设计简介

摘 要:

汽车变速器发展经历了100 多年,从最初采用侧链传动到手动变速器到现在的液力自动变速器和电控机械式自动变速器,再向无级自动变速器方向发展。发动机是汽车的心脏,发动机产生的动力必须经过传动系统才能驱动车轮转动。传动系统的心脏是变速器。由于发动机的转速和转矩的变化范围小,而汽车行驶速度的变化范围广,所以一开始传动系统就设置了变速器。变速器的作用: ①改变汽车的传动比,扩大驱动车轮转矩和转速的范围,使车辆适应各种变化的行驶工况,同时使发动机在理想的工况下工作; ② 在发动机转矩方向不变的前提下,实现汽车的倒退行驶; ③实现空挡,中断发动机传递给车轮的动力,使发动机能够起动、怠速。100 多年中,变速器经历了用变速杆改变链条的传动比→手动变速器→有级自动变速器→无级自动变速器的发展历程。

关键词: 汽车;变速器;工作原理;发展历史;发展趋势

Abstract

The development of auto transmission has experienced more than 100 years’ history, from the initial use of side-chain drive to the manual transmission, to the current hydraulic. Automatic transmission and electronically controlled automatic mechanical transmission, to the no-class automatic transmission direction. The engine is the heart of the car. The power of the engine transmission system must drive the wheels turning. Transmission System is the heart of transmission. As the engine speed and torque are on the scope of the changes, but vehicle’s speed and scope of change, so at beginning on the transmission system set up a transmission. The role of the transmission : ① change the transmission ratio of motor vehicles, wheel drive torque to expand the scope and speed to adapt to changes in the vehicle driving cycle, at the same time it can make the engine in good working condition; ② not in the direction of engine torque. Under the premise of change, it can make cars on the retrogression; ③ achieve in neutral gear, interrupted the power of the wheels transmission by the engine so that the engine can start, idling. More than 100 years, the transmission has changed from Bian Sugan → the chain of transmission ratio → manual transmission → a class-automatic transmission → no class automatic transmission → course of development.

Keywords: Automotive; transmission; principle; history of development; development trend

