设计简介

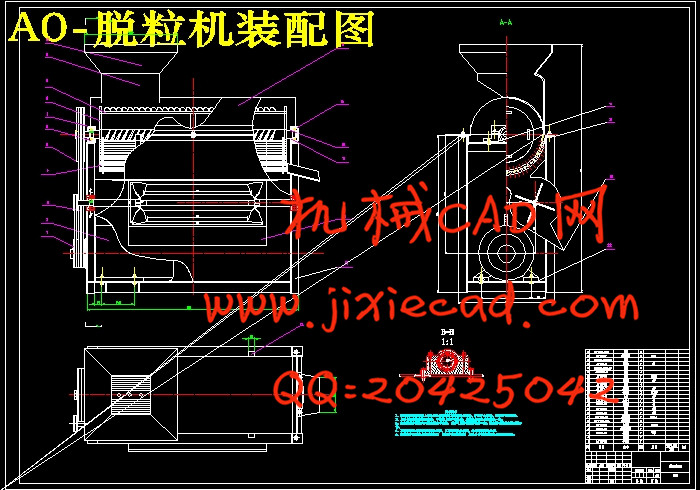

摘 要:为了降低农民在玉米脱粒时劳动强度、提高工作效率,设计玉米脱粒机。该机主要有入料口、栅格式凹板和钉齿脱粒滚筒及传动部件等组成。以电动机为动力源,动力由电动机输出轴输出,再通过传动带传递到钉齿脱粒滚筒上,钉齿脱粒滚筒配合栅格式凹板将玉米脱粒,玉米粒从栅格式凹板分离并排出机体外,而玉米芯从入料的另一端排出机体之外。

关键词:玉米;脱粒机;效率;结构;设计;

Abstract: For reducing a peasant during the period of the maize threshes, the intensity of labour, raises working efficiency , designs maize sheller. Be machine's turn to have mainly enter expect that the mouth , bars form notch board and nail tooth the cylinder threshing and drive component etc. are composed of. Take electric motor as driving force source, driving force exports axis output from the electric motor , the nail tooth seed-husking cylinder threshes on the cylinder threshing again by the fact that belt delivery arrives at the nail tooth, coordinating bars form notch board with the maize, besides niblet complies with bars form notch board separation and the outside discharging airframe, but the maize core discharges airframe from another one end entering material.

