设计简介

CA6140车床刀具温度单片机控制系统设计

在机械制造业中, 虽然已发展出各种不同的零件成型工艺, 但目前仍有90% 以上的机械零件是通过切削加工制成。在切削过程中, 机床作功转换为等量的切削热, 这些切削热除少量逸散到周围介质中以外, 其余均传入刀具、切屑和工件中, 刀具、工件和机床温升将加速刀具磨损, 引起工件热变形, 严重时甚至引起机床热变形。因此,在机床的切削加工过程当中,对切削温度的测量非常重要。在高速车床当中,为了提高车床加工精度,刀具在切削过程中的受热变形一定要控制住,这个仅仅知道刀具温度是不够的,还需要引入自动控制技术进行实时控制。

本论文以CA6140普通车床为研究对象,根据数控技术原理,运用了单片机应用技术、自动控制技术和测试传感器技术,提出了车床刀具温度的控制系统方案。设计了基于MCS-51单片机的车床刀具温度控制电路和软件。

关键词:数控车床;刀具温度;单片机控制

In mechanical manufacturing industry, there are more than 90% mechanical parts are manufactured by machining. In the process of cutting, machine work into cutting heat equivalent, the cutting heat in addition to a small number of escapes into the surrounding medium, the rest are into the tool, chip and work piece, tool wear will accelerate the rise of cutting tool, work piece and tool temperature, caused by the thermal deformation caused by the thermal deformation of machine tools, even when serious. Therefore, in the process of cutting machine, measurement of cutting temperature is very important. In the high speed lathe, in order to improve the machining precision lathe, cutting tool in the cutting process of thermal deformation must be controlled, this just know the tool temperature is not enough, also need to introduce automatic control technology for real-time control.

In this thesis, the CA6140 lathe as the research object, according to the principle of NC technology, uses the single chip microcomputer application technology, automatic control technology and sensor technology, put forward control scheme of lathe cutting tool temperature. Design of MCS-51 MCU lathe tool temperature control circuit and software.

Keywords: CNC;lathe tool temperature; MCU control;

