设计简介

轮式挖掘机的万向节传动及驱动桥的设计

摘 要

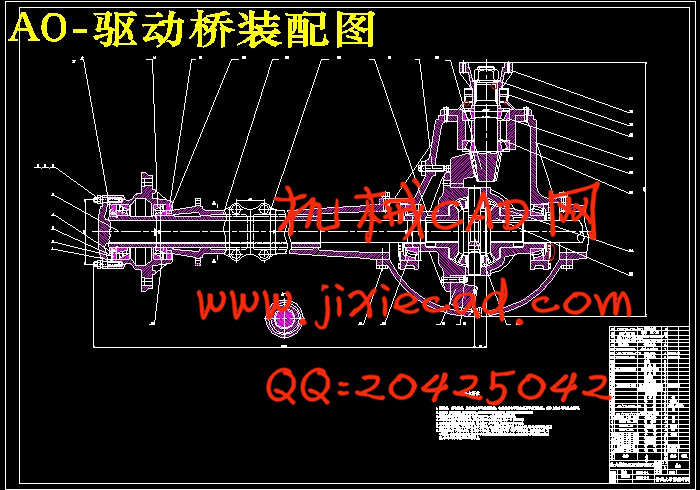

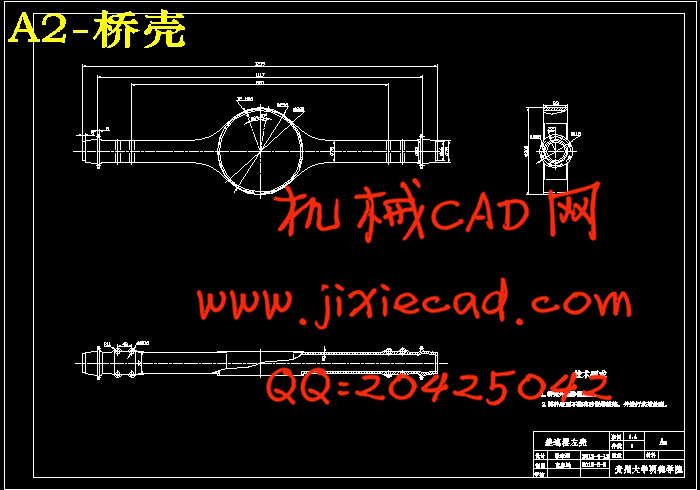

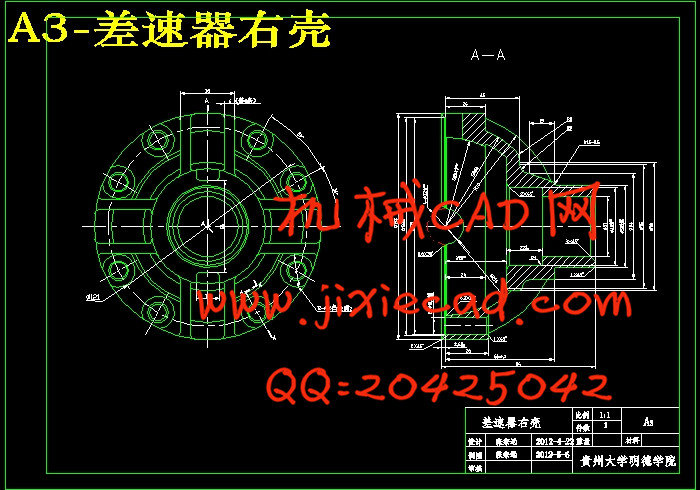

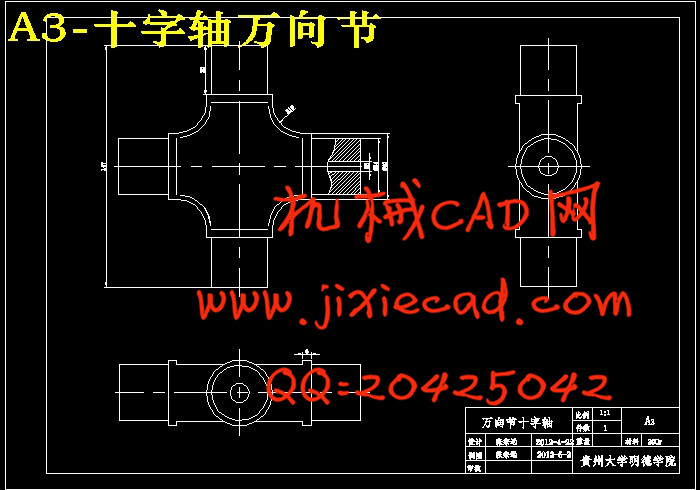

本设计是做轮式挖掘机的万向节传动及驱动桥的设计,它处于传动系统的末端,传递较大的转矩,其工作的好坏直接影响到整机的工作性能。驱动桥的功用是通过主传动来改变转矩旋转轴线的方向,把纵置发动机的转矩传递到横置驱动桥两边的驱动轮上。通过主传动的锥齿轮改变传力方向,通过最终传动和主传动将变速箱输出轴的转速降低,增大转矩;通过差速器解决左右差速问题,减小转向阻力和轮胎磨损,从而协助转向。此外驱动桥壳还起传力和承重作用。

此次设计主要是对轮式挖掘机的整个驱动桥内部零部件进行设计计算,包括主减速器部分、差速器、轮边减速器部分以及万向节的选择,由于驱动桥部件的设计技术已有很好的发展,所以这次设计主要借鉴的是詹阳动力JYL608型挖掘机的一些参数展开的。此次设计的意义在于熟悉了机械设计的流程和对大学四年所学知识有一个整体的了解。

关键词:驱动桥,主减速器,差速器,轮边减速,万向节

The design of the universal joint transmission and drive axle of the wheeled excavator

Abstract

The design is the design of the universal joint transmission and drive axle wheel excavator, it is the end of the transmission system, passing a large torque, its work will have a direct impact on the work performance of the machine.The function of the drive axle of the main drive to change the torque in the direction of the rotation axis, a longitudinal engine torque to the transverse drive axle on both sides of the driving wheel. Change the direction of the force transmission through the main drive bevel gear final drive and the main transmission gearbox output shaft speed is reduced, increasing the torque; solve the differential left and right through the differential to reduce steering resistance and tire wear, which to assist steering. In addition, the drive axle housing also from the power transmission and load-bearing role.

The design of the main internal parts of the drive axle of the wheel excavators, design calculations, including the choice of part of the main gear box, differential, wheel reducer part and universal joints, drive axle parts design techniques already well developed, so this design is the main reference is the parameter expansion Zhan Yang the power JYL608 excavator. The significance of the design is familiar with an overall understanding of the mechanical design process and four years of college knowledge.

Keywords: drive axle, main reducer, differential, wheel speed, universal joint