设计简介

摘 要

提出了电极圆锥内螺纹的图像处理及检测方法。原始灰度图像为CCD采集的经过工件轴线的截面

图像,该截面为一个特殊加工的剖分式轴截面,其定位与加工方法同电极内螺纹一样,以此作为抽检来判别电极圆锥内螺纹的几何参数及刀具磨损状况,通过对直径的测量,获得了刀具磨损的相关信息。图像处理过程包括几何变换、灰度级变换、图像平滑、滤波降噪、阈值选取及二值化、边缘提取等,并对不同处理方法进行了比较。在测量尺寸时,使用自编程序计算测量内螺纹的螺距、牙型半角及锥角,测量精度分别达到±0.012 mm、±0.17°和±0.018°,满足产品的技术要求,并分析了误差产生的原因。

[关键词]:圆锥内螺纹 测量 误差

Abstract

A method of the image processing and measurement of the internal taper thread was proposed. Original gray level image was a section image collected by CCD through work piece' s axes. The section was a special machined apart section crossed axes, and its orientation and processing method were the same as internal thread of electrode. According to the section image,the geometry parameters of the work piece and cutter' s abrasion status were judged, and relevant information of cutter' s abrasion by measuring the middle diameter of the work piece was obtained. Image processing mainly dealt with gray-scale transformation, image smoothing and filtering, noise reducing, threshold selecting, binary image, edge detecting and its extractinget al, different processing methods were compared. When measuring, based on the segmented contour line of thread, we used the compiled measurement program to calculate and measure the geometrical parameters of the internal taper thread as pitch, half of thread angle and taper angle. Precisions of pitch, half of thread angle and taper angle reached±0.012 mm,±0.17°and±0.018°. The results satisfied with the technique requirement of production. The reason of error was analyzed.

[Key words]: Internal taper thread Measurement Error

目录

第1章 绪论…………………………………………………………………………..4

1 检测的发展现状…………………………………………………………………...4

2 多楔带的简述…………………………………………………………………….13

3 多谢带检测技术………………………………………………………………….15

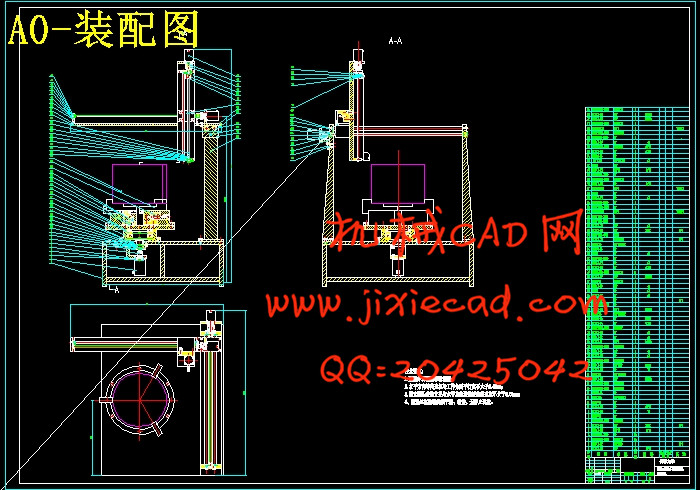

第2章 机构总体设计方案………………………………………..….……………17

2.1测试系统的机构和方案设计…………………………………………………...17

第3章 家电成型多谢带模具测量机各部分计算…………………………………21

3.1家电成型多谢带模具测量机设计计算………………………………………...21

第4章 轴的设计与计算……………………………………………………………25

4.1轴的种类与特点………………………………………………………………...25

4.2轴的常用材料…………………………………………………………………...25

4.3轴的结构设计…………………………………………………………………...25

4.4轴的强度校核计算……………………………………………………………...26

第5章 轴承的计算…………………………………………………………………28

5.1滚动轴承的分类………………………………………………………………...28

5.2滚动轴承的代号方法…………………………………………………………...28

5.3滚动轴承类型的选择…………………………………………………………...29

5.4滚动轴承寿命的计算…………………………………………………………...29

第6章 丝杠的受力计算……………………………………………………………31

第7章 设计与人机工程学…………………………………………………………35

7.1根据人体度确定设备的合理尺寸……………………………………………...35

7.2根据人体的力参数合理设计操作装置………………………………………...35

致谢………………………………………………………………………………….36

参考文献.....................................................................................................................37

提出了电极圆锥内螺纹的图像处理及检测方法。原始灰度图像为CCD采集的经过工件轴线的截面

图像,该截面为一个特殊加工的剖分式轴截面,其定位与加工方法同电极内螺纹一样,以此作为抽检来判别电极圆锥内螺纹的几何参数及刀具磨损状况,通过对直径的测量,获得了刀具磨损的相关信息。图像处理过程包括几何变换、灰度级变换、图像平滑、滤波降噪、阈值选取及二值化、边缘提取等,并对不同处理方法进行了比较。在测量尺寸时,使用自编程序计算测量内螺纹的螺距、牙型半角及锥角,测量精度分别达到±0.012 mm、±0.17°和±0.018°,满足产品的技术要求,并分析了误差产生的原因。

[关键词]:圆锥内螺纹 测量 误差

Abstract

A method of the image processing and measurement of the internal taper thread was proposed. Original gray level image was a section image collected by CCD through work piece' s axes. The section was a special machined apart section crossed axes, and its orientation and processing method were the same as internal thread of electrode. According to the section image,the geometry parameters of the work piece and cutter' s abrasion status were judged, and relevant information of cutter' s abrasion by measuring the middle diameter of the work piece was obtained. Image processing mainly dealt with gray-scale transformation, image smoothing and filtering, noise reducing, threshold selecting, binary image, edge detecting and its extractinget al, different processing methods were compared. When measuring, based on the segmented contour line of thread, we used the compiled measurement program to calculate and measure the geometrical parameters of the internal taper thread as pitch, half of thread angle and taper angle. Precisions of pitch, half of thread angle and taper angle reached±0.012 mm,±0.17°and±0.018°. The results satisfied with the technique requirement of production. The reason of error was analyzed.

