设计简介

摘要

传统的减速器设计通常以一些设计手册为依据,根据经验并运用公式进行设计。设计中存在很大的局限性。通常设计与制造过程不平行,如果设计出来的产品零部件装配失败只能重新设计,重新装配来检验产品的合规性。为了解决减速器的设计周期长,设计成本高,传动质量较低等问题,本文以蜗轮蜗杆减速器设计为例,采用参数设计并利用Pro/Engineer软件实现减速器的设计、建模、装配。相对于产品而言,我们可以把它看成几何模型,而无论多么复杂的几何模型,都可以分解成有限数量的构成特征,而每一种构成特征,都可以用有限的参数完全约束,这就是参数化的基本概念。Pro/Engineer操作软件是美国参数技术公司(PTC)旗下的CAD/CAM/CAE一体化的三维软件。Pro/Engineer软件以参数化著称,是参数化技术的最早应用者,在目前的三维造型软件领域中占有着重要地位。Pro/Engineer作为当今世界机械CAD/CAE/CAM领域的新标准而得到业界的认可和推广,是现今主流的CAD/CAM/CAE软件之一,特别是在国内产品设计领域占据重要位置。本文利用Pro/Engineer对蜗轮蜗杆进行参数化设计并实体建模装配设计。

设计思路:(1)通过对单级蜗杆减速器工作状况和设计要求对其结构形状进行分析,得出总体方案(2)按总体方案对各零部件的运动关系进行分析得出单级蜗杆减速器的整体结构尺寸(3)以各个系统为模块分别进行具体零部件的设计校核计算,得出各零部件的具体尺寸(4)用Pro/E实体建模各个零件并形成总装配。

关键词:减速器;参数化;Pro/Engineer;建模

ABSTRACT

Traditional gearbox design is usually based on some design manual, according to the experienceand the use of formula design. There is a lot of limitations in design.. Usually design and manufacturing process are not parallel, if design of products, parts and components assembly failure can only be re design, re assembly to test the product compliance. In order to solve the deceleration device design cycle is long, high design cost, low transmission quality problem, this paper takes the worm and worm gear deceleration device design as an example, the design parameters and the use of pro / engineer software implementation of reducer design, modeling and assembly. Compared with the product, we can regard it as geometric model, and no matter how complex geometric model can decomposed into a finite number of composition characteristics, and each composition characteristics can be fully constrained to a limited number of parameters, this is parameterized basic concepts. Pro/engineer software is a parametric technology corporation ptc (ptc) cad/cam/cae software integration under the. Pro / engineer software parametric is known, is the earliest application of parametric technology, in the present three-dimensional modeling software occupies an important position. Pro / engineer as one of the world's mechanical cad / cae / cam in the field of new standards and industry recognition and promotion, is one of today's mainstream cad / cam / cae software, especially to occupy an important position in the field of domestic product design. In this paper by using pro/engineer parametric design andsolid modeling assembly design of worm gear.

Design ideas: (1) by single stage worm deceleration machine work condition and design requirements on its structure and shape analysis and draws the overall scheme (2) according to the overall plan of various parts movement relationship of analysis of single stage worm deceleration is the dimension of the structure (3) to each system module are specific components of the design and checking calculation, that various components of the specific size (4) with various components of the Pro / E modeling and the formation of the general assembly.