目录

摘 要............................................................I

第1章 绪论......................................................1

1.1. 课题的目的和意义.........................................1

1.2. 课题研究的现状...........................................1

1.3. 变速器的设计思想.........................................2

1.4. 研究的主要工作内容.......................................2

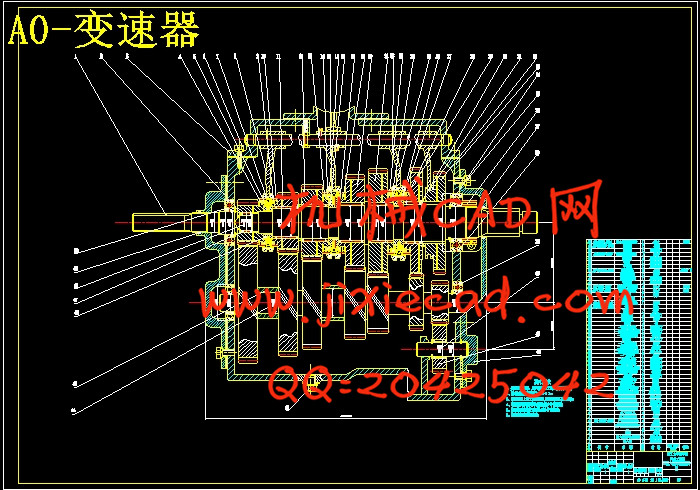

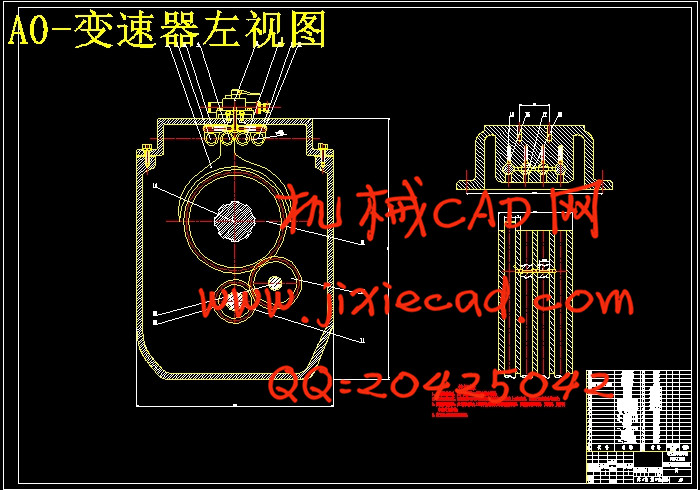

第2章 变速器设计的总体方案......................................4

2.1. 设计依据.................................................4

2.2. 传动机构布置方案分析,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,4

2.3. 变速器基本参数的确定,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,6

第3章 主要零部件的设计及计算,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,11

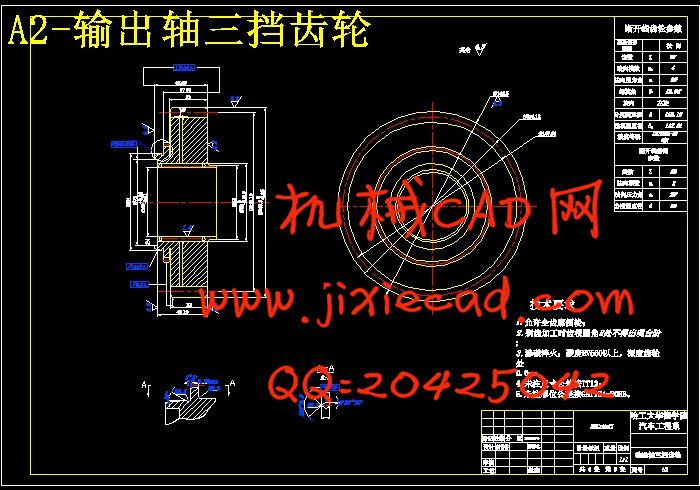

3.1. 齿轮的设计及校核,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,11

3.1.1. 齿轮参数确定及各档齿轮齿数分配,,,,,,,,,,,,,,,,,,,,,11

3.1.2. 齿轮强度计算,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,18

3.1.3. 变速器齿轮的材料及热处理,,,,,,,,,,,,,,,,,,,,,,,,,,,21

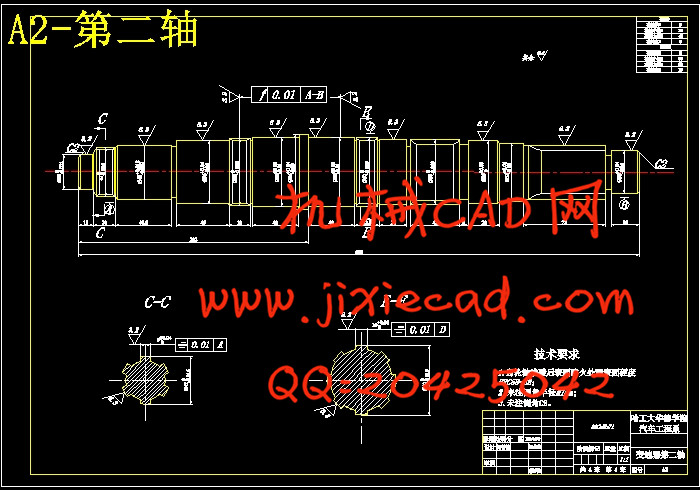

3.2. 轴的设计及校核,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,21

3.2.1. 初选轴的直径.......................................21

3.2.2. 轴的刚度计算.......................................22

3.2.3. 轴的强度计算.......................................31

第4章 同步器的选择.............................................37

4.1. 惯性式同步器............................................37

4.1.1. 锁环式同步器的机构.................................37

4.1.2. 锁环式同步器的工作原理.............................38

4.1.3. 锁环式同步器主要尺寸的确定.........................38

4.2. 主要参数的确定..........................................39

4.2.1 摩擦因数 f..........................................39

4.2.2 同步环主要尺寸的确定................................40

4.2.3 锁止角β............................................41

4.2.4 同步时间............................................41

4.2.5 转动惯量的计算......................................42

第5章 变速器操纵机构的选择和箱体设计原则.......................43

5.1. 变速器操纵机构的选择....................................43

5.2. 变速器箱体设计原则......................................43

致 谢...........................................................44

参考文献........................................................45

汽车变速器发展经历了100 多年,从最初采用侧链传动到手动变速器到现在的液力自动变速器和电控机械式自动变速器,再向无级自动变速器方向发展。发动机是汽车的心脏,发动机产生的动力必须经过传动系统才能驱动车轮转动。传动系统的心脏是变速器。由于发动机的转速和转矩的变化范围小,而汽车行驶速度的变化范围广,所以一开始传动系统就设置了变速器。变速器的作用: ①改变汽车的传动比,扩大驱动车轮转矩和转速的范围,使车辆适应各种变化的行驶工况,同时使发动机在理想的工况下工作; ② 在发动机转矩方向不变的前提下,实现汽车的倒退行驶; ③实现空挡,中断发动机传递给车轮的动力,使发动机能够起动、怠速。100 多年中,变速器经历了用变速杆改变链条的传动比→手动变速器→有级自动变速器→无级自动变速器的发展历程。

关键词: 汽车;变速器;工作原理;发展历史;发展趋势

Abstract

