设计简介

摘要:油菜是我国优势农作物,长江流域是我国油菜主产区和优势产业带,油菜面

积占我国油菜总面积的85%左右。据农业部2007年底统计,湖南省冬种油菜面积1459万亩。

而冬季可种植油菜的总面积高达3000多万亩,发展油菜潜力巨大。由于我国移栽机械发展缓

慢,秧苗移栽几乎全部由人工完成,劳动强度大、生产效率低、栽植质量差、生产成本高。

因此,实现油菜移栽机械化已成为农业生产的迫切需要。随着钵体育苗技术的日趋完善,钵

苗栽植技术在国内外被广泛应用。

关键词:移栽;机械化;钵体育苗;油菜

The Structure Design of Taking The Seedling Automatically in Thes

(College of Engineering, Hunan Agricultural University, Changsha 410128, China)

Abstract:Rape is one of a superior crop in China, the Yangtze river basin is a main

producing area and advantageous belt of rape, which planting area is about 85% of the total area in

China. From the statistics of agriculture ministry in the end of 2007, the area for winter planting

rape is 14.59 million mu in Hunan province, and the area suit for winter planting rape can reach up

to 30.00 million mu , which reveal a large potential in the rape industry. The development of

transplant machine is slowly in China, so the transplant of seedling is almost all completed by

artificial, which high in labor intensity and production costs but low in production efficiency and

transplanting quality. Therefore, to realize mechanization of the rape-transplant is in a hurry for

agricultural production. The bowl seeding planting technology is widely used in the domestic and

overseas with the gradually maturing bowl seeding technology.

Key words:ransplant, mechanization, bowl seeding , rape

目

录

摘要........................................................................................................................3

关键词....................................................................................................................3

1前言..................................................................................................................4

1.1课题研究的意义..........................................................................................4

1.2研究课题所涉及的领域在国内外的研究现状及发展趋势......................4

1.2.1国内外移栽机的发展现状......................................................................4

1.2.2自动取苗装置的发展现状......................................................................5

1.3国内移栽机械化发展存在的主要问题......................................................5

1.4本课题的研究内容......................................................................................5

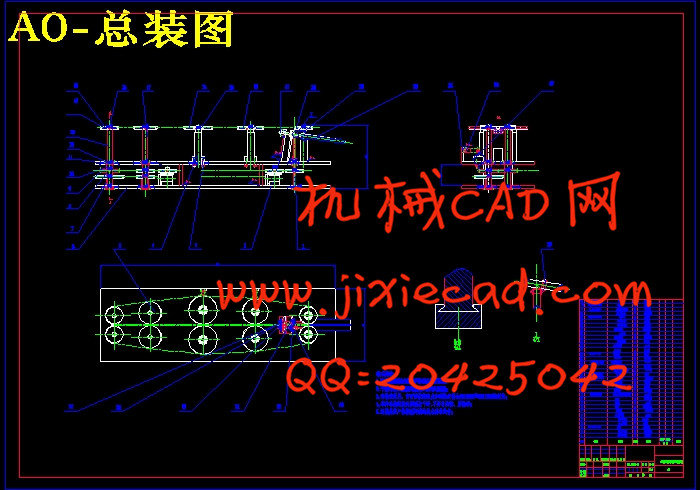

2取苗机构的设计..............................................................................................5