目录

摘要 1

ABSTRACT 2

第一章 绪论 5

1.1课题的研究背景和研究意义 5

1.2国内外研究现状 5

1.2.1国外研究现状 5

1.2.2国内研究现状 6

1.3方案背景技术简介 6

1.3.1数控车床 6

1.3.2温度检测的主要方法 7

1.4本课题的主要研究内容 8

1.5本章小结 8

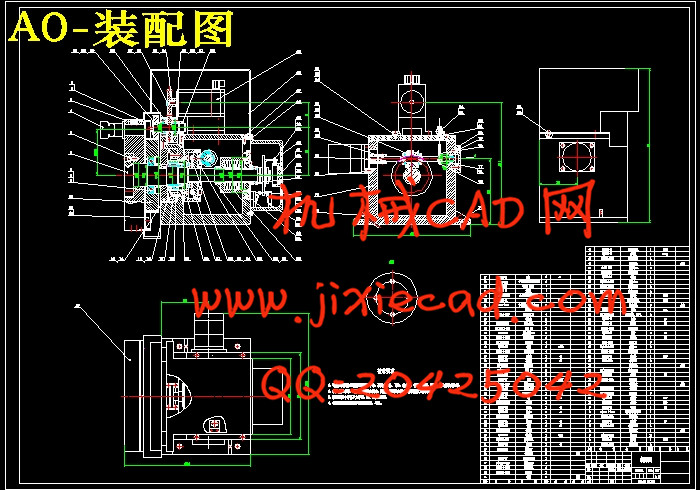

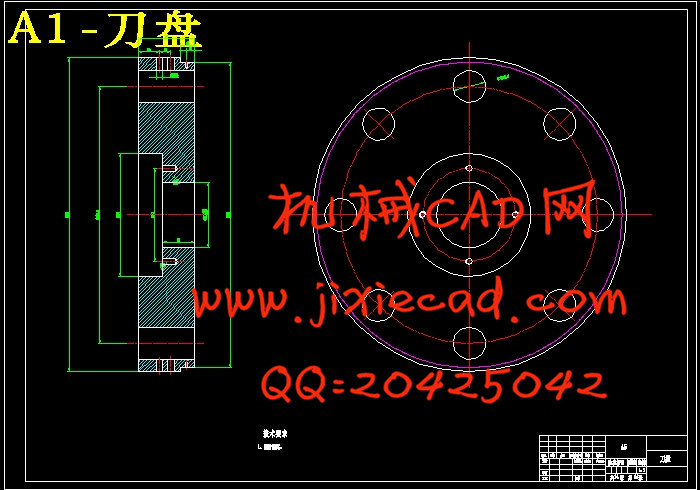

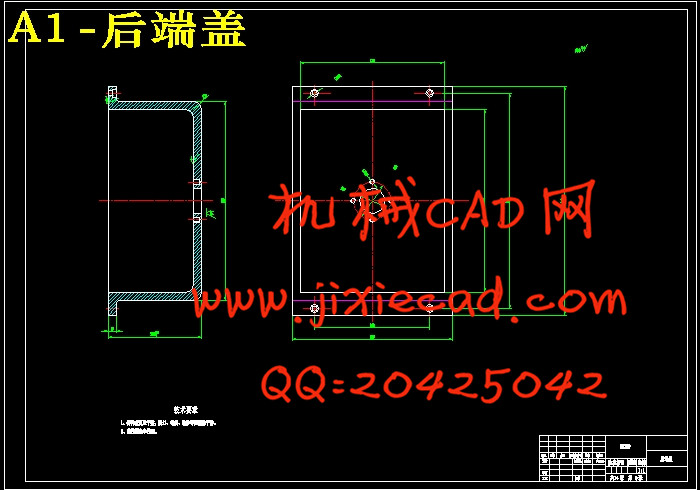

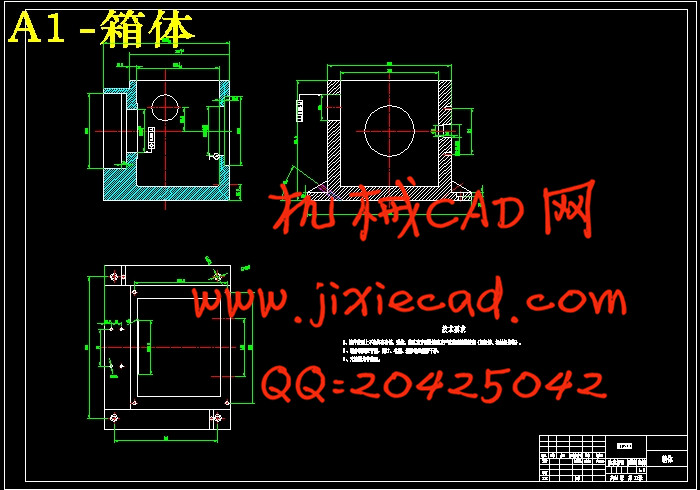

第二章 车床结构及系统总体设计方案 9

2.1 CA6140车床简介 9

2.2系统总体设计方案 10

2.3本章小结 10

第三章 系统硬件设计 11

3.1系统硬件设计方案 11

3.2 中央处理器 11

3.2.1 AT89C51简介 11

3.2.2 AT89C51主要性能参数 12

3.2.3管脚说明 12

3.2.3特殊功能存储器 14

3.2.4芯片擦除 15

3.2.5复位电路的设计 15

3.2.6时钟电路设计 16

3.3红外测温传感器 16

3.3.1 红外测温传感器的工作原理 16

3.3.2红外测温传感器的选择 17

3.4信号调理电路 18

3.5 A/D转换电路 19

3.6 LED显示 21

3.7 键盘接口 25

3.7 控制电路 26

第四章 系统软件设计 27

4.1程序初始化 28

4.2主程序 29

4.3 A/D转换子程序 30

4.4 显示子程序 31

4.5 键盘子程序 33

4.6本章小结 36

第五章 结论与展望 37

5.1主要研究工作及结论 37

5.2本课题的展望 37

参考文献 38

致谢 40

摘要

当今社会上各种机械加工业都在迅猛发展,车床是机械加工核心工具,随着科学技术的发展,车床也在不断向着高精度、高效率、高自动化方向发展,数控车床已经成为主流设备,逐渐取代老旧的普通车床。我国目前机床总量约400余万台,但其中数控机床总数只有20余万台,机床的数控化率极低。国内起步较晚,技术较为落后,有着大量的老旧车床,又因其缺乏专业的维修与保养,促使机床的工作精度大大降低。而从国外购置新型数控车床的价格又颇为昂贵,普通企业根本无法负担。在机械制造业中, 虽然已发展出各种不同的零件成型工艺, 但目前仍有90% 以上的机械零件是通过切削加工制成。在切削过程中, 机床作功转换为等量的切削热, 这些切削热除少量逸散到周围介质中以外, 其余均传入刀具、切屑和工件中, 刀具、工件和机床温升将加速刀具磨损, 引起工件热变形, 严重时甚至引起机床热变形。因此,在机床的切削加工过程当中,对切削温度的测量非常重要。在高速车床当中,为了提高车床加工精度,刀具在切削过程中的受热变形一定要控制住,这个仅仅知道刀具温度是不够的,还需要引入自动控制技术进行实时控制。

本论文以CA6140普通车床为研究对象,根据数控技术原理,运用了单片机应用技术、自动控制技术和测试传感器技术,提出了车床刀具温度的控制系统方案。设计了基于MCS-51单片机的车床刀具温度控制电路和软件。

关键词:数控车床;刀具温度;单片机控制

ABSTRACT

Today's society, a variety of mechanical processing industry in rapid development, machining lathe is the core tools, with the development of science and technology, the lathe has been towards high precision, high efficiency, high automation, CNC lathes have become the mainstream equipment, gradually taking the place of ordinary lathe old. My current machine total about more than 400 units, but the total number of CNC machine tool is only more than 20, the rate of CNC machine tools is very low. China started late, the technology is relatively backward, there are lots of old lathe, also because of the lack of repair and maintenance of professional, the