设计简介

摘要

我设计的平板硫化机,属于一种圆筒型,工作时,模具通过气缸自动推拉到模板自动退出和模板可以自动打开一角,能够方便于取出成型的制品。与锁模式持有主缸压力的电加热是由电加热,加热。上下螺母固定在立柱上从而固定上横梁,这样就可以调节上下横梁间的间距。

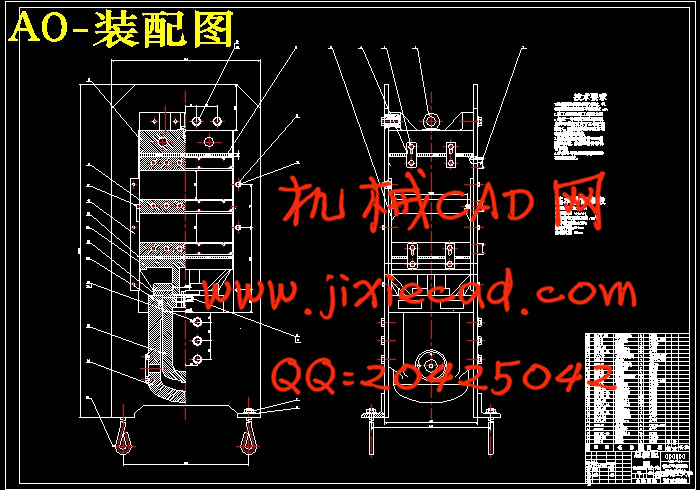

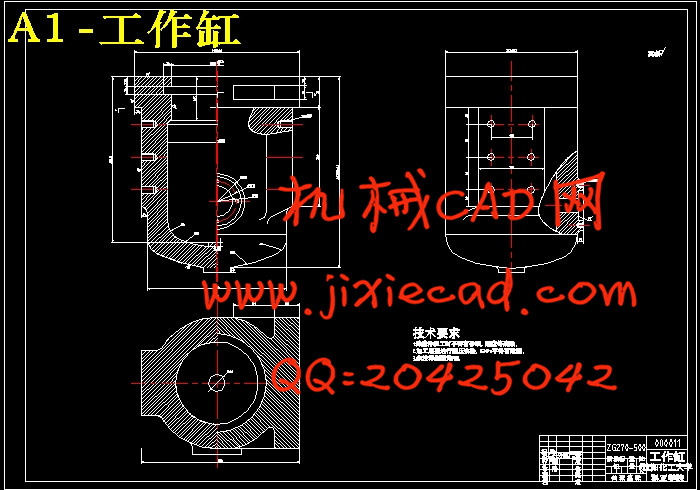

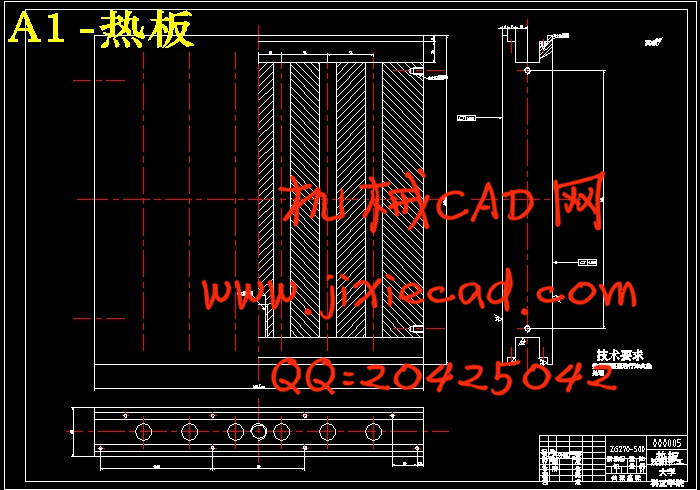

平板硫化机是橡胶产业经常使用的配置之一,其组成构件分别为:工作缸、热板、柱塞等,封闭受力构件,加热机构组成。其作用是提供硫化过程中所需要的压力和温度。

橡胶平板硫化机具有很多优点包括:1、设备操作可靠;2、维修量少;3,对各种优势的压力热板区,其主要功能是提供用于固化所需的温度和压力。它的主要用途就是硫化平型胶带。与我国传统常使用柱式结构与硫化机相比,具有巨大的优势。根据液压系统的工作介质可分为液压油的压力。根据工作层数分为单层和双层。它的工作原理是液压缸产生压力,加热介质提供温度