The development of auto transmission has experienced more than 100 years’ history, from the initial use of side-chain drive to the manual transmission, to the current hydraulic. Automatic transmission and electronically controlled automatic mechanical transmission, to the no-class automatic transmission direction. The engine is the heart of the car. The power of the engine transmission system must drive the wheels turning. Transmission System is the heart of transmission. As the engine speed and torque are on the scope of the changes, but vehicle’s speed and scope of change, so at beginning on the transmission system set up a transmission. The role of the transmission : ① change the transmission ratio of motor vehicles, wheel drive torque to expand the scope and speed to adapt to changes in the vehicle driving cycle, at the same time it can make the engine in good working condition; ② not in the direction of engine torque. Under the premise of change, it can make cars on the retrogression; ③ achieve in neutral gear, interrupted the power of the wheels transmission by the engine so that the engine can start, idling. More than 100 years, the transmission has changed from Bian Sugan → the chain of transmission ratio → manual transmission → a class-automatic transmission → no class automatic transmission → course of development.

Keywords: Automotive; transmission; principle; history of development; development trend

目录

摘 要............................................................I

第1章 绪论......................................................1

1.1. 课题的目的和意义.........................................1

1.2. 课题研究的现状...........................................1

1.3. 变速器的设计思想.........................................2

1.4. 研究的主要工作内容.......................................2

第2章 变速器设计的总体方案......................................4

2.1. 设计依据.................................................4

2.2. 传动机构布置方案分析,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,4

2.3. 变速器基本参数的确定,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,6

第3章 主要零部件的设计及计算,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,11

3.1. 齿轮的设计及校核,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,11

3.1.1. 齿轮参数确定及各档齿轮齿数分配,,,,,,,,,,,,,,,,,,,,,11

3.1.2. 齿轮强度计算,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,18

3.1.3. 变速器齿轮的材料及热处理,,,,,,,,,,,,,,,,,,,,,,,,,,,21

3.2. 轴的设计及校核,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,21

3.2.1. 初选轴的直径.......................................21

3.2.2. 轴的刚度计算.......................................22

3.2.3. 轴的强度计算.......................................31

第4章 同步器的选择.............................................37

4.1. 惯性式同步器............................................37

4.1.1. 锁环式同步器的机构.................................37

4.1.2. 锁环式同步器的工作原理.............................38

4.1.3. 锁环式同步器主要尺寸的确定.........................38

4.2. 主要参数的确定..........................................39

4.2.1 摩擦因数 f..........................................39

4.2.2 同步环主要尺寸的确定................................40

4.2.3 锁止角β............................................41

4.2.4 同步时间............................................41

4.2.5 转动惯量的计算......................................42

第5章 变速器操纵机构的选择和箱体设计原则.......................43

5.1. 变速器操纵机构的选择....................................43

5.2. 变速器箱体设计原则......................................43

致 谢...........................................................44

参考文献........................................................45