machine tool working accuracy greatly reduced. From the foreign purchase of new CNC lathe price is quite expensive, ordinary enterprises simply can not afford.In mechanical manufacturing industry, there are more than 90% mechanical parts are manufactured by machining. In the process of cutting, machine work into cutting heat equivalent, the cutting heat in addition to a small number of escapes into the surrounding medium, the rest are into the tool, chip and work piece, tool wear will accelerate the rise of cutting tool, work piece and tool temperature, caused by the thermal deformation caused by the thermal deformation of machine tools, even when serious. Therefore, in the process of cutting machine, measurement of cutting temperature is very important. In the high speed lathe, in order to improve the machining precision lathe, cutting tool in the cutting process of thermal deformation must be controlled, this just know the tool temperature is not enough, also need to introduce automatic control technology for real-time control.

In this thesis, the CA6140 lathe as the research object, according to the principle of NC technology, uses the single chip microcomputer application technology, automatic control technology and sensor technology, put forward control scheme of lathe cutting tool temperature. Design of MCS-51 MCU lathe tool temperature control circuit and software.

Keywords: CNC;lathe tool temperature; MCU control;

目录

摘要 1

ABSTRACT 2

第一章 绪论 5

1.1课题的研究背景和研究意义 5

1.2国内外研究现状 5

1.2.1国外研究现状 5

1.2.2国内研究现状 6

1.3方案背景技术简介 6

1.3.1数控车床 6

1.3.2温度检测的主要方法 7

1.4本课题的主要研究内容 8

1.5本章小结 8

第二章 车床结构及系统总体设计方案 9

2.1 CA6140车床简介 9

2.2系统总体设计方案 10

2.3本章小结 10

第三章 系统硬件设计 11

3.1系统硬件设计方案 11

3.2 中央处理器 11

3.2.1 AT89C51简介 11

3.2.2 AT89C51主要性能参数 12

3.2.3管脚说明 12

3.2.3特殊功能存储器 14

3.2.4芯片擦除 15

3.2.5复位电路的设计 15

3.2.6时钟电路设计 16

3.3红外测温传感器 16

3.3.1 红外测温传感器的工作原理 16

3.3.2红外测温传感器的选择 17

3.4信号调理电路 18

3.5 A/D转换电路 19

3.6 LED显示 21

3.7 键盘接口 25

3.7 控制电路 26

第四章 系统软件设计 27

4.1程序初始化 28

4.2主程序 29

4.3 A/D转换子程序 30

4.4 显示子程序 31

4.5 键盘子程序 33

4.6本章小结 36

第五章 结论与展望 37

5.1主要研究工作及结论 37

5.2本课题的展望 37

参考文献 38

致谢 40