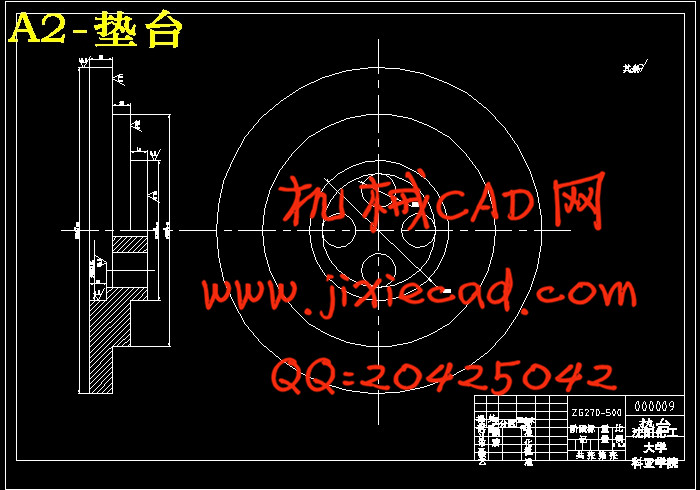

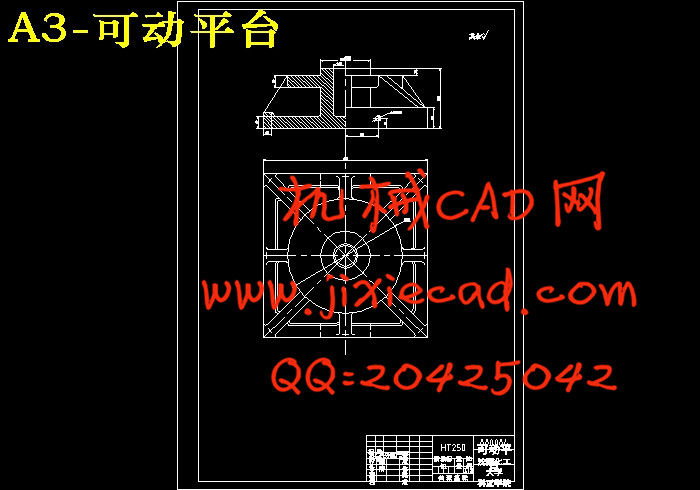

框式平板硫化机的主要零部件:柱塞、液压缸、密封圈、垫台、活动平台、加热板、隔热板、上横梁和框板等。橡胶平板硫化机主要用于硫化平型胶带,它具有热板单位面积压力大,设备操作可靠和维修量少等优点。平板硫化机的主要功能就是提供硫化所需的压力和温度。压力由液压系统通过液压缸产生,温度油加热介质所提供。在平板硫化机橡胶工业中,柱式平板硫化机主机是使用较早的一种机型,我国过去使用的平带平板硫化机也多为柱式,但目前则多采用框式结构。

而它的发展的动向是提高机械化自动水平,改善劳动条件,提高生产效率,减少机占底面积,完善附属装置和延长使用寿命等方面。

关键词:框式平板硫化机; 主要零件; 发展; 优缺点

我设计的平板硫化机,属于一种圆筒型,工作时,模具通过气缸自动推拉到模板自动退出和模板可以自动打开一角,能够方便于取出成型的制品。与锁模式持有主缸压力的电加热是由电加热,加热。上下螺母固定在立柱上从而固定上横梁,这样就可以调节上下横梁间的间距。

