设计简介

摘要

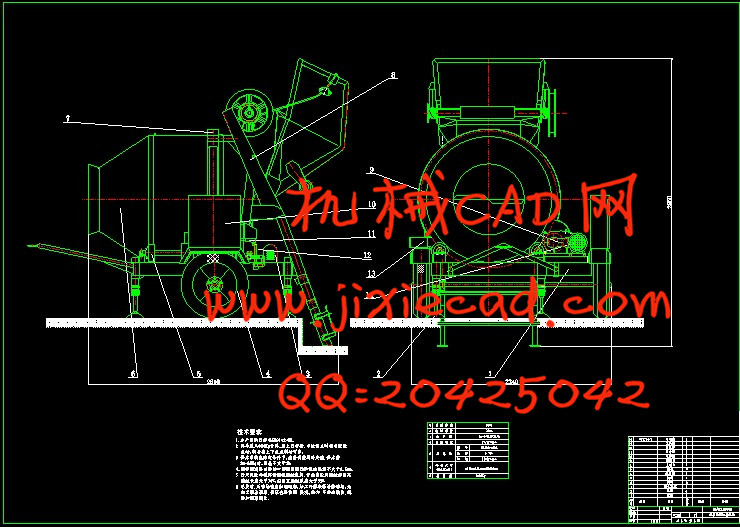

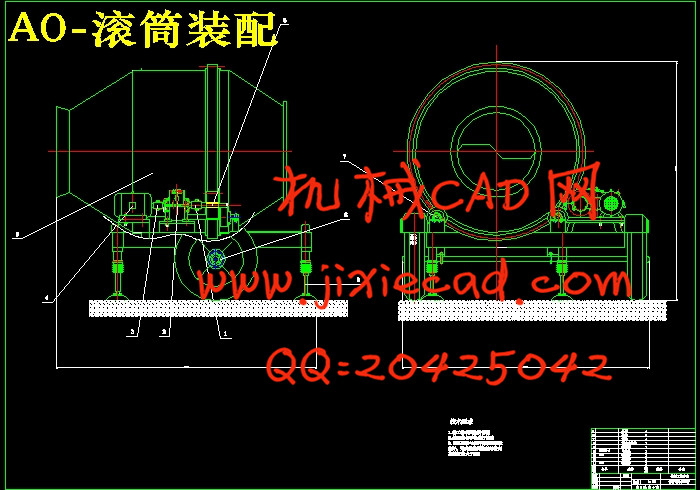

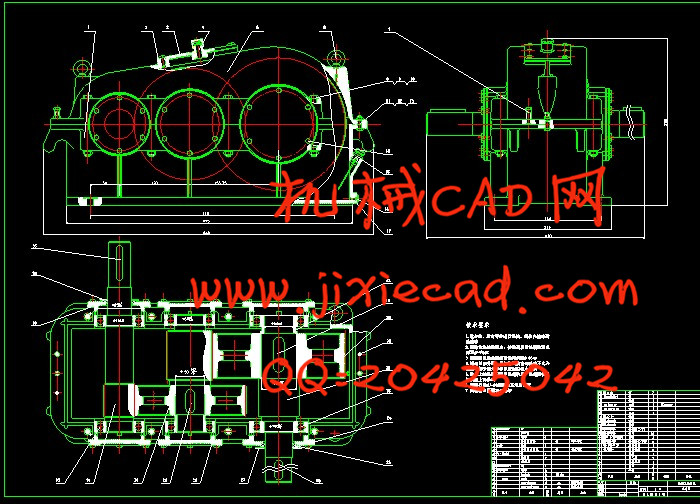

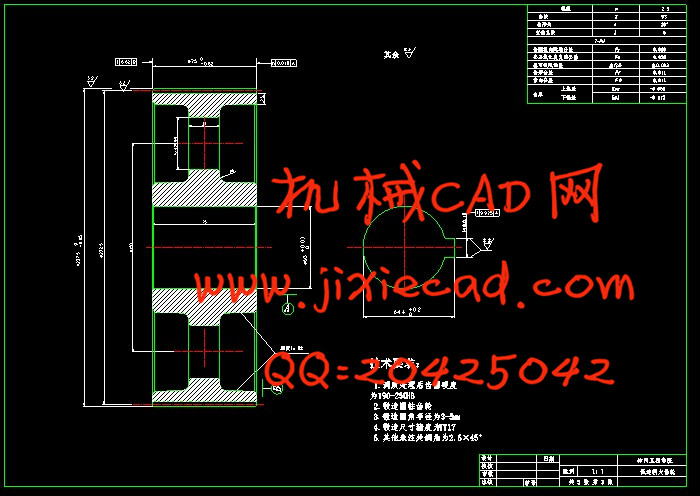

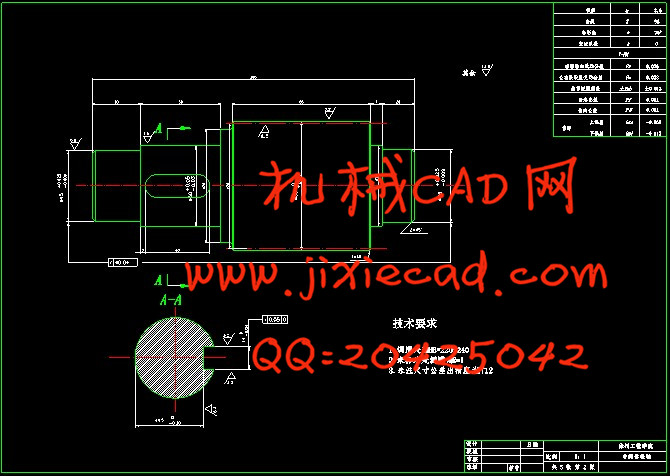

为了适应不同的搅拌要求,搅拌机发展了许多机型,本设计中首先对混凝土搅拌机进行选型,通过对比最后确定选用自落式锥形反转出料搅拌机。选型后,对搅拌机的传动部分进行设计计算,首先通过对搅拌筒的设计计算确定搅拌功率,选择电机,后对减速器的设计,这是本设计中的重要部分,在对减速器的设计中,参考资料,按照搅拌机的设计步骤,计算设计减速器各组成部件,完成减速器的设计后,对搅拌筒外的开式大齿轮进行设计计算,这是本设计中的难点,因为这个齿轮传动比较大,需要很好地解决这个问题才能最终完成搅拌机的传动部分的设计,然后选用适合的联轴器对传动部分的各个装置进行联接,完成传动部分的设计后,对上料部分进行简单的设计,最后合成出混凝土搅拌机的总体部分。

关键词 锥形反转;搅拌筒;减速器;联轴器

Abstract

In order to meet the needs of different mixing, many models of the mixer have been developed. In this design, choose the type of the concrete mixer at first. Through comparing, the taper mixer which produces the material reversely is chosen for use. After the selecting the type, the transmission of the mixer is designed. Through calculating the tube of the mixer, the power of mixing can be confirmed at first. After choosing the electrical machinery, the reduction gear can be designed. This is an important part in this design. In the design of the reduction gear, reference information, and then calculate and design each part of the reduction gear according to the design step of the mixer. After finishing the design of the reduction gear, the opening gear wheel outside the mixing tube can be calculated and designed. This is a difficult point in this design, because that the transmission of this gear wheel is big. This problem is needed to well solve, and then the transmission of the mixer can be finished finally. Then the suitable shaft coupling can be chosen to link each part of the transmission well. After finishing the design of the transmission, the part of taking material is designed simply .The overall part of the concrete mixer is compounded out finally.

