设计简介

摘 要

矿用回柱绞车,又称慢速绞车,是用来拆除和回收矿山回采工作面顶柱的机械设备的提升机。牵引力大和牵引速度慢是矿用回柱绞车的主要性能。现阶段,我国煤矿工业正以日新月异的速度发展。在井下回采工作中,当一个工作面的煤层开采完了以后,就要进行放顶。由于回柱作业属危险性工作,工作人员不能直接进入回柱空顶区,而且金属成本较高,液压支柱若不收回,则必然造成极大的浪费。如果人工回收支柱,安全性差、效率也很低。此时可把回柱绞车布置在距回柱空顶危险区段较远的安全地段,用钢丝绳钩头来拉倒和回收顶柱。由于它的高度较低重量又轻,持别适用于薄煤层、和急倾斜煤层采煤工作面,以及各种采煤工作面回收沉入底板或被矸石压埋的金属支杖。回柱绞车除可用来回柱放顶工作外,也可用来拖运重物和调运车辆等。使用回柱绞车回收既经济,又迅速,符合现代化工业生产的高生产率和先进的技术经济指标。

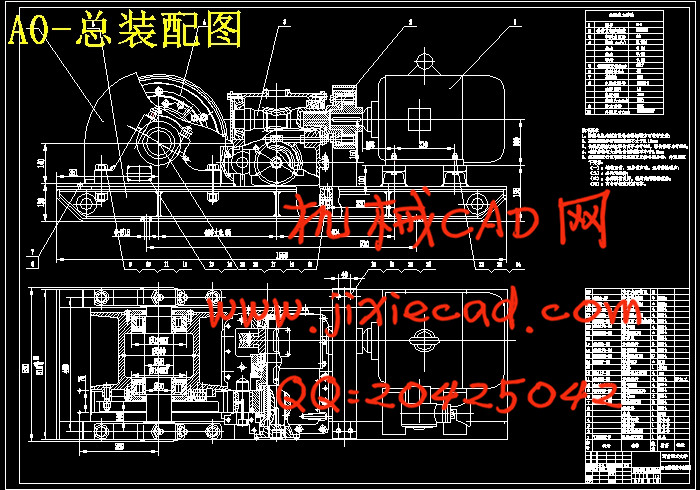

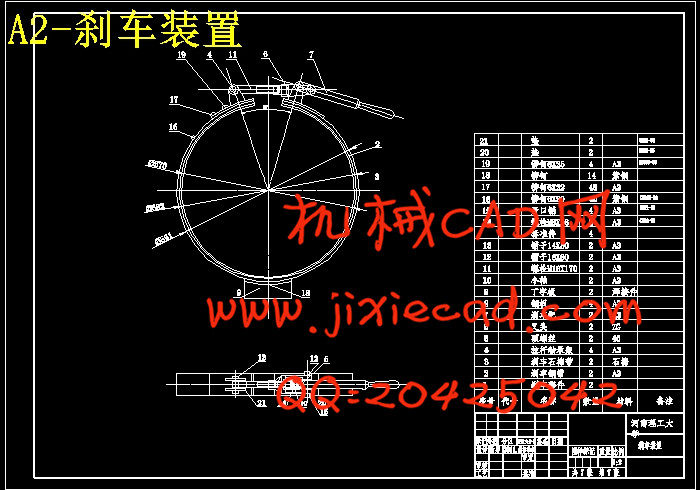

根据矿山机械的特殊要求,本文重点设计齿轮传部分和卷筒部件与制动器部件,两个部件是提升机的关键部分,卷筒强度不够导致的直接后果就是筒壳被压溃、焊缝开裂等;制动器是绞车的制动装置,制动装置的作用是克服和抵消提升机运动系统的惯性力,使之停止运动;以及在系统处于停止状态下时,制动系统可能由于重力作用产生的运动。总之,是为了制动提升机的运动,使之处于停运状态的一些设置。

