设计简介

摘 要

电梯导轨垂直度是电梯安全、舒适运行的一项重要性能指标,对电梯导轨垂直度的测量贯穿于电梯安装和维护的整个阶段。传统的检测方法费时费力,效率低。

为了实现电梯导轨检测的自动化和智能化,本文提出来一种检测电梯导轨垂直度的全新检测原理,克服了现有技术的不足,设计了一款能沿电梯导轨自动上下运行的检测机器人。此方法提高了检测效率和精度,节省了大量的人力、物力。

本文首先介绍了电梯导轨垂直度检测的国家标准,详细分析了机器人的检测原理。依据检测原理,完成了机器人机械结构设计,利用相关力学理论进行了受力分析,最终选定了驱动和传动方案。并根据 T 型导轨的结构和材料特征,设计了多磁轮吸附机构,并利用磁导法进行了磁轮磁路的优化。

设计了基于单片机的控制系统。利用高精度倾角传感器测量倾角,采用光电编码器测距,应用无线数传模块对控制信息和采集信号进行无线传输。进行了控制系统的硬件电路设计,并根据控制方案进行了软件系统编程,实现了预定功能。

关键词:电梯导轨,垂直度,机器人,机构设计,控制系统

电梯导轨垂直度是电梯安全、舒适运行的一项重要性能指标,对电梯导轨垂直度的测量贯穿于电梯安装和维护的整个阶段。传统的检测方法费时费力,效率低。

为了实现电梯导轨检测的自动化和智能化,本文提出来一种检测电梯导轨垂直度的全新检测原理,克服了现有技术的不足,设计了一款能沿电梯导轨自动上下运行的检测机器人。此方法提高了检测效率和精度,节省了大量的人力、物力。

本文首先介绍了电梯导轨垂直度检测的国家标准,详细分析了机器人的检测原理。依据检测原理,完成了机器人机械结构设计,利用相关力学理论进行了受力分析,最终选定了驱动和传动方案。并根据 T 型导轨的结构和材料特征,设计了多磁轮吸附机构,并利用磁导法进行了磁轮磁路的优化。

设计了基于单片机的控制系统。利用高精度倾角传感器测量倾角,采用光电编码器测距,应用无线数传模块对控制信息和采集信号进行无线传输。进行了控制系统的硬件电路设计,并根据控制方案进行了软件系统编程,实现了预定功能。

关键词:电梯导轨,垂直度,机器人,机构设计,控制系统

ABSTRACT

The verticality of elevator guide is an important performance index for security and comfortin the elevator operation. And its measurement exists throughout installation and maintainment.The traditional test method is time-consuming and low efficiency.

In order to realize the automation and intelligence for the test process of elevator guide, thispaper propose a new principle for verticality testing. This method overcomes the existingtechnical shortages. An inspection robot which can move along the elevator guide automaticlywas designed. This method improves the measuring precision and efficiency, and saves a lot ofmanpower and material resources.

First, this paper introduces the national standards of verticality measurement for elevatorguide, and analysis the detection principle of the robot. Mechanical stress analysis wasproceeded. Absorbing mechanism with multiple magnetic wheels was designed. And magneticcircuit was optimized to ensure the operation security.

The control system based on Freescale SCM was designed.When it reaches thepredetermined location or receives reversal signal, it will get back along the elevator guidequickly. This control system can achieve the following functions: acquisit and process data fromangle sensor and photoelectric encoder, and put the data to the upper computer though digitaltransfers module. Besides, the hardware circuit of the control system and software program wasdesigned.

KEY WORDS: elevator guide, verticality, robot, mechanical structure, control system

目 录

摘 要 IThe verticality of elevator guide is an important performance index for security and comfortin the elevator operation. And its measurement exists throughout installation and maintainment.The traditional test method is time-consuming and low efficiency.

In order to realize the automation and intelligence for the test process of elevator guide, thispaper propose a new principle for verticality testing. This method overcomes the existingtechnical shortages. An inspection robot which can move along the elevator guide automaticlywas designed. This method improves the measuring precision and efficiency, and saves a lot ofmanpower and material resources.

