设计简介

电动单梁起重机设计

摘 要

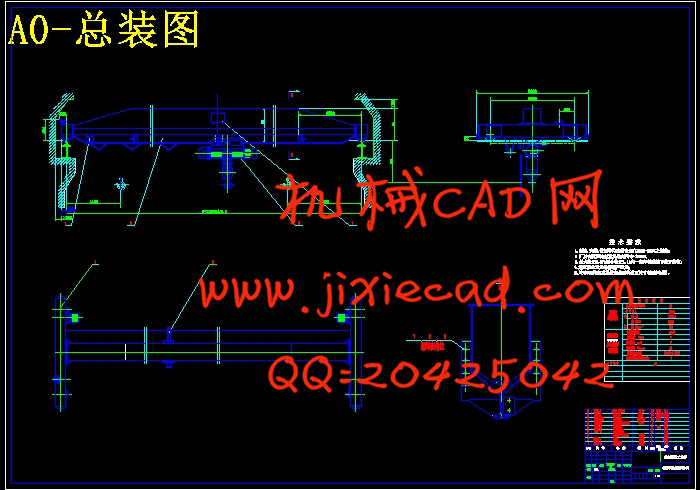

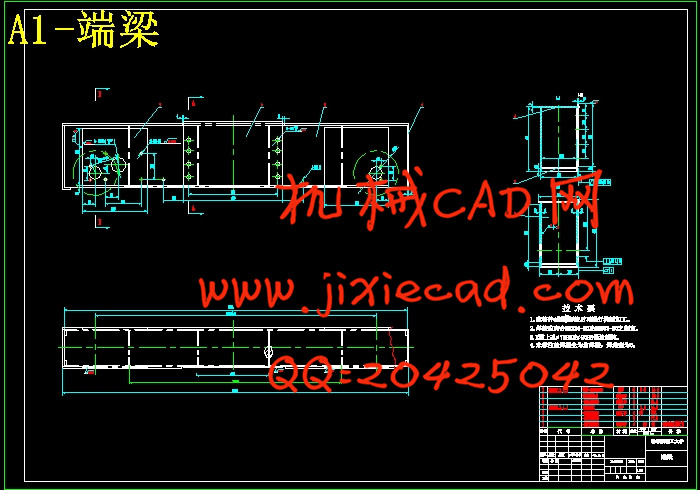

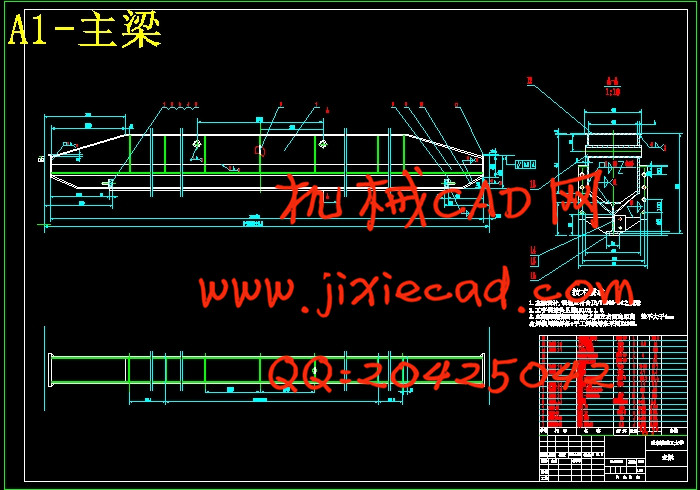

本文是对电动单梁起重机进行功能分析和结构设计。首先分析了电动单梁起重机的现状以及国内外发展趋势,然后确定自己设计的目标。然后,进行了详细设计,主要包括确定主梁和端梁的参数,连接方式,分析计算主梁在载荷作用下工字钢的所承受的弯曲应力,以及起重机在动态和静态下主梁刚度。此后,又详细分析计算了载荷在不同位置时,各个车轮的轮压以及对端梁的作用力,在选择电动葫芦型号时,从钢丝绳、卷筒、电动机、减速器方面着手,经过详细的分析和计算,最后确定起升电动机为ZD141-4,运行电动机为ZDY121-4的CD型5t电动葫芦作为起升和运行传动装置。本文还分析了小车起升和运行两种不同运行机构,确定大车的电动机型号为ZDR100-4C型绕线式电动机。最后,详细介绍了起重机安装和试车注意事项。