Key words: Maize; Sheller;Efficiency; Structure; Design

目 录

摘要……………………………………………………………………………1

关键词…………………………………………………………………………1

1前言…………………………………………………………………………1

2设计任务书…………………………………………………………………3

3计算说明书…………………………………………………………………4

3.1电动机的选择……………………………………………………………4

3.1.1电动机的功率…………………………………………………………5

3.1.2电动机的转速…………………………………………………………5

3.1.3电动机的型号和技术参数及传动比…………………………………6

3.2传动装置的设计…………………………………………………………6

3.2.1传动带的设计…………………………………………………………6

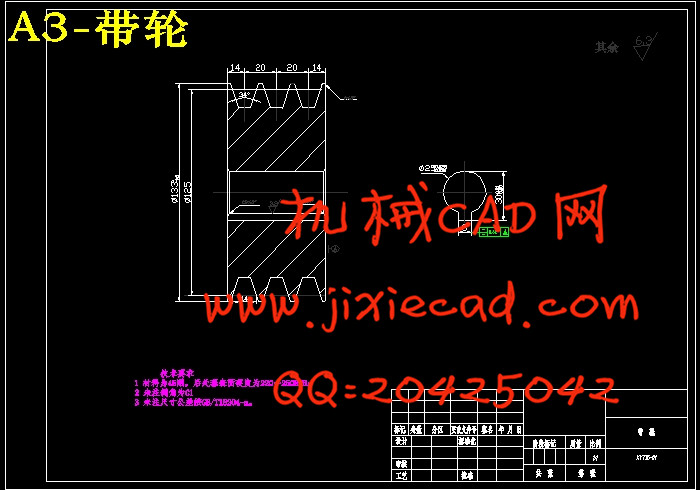

3.2.2 V带带轮的设计………………………………………………………8

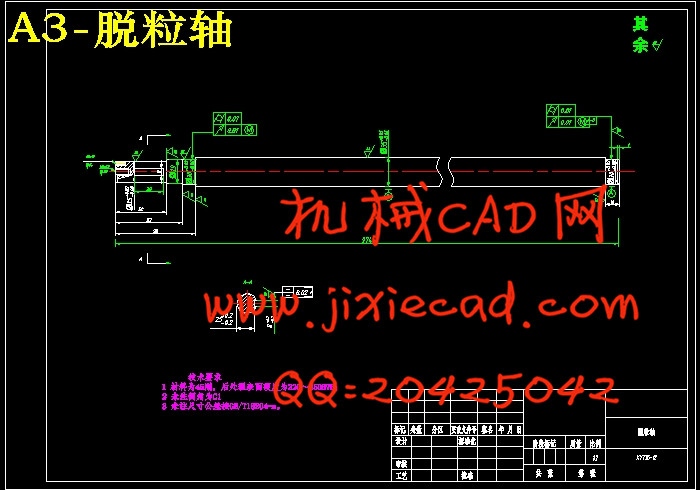

3.3脱粒轴的设计……………………………………………………………9

3.3.1根据轴向定位的要求确定轴的各段直径和长度……………………10

3.3.2按弯扭合成条件校核轴的强度………………………………………11

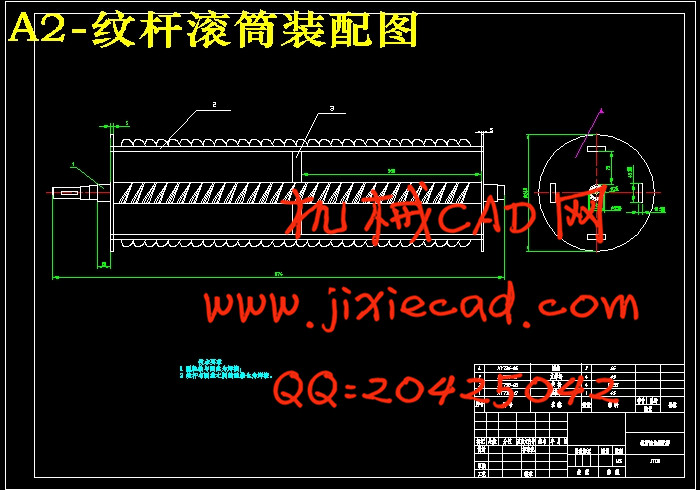

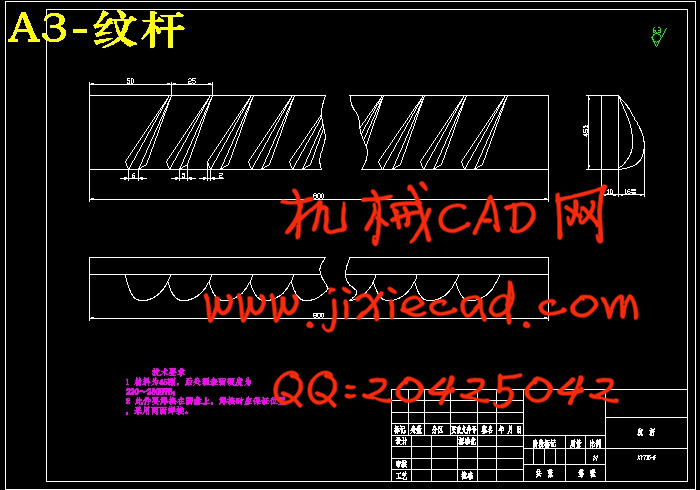

3.4纹杆的总体结构设计…………………………………………………14

3.4.1纹杆的设计……………………………………………………………15

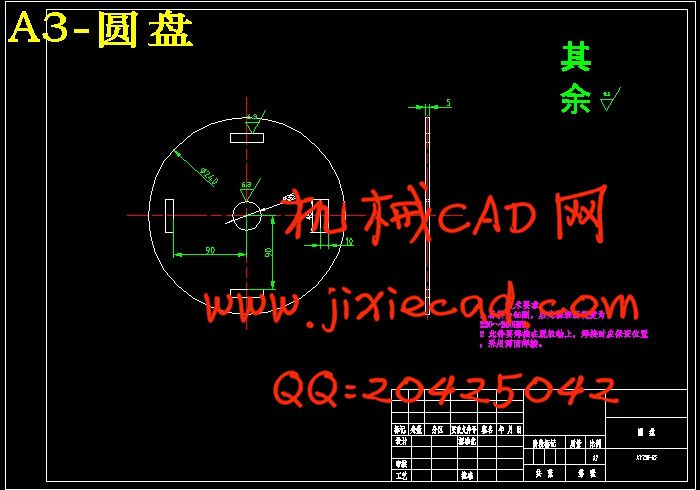

3.5圆盘的设计………………………………………………………………15

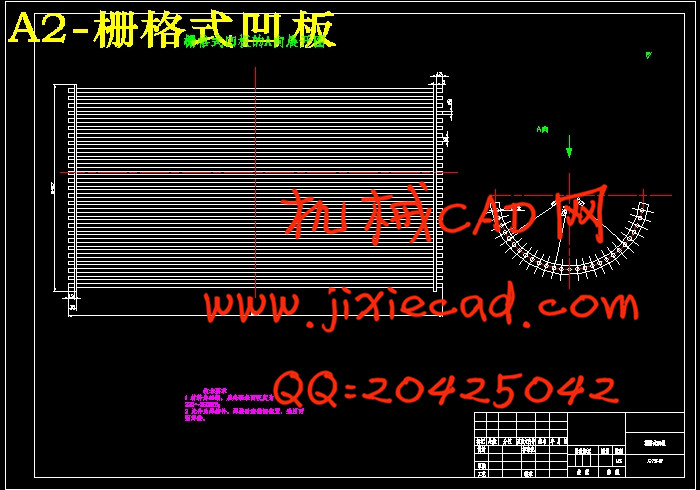

3.6栅格式凹板的设计………………………………………………………16

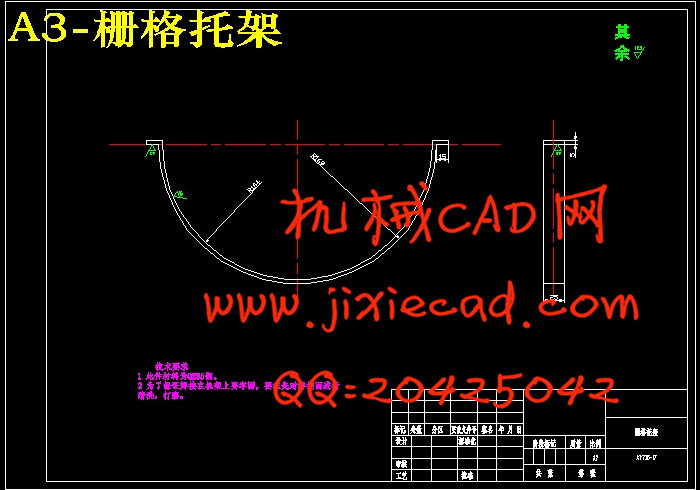

3.7栅格托架的设计…………………………………………………………16

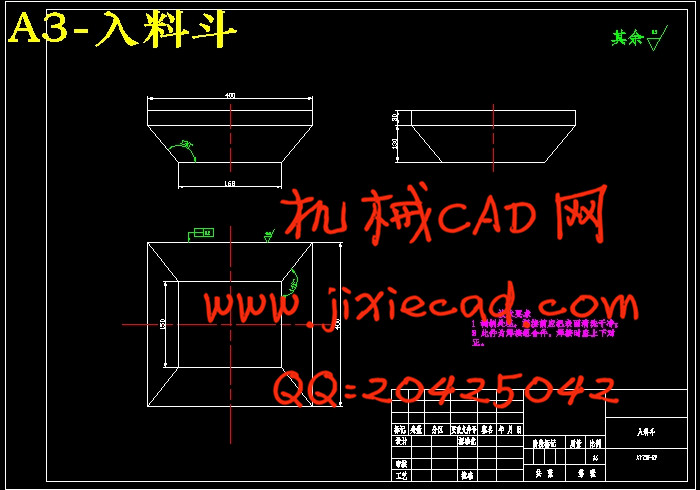

3.8入料斗和进料口的设计…………………………………………………16

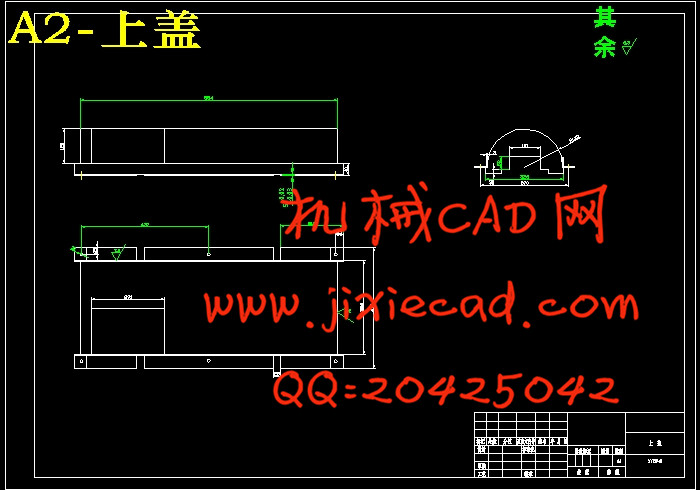