平板硫化机是橡胶产业经常使用的配置之一,其组成构件分别为:工作缸、热板、柱塞等,封闭受力构件,加热机构组成。其作用是提供硫化过程中所需要的压力和温度。

橡胶平板硫化机具有很多优点包括:1、设备操作可靠;2、维修量少;3,对各种优势的压力热板区,其主要功能是提供用于固化所需的温度和压力。它的主要用途就是硫化平型胶带。与我国传统常使用柱式结构与硫化机相比,具有巨大的优势。根据液压系统的工作介质可分为液压油的压力。根据工作层数分为单层和双层。它的工作原理是液压缸产生压力,加热介质提供温度

框式平板硫化机的主要零部件:柱塞、液压缸、密封圈、垫台、活动平台、加热板、隔热板、上横梁和框板等。橡胶平板硫化机主要用于硫化平型胶带,它具有热板单位面积压力大,设备操作可靠和维修量少等优点。平板硫化机的主要功能就是提供硫化所需的压力和温度。压力由液压系统通过液压缸产生,温度油加热介质所提供。在平板硫化机橡胶工业中,柱式平板硫化机主机是使用较早的一种机型,我国过去使用的平带平板硫化机也多为柱式,但目前则多采用框式结构。

而它的发展的动向是提高机械化自动水平,改善劳动条件,提高生产效率,减少机占底面积,完善附属装置和延长使用寿命等方面。

关键词:框式平板硫化机; 主要零件; 发展; 优缺点

Abstract

I design the flat vulcanizing machine, which belongs to a kind of cylinder type, work, mold through the cylinder automatic push pull to the template automatically exit and template can automatically open a corner, to facilitate the removal of molding products. The electric heating with lock mode holding the main cylinder pressure is heated by electric heating. The upper and lower nuts are fixed on the column so that the upper member can adjust the spacing between the upper and lower beams.

The plate curing machine is one of the configurations of rubber industry, and its component parts are: working cylinder, hot plate, piston, etc.. Its role is to provide the pressure and temperature required during the curing process.

Rubber vulcanizing machine has many advantages including: 1, equipment operation and reliable; 2, small amount of maintenance; 3, the advantages of various pressure hot plate area, its main function is provided for the temperature and pressure required to cure. Its main purpose is to cure flat belt. With China's traditional commonly used column structure and vulcanizing machine, has a huge advantage. According to hydraulic system working medium can be divided into hydraulic oil pressure. According to the work layer, the layer is divided into single layer and double layer. Its working principle is hydraulic cylinder pressure, heating medium provides temperature.

The main parts of the frame type plate curing machine: the piston, the hydraulic cylinder, the sealing ring, the pad table, the movable platform, the heating plate, the heat shield, the upper beam and the frame plate, etc.. Rubber vulcanizing machine is mainly used for curing flat belt. It has hot plate pressure per unit area, equipment and reliable operation and low maintenance advantages. The main function of the flat plate curing machine is to provide the pressure and temperature required for curing.. The pressure is provided by the hydraulic pressure system through the hydraulic cylinder, and the temperature oil heating medium is provided.. In flat vulcanizing machine, rubber industry, the column plate vulcanizing machine is a use of earlier models, our past use of flat belt vulcanizing machine for column. But for now, the frame type structure.

The trend of its development is to improve the automatic level of mechanization, improve labor conditions, improve production efficiency, reduce the floor area, improve the auxiliary equipment and prolong service life and so on.

Key words: Frame type plate curing machine; Main parts; Development; Advantages and disadvantages

I design the flat vulcanizing machine, which belongs to a kind of cylinder type, work, mold through the cylinder automatic push pull to the template automatically exit and template can automatically open a corner, to facilitate the removal of molding products. The electric heating with lock mode holding the main cylinder pressure is heated by electric heating. The upper and lower nuts are fixed on the column so that the upper member can adjust the spacing between the upper and lower beams.

The plate curing machine is one of the configurations of rubber industry, and its component parts are: working cylinder, hot plate, piston, etc.. Its role is to provide the pressure and temperature required during the curing process.