First, this paper introduces the national standards of verticality measurement for elevatorguide, and analysis the detection principle of the robot. Mechanical stress analysis wasproceeded. Absorbing mechanism with multiple magnetic wheels was designed. And magneticcircuit was optimized to ensure the operation security.

The control system based on Freescale SCM was designed.When it reaches thepredetermined location or receives reversal signal, it will get back along the elevator guidequickly. This control system can achieve the following functions: acquisit and process data fromangle sensor and photoelectric encoder, and put the data to the upper computer though digitaltransfers module. Besides, the hardware circuit of the control system and software program wasdesigned.

KEY WORDS: elevator guide, verticality, robot, mechanical structure, control system

目 录

ABSTRACT II

第一章 绪论 1

1.1概述 1

1.2电梯导轨垂直度检测研究现状分析 2

1.2.1传统吊线法 2

1.2.2激光垂准测量法 4

1.2.3测量仪随轿厢运行检测法 5

1.2.4测量仪独立运行检测法 7

1.3 课题研究的主要内容 8

第二章 检测原理的分析 10

2.1引言 10

2.2 电梯导轨垂直度误差国家标准 10

2.3 导轨安装及垂直误差表现形式 11

2.4机器人检测原理分析 14

2.4.1检测要点分析 14

2.4.2检测原理分析 16

2.4.3检测精度的影响因素 18

