设计简介

本文通过研究铸坯火焰切割机的系统结构,将PLC控制技术应用于连铸火焰切割机,以解决连铸生产线上铸坯的定尺精度,切割质量等关键技术问题。该系统的特点有:定尺测量系统工作可靠,切割机与铸坯同步运行平稳、可靠、无滞后现象,快速返回原点定位误差小,其应用了可编程控制器为控制单元的新型火焰切割机控制系统。本课题选用的可编程控制器是西门子S7-200,并对软硬件进行了详细设计。其中PLC是火焰切割机的控制单元,通过它采集火焰切割机上各类传感器信号、工作参数、及工作状态等信息来向控制系统发送操作命令。实践证明,本文所设计的基于西门子PLC的铸坯火焰切割系统的软硬件是成功的,结构简单,性能良好,为今后开发类似系统奠定了良好基础。

关键词 可编程控制器 连铸火焰切割机 定尺系统

Abstract

The system structure of cast slab flame cutting machine is briefly introduced in this paper, and PLC control technology is applied to solve the scale accuracy on continuous casting production line, besides cutting quality control and other key technologies are analyzed. The features of the system are as follows: reliable measurement system of scale, saving time of billet subsection, steady and unlagged synchronous running between the flame cutting machine and casting blank, the accuracy of rapid return to the grass root and application of the programmable logic controller as control unit for a new type of flame cutting machine control system. Siemens S7-200 is chosen as the programmable logic controller in this paper and makes design of hardware and software. PLC is control unit of flame cutting machine, with which the operator send signals to the control system. In addition, it would also collect the signals of flame cutting machine’s and other types of switches, as well as the work status, etc..The practice has proved that the design of the cast slab flame cutting system based on Siemens PLC software and hardware flame to be a successful, with simple structure, good performance which lay a solid foundation for the future development of a similar system.

Keywords Programmable logic controller Cast slab flame cutting machine Fixed scale system

目 录

1 引言 1

1.1 设计的目的、意义、以及应达到的技术要求 1

1.2 国内外的发展状况及存在的问题 2

1.3 设计时应注意的问题 4

2 系统分析 5

2.1 铸坯火焰自动切割系统总体结构分析 5

2.2 电控系统分析 7

3 低压电气选择 8

3.1 磁阀的选型 8

3.2 接触器的选型 9

3.3 按钮的选型 10

3.4 转换开关的选型 11

3.3 接近开关的选型 11

4 基于西门子PLC铸坯火焰自动切割系统硬件设计 13

4.1 铸坯火焰切割系统PLC选择与设计 13

4.2 红外定尺技术简介 16

4.3 铸坯火焰自动切割系统PLC I/O接线图设计 17

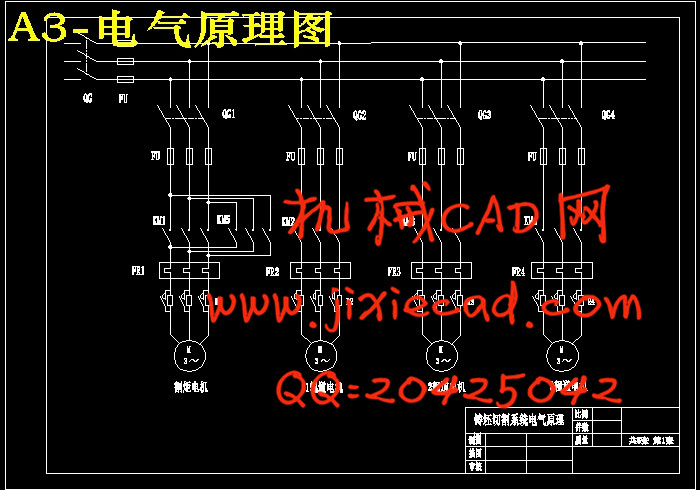

4.4 铸坯火焰自动切割系统电气原理图设计 17

5 铸坯火焰自动切割系统软件设计 19

5.1 铸坯火焰自动切割系统控制要求 19

5.2 所用指令介绍 19

5.3 铸坯火焰自动切割系统PLC I/O地址分配 21

5.4 铸坯火焰自动切割系统控制流程图设计 21

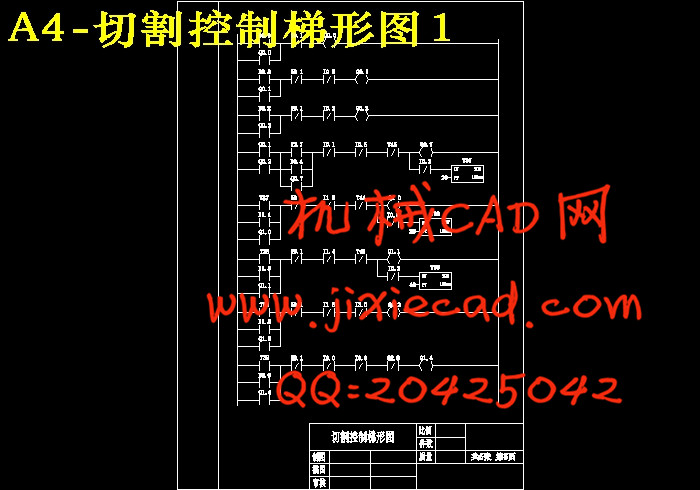

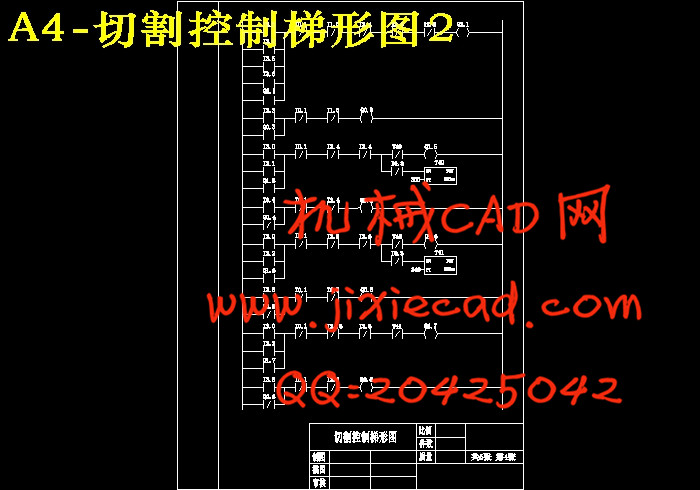

