设计简介

摘 要

电动叉车利用蓄电池作为动力源,由电机将电能转换为机械能。电动叉车由于其操作控制简便,灵活外,其操作人员的操作强度要相对内燃叉车而言轻很多,其电动转向系统,加速控制系统,液压控制系统以及刹车系统都由电信号来控制,大大降低了操作人员的劳动强度,这样一来对于提高其工作效率以及工作的准确性有非常大的帮助。且相较于内燃叉车,电动车辆的低噪音,无尾气排放的优势也已得到许多用户的认可。电子控制技术的快速发展使得电动叉车操作变得越来越舒适,适用范围越广,解决物流的方案越来越多。

国内外用户对电动叉车的需求量不断增加,电动叉车在整个叉车销量中所占比例稳步上升。在发达国家,电动叉车需求远远大于内燃叉车,尤其是在港口、仓库以及烟草、食品、轻纺等行业,电动叉车正在逐步替代内燃叉车。

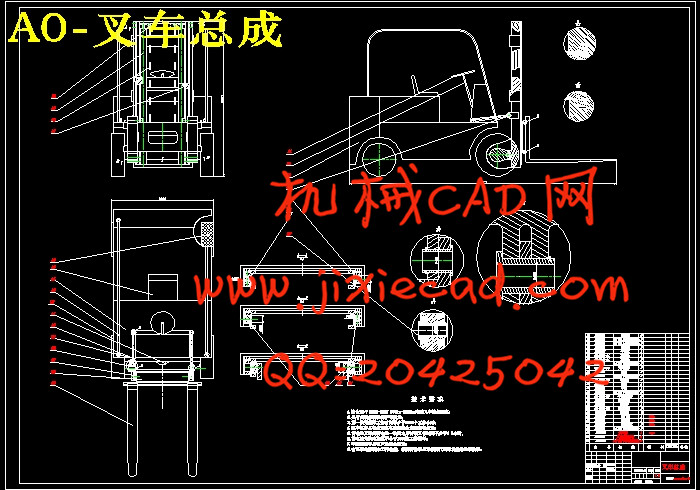

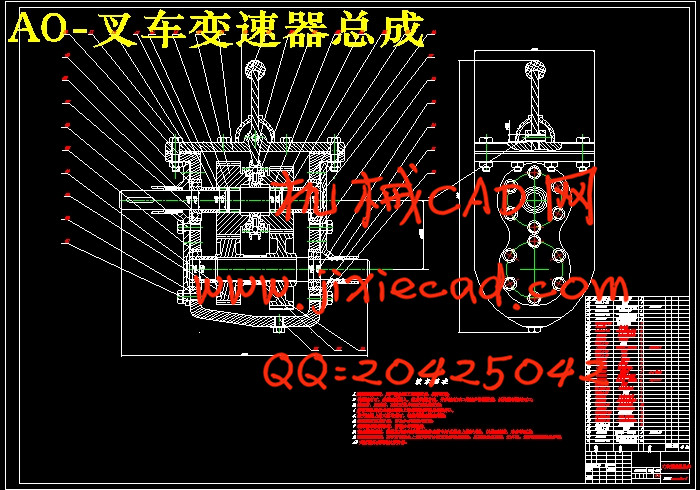

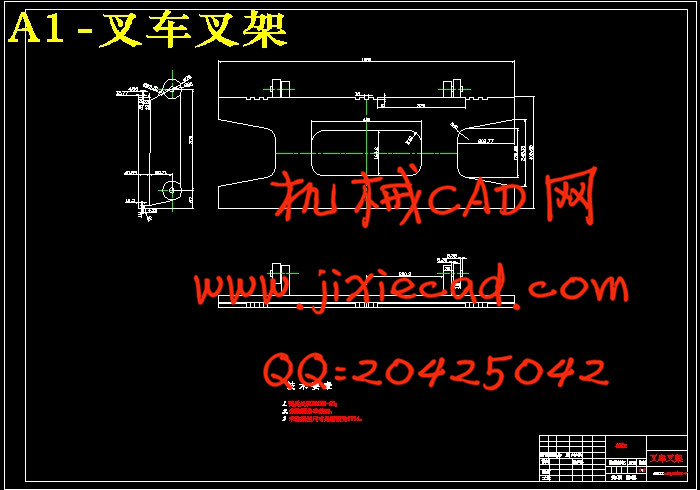

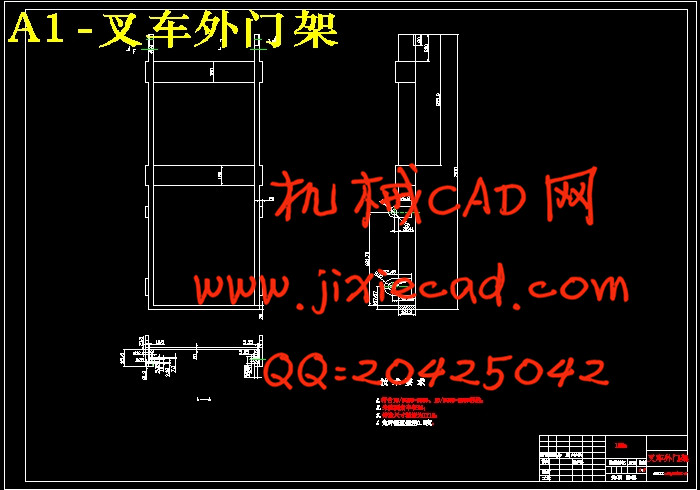

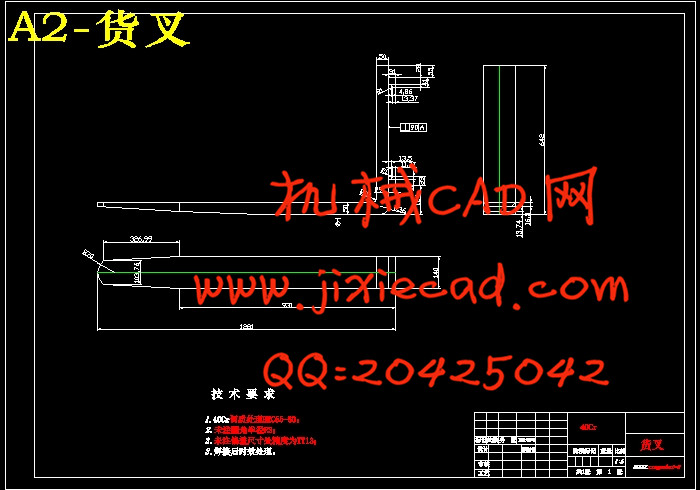

本设计将要运用所学过的知识完成对蓄电池、行走电机的选择,完成叉车变速器齿轮、轴、轴承和整体尺寸的设计及校核,并对叉车的货叉、内外门架、叉架进行设计及校核,运用AutoCAD软件完成叉车变速器二维结构、叉车整车和货叉部分的二维结构图,利用Pro/E软件对叉车的内外门架、货叉、叉架等零部件进行建模并完成整机装配,完成整车的造型设计,运用ANSYS有限元分析软件对货叉和外门架进行静力分析。

关键词:电动叉车; 叉车变速器; 货叉 ;门架 ;结构设计;三维建模;有限元分析

ABSTRACT

Electric forklift battery which converts electrical energy into mechanical energy is used by the motor as a power source. Because electric forklift is simple, flexible, it is relatively lighter internal combustion forklift trucks, the electric power steering system, the speed control system, hydraulic control system and by the electrical signal to control the brake system greatly reduces The operator's labor intensity, so that its work for improving the efficiency and accuracy of the work has a very big help. And compared to internal combustion forklifts, electric vehicles, low noise, no emissions advantage has also been recognized by many users. The rapid development of electronic control technology makes electric forklift operation becomes more and more comfortable the more widely the scope to address the logistics of the program more and more. Domestic and foreign users of the increasing demand for electric forklifts, electric forklift trucks in the percentage of sales increased steadily. In developed countries, demand is far greater than internal combustion electric forklift truck, Especially in ports, warehouses, and tobacco, food, textile and other industries, electric forklift is gradually replaced internal combustion forklifts.

The design will have to apply the knowledge to complete the battery, the choice of running the motor to complete the truck transmission gears, shafts, bearings, and the overall size of the design and verification, and forklift forks, internal and external door frame, fork design And check, using AutoCAD software to complete the two-dimensional structure of transmission forklift, forklift fork part of the vehicle and two-dimensional structure, the use of Pro / E, both inside and outside of the truck's door frame, fork, fork and other parts modeling And complete machine assembly, complete vehicle design, finite element analysis using ANSYS software and the outside door frame fork for static analysis.

