设计简介

随着科学技术和社会生产的不断发展,对机械产品的质量和生产率提出了越来越高的要求。机械加工工艺过程的自动化是实现上述要求的最重要措施之一,它不仅能够提高生产效率,降低生产成本,还能够大大改善工人的劳动条件。

全功能的数控系统虽然功能丰富,但成本高,我国一般的中小型企业购置困难,但是中小型企业为了发展生产,希望对原有机床进行改造,进行数控化、自动化改造,以提高生产效率。并且,目前各企业都有大量的普通机床,完全用数控机床替换根本不可能,而且替代下来的机床闲置起来又会造成浪费,要解决这些问题,应走普通机床的数控改造之路。也就是在这样的情况下,提出了普通车床的数控改造。

并且从美国、日本等国家工业化进程看,机床的数控改造也必不可少。数控改造机床占有较大比例,如在早期,日本的大企业中有26%的机床经过数控改造,中小企业则是74%,在美国有许多数控专业化公司,为世界各地提供机床数控改造服务。因此,普通机床的数控改造不但有存在的必要,而且大有可为,尤其对一些中小企业更是如此。

数控改造一般是对普通机床某些部位做一定的改造,配上数控装置,从而使机床具有数控加工能力,其改造的目的有以下几点:

(1)从提高资本效率出发,改造闲置设备,发挥机床的原有功能和改造后的新增功能,提高机床的使用价值。

(2)为了提高生产效率进行数控改造。

(3)为了适应多品种,小批量零件生产而进行数控改造。

(4)为了使技术等级较低的工人也能加工出高质量的产品零件和提高生产效率而进行数控改造。

( 5 )为了减少整个设备投资计划而进行数控改造。所有这些目的都围绕一点,即提高机床的性能价格比,用较少的价格得到较高的机床性能。为此,我们以普通车床CA6140为研究对象。

本次设计的原则是:在满足机床总体布局的条件下尽可能的利用原来的零、部件,尽量减少改动,尤其是对机床的较大部件。这样可以大大地降低成本,缩短制造周期。在进行经济型数控机床设计时,虽然结构尺寸不像改造设计那样严格,但也应参考同类型机床。在初步计算后,在进行类比,是结构尺寸比较紧凑。

设计的主要任务有:

1、 翻译5000印刷符号的外文资料。

2、 机械部分改装设计:

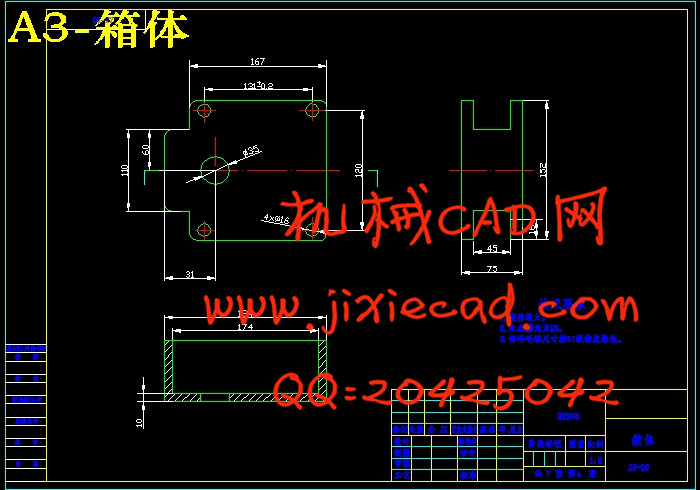

(1)进给部分装配图一套,0号图纸;

(2)主要零件图若干。

3、硬件设计

画出数控系统硬件电路图,1号图纸。

4、软件设计:

(1)数控程序框图设计,1号图纸;

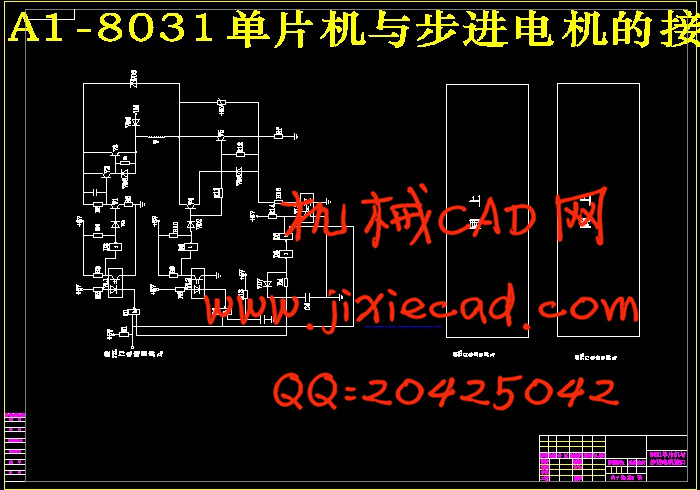

(2)8031单片机与步进电机接口图,1号图纸。

实际的任务有:确定整体方案;机械各个部分(滚珠丝杠、齿轮传动、步进电机)的具体设计;数控系统硬件部分的设计和软件部分的设计。

设计中的系统配置及主要技术规格:

该系统由MCS-51中的8031单片机系统、接口电路、驱动线路及步进电机等组成,,系统属开环控制系统。其主要技术性能和参数如下:

(1)系统控制部分。采用8031系统,键盘和显示部分装在面板上。

(2)系统环境工作条件。温度-10~+40℃;湿度为40% ~80%。

(3)步进电机。150BF型电机一台,驱动电压为110V;相电流为2.5A;步距角为0.75°/步。

改造后的数控车床的加工能力、自动化水平和加工精度明显提高,而且总体生产效率得到了极大的提高,对当时我国的经济状况来说,是一个很好的科研方向。

GENERAL DESING INTRODUCTION

As science and technology and social development of the continuous production of the machine product quality and productivity of the ever-increasing demands. Machining process automation to achieve the above request is the most important one, It not only improve the efficiency of production and reduce production costs, but also improve the worker's labor condition consumedly.Full-function CNC System although function abundant, but the cost is high, my general difficulties in the acquisition of small and medium enterprises. our country general of medium the small scaled business enterprise purchase difficulty, and hope to transform the original machine, NC, automation transformation, to improve production efficiency. Moreover, enterprises now have a large number of general machine tools, complete with CNC machine tools is simply impossible to replace. and alternative from the machine idle up will lead to waste, in order to solve these problems, should follow the general transformation of CNC machine tool path. It is in such circumstances, the general transformation of CNC lathe.

And from the United States, Japan and other countries the process of industrialization, transformation of CNC machine tools is also essential. Number control reformation tool machine to occupy a greater comparison, such as in earlier period, Japan of have 26 percent tool machines to pass by in the big business enterprise number control a reformation, in small business enterprise then 74 percent have in the United States many number control profession to turn a company, provide a tool machine number to control a reformation service for the world-wide locations.Therefore, the general transformation of CNC machine tools is not only the necessary and promising. especially the SMEs especially.

NC general transformation of general machine tools must do certain parts of the transformation, accompanied NC devices so that the NC machine tools with its ability to transform the purpose of the following :

(1)From the capital increase efficiency and transform the idle equipment, machine tools to play the original functions and transformation of the new features, raising machine value.

(2)In order to improve production efficiency NC transformation.

(3)In order to adapt to multiple types of small batch production of parts for NC transformation.

(4)For technical workers with lower grades can be processed into high-quality parts and products to improve productivity for NC transformation.

(5)To reduce the overall equipment investment for the project NC transformation. All these objectives are centered on the fact that raising the functional machine with relatively small price to be higher machine performance. To this end, we ordinary CA6140 lathe for the study.

The design principle is : to satisfy the overall layout of the machine under the conditions of the original as much as possible the use of zero, components, minimize the changes, particularly for the larger machine parts. This can greatly reduce costs and shorten the manufacturing cycle. Undertaking economic NC machine tool design, although unlike the transformation of structure size stringent design, However, we should also make reference to the same type of machine. In preliminary calculation then, fashion, the structure is relatively compact size.

Design of the main tasks are :

1,Translate the 5000 printing symbols foreign materials.

2,Mechanical parts design modifications :

(1) Feed a part of assembly drawings, blueprints, 0

(2) Several major components map.

3, The hardware design

NC paint system hardware circuit, drawing on the 1st.

4, software design :

(1) NC program diagram design, drawing on the 1st;

(2) 8031 MCU and stepper motor interface maps, drawings on the 1st.

The actual tasks are : to identify the overall program; Mechanical parts (ball screw and gear drive stepper motor) the specific design; CNC system hardware design and software design.

Design of system configuration and main technical specifications :

The system consists of MCS-51 microcontroller 8031 the system, interface circuit, driving circuits and components such as stepper motors, and open-loop system is a control system. Its main technical functions and parameters are as follows :

system control part. Used 8031 system, the keyboard and display panel mounted on.