3.9上盖的设计………………………………………………………………17

3.10键强度的校核……………………………………………………………17

3.11轴承的选择和校核………………………………………………………18

3.12机架的设计………………………………………………………………18

3.13玉米脱粒机上标准件的选择……………………………………………19

3.13.1螺栓的选择……………………………………………………………19

3.13.2钩头楔键的选择………………………………………………………20

4 结论…………………………………………………………………………20

参考文献…………………………………………………………………………21

致谢………………………………………………………………………………21

关键词:玉米;脱粒机;效率;结构;设计;

Abstract: For reducing a peasant during the period of the maize threshes, the intensity of labour, raises working efficiency , designs maize sheller. Be machine's turn to have mainly enter expect that the mouth , bars form notch board and nail tooth the cylinder threshing and drive component etc. are composed of. Take electric motor as driving force source, driving force exports axis output from the electric motor , the nail tooth seed-husking cylinder threshes on the cylinder threshing again by the fact that belt delivery arrives at the nail tooth, coordinating bars form notch board with the maize, besides niblet complies with bars form notch board separation and the outside discharging airframe, but the maize core discharges airframe from another one end entering material.

Key words: Maize; Sheller;Efficiency; Structure; Design

目 录

摘要……………………………………………………………………………1

关键词…………………………………………………………………………1

1前言…………………………………………………………………………1

2设计任务书…………………………………………………………………3

3计算说明书…………………………………………………………………4

3.1电动机的选择……………………………………………………………4

3.1.1电动机的功率…………………………………………………………5

3.1.2电动机的转速…………………………………………………………5

3.1.3电动机的型号和技术参数及传动比…………………………………6

3.2传动装置的设计…………………………………………………………6

3.2.1传动带的设计…………………………………………………………6

3.2.2 V带带轮的设计………………………………………………………8

3.3脱粒轴的设计……………………………………………………………9

3.3.1根据轴向定位的要求确定轴的各段直径和长度……………………10

3.3.2按弯扭合成条件校核轴的强度………………………………………11

3.4纹杆的总体结构设计…………………………………………………14

3.4.1纹杆的设计……………………………………………………………15

3.5圆盘的设计………………………………………………………………15

3.6栅格式凹板的设计………………………………………………………16

3.7栅格托架的设计…………………………………………………………16

3.8入料斗和进料口的设计…………………………………………………16

3.9上盖的设计………………………………………………………………17

3.10键强度的校核……………………………………………………………17

3.11轴承的选择和校核………………………………………………………18

3.12机架的设计………………………………………………………………18

3.13玉米脱粒机上标准件的选择……………………………………………19

3.13.1螺栓的选择……………………………………………………………19

3.13.2钩头楔键的选择………………………………………………………20

4 结论…………………………………………………………………………20

参考文献…………………………………………………………………………21

致谢………………………………………………………………………………21