第三章 检测机器人的机械结构设计 19

3.1 引言 19

3.2 机身材料选择 20

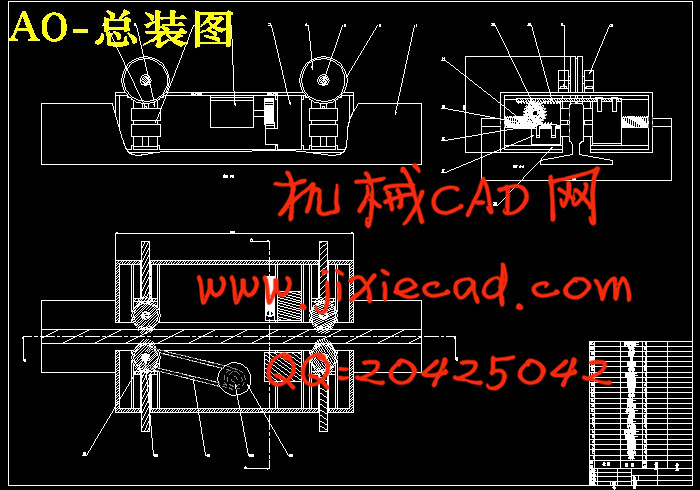

3.3机器人整体结构 22

3.3.1整体结构框图 22

3.3.2机器人受力分析计算 23

3.3.3驱动轮受力分析 24

3.3.4顶磁轮受力分析 26

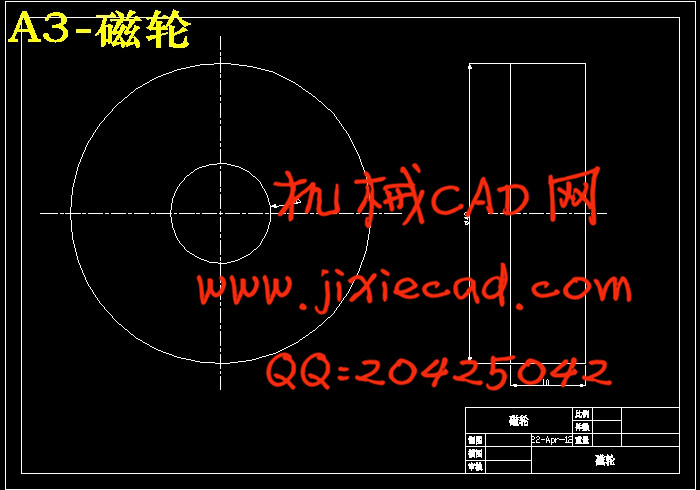

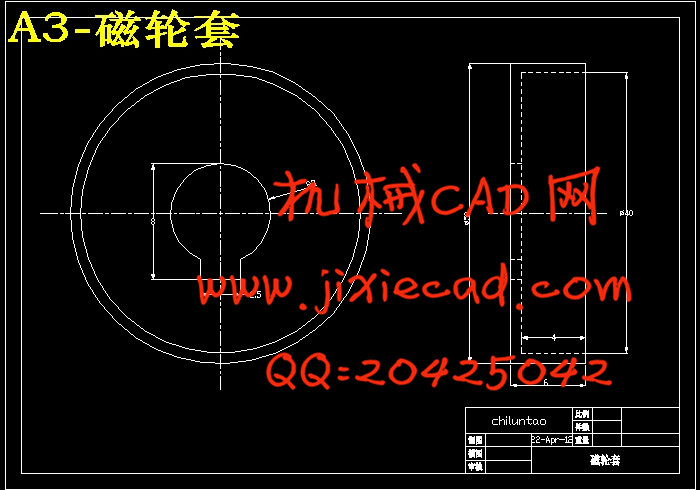

3.4磁轮吸附方式设计 27

3.4.1永磁材料的选择 28

3.4.2软磁材料的选择 30

3.4.3磁轮磁路设计 31

3.5磁轮磁路的分析计算 32

3.5.1磁轮优化设计的可行性分析 32

3.5.2基于磁导法进行磁路的优化设计 34

3.5.3磁轮的封装 38

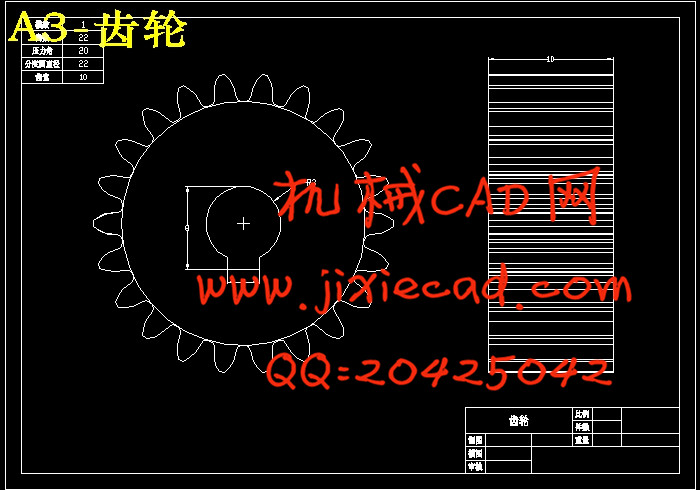

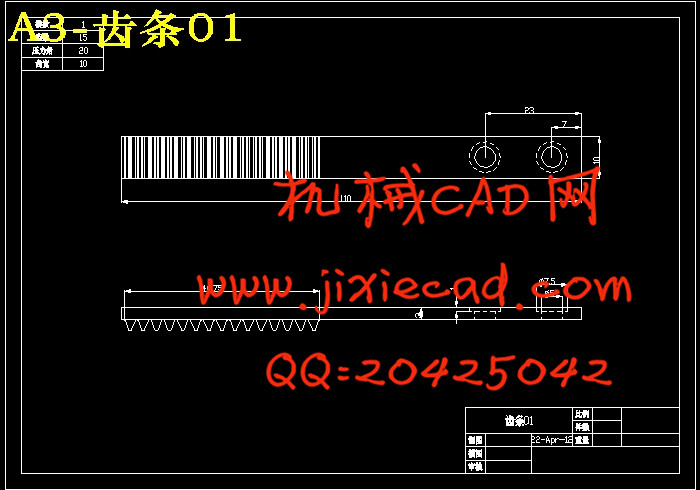

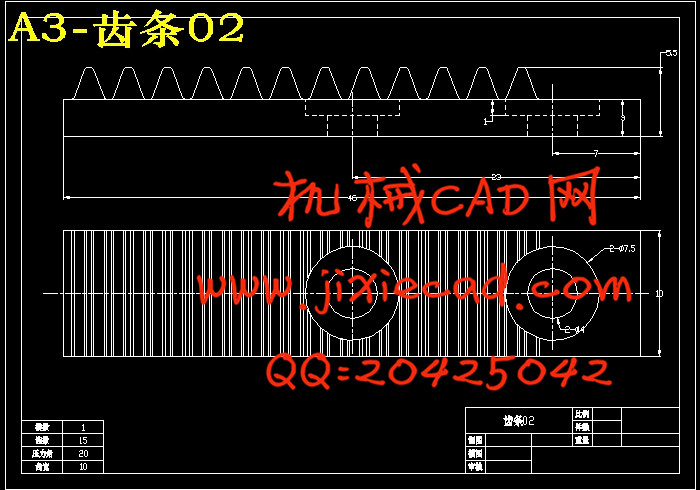

3.6传动系统的设计 40

3.6.1传动方式的选择 41

3.6.2电机的选择 42