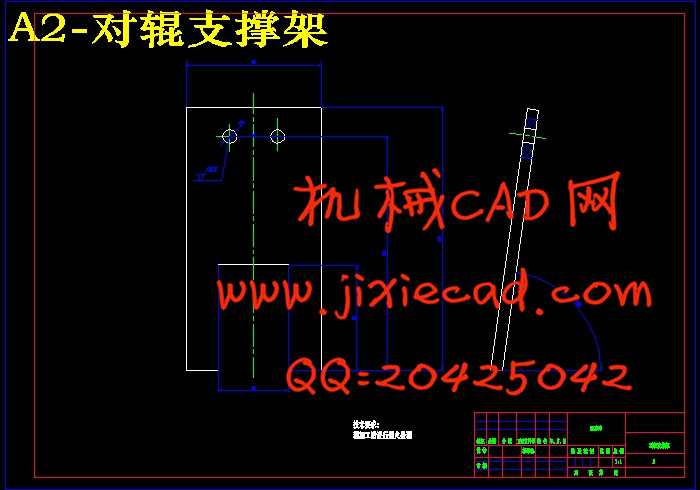

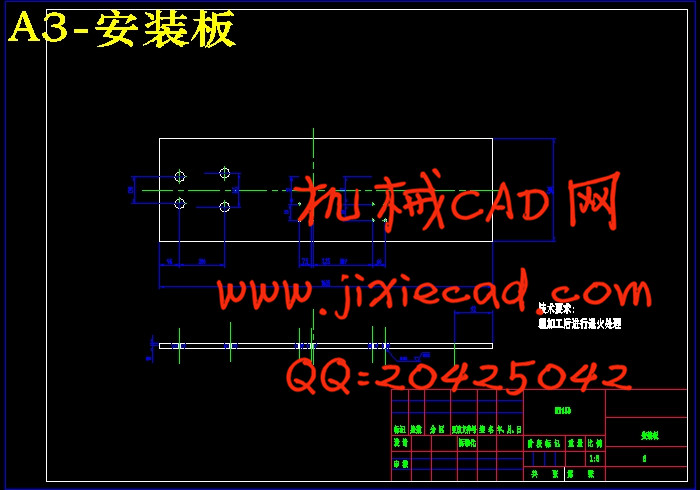

2.1拔苗机构的设计..........................................................................................6

2.1.1本装置的主要结构及安装......................................................................7

2.1.2工作原理..................................................................................................7

