设计简介

摘要

当前国际间的竞争主要是生产力的竞争,如果要想在未来激烈的竞争中生存下去,就必须不断的加快生产力的发展,归根结底是要不断地提高生产率,对现有的钻床进行改进设计,以多轴多钻头的形式进行工件的加工。改进后的钻床不仅可以实现一次性加工多个孔,而且可以在不更换钻头的情况下加工不同尺寸的孔。多轴多钻头钻床在生产中的应用,会解决普通钻床加工多孔工件时逐孔加工浪费时间和人工这两个重要问题。据统计,一般在车间中普通机床的平均钻削时间很少超过全部工作时间的15% 。大部分时间用来看图,装卸工件,调换刀具,操作机床,测量,以及清除费屑等等。使用数控机床虽然能提高85%的工作效率,但购置费用大。某些情况下,即使生产效率高,但加工相同的零件,其成本不一定比普通机床低。所以必须有更多的方法去减少加工时间,提高加工效率。不同的加工方法有不同的特点,就钻削加工而言,多钻头钻床加工是一种通过少量投资来提高生产效率的有效措施。多钻头钻床的出现势必会提高钻削加工的工作效率,具有一定的研究价值。

关键词:多钻头钻床 主轴箱 轴 齿轮 轴承 键

Abstract

The international competition is mainly the competition of productivity, if you want to survive in the future fierce competition, we must continue to accelerate productivity development, in the final analysis, is to continue to raise productivity, improve design of existing drilling machine, the workpiece in the form of multi axis and multi bit processing. The improved drilling machine can not only realize the one-time machining multiple holes, but also can not change the drill case to process different size hole. The application of multi - axis and multi - bit drilling machine in production will solve the problem of hole - hole machining waste time and manual machining of porous workpiece in ordinary drilling machine. According to statistics, the average cutting time of ordinary machine tools in the workshop rarely exceeds the total working time of 15%. Most of the time to look at the pictures, exchange tool, workpiece handling, machine operation, measurement, and chip clearance fees etc..Although the use of numerical control machine tool can improve the work efficiency of 85%, but purchase cost is big.In some cases, even though the production efficiency is high, but the same parts, the cost is not necessarily lower than the ordinary machine tool. So there must be more ways to reduce the processing time, improve the processing efficiency.Different processing methods have different characteristics, drilling and machining, drilling machine drilling is a kind of effective measures to improve production efficiency through a few investment.. The emergence of multi drill press will inevitably improve the efficiency of drilling, and has some research value..

Keywords: multi drill press, spindle box, shaft, gear, bearing, key

目录.

当前国际间的竞争主要是生产力的竞争,如果要想在未来激烈的竞争中生存下去,就必须不断的加快生产力的发展,归根结底是要不断地提高生产率,对现有的钻床进行改进设计,以多轴多钻头的形式进行工件的加工。改进后的钻床不仅可以实现一次性加工多个孔,而且可以在不更换钻头的情况下加工不同尺寸的孔。多轴多钻头钻床在生产中的应用,会解决普通钻床加工多孔工件时逐孔加工浪费时间和人工这两个重要问题。据统计,一般在车间中普通机床的平均钻削时间很少超过全部工作时间的15% 。大部分时间用来看图,装卸工件,调换刀具,操作机床,测量,以及清除费屑等等。使用数控机床虽然能提高85%的工作效率,但购置费用大。某些情况下,即使生产效率高,但加工相同的零件,其成本不一定比普通机床低。所以必须有更多的方法去减少加工时间,提高加工效率。不同的加工方法有不同的特点,就钻削加工而言,多钻头钻床加工是一种通过少量投资来提高生产效率的有效措施。多钻头钻床的出现势必会提高钻削加工的工作效率,具有一定的研究价值。