KeyWords: reducer; parameterization; Pro/Engineer; modeling

目 录

第一章 绪论 1

1.1蜗轮蜗杆减速器简介 1

1.2基于Pro/ENGINEER的设计意义 1

第二章 总体方案确定 2

2.1已知参数 2

2.2传动装置总体设计 2

第三章 电动机的选择和动力学参数计算 3

3.1电动机类型的选择 3

3.2电动机功率的选择 3

3.3确定电动机型号 3

3.4计算各级的传动比 4

3.5运动参数计算 5

第四章 传动零件的设计计算 7

4.1蜗杆蜗轮的选择 7

4.2按齿面接触疲劳强度设计 7

4.3蜗杆与涡轮的主要参数与尺寸 8

第五章 涡轮蜗杆基本尺寸设计 12

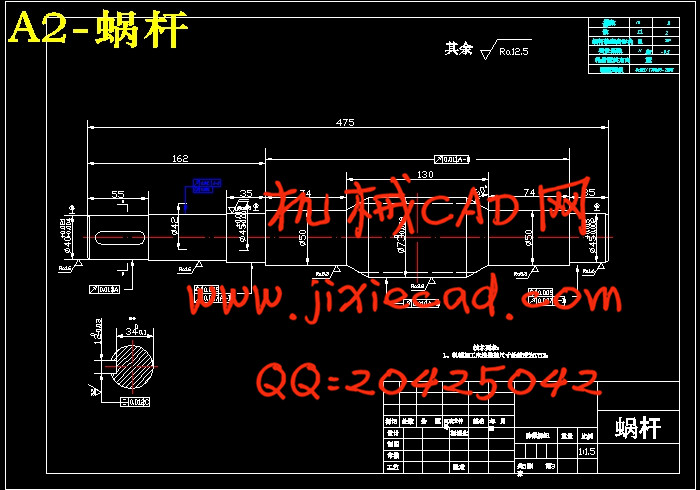

5.1蜗杆基本尺寸设计 12

5.1.1初步估计蜗杆轴外伸段的直径 12

5.1.2计算转矩 12

5.1.3轴的结构设计 12

5.1.4 Pro/E建模蜗杆外形 13

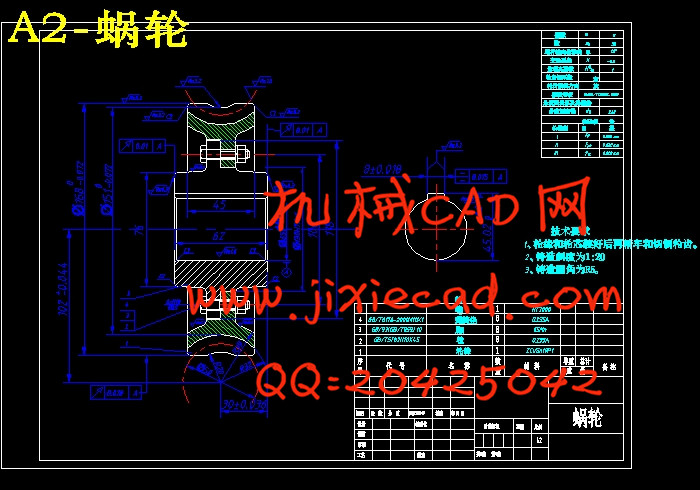

5.2蜗轮基本尺寸设计 13

5.2.1蜗轮结构及基本尺寸表 13

5.2.2 Pro/E建模涡轮外形 14

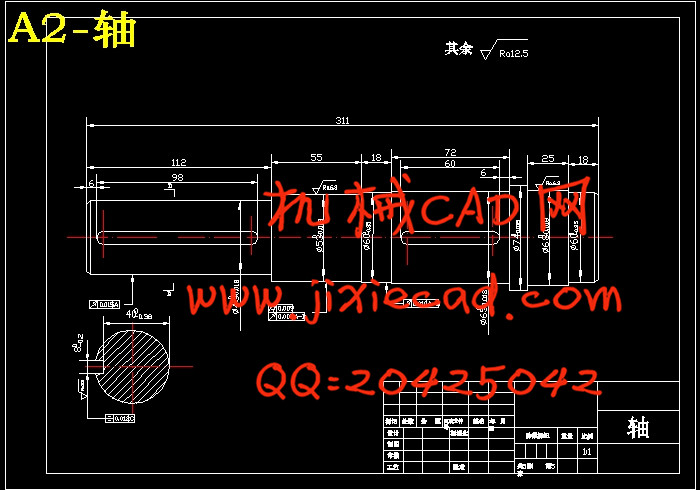

第六章 涡轮轴的尺寸设计与校核 15

6.1 轴的直径与长度的确定 15

6.2轴的受力分析 16

6.3轴的校核计算 18

第七章 滚动轴承的选择及校核计算 20

7.1计算输入轴轴承 20

7.2计算输出轴轴承 21

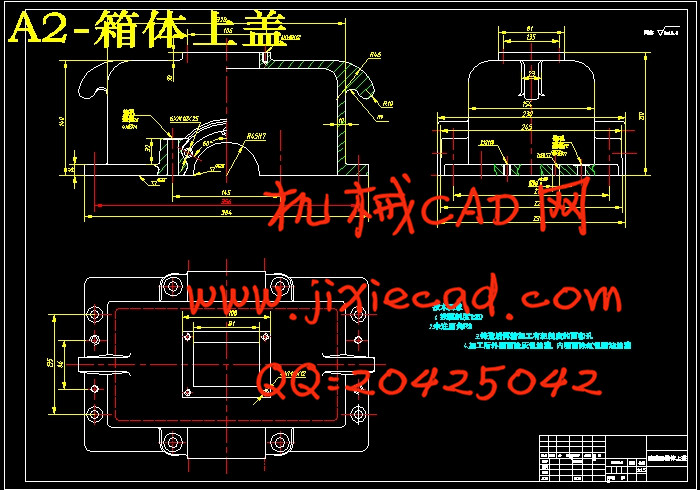

第八章 减速器箱体的结构设计 23