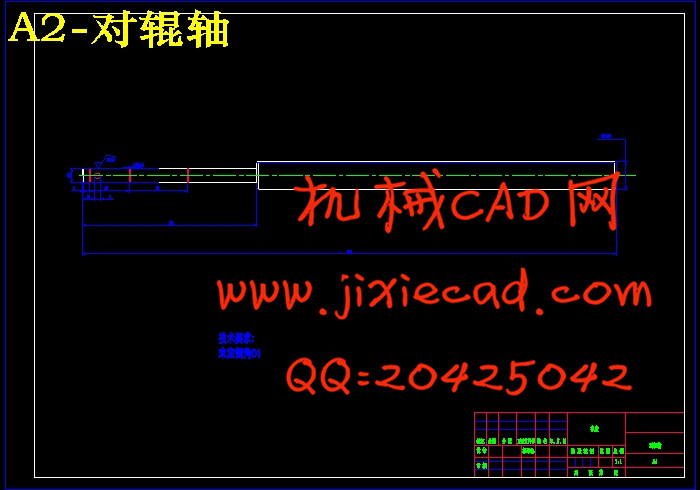

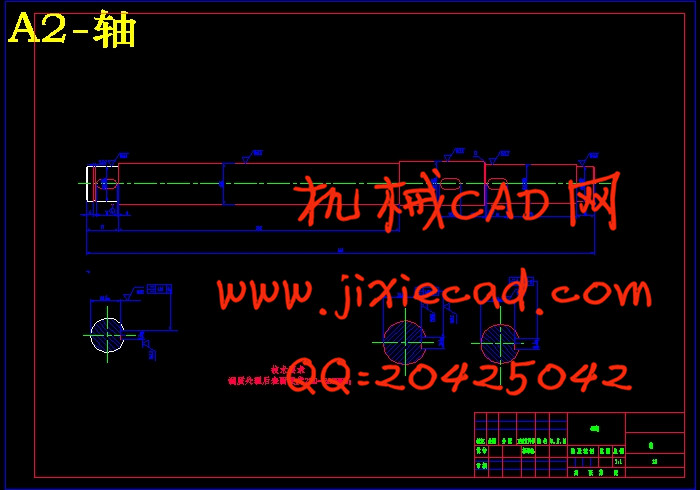

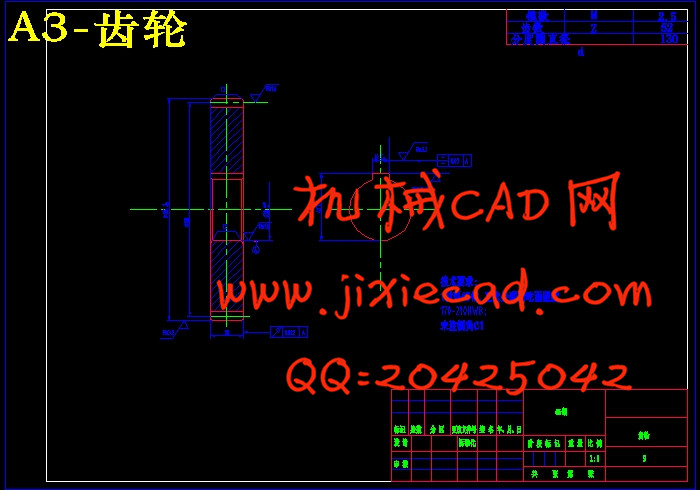

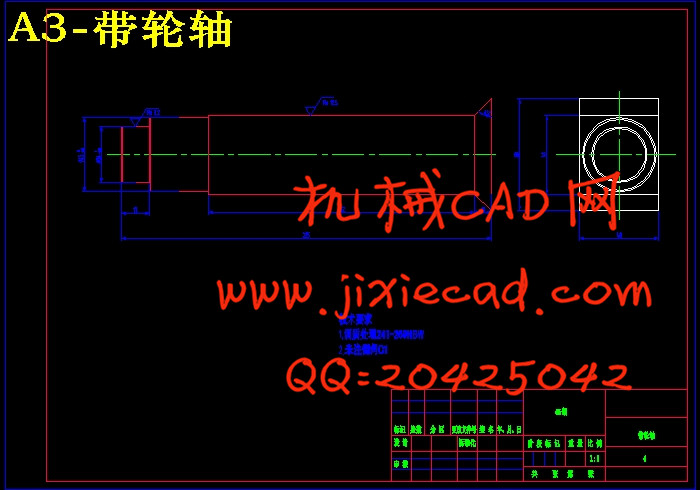

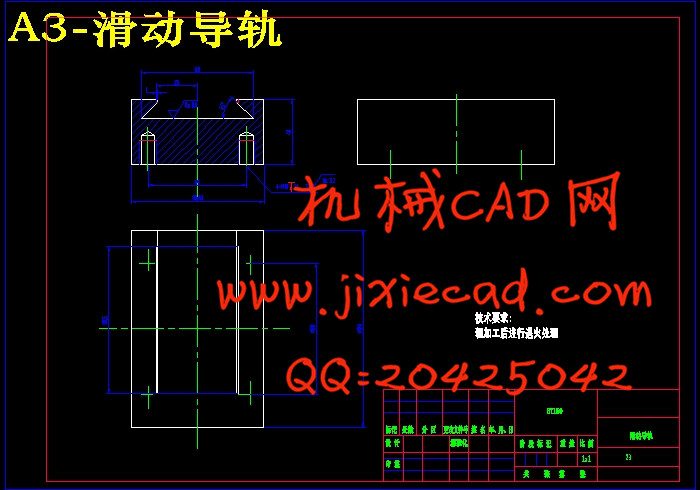

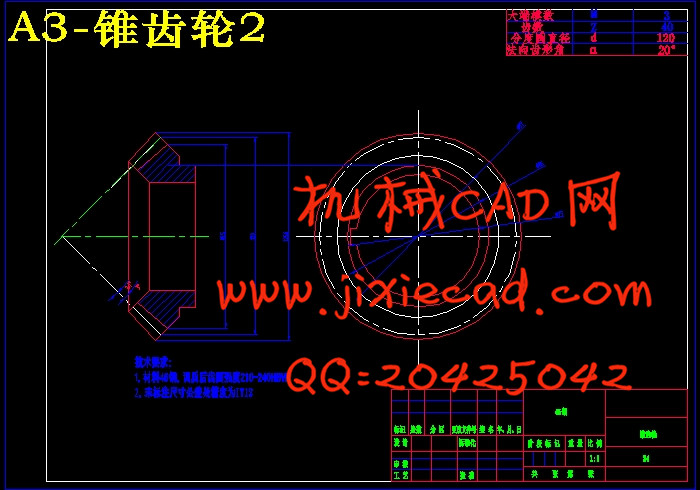

2.1.3对辊轴的参数设计及动力选择..............................................................7