关键词:多钻头钻床 主轴箱 轴 齿轮 轴承 键

Abstract

The international competition is mainly the competition of productivity, if you want to survive in the future fierce competition, we must continue to accelerate productivity development, in the final analysis, is to continue to raise productivity, improve design of existing drilling machine, the workpiece in the form of multi axis and multi bit processing. The improved drilling machine can not only realize the one-time machining multiple holes, but also can not change the drill case to process different size hole. The application of multi - axis and multi - bit drilling machine in production will solve the problem of hole - hole machining waste time and manual machining of porous workpiece in ordinary drilling machine. According to statistics, the average cutting time of ordinary machine tools in the workshop rarely exceeds the total working time of 15%. Most of the time to look at the pictures, exchange tool, workpiece handling, machine operation, measurement, and chip clearance fees etc..Although the use of numerical control machine tool can improve the work efficiency of 85%, but purchase cost is big.In some cases, even though the production efficiency is high, but the same parts, the cost is not necessarily lower than the ordinary machine tool. So there must be more ways to reduce the processing time, improve the processing efficiency.Different processing methods have different characteristics, drilling and machining, drilling machine drilling is a kind of effective measures to improve production efficiency through a few investment.. The emergence of multi drill press will inevitably improve the efficiency of drilling, and has some research value..

Keywords: multi drill press, spindle box, shaft, gear, bearing, key

目录.

第一章 概论 ......................................................1

第二章 钻床的总体设计...............................................2

2.1 概述 ............................................................2

2.2主动参数的确定 ...................................................4

2.3转速图的拟定 ...................................................5

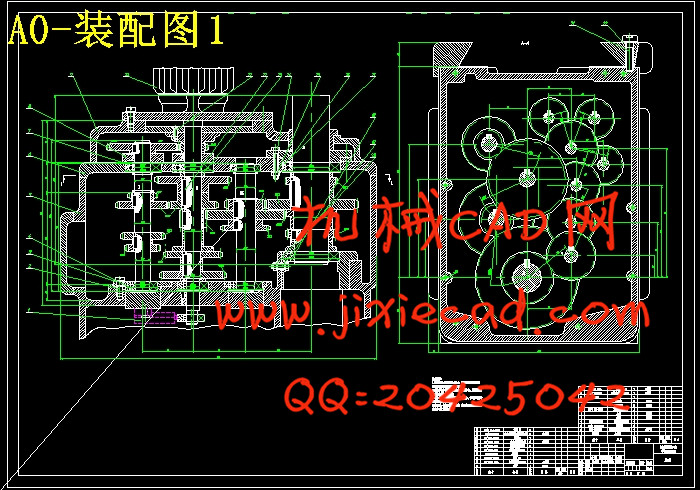

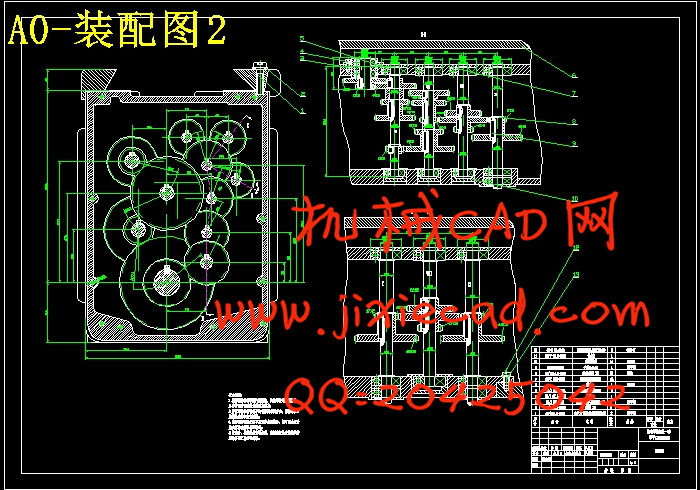

2.4绘制传动系统图 ..................................................7

2.5结构的设计 .....................................................9

2.6齿轮的设计与校核 ............................................... 10

2.7主轴的设计与校核 ..............................................15

2.8主轴与齿轮的连接 ...............................................18

第三章 多钻头方案的设计.............................................20

3.1主轴的分布方式...................................................20

3.2对输出轴的控制...............................................20

第四章 钻削加工的确定...............................................23

4.1钻削加工的工艺特点..........................................23

4.2 钻削加工的工艺范围...............................................23

第五章 轴承的选用与校核...........................................25

5.1主轴轴承常用的类型...............................................25

5.2轴承的配置.......................................................25第二章 钻床的总体设计...............................................2