(2) System environment working conditions. The range of temperature is from 12 degrees below zero centigrade to 40 centigrade; The range of humidity is from of 40 percent to 80 percent .

(3) stepper motor. 150BF a Taiwan-based motor driving voltage of 110 V; Current Phase is 2 .5A ; step angle is 0 . 75 ° / step.

After transformation, CNC lathe processing capacity, the level of automation and processing accuracy noticeably improved, and overall production efficiency has been greatly improved, then our economic situation, it is a good direction for research.

GENERAL DESING INTRODUCTIOⅢ

目 录 Ⅵ

第一章 引 言 1

1.1数控机床的发展 1

1.2数控机床的改造的必要性 2

1.3本课题的研究对象及其相关参数 3

第二章纵向进给系统总体方案的拟订和论证 4

2.1 设计任务 4

2.2总体方案的论证 4

2.3总体方案的确定 5

第三章进给伺服系统机械部分设计 6

3.1切削力的计算 6

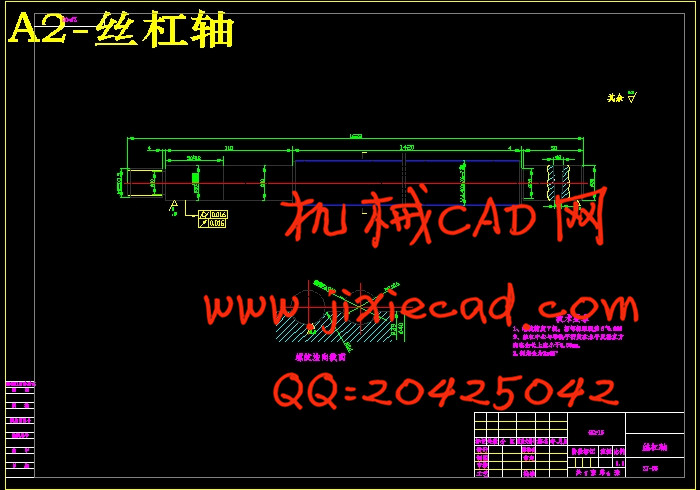

3.2滚珠丝杆螺母副的计算和选型 7

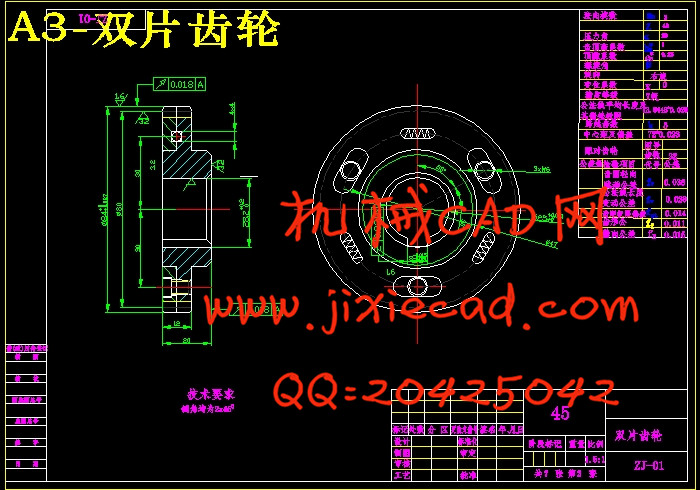

3.3齿轮传动比的计算 10

3.4步进进电机的计算和选型 11

第四章 数控系统硬件控制设计 16

4.1控制系统方案确定 16

4.1.1数控系统基本硬件组成 16

4.1.2总体组成 16

4.2总体组成及软硬件的分配 16

4.3主控部分的设计 17

4.3.1主控芯片选择 17

4.3.2 MCS—51系列单片机介绍 17

4.3.3三总线结构 19

4.3.4存储器结构 19

4.3.5时序 19

4.3.6中断功能 20

4.3.7MCS---51单片机常用系统扩展芯片 21

4.4存储器扩展设计 22

4.4.1芯片选择22

4.4.2地址分配及译码23

4.5接口电路及辅助电路具体设计26

4.5.1.步进电机接口电路 26

4.5.2.键盘、显示接口 27

4.5.3其他辅助电路 29

第五章经济型数控系统软件设计 30

5.1软件的组成 30

5.2插补原理及其程序设计 30

5.2.1插补方法概述 30

5.2.2逐点比较法的直线插补及其程序设计 31

5.2.3逐点比较法的圆弧插补及其程序设计 34

5.3步进电机运行程序控制设计 36

5.4经济性数控系统的软件模型 37

5.4.1模块组成 37

5.4.2缓冲区设置 37

5.4.3中段处理器 38

5.4.4各模块说明及流程图 38

结论 42

参考文献 43

致谢及声明 44

全功能的数控系统虽然功能丰富,但成本高,我国一般的中小型企业购置困难,但是中小型企业为了发展生产,希望对原有机床进行改造,进行数控化、自动化改造,以提高生产效率。并且,目前各企业都有大量的普通机床,完全用数控机床替换根本不可能,而且替代下来的机床闲置起来又会造成浪费,要解决这些问题,应走普通机床的数控改造之路。也就是在这样的情况下,提出了普通车床的数控改造。