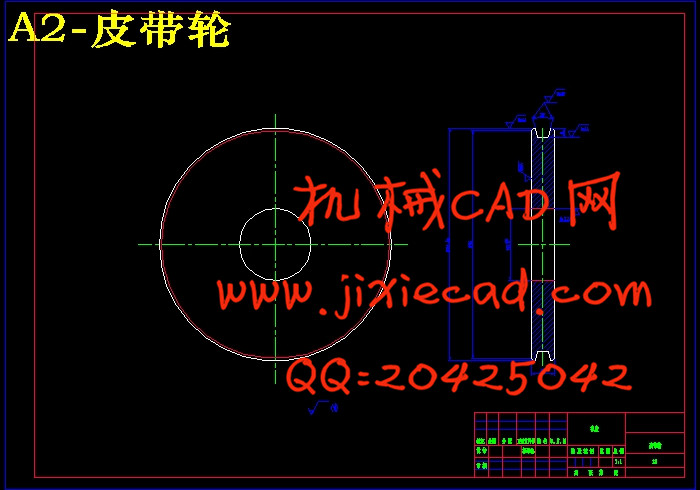

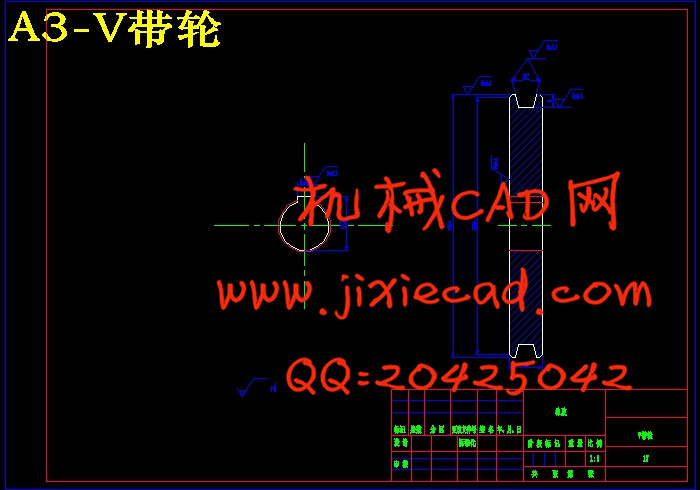

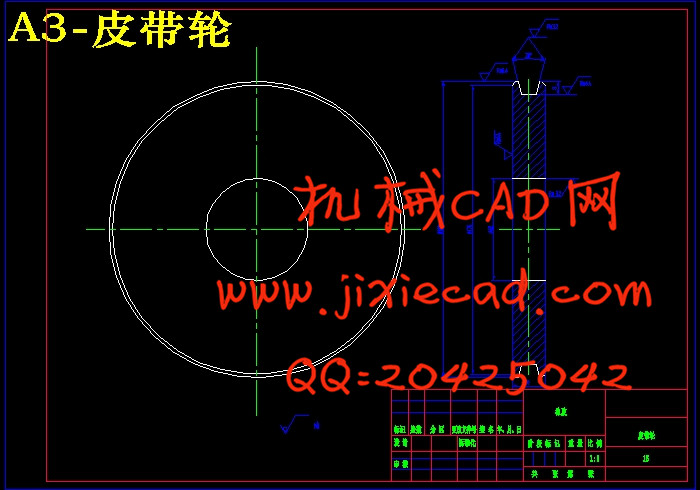

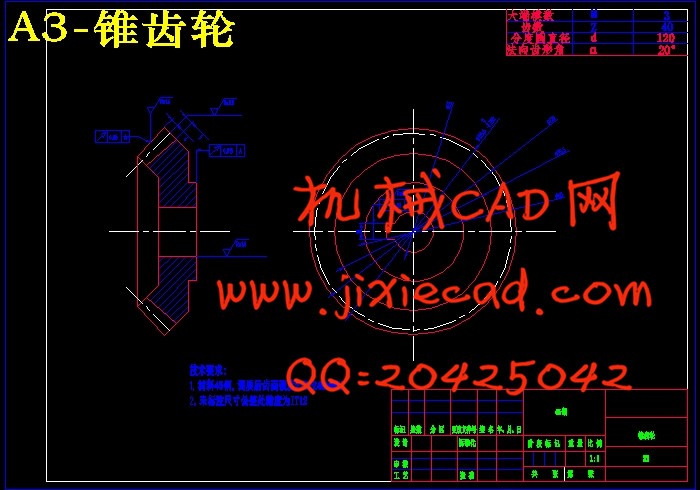

2.1.4动力传输装置..........................................................................................8