2.1 概述 ............................................................2

2.2主动参数的确定 ...................................................4

2.3转速图的拟定 ...................................................5

2.4绘制传动系统图 ..................................................7

2.5结构的设计 .....................................................9

2.6齿轮的设计与校核 ............................................... 10

2.7主轴的设计与校核 ..............................................15

2.8主轴与齿轮的连接 ...............................................18

第三章 多钻头方案的设计.............................................20

3.1主轴的分布方式...................................................20

3.2对输出轴的控制...............................................20

第四章 钻削加工的确定...............................................23

4.1钻削加工的工艺特点..........................................23

4.2 钻削加工的工艺范围...............................................23

第五章 轴承的选用与校核...........................................25

5.1主轴轴承常用的类型...............................................25

5.3轴承的精度与配合...............................................25

5.4轴承间隙的调整.................................................26

5.5轴承的寿命计算..........................................26

第六章 钻头的选择...................................................29

6.1硬质合金钻头的类型...........................................29

6.2用硬质合金钻头的考虑因素.......................................30

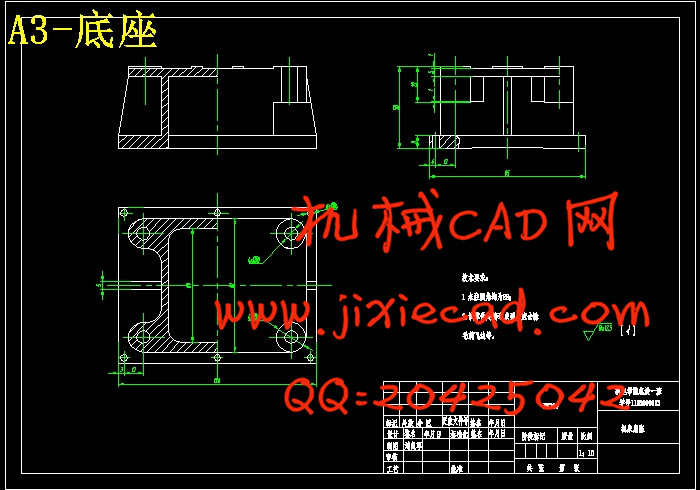

第七章 底座的设计...................................................32

7.1机床底座的作用...................................................32

7.2材料的选择..................................................32

7.3结构设计.....................................................32

7.4尺寸的确定.......................................................32

第八章 润滑与密封问题..............................................34

8.1润滑与密封.......................................................34

8.2其他问题.........................................................34

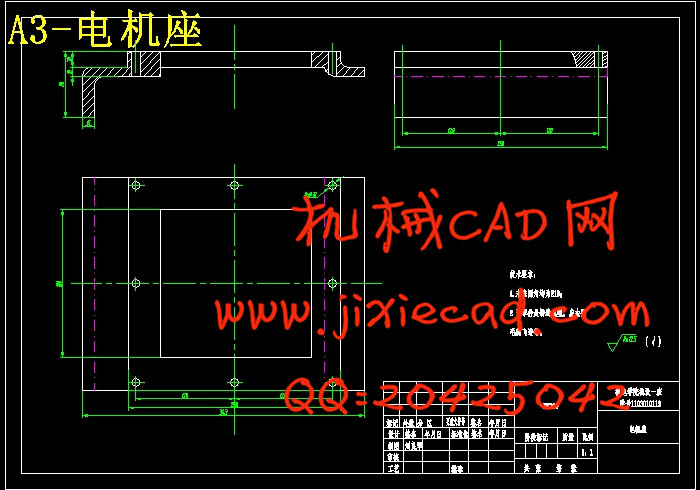

第九章 机床总体布局分析与使用说明.................................35

9.1同类机床总体布局分析.............................................35

9.2传动部件的布局...................................................36

9.3机床设备操作注意事项与规程....................................36

参考文献...........................................................39

谢辞..............................................................40