[Key words]: Internal taper thread Measurement Error

目录

第1章 绪论…………………………………………………………………………..4

1 检测的发展现状…………………………………………………………………...4

2 多楔带的简述…………………………………………………………………….13

3 多谢带检测技术………………………………………………………………….15

第2章 机构总体设计方案………………………………………..….……………17

2.1测试系统的机构和方案设计…………………………………………………...17

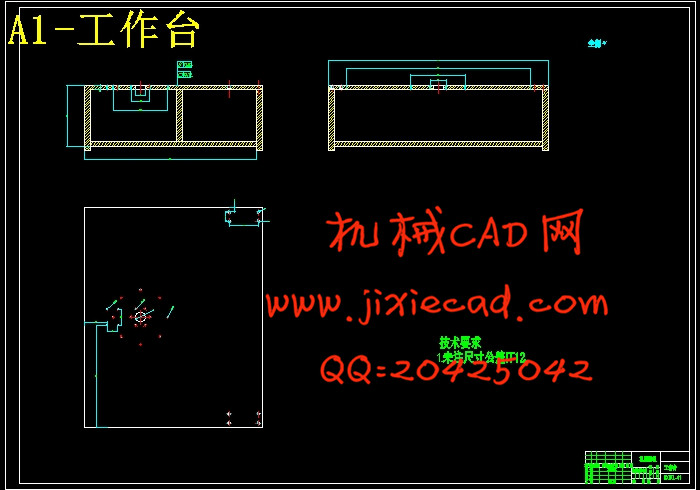

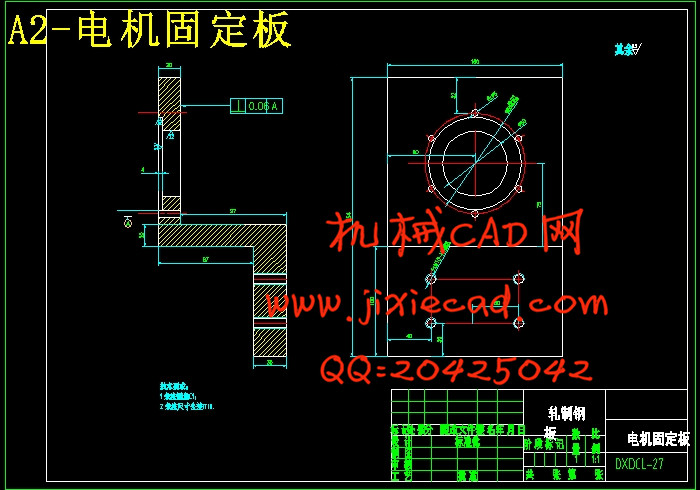

第3章 家电成型多谢带模具测量机各部分计算…………………………………21

3.1家电成型多谢带模具测量机设计计算………………………………………...21

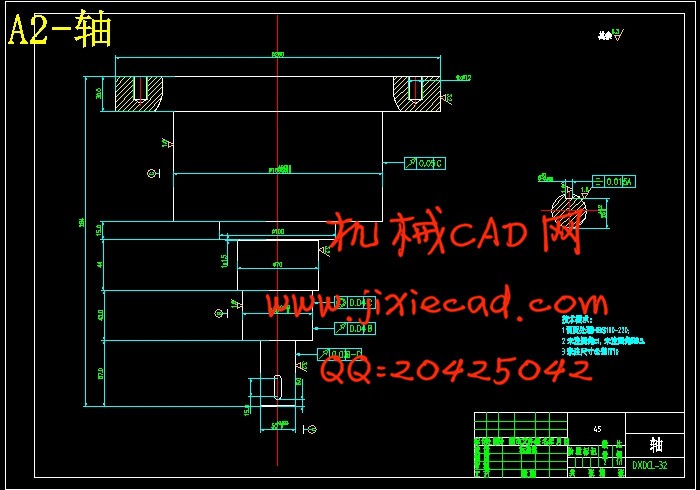

第4章 轴的设计与计算……………………………………………………………25

4.1轴的种类与特点………………………………………………………………...25

4.2轴的常用材料…………………………………………………………………...25

4.3轴的结构设计…………………………………………………………………...25

4.4轴的强度校核计算……………………………………………………………...26

第5章 轴承的计算…………………………………………………………………28

5.1滚动轴承的分类………………………………………………………………...28

5.2滚动轴承的代号方法…………………………………………………………...28

5.3滚动轴承类型的选择…………………………………………………………...29

5.4滚动轴承寿命的计算…………………………………………………………...29

第6章 丝杠的受力计算……………………………………………………………31

第7章 设计与人机工程学…………………………………………………………35

7.1根据人体度确定设备的合理尺寸……………………………………………...35

7.2根据人体的力参数合理设计操作装置………………………………………...35

致谢………………………………………………………………………………….36

参考文献.....................................................................................................................37