Key words: Electric forklift; Forklift transmission; Fork; Door frame; Structural design; Three-dimensional modeling; Finite element analysis

目 录

摘 要 I电动叉车利用蓄电池作为动力源,由电机将电能转换为机械能。电动叉车由于其操作控制简便,灵活外,其操作人员的操作强度要相对内燃叉车而言轻很多,其电动转向系统,加速控制系统,液压控制系统以及刹车系统都由电信号来控制,大大降低了操作人员的劳动强度,这样一来对于提高其工作效率以及工作的准确性有非常大的帮助。且相较于内燃叉车,电动车辆的低噪音,无尾气排放的优势也已得到许多用户的认可。电子控制技术的快速发展使得电动叉车操作变得越来越舒适,适用范围越广,解决物流的方案越来越多。

国内外用户对电动叉车的需求量不断增加,电动叉车在整个叉车销量中所占比例稳步上升。在发达国家,电动叉车需求远远大于内燃叉车,尤其是在港口、仓库以及烟草、食品、轻纺等行业,电动叉车正在逐步替代内燃叉车。

本设计将要运用所学过的知识完成对蓄电池、行走电机的选择,完成叉车变速器齿轮、轴、轴承和整体尺寸的设计及校核,并对叉车的货叉、内外门架、叉架进行设计及校核,运用AutoCAD软件完成叉车变速器二维结构、叉车整车和货叉部分的二维结构图,利用Pro/E软件对叉车的内外门架、货叉、叉架等零部件进行建模并完成整机装配,完成整车的造型设计,运用ANSYS有限元分析软件对货叉和外门架进行静力分析。

关键词:电动叉车; 叉车变速器; 货叉 ;门架 ;结构设计;三维建模;有限元分析

ABSTRACT

Electric forklift battery which converts electrical energy into mechanical energy is used by the motor as a power source. Because electric forklift is simple, flexible, it is relatively lighter internal combustion forklift trucks, the electric power steering system, the speed control system, hydraulic control system and by the electrical signal to control the brake system greatly reduces The operator's labor intensity, so that its work for improving the efficiency and accuracy of the work has a very big help. And compared to internal combustion forklifts, electric vehicles, low noise, no emissions advantage has also been recognized by many users. The rapid development of electronic control technology makes electric forklift operation becomes more and more comfortable the more widely the scope to address the logistics of the program more and more. Domestic and foreign users of the increasing demand for electric forklifts, electric forklift trucks in the percentage of sales increased steadily. In developed countries, demand is far greater than internal combustion electric forklift truck, Especially in ports, warehouses, and tobacco, food, textile and other industries, electric forklift is gradually replaced internal combustion forklifts.

The design will have to apply the knowledge to complete the battery, the choice of running the motor to complete the truck transmission gears, shafts, bearings, and the overall size of the design and verification, and forklift forks, internal and external door frame, fork design And check, using AutoCAD software to complete the two-dimensional structure of transmission forklift, forklift fork part of the vehicle and two-dimensional structure, the use of Pro / E, both inside and outside of the truck's door frame, fork, fork and other parts modeling And complete machine assembly, complete vehicle design, finite element analysis using ANSYS software and the outside door frame fork for static analysis.

Key words: Electric forklift; Forklift transmission; Fork; Door frame; Structural design; Three-dimensional modeling; Finite element analysis

目 录

ABSTRACT II

第1章 绪 论 1

1.1 课题研究目的和意义 1

1.2 课题的研究现状 1

1.3 课题的研究内容 3

1.4 课题的研究方法 3

第2章 叉车变速器的设计及校核 5

2.1 蓄电池的选择 5

2.2 行走电机的选择 6

2.3 基本数据的选择设计 7

2.3.1 变速器齿轮的设计及校核 7

2.3.2变速器轴的设计及校核 17

2.3.3变速器轴承的选择 24

2.4 本章小结 25

第3章 货叉的设计与校核 26

3.1 货叉的类型、构造选择及设计 26

3.2 内外门架及叉架的构造设计 28

3.2.1 内外门架的构造设计 28

3.2.2 叉架构造的设计 29

3.3 货叉、叉架的刚度强度校核 30

3.4 叉车整车的稳定性校核 33

3.5 本章小结 35

第4章 货叉三维建模及整车造型 36

4.1 Pro/E软件简介 36

4.2 三维模型 36

4.3 Pro/E整机装配及爆炸图 40

4.4 本章小结 41

第5章 货叉有限元分析 42

5.1 有限元分析的简介 42

5.2 Pro/E和ANSYS接口的创建 44

5.3 货叉、外门架的有限元分析 46

5.4 本章小结 61

结 论 62

致 谢 65