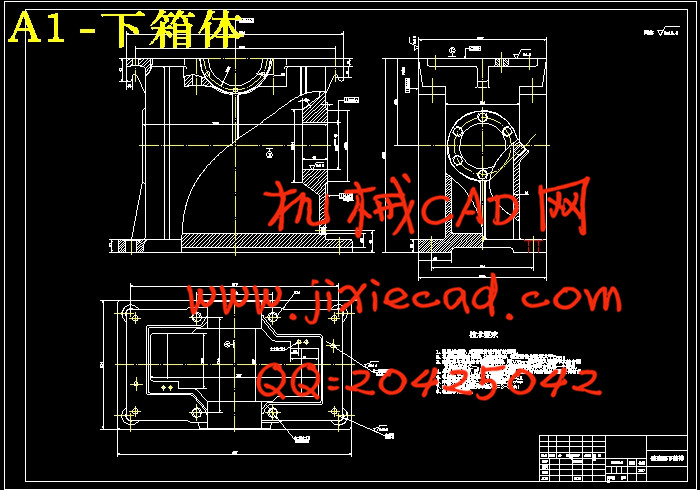

8.1箱体尺寸的计算 23

8.2确定齿轮位置和箱体内壁线 24

第九章 减速器其他零件的选择 26

9.1键选择 26

9.2轴承选择 26

9.3密封圈选择 27

9.4弹簧垫圈选择 27

第十章 减速器的润滑 28

第十一章 Pro/E建模减速器及分析 29

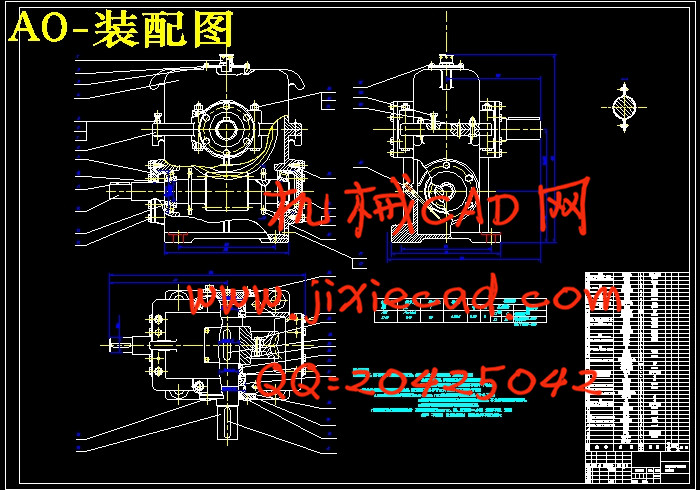

11.1 Pro/E建模减速器其它附件和总装 29

11.2 使用Pro/E进行干涉分析 32

第十二章 结论 36

参考文献 37

致 谢 38

传统的减速器设计通常以一些设计手册为依据,根据经验并运用公式进行设计。设计中存在很大的局限性。通常设计与制造过程不平行,如果设计出来的产品零部件装配失败只能重新设计,重新装配来检验产品的合规性。为了解决减速器的设计周期长,设计成本高,传动质量较低等问题,本文以蜗轮蜗杆减速器设计为例,采用参数设计并利用Pro/Engineer软件实现减速器的设计、建模、装配。相对于产品而言,我们可以把它看成几何模型,而无论多么复杂的几何模型,都可以分解成有限数量的构成特征,而每一种构成特征,都可以用有限的参数完全约束,这就是参数化的基本概念。Pro/Engineer操作软件是美国参数技术公司(PTC)旗下的CAD/CAM/CAE一体化的三维软件。Pro/Engineer软件以参数化著称,是参数化技术的最早应用者,在目前的三维造型软件领域中占有着重要地位。Pro/Engineer作为当今世界机械CAD/CAE/CAM领域的新标准而得到业界的认可和推广,是现今主流的CAD/CAM/CAE软件之一,特别是在国内产品设计领域占据重要位置。本文利用Pro/Engineer对蜗轮蜗杆进行参数化设计并实体建模装配设计。

