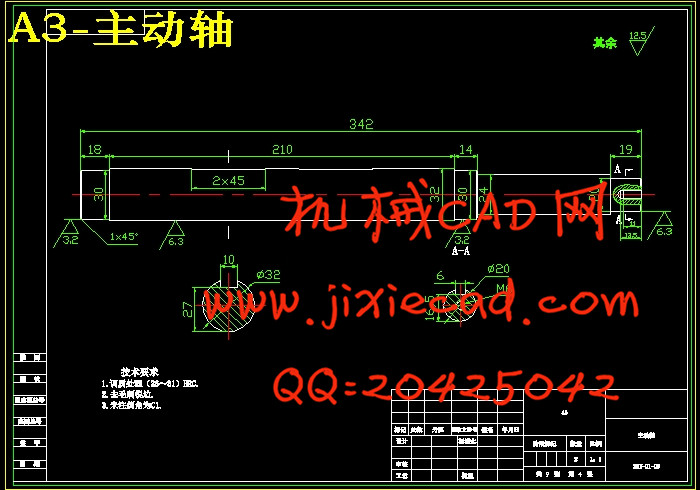

3.4.1 主动轴的设计 11

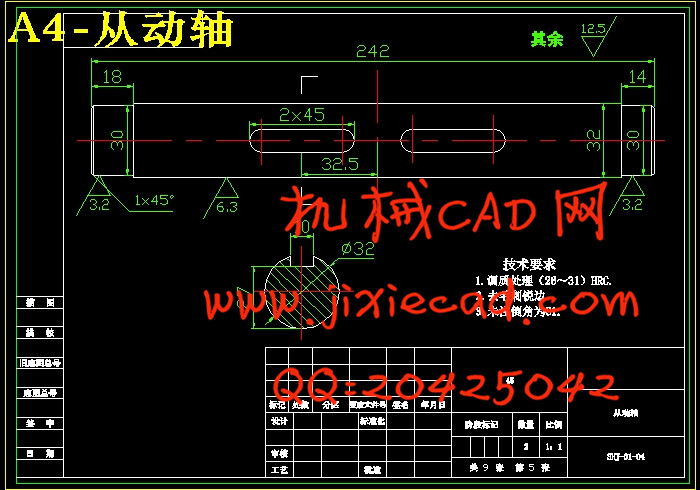

3.4.2 从动轴的设计 13

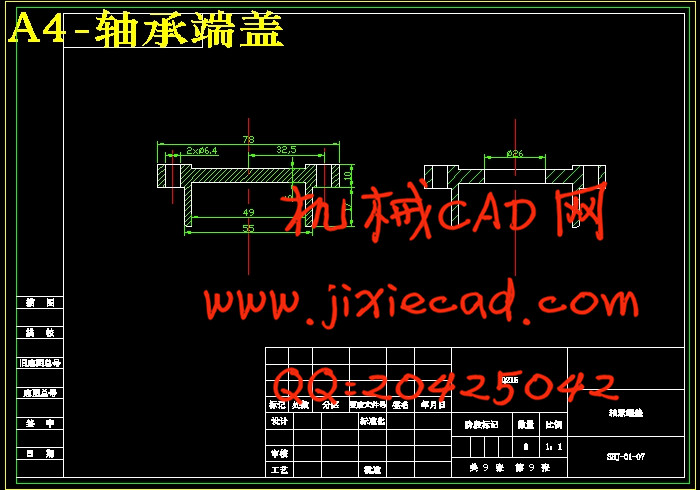

3.5 端盖14

3.6 支承轴的设计14

4 结论 15

4.1主要结论 16

4.2 问题与展望 16

5 设计心得 17

参考文献 18

致谢 19

随着新的农业生产模式和新技术的发展与应用,农业机器人将成为农业生产的主力军。该文在分析大白菜收获机工作特点的基础上,从大白菜的采摘、转运、打包等方面进行分析。其中主要对提升运输部分做了详细的设计说明。该大白菜收获机适用于中小规模收割大白菜,结构简单、制造成本低。

该大白菜收获机的提升运输部分采用带式输送,而张紧装置作为带式输送机构中不可缺少的重要组成部分,对带式输送机的稳定运行有着至关重要的作用。本文内容包括机架设计方案,平带带轮和平带的选择,轴的校核,以及张紧装置的作用、类型,且设计了张紧装置的总体方案,对其主要零部件的设计和选型进行了说明。所设计的张紧装置使用螺杆作为张紧执行元件,具有张紧力可调、结构简单、适应性强、控制方便、安全性能好等特点。

关键词:大白菜、收获机、带式提升输送装置、张紧装置、螺杆

Designing Of Hoisting And Transporting Mechanism

For Cabbage Harvest Machinery

Abstract

Farm machinery is to become the capital ship of the agriculture.This paper introduced gathering ,transporting and packing cabbage,on the basis of the working peculiarity of the cabbage harvest machinery,and it mainly introduced its transporting mechanism. The cabbage harvest machinery is suitable to gather in the cabbage for family expenses.

The cabbage harvest machinery use belt conveyors as its transporting mechanism,while Tensioning device, as an important and indispensable component of the belt conveyor, has a vital role to the stable operation of the belt conveyor . This paper introduces the role of the tensioning device,type,installation layout principles, and its development profile.And then raised the tension of the belt conveyor to the tension and take-up device requirements, on the basis the analysis of the principle of the transmission belt conveyor. In this paper, the main device design programme of the automatically tensioning device have been introduced, and descripte its main components for the design and selection of the note.The tensioning device use the screwstaff as the take-up of the implementation component.,with adjustable tension, simple, strong adaptability and control convenience, performance and safety and so on.

Keywords:Cabbage harvest; machinery; Belt hoisting and transporting mechanism; tensioning;Screwstaff

目 录

1 绪论 1

2 大白菜收获机总体和主要部件简介2

2.1. 大白菜收获机工作原理和结构简介2

2.2 收获机提升运输装置简介 2

2.3 其他装置简介3

2.3.1 收获机输送部分简介3

2.3.2 锁紧装置简介4

3 提升运输装置主要零部件的设计 7

3.1 机架的设计 7

3.1.1 机架外形7

3.1.2 计算部分8

3.1.3 机架结构的确定8

3.2平带带轮的设计 9

3.3平带的选择 10

3.4平带带轮轴的设计 11

3.4.1 主动轴的设计 11

3.4.2 从动轴的设计 13

3.5 端盖14

3.6 支承轴的设计14

4 结论 15

4.1主要结论 16

4.2 问题与展望 16

5 设计心得 17

参考文献 18

致谢 19