关键词:回柱绞车 齿轮传动 卷筒部件 制动器

Abstract

Mine recycling mainstay winch, which is also called slowly winch, it is widely used to dismantle and recovery the coal mining machinery and equipments, larger traction engine and slowly speed are the main properties of the recycling mainstay winch. Currently, our country's coal mining industry is developing rapidly,In the work of underground coaling, we will release top-coal when a place of work after the coal mining. Due to the recovery of hydraulic prop assignments, workers cannot risk directly into the whole area, prop-pulling, And the high cost of metal, If hydraulic prop cannot be recovered, It will cause a larger waste. If using artificial recycling hydraulic props, It is poor safety and low efficiency。This can be arranged in winch is empty section top prop-pulling far safer ground, use rope hook head to pull down and recycling spots. Because of its low weight light, it is very applicable in the thin coal seam, and steep coal seam mining face, and various mining face slab or sink recycling waste metal staff of pressure. Prop-pulling hoist can recycle hydraulic prop,release top coal ,it is also available to transfer the weight and the transport vehicles, etc. It is economic and quickly to use prop-pulling hoist to recycle hydraulic props, It complies with the standards of modern industrial's high productivity and advanced technical economic indexes.

According to the special requirements of mining machinery, This article mainly design gear-transmission, drum brake parts and roll-cylinder, two parts is the key part of the hoist, insufficient strength to block the direct consequence of cylinder shells were crushing, weld cracking, etc. The brake is hoist brake, brake is overcome and offset machine movement of the inertial force system, stop motion, And in the system to a standstill, braking system may be due to the gravity of movement. Anyhow, in order to brake, the movement of some lines in the state.

Key words: recycling mainstay winch gear-transmission

braking system roll-cylinder

目录

前 言 1矿用回柱绞车,又称慢速绞车,是用来拆除和回收矿山回采工作面顶柱的机械设备的提升机。牵引力大和牵引速度慢是矿用回柱绞车的主要性能。现阶段,我国煤矿工业正以日新月异的速度发展。在井下回采工作中,当一个工作面的煤层开采完了以后,就要进行放顶。由于回柱作业属危险性工作,工作人员不能直接进入回柱空顶区,而且金属成本较高,液压支柱若不收回,则必然造成极大的浪费。如果人工回收支柱,安全性差、效率也很低。此时可把回柱绞车布置在距回柱空顶危险区段较远的安全地段,用钢丝绳钩头来拉倒和回收顶柱。由于它的高度较低重量又轻,持别适用于薄煤层、和急倾斜煤层采煤工作面,以及各种采煤工作面回收沉入底板或被矸石压埋的金属支杖。回柱绞车除可用来回柱放顶工作外,也可用来拖运重物和调运车辆等。使用回柱绞车回收既经济,又迅速,符合现代化工业生产的高生产率和先进的技术经济指标。

根据矿山机械的特殊要求,本文重点设计齿轮传部分和卷筒部件与制动器部件,两个部件是提升机的关键部分,卷筒强度不够导致的直接后果就是筒壳被压溃、焊缝开裂等;制动器是绞车的制动装置,制动装置的作用是克服和抵消提升机运动系统的惯性力,使之停止运动;以及在系统处于停止状态下时,制动系统可能由于重力作用产生的运动。总之,是为了制动提升机的运动,使之处于停运状态的一些设置。

关键词:回柱绞车 齿轮传动 卷筒部件 制动器

Abstract

Mine recycling mainstay winch, which is also called slowly winch, it is widely used to dismantle and recovery the coal mining machinery and equipments, larger traction engine and slowly speed are the main properties of the recycling mainstay winch. Currently, our country's coal mining industry is developing rapidly,In the work of underground coaling, we will release top-coal when a place of work after the coal mining. Due to the recovery of hydraulic prop assignments, workers cannot risk directly into the whole area, prop-pulling, And the high cost of metal, If hydraulic prop cannot be recovered, It will cause a larger waste. If using artificial recycling hydraulic props, It is poor safety and low efficiency。This can be arranged in winch is empty section top prop-pulling far safer ground, use rope hook head to pull down and recycling spots. Because of its low weight light, it is very applicable in the thin coal seam, and steep coal seam mining face, and various mining face slab or sink recycling waste metal staff of pressure. Prop-pulling hoist can recycle hydraulic prop,release top coal ,it is also available to transfer the weight and the transport vehicles, etc. It is economic and quickly to use prop-pulling hoist to recycle hydraulic props, It complies with the standards of modern industrial's high productivity and advanced technical economic indexes.