Rubber vulcanizing machine has many advantages including: 1, equipment operation and reliable; 2, small amount of maintenance; 3, the advantages of various pressure hot plate area, its main function is provided for the temperature and pressure required to cure. Its main purpose is to cure flat belt. With China's traditional commonly used column structure and vulcanizing machine, has a huge advantage. According to hydraulic system working medium can be divided into hydraulic oil pressure. According to the work layer, the layer is divided into single layer and double layer. Its working principle is hydraulic cylinder pressure, heating medium provides temperature.

The main parts of the frame type plate curing machine: the piston, the hydraulic cylinder, the sealing ring, the pad table, the movable platform, the heating plate, the heat shield, the upper beam and the frame plate, etc.. Rubber vulcanizing machine is mainly used for curing flat belt. It has hot plate pressure per unit area, equipment and reliable operation and low maintenance advantages. The main function of the flat plate curing machine is to provide the pressure and temperature required for curing.. The pressure is provided by the hydraulic pressure system through the hydraulic cylinder, and the temperature oil heating medium is provided.. In flat vulcanizing machine, rubber industry, the column plate vulcanizing machine is a use of earlier models, our past use of flat belt vulcanizing machine for column. But for now, the frame type structure.

The trend of its development is to improve the automatic level of mechanization, improve labor conditions, improve production efficiency, reduce the floor area, improve the auxiliary equipment and prolong service life and so on.

Key words: Frame type plate curing machine; Main parts; Development; Advantages and disadvantages

目 录

第一章 概述 1

1.1平板硫化机的最新进展 1

1.1.1用平板硫化机进行模压成型和硫化 1

1.1.2平板硫化机模具设计的重要性 1

1.1.3平板硫化机在硫化成型中的不良现象及其预防措施 1

1.2平板硫化机的用途,类型及工作原理 1

1.2.1 用途和类型 1

第二章 基本性能参数 2

第三章 主要零部件的设计及校核 3

3.1 柱塞 3

3.1.1 结构与材料 3

3.1.2 结构尺寸及强度计算 3

3.2 液压缸 5

3.2.1 结构与材料 5

3.2.2 结构尺寸 5

3.3 密封装置 8

3.3.1 密封装置的要求 9

3.3.2 密封件 9

3.4 热板 9

3.4.1 材料 10

3.4.2 选择电热元件 10

3.4.3 安装方法 10

3.5 活动平台 11

3.5.1 结构材料 11

3.5.2平台负载荷及弯曲受力情况 12

3.5.3 强度校核 13

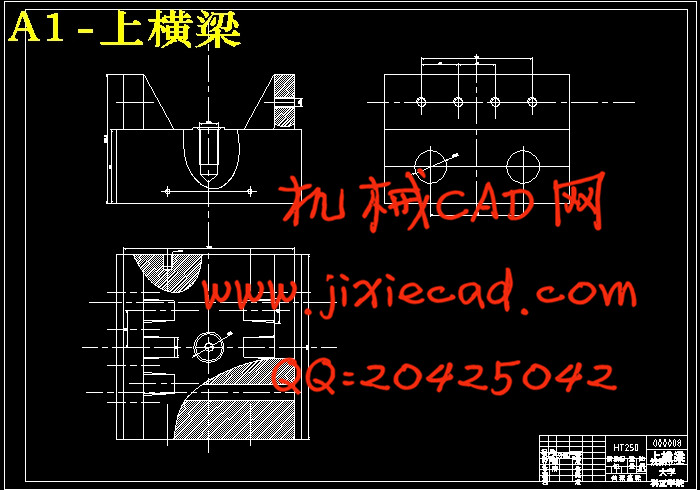

3.6 上横梁 15

3.6.1 材料 15

3.6.2 受力分析 15

3.6.3 弯矩及弯曲应力 16

3.6.4 上横梁最大挠度 19

3.7.1 结构及尺寸 20

3.7.2 材料 20

3.8 主机结构综述 21

结 论 22

参考文献 23

致 谢 29