Key words taper reverse mix tube reduction gear shaft coupling

目 录

1 绪论 1

1.1 混凝土搅拌机械 1

1.2 混凝土搅拌机的周期作业 2

2传动部分设计 3

2.1搅拌筒设计 3

2.2减速器的设计 5

2.2.1电动机的选择 6

2.2.2传动比的分配 9

2.2.3计算传动装置的运动和动力参数 9

2.2.4第一级齿轮传动的设计 11

2.2.5第二级齿轮传动的设计 16

2.2.6轴的校核 20

2.2.7键的选择 23

2.2.8轴承的选择因素 24

2.2.9联轴器 26

2.2.10减速器的润滑和密封 27

2.2.11开式齿轮的设计 29

3料斗的设计 33

3.1钢丝绳的选择 33

3.2卷筒的设计计算 34

3.3滑轮组的设计计算 38

3.4离合器的设计计算 39

3.5制动器的设计计算 40

4搅拌机的使用与维护 42

4.1搅拌机使用的注意事项 42

4.2搅拌机的日常保养 42

结论 44

致谢 45

参考文献 46

为了适应不同的搅拌要求,搅拌机发展了许多机型,本设计中首先对混凝土搅拌机进行选型,通过对比最后确定选用自落式锥形反转出料搅拌机。选型后,对搅拌机的传动部分进行设计计算,首先通过对搅拌筒的设计计算确定搅拌功率,选择电机,后对减速器的设计,这是本设计中的重要部分,在对减速器的设计中,参考资料,按照搅拌机的设计步骤,计算设计减速器各组成部件,完成减速器的设计后,对搅拌筒外的开式大齿轮进行设计计算,这是本设计中的难点,因为这个齿轮传动比较大,需要很好地解决这个问题才能最终完成搅拌机的传动部分的设计,然后选用适合的联轴器对传动部分的各个装置进行联接,完成传动部分的设计后,对上料部分进行简单的设计,最后合成出混凝土搅拌机的总体部分。

关键词 锥形反转;搅拌筒;减速器;联轴器

Abstract

In order to meet the needs of different mixing, many models of the mixer have been developed. In this design, choose the type of the concrete mixer at first. Through comparing, the taper mixer which produces the material reversely is chosen for use. After the selecting the type, the transmission of the mixer is designed. Through calculating the tube of the mixer, the power of mixing can be confirmed at first. After choosing the electrical machinery, the reduction gear can be designed. This is an important part in this design. In the design of the reduction gear, reference information, and then calculate and design each part of the reduction gear according to the design step of the mixer. After finishing the design of the reduction gear, the opening gear wheel outside the mixing tube can be calculated and designed. This is a difficult point in this design, because that the transmission of this gear wheel is big. This problem is needed to well solve, and then the transmission of the mixer can be finished finally. Then the suitable shaft coupling can be chosen to link each part of the transmission well. After finishing the design of the transmission, the part of taking material is designed simply .The overall part of the concrete mixer is compounded out finally.

Key words taper reverse mix tube reduction gear shaft coupling

目 录

1 绪论 1

1.1 混凝土搅拌机械 1

1.2 混凝土搅拌机的周期作业 2

2传动部分设计 3

2.1搅拌筒设计 3

2.2减速器的设计 5

2.2.1电动机的选择 6

2.2.2传动比的分配 9

2.2.3计算传动装置的运动和动力参数 9

2.2.4第一级齿轮传动的设计 11

2.2.5第二级齿轮传动的设计 16

2.2.6轴的校核 20

2.2.7键的选择 23

2.2.8轴承的选择因素 24

2.2.9联轴器 26

2.2.10减速器的润滑和密封 27

2.2.11开式齿轮的设计 29

3料斗的设计 33

3.1钢丝绳的选择 33

3.2卷筒的设计计算 34

3.3滑轮组的设计计算 38

3.4离合器的设计计算 39

3.5制动器的设计计算 40

4搅拌机的使用与维护 42

4.1搅拌机使用的注意事项 42

4.2搅拌机的日常保养 42

结论 44

致谢 45

参考文献 46