并且从美国、日本等国家工业化进程看,机床的数控改造也必不可少。数控改造机床占有较大比例,如在早期,日本的大企业中有26%的机床经过数控改造,中小企业则是74%,在美国有许多数控专业化公司,为世界各地提供机床数控改造服务。因此,普通机床的数控改造不但有存在的必要,而且大有可为,尤其对一些中小企业更是如此。

数控改造一般是对普通机床某些部位做一定的改造,配上数控装置,从而使机床具有数控加工能力,其改造的目的有以下几点:

(1)从提高资本效率出发,改造闲置设备,发挥机床的原有功能和改造后的新增功能,提高机床的使用价值。

(2)为了提高生产效率进行数控改造。

(3)为了适应多品种,小批量零件生产而进行数控改造。

(4)为了使技术等级较低的工人也能加工出高质量的产品零件和提高生产效率而进行数控改造。

( 5 )为了减少整个设备投资计划而进行数控改造。所有这些目的都围绕一点,即提高机床的性能价格比,用较少的价格得到较高的机床性能。为此,我们以普通车床CA6140为研究对象。

本次设计的原则是:在满足机床总体布局的条件下尽可能的利用原来的零、部件,尽量减少改动,尤其是对机床的较大部件。这样可以大大地降低成本,缩短制造周期。在进行经济型数控机床设计时,虽然结构尺寸不像改造设计那样严格,但也应参考同类型机床。在初步计算后,在进行类比,是结构尺寸比较紧凑。

设计的主要任务有:

1、 翻译5000印刷符号的外文资料。

2、 机械部分改装设计:

(1)进给部分装配图一套,0号图纸;

(2)主要零件图若干。

3、硬件设计

画出数控系统硬件电路图,1号图纸。

4、软件设计:

(1)数控程序框图设计,1号图纸;

(2)8031单片机与步进电机接口图,1号图纸。

实际的任务有:确定整体方案;机械各个部分(滚珠丝杠、齿轮传动、步进电机)的具体设计;数控系统硬件部分的设计和软件部分的设计。

设计中的系统配置及主要技术规格:

该系统由MCS-51中的8031单片机系统、接口电路、驱动线路及步进电机等组成,,系统属开环控制系统。其主要技术性能和参数如下:

(1)系统控制部分。采用8031系统,键盘和显示部分装在面板上。

(2)系统环境工作条件。温度-10~+40℃;湿度为40% ~80%。

(3)步进电机。150BF型电机一台,驱动电压为110V;相电流为2.5A;步距角为0.75°/步。

改造后的数控车床的加工能力、自动化水平和加工精度明显提高,而且总体生产效率得到了极大的提高,对当时我国的经济状况来说,是一个很好的科研方向。

GENERAL DESING INTRODUCTION

As science and technology and social development of the continuous production of the machine product quality and productivity of the ever-increasing demands. Machining process automation to achieve the above request is the most important one, It not only improve the efficiency of production and reduce production costs, but also improve the worker's labor condition consumedly.Full-function CNC System although function abundant, but the cost is high, my general difficulties in the acquisition of small and medium enterprises. our country general of medium the small scaled business enterprise purchase difficulty, and hope to transform the original machine, NC, automation transformation, to improve production efficiency. Moreover, enterprises now have a large number of general machine tools, complete with CNC machine tools is simply impossible to replace. and alternative from the machine idle up will lead to waste, in order to solve these problems, should follow the general transformation of CNC machine tool path. It is in such circumstances, the general transformation of CNC lathe.

And from the United States, Japan and other countries the process of industrialization, transformation of CNC machine tools is also essential. Number control reformation tool machine to occupy a greater comparison, such as in earlier period, Japan of have 26 percent tool machines to pass by in the big business enterprise number control a reformation, in small business enterprise then 74 percent have in the United States many number control profession to turn a company, provide a tool machine number to control a reformation service for the world-wide locations.Therefore, the general transformation of CNC machine tools is not only the necessary and promising. especially the SMEs especially.