According to the special requirements of mining machinery, This article mainly design gear-transmission, drum brake parts and roll-cylinder, two parts is the key part of the hoist, insufficient strength to block the direct consequence of cylinder shells were crushing, weld cracking, etc. The brake is hoist brake, brake is overcome and offset machine movement of the inertial force system, stop motion, And in the system to a standstill, braking system may be due to the gravity of movement. Anyhow, in order to brake, the movement of some lines in the state.

Key words: recycling mainstay winch gear-transmission

braking system roll-cylinder

目录

1 JH-8型回柱绞车的概述 2

2 原始数据 8

3 工作条件 8

4 方案的初步拟定 9

5 总体设计 12

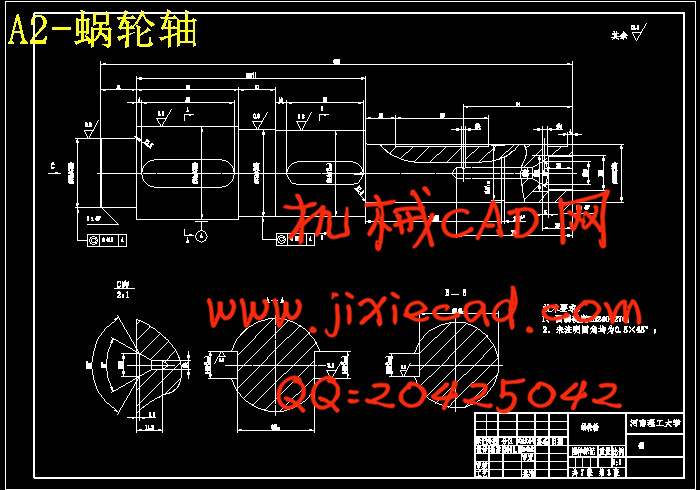

6 蜗轮蜗杆传动件设计 16

7 齿轮的传动设计 19

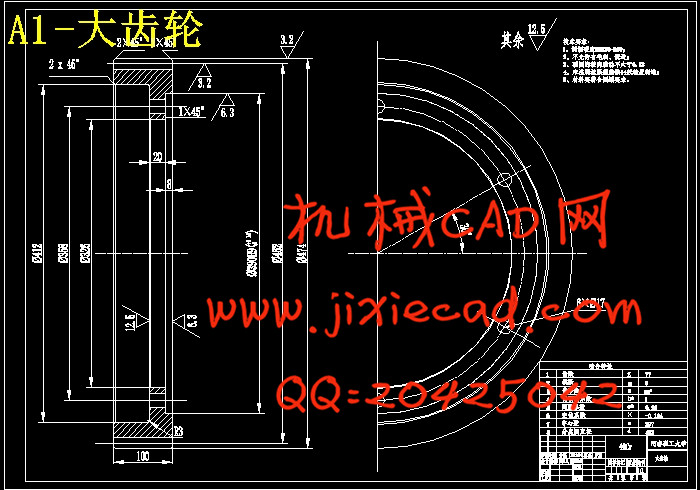

7.1齿轮模数的确定 19

7.2齿轮的变位 21

7.3齿轮结构设计 31

7.4齿轮结构的润滑 31

8 蜗轮齿轮轴设计 32

8.1轴的材料选择 32

8.2求作用在蜗轮和齿轮上的力 32

9 中间轴设计 35

9.1选材 35

9.2基本轴径估算 35

9.3轴上零件布置 35

9.4轴的结构设计 35

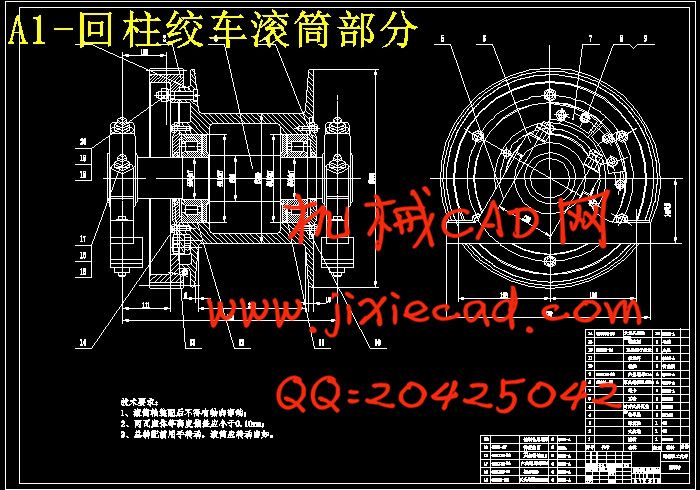

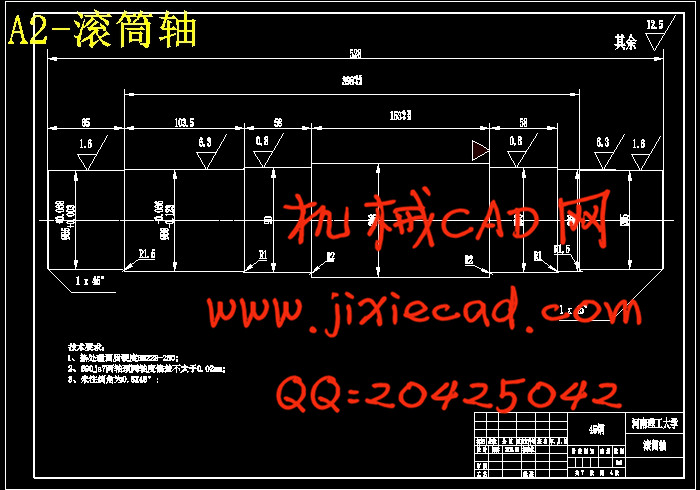

10 滚筒及主轴的设计计算 37

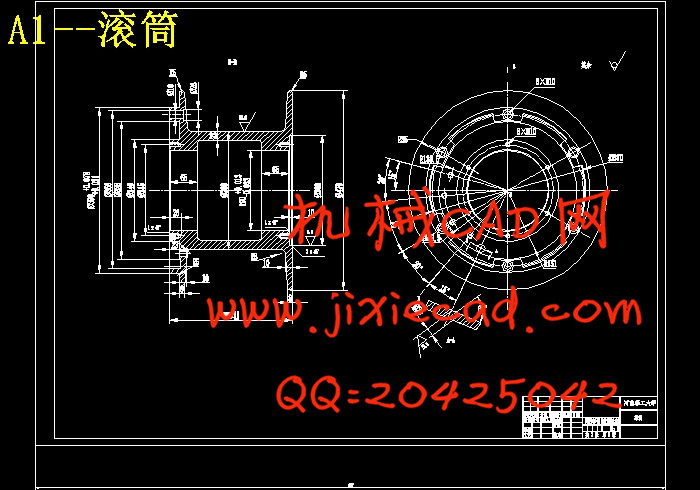

10.1滚筒的设计 37

10.2主轴的设计 38

10.3主轴的强度校核 40

11 轴承的校核 44

12 键的选择与校核 45

13 联轴器的选择 45

14 回柱绞车制动器设计 45

14.1绞车上应有的安全装置 47

14.2回柱绞车制动器的作用 48

14.3回柱绞车制动器的选用和设计 48

14.4回柱绞车的使用与维修 52

致 谢 56

参考文献 57