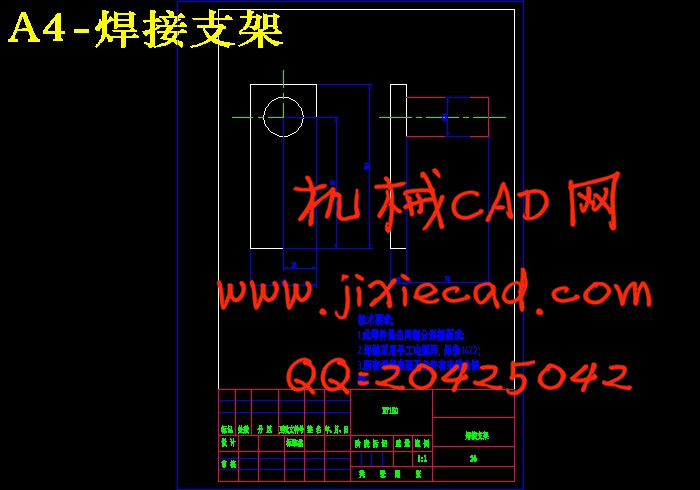

2.2输送装置的设计..........................................................................................9

2.2.1主要构成部分:......................................................................................9

2.2.2工作原理................................................................................................10

2.2.3输送装置的参数选择与计算................................................................11

2.3落苗机构的理论设计................................................................................19

2.3.1落苗机构的结构....................................................................................19

2.3.2落苗机构的工作原理............................................................................19

3其他主要零件的选择与顺滑........................................................................19

4结束语............................................................................................................19

4.1本实用新型与现有技术相比具有以下优点:........................................20

4.2论文的不足与展望....................................................................................21

参考文献..............................................................................................................21

致谢......................................................................................................................23

积占我国油菜总面积的85%左右。据农业部2007年底统计,湖南省冬种油菜面积1459万亩。

而冬季可种植油菜的总面积高达3000多万亩,发展油菜潜力巨大。由于我国移栽机械发展缓

慢,秧苗移栽几乎全部由人工完成,劳动强度大、生产效率低、栽植质量差、生产成本高。

因此,实现油菜移栽机械化已成为农业生产的迫切需要。随着钵体育苗技术的日趋完善,钵

苗栽植技术在国内外被广泛应用。

关键词:移栽;机械化;钵体育苗;油菜

The Structure Design of Taking The Seedling Automatically in Thes

(College of Engineering, Hunan Agricultural University, Changsha 410128, China)

Abstract:Rape is one of a superior crop in China, the Yangtze river basin is a main

producing area and advantageous belt of rape, which planting area is about 85% of the total area in

China. From the statistics of agriculture ministry in the end of 2007, the area for winter planting

rape is 14.59 million mu in Hunan province, and the area suit for winter planting rape can reach up

to 30.00 million mu , which reveal a large potential in the rape industry. The development of

transplant machine is slowly in China, so the transplant of seedling is almost all completed by

artificial, which high in labor intensity and production costs but low in production efficiency and

transplanting quality. Therefore, to realize mechanization of the rape-transplant is in a hurry for

agricultural production. The bowl seeding planting technology is widely used in the domestic and

overseas with the gradually maturing bowl seeding technology.

Key words:ransplant, mechanization, bowl seeding , rape

目

录

摘要........................................................................................................................3

关键词....................................................................................................................3

1前言..................................................................................................................4

1.1课题研究的意义..........................................................................................4

1.2研究课题所涉及的领域在国内外的研究现状及发展趋势......................4

1.2.1国内外移栽机的发展现状......................................................................4

1.2.2自动取苗装置的发展现状......................................................................5

1.3国内移栽机械化发展存在的主要问题......................................................5

1.4本课题的研究内容......................................................................................5

2取苗机构的设计..............................................................................................5

2.1拔苗机构的设计..........................................................................................6

2.1.1本装置的主要结构及安装......................................................................7

2.1.2工作原理..................................................................................................7

2.1.3对辊轴的参数设计及动力选择..............................................................7

2.1.4动力传输装置..........................................................................................8

2.2输送装置的设计..........................................................................................9

2.2.1主要构成部分:......................................................................................9

2.2.2工作原理................................................................................................10

2.2.3输送装置的参数选择与计算................................................................11

2.3落苗机构的理论设计................................................................................19

2.3.1落苗机构的结构....................................................................................19

2.3.2落苗机构的工作原理............................................................................19

3其他主要零件的选择与顺滑........................................................................19

4结束语............................................................................................................19

4.1本实用新型与现有技术相比具有以下优点:........................................20

4.2论文的不足与展望....................................................................................21

参考文献..............................................................................................................21

致谢......................................................................................................................23