本文所设计是LD型电动单梁起重机,适应于车间、仓库等处的物品装卸工作,具有安装方便、操作简单、运行平稳等特点,整个机构安全可靠,在很大程度上节约了人力资源,具备实际应用价值。

关键词 主梁;端梁;电动葫芦

Electric Single Girder Crane Design

Abstract

This article is an electric single-girder cranes functional analysis and structural design. Firstly, the electric single-girder cranes status quo and development trend of domestic and foreign, and then determine their own design goals. Then, detailed design, including determining parameters of the main beam and the end beam connection, main beam analysis and calculation under load beam subjected to bending stress, and the crane main beam under dynamic and static stiffness. Since then, a detailed analysis of the calculated loads at different positions, wheel pressure and force on each wheel end of the beam, in the choice of model electric hoist, wire rope from the reel, motor, reducer aspects, after detailed analysis and computing finalize lifting motor is ZD141-4, run the motor for the CD-type electric hoist 5t ZDY121-4 as lifting and running gear. This paper also analyzes the car lifting and running two different operating agencies to determine the motor Model ZDR100-4C carts winding type motor. Finally, detailing the crane installation and commissioning notes.

This article is designed LD electric single-girder cranes, suitable for workshops, warehouses and other places of loading and unloading goods, with easy installation, simple operation, smooth running characteristics, the entire organization is safe and reliable, in large savings in human resources, have practical value.