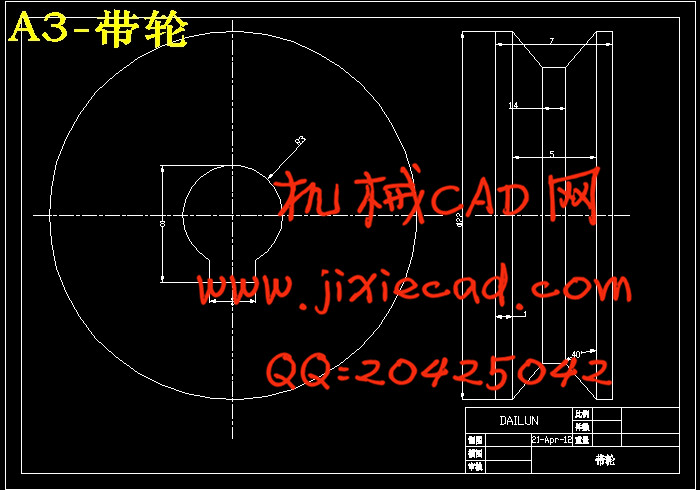

3.6.3 V带的设计 44

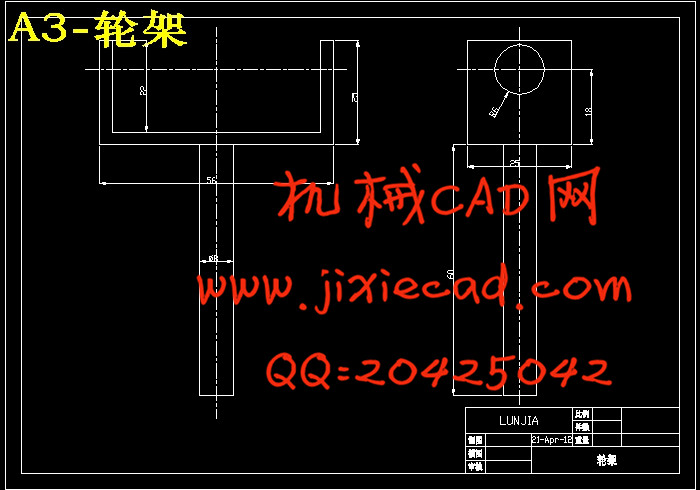

3.7压紧机构的设计 46

3.8各零件的详细设计及计算 47

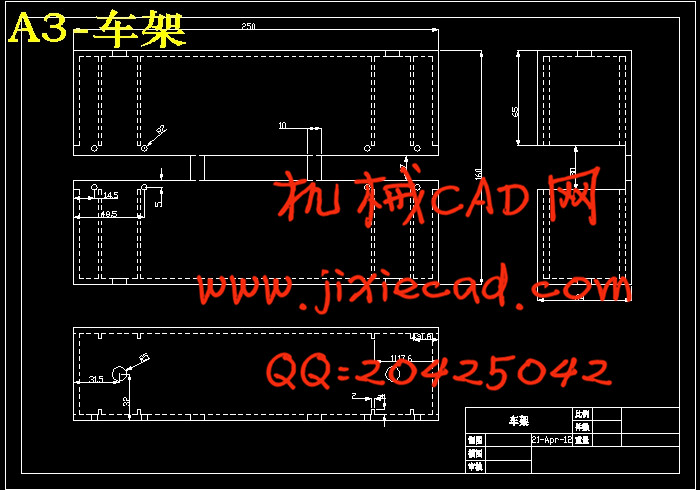

3.8.1车架的设计 47

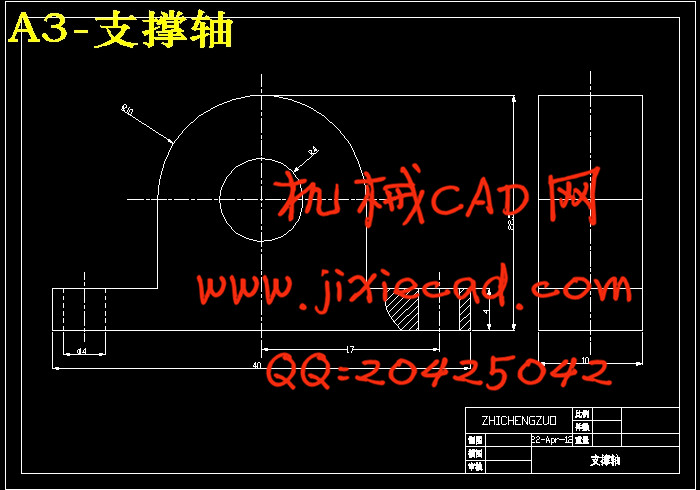

3.8.2轴的设计与校核 48

3.8.3轴承的校核 52

3.8.4键的选择计算及强度校核 53

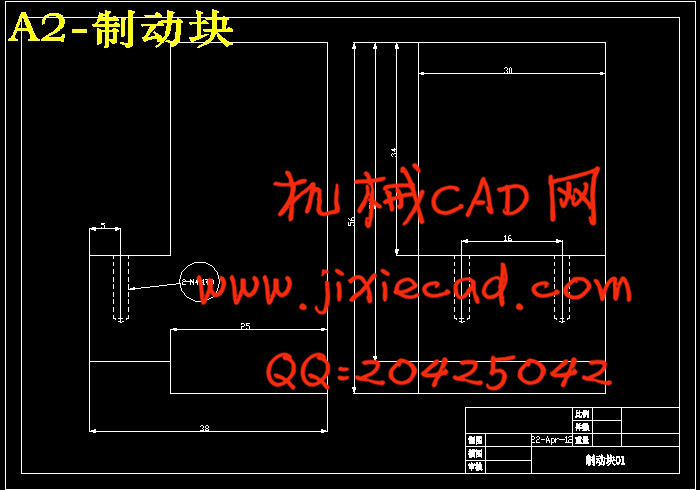

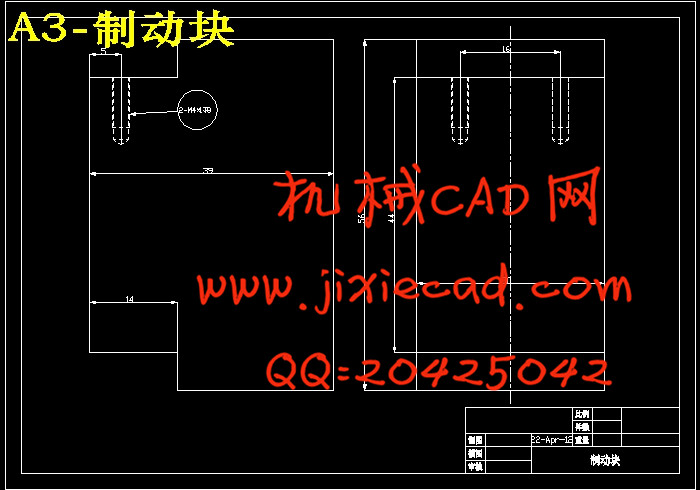

3.9紧急制动机构设计 53

第四章 检测机器人控制系统的设计 55

4.1引言 55

4.2控制系统的组成 55

4.3核心控制器的选择 57

4.4控制系统的软件设计 58

4.4.1倾角信号采集系统软件设计 58

4.4.2步进电机驱动系统软件设计 60

4.4.3光电编码器的信号采集系统软件设计 60

第五章 总结与展望 63

5.1总结 63

5.2展望 64

参考文献 V