设计思路:(1)通过对单级蜗杆减速器工作状况和设计要求对其结构形状进行分析,得出总体方案(2)按总体方案对各零部件的运动关系进行分析得出单级蜗杆减速器的整体结构尺寸(3)以各个系统为模块分别进行具体零部件的设计校核计算,得出各零部件的具体尺寸(4)用Pro/E实体建模各个零件并形成总装配。

关键词:减速器;参数化;Pro/Engineer;建模

ABSTRACT

Traditional gearbox design is usually based on some design manual, according to the experienceand the use of formula design. There is a lot of limitations in design.. Usually design and manufacturing process are not parallel, if design of products, parts and components assembly failure can only be re design, re assembly to test the product compliance. In order to solve the deceleration device design cycle is long, high design cost, low transmission quality problem, this paper takes the worm and worm gear deceleration device design as an example, the design parameters and the use of pro / engineer software implementation of reducer design, modeling and assembly. Compared with the product, we can regard it as geometric model, and no matter how complex geometric model can decomposed into a finite number of composition characteristics, and each composition characteristics can be fully constrained to a limited number of parameters, this is parameterized basic concepts. Pro/engineer software is a parametric technology corporation ptc (ptc) cad/cam/cae software integration under the. Pro / engineer software parametric is known, is the earliest application of parametric technology, in the present three-dimensional modeling software occupies an important position. Pro / engineer as one of the world's mechanical cad / cae / cam in the field of new standards and industry recognition and promotion, is one of today's mainstream cad / cam / cae software, especially to occupy an important position in the field of domestic product design. In this paper by using pro/engineer parametric design andsolid modeling assembly design of worm gear.

Design ideas: (1) by single stage worm deceleration machine work condition and design requirements on its structure and shape analysis and draws the overall scheme (2) according to the overall plan of various parts movement relationship of analysis of single stage worm deceleration is the dimension of the structure (3) to each system module are specific components of the design and checking calculation, that various components of the specific size (4) with various components of the Pro / E modeling and the formation of the general assembly.

KeyWords: reducer; parameterization; Pro/Engineer; modeling

目 录

第一章 绪论 1

1.1蜗轮蜗杆减速器简介 1

1.2基于Pro/ENGINEER的设计意义 1

第二章 总体方案确定 2

2.1已知参数 2

2.2传动装置总体设计 2

第三章 电动机的选择和动力学参数计算 3

3.1电动机类型的选择 3

3.2电动机功率的选择 3

3.3确定电动机型号 3

3.4计算各级的传动比 4

3.5运动参数计算 5

第四章 传动零件的设计计算 7

4.1蜗杆蜗轮的选择 7

4.2按齿面接触疲劳强度设计 7

4.3蜗杆与涡轮的主要参数与尺寸 8

第五章 涡轮蜗杆基本尺寸设计 12

5.1蜗杆基本尺寸设计 12

5.1.1初步估计蜗杆轴外伸段的直径 12

5.1.2计算转矩 12

5.1.3轴的结构设计 12

5.1.4 Pro/E建模蜗杆外形 13

5.2蜗轮基本尺寸设计 13

5.2.1蜗轮结构及基本尺寸表 13

5.2.2 Pro/E建模涡轮外形 14

第六章 涡轮轴的尺寸设计与校核 15

6.1 轴的直径与长度的确定 15

6.2轴的受力分析 16

6.3轴的校核计算 18

第七章 滚动轴承的选择及校核计算 20

7.1计算输入轴轴承 20

7.2计算输出轴轴承 21

第八章 减速器箱体的结构设计 23

8.1箱体尺寸的计算 23

8.2确定齿轮位置和箱体内壁线 24

第九章 减速器其他零件的选择 26

9.1键选择 26

9.2轴承选择 26

9.3密封圈选择 27

9.4弹簧垫圈选择 27

第十章 减速器的润滑 28

第十一章 Pro/E建模减速器及分析 29

11.1 Pro/E建模减速器其它附件和总装 29

11.2 使用Pro/E进行干涉分析 32

第十二章 结论 36

参考文献 37

致 谢 38