Keywords Main girders,End beam,Electric hoist

目 录

摘要 I

Abstract II

第1章 电动单梁起重机的概述 1

1.1 电动单梁起重机的整体描述 1

1.2 LD型电动单梁起重机各部件的作用 1

1.3 电动单梁起重机的发展趋势 2

1.4 本章小结 3

第2章 设计参数和承重梁计算 4

2.1 设计要求 4

2.2 电动葫芦的选型 4

2.3 主梁计算 4

2.4 端梁计算 10

2.5 起重机最大轮压 11

2.6 最大歪斜侧向力 13

2.7 车轮轴对端梁腹板的挤压应力 14

2.8 端梁中央断面合成应力 14

2.9 主、端梁连接计算 15

2.10 本章小结 18

第3章 小车起升和运行机构的设计 19

3.1 电动葫芦起升机构设计 19

3.2 电动葫芦运行机构设计 24

3.3本章小结 26

第4章 大车运行机构设计 27

4.1确定机构传动方案 27

4.2传动装置设计 28

4.3设计减速装置 29

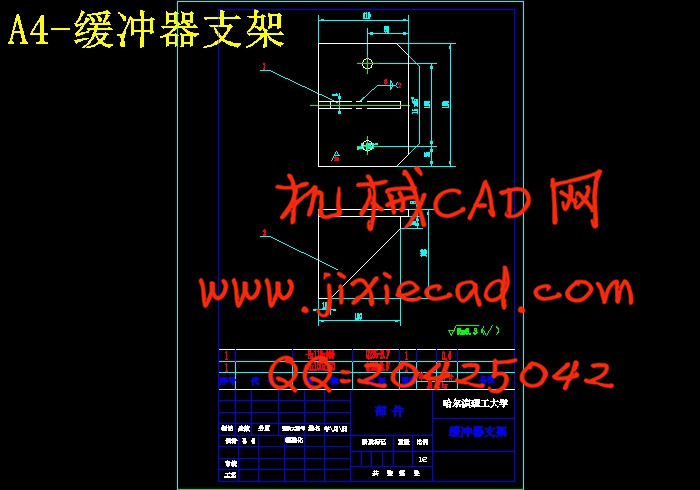

4.4起重机的安全装置 30

4.5起重机的组装及试车要求 31

4.6 本章小结 32

结论 33

致谢 34

参考文献 35

摘 要

本文是对电动单梁起重机进行功能分析和结构设计。首先分析了电动单梁起重机的现状以及国内外发展趋势,然后确定自己设计的目标。然后,进行了详细设计,主要包括确定主梁和端梁的参数,连接方式,分析计算主梁在载荷作用下工字钢的所承受的弯曲应力,以及起重机在动态和静态下主梁刚度。此后,又详细分析计算了载荷在不同位置时,各个车轮的轮压以及对端梁的作用力,在选择电动葫芦型号时,从钢丝绳、卷筒、电动机、减速器方面着手,经过详细的分析和计算,最后确定起升电动机为ZD141-4,运行电动机为ZDY121-4的CD型5t电动葫芦作为起升和运行传动装置。本文还分析了小车起升和运行两种不同运行机构,确定大车的电动机型号为ZDR100-4C型绕线式电动机。最后,详细介绍了起重机安装和试车注意事项。

本文所设计是LD型电动单梁起重机,适应于车间、仓库等处的物品装卸工作,具有安装方便、操作简单、运行平稳等特点,整个机构安全可靠,在很大程度上节约了人力资源,具备实际应用价值。

关键词 主梁;端梁;电动葫芦

Electric Single Girder Crane Design

Abstract

This article is an electric single-girder cranes functional analysis and structural design. Firstly, the electric single-girder cranes status quo and development trend of domestic and foreign, and then determine their own design goals. Then, detailed design, including determining parameters of the main beam and the end beam connection, main beam analysis and calculation under load beam subjected to bending stress, and the crane main beam under dynamic and static stiffness. Since then, a detailed analysis of the calculated loads at different positions, wheel pressure and force on each wheel end of the beam, in the choice of model electric hoist, wire rope from the reel, motor, reducer aspects, after detailed analysis and computing finalize lifting motor is ZD141-4, run the motor for the CD-type electric hoist 5t ZDY121-4 as lifting and running gear. This paper also analyzes the car lifting and running two different operating agencies to determine the motor Model ZDR100-4C carts winding type motor. Finally, detailing the crane installation and commissioning notes.

This article is designed LD electric single-girder cranes, suitable for workshops, warehouses and other places of loading and unloading goods, with easy installation, simple operation, smooth running characteristics, the entire organization is safe and reliable, in large savings in human resources, have practical value.

Keywords Main girders,End beam,Electric hoist

目 录

摘要 I

Abstract II

第1章 电动单梁起重机的概述 1

1.1 电动单梁起重机的整体描述 1

1.2 LD型电动单梁起重机各部件的作用 1

1.3 电动单梁起重机的发展趋势 2

1.4 本章小结 3

第2章 设计参数和承重梁计算 4

2.1 设计要求 4

2.2 电动葫芦的选型 4

2.3 主梁计算 4

2.4 端梁计算 10

2.5 起重机最大轮压 11

2.6 最大歪斜侧向力 13

2.7 车轮轴对端梁腹板的挤压应力 14

2.8 端梁中央断面合成应力 14

2.9 主、端梁连接计算 15

2.10 本章小结 18

第3章 小车起升和运行机构的设计 19

3.1 电动葫芦起升机构设计 19

3.2 电动葫芦运行机构设计 24

3.3本章小结 26

第4章 大车运行机构设计 27

4.1确定机构传动方案 27

4.2传动装置设计 28

4.3设计减速装置 29

4.4起重机的安全装置 30

4.5起重机的组装及试车要求 31

4.6 本章小结 32

结论 33

致谢 34

参考文献 35