NC general transformation of general machine tools must do certain parts of the transformation, accompanied NC devices so that the NC machine tools with its ability to transform the purpose of the following :

(1)From the capital increase efficiency and transform the idle equipment, machine tools to play the original functions and transformation of the new features, raising machine value.

(2)In order to improve production efficiency NC transformation.

(3)In order to adapt to multiple types of small batch production of parts for NC transformation.

(4)For technical workers with lower grades can be processed into high-quality parts and products to improve productivity for NC transformation.

(5)To reduce the overall equipment investment for the project NC transformation. All these objectives are centered on the fact that raising the functional machine with relatively small price to be higher machine performance. To this end, we ordinary CA6140 lathe for the study.

The design principle is : to satisfy the overall layout of the machine under the conditions of the original as much as possible the use of zero, components, minimize the changes, particularly for the larger machine parts. This can greatly reduce costs and shorten the manufacturing cycle. Undertaking economic NC machine tool design, although unlike the transformation of structure size stringent design, However, we should also make reference to the same type of machine. In preliminary calculation then, fashion, the structure is relatively compact size.

Design of the main tasks are :

1,Translate the 5000 printing symbols foreign materials.

2,Mechanical parts design modifications :

(1) Feed a part of assembly drawings, blueprints, 0

(2) Several major components map.

3, The hardware design

NC paint system hardware circuit, drawing on the 1st.

4, software design :

(1) NC program diagram design, drawing on the 1st;

(2) 8031 MCU and stepper motor interface maps, drawings on the 1st.

The actual tasks are : to identify the overall program; Mechanical parts (ball screw and gear drive stepper motor) the specific design; CNC system hardware design and software design.

Design of system configuration and main technical specifications :

The system consists of MCS-51 microcontroller 8031 the system, interface circuit, driving circuits and components such as stepper motors, and open-loop system is a control system. Its main technical functions and parameters are as follows :

system control part. Used 8031 system, the keyboard and display panel mounted on.

(2) System environment working conditions. The range of temperature is from 12 degrees below zero centigrade to 40 centigrade; The range of humidity is from of 40 percent to 80 percent .

(3) stepper motor. 150BF a Taiwan-based motor driving voltage of 110 V; Current Phase is 2 .5A ; step angle is 0 . 75 ° / step.

After transformation, CNC lathe processing capacity, the level of automation and processing accuracy noticeably improved, and overall production efficiency has been greatly improved, then our economic situation, it is a good direction for research.

目 录

设 计 总 说 明 IGENERAL DESING INTRODUCTIOⅢ

目 录 Ⅵ

第一章 引 言 1

1.1数控机床的发展 1

1.2数控机床的改造的必要性 2

1.3本课题的研究对象及其相关参数 3

第二章纵向进给系统总体方案的拟订和论证 4

2.1 设计任务 4

2.2总体方案的论证 4

2.3总体方案的确定 5

第三章进给伺服系统机械部分设计 6

3.1切削力的计算 6

3.2滚珠丝杆螺母副的计算和选型 7

3.3齿轮传动比的计算 10

3.4步进进电机的计算和选型 11

第四章 数控系统硬件控制设计 16

4.1控制系统方案确定 16

4.1.1数控系统基本硬件组成 16

4.1.2总体组成 16

4.2总体组成及软硬件的分配 16

4.3主控部分的设计 17

4.3.1主控芯片选择 17

4.3.2 MCS—51系列单片机介绍 17

4.3.3三总线结构 19

4.3.4存储器结构 19

4.3.5时序 19

4.3.6中断功能 20

4.3.7MCS---51单片机常用系统扩展芯片 21

4.4存储器扩展设计 22

4.4.1芯片选择22

4.4.2地址分配及译码23

4.5接口电路及辅助电路具体设计26

4.5.1.步进电机接口电路 26

4.5.2.键盘、显示接口 27

4.5.3其他辅助电路 29

第五章经济型数控系统软件设计 30

5.1软件的组成 30

5.2插补原理及其程序设计 30

5.2.1插补方法概述 30

5.2.2逐点比较法的直线插补及其程序设计 31

5.2.3逐点比较法的圆弧插补及其程序设计 34

5.3步进电机运行程序控制设计 36

5.4经济性数控系统的软件模型 37

5.4.1模块组成 37

5.4.2缓冲区设置 37

5.4.3中段处理器 38

5.4.4各模块说明及流程图 38

结论 42

参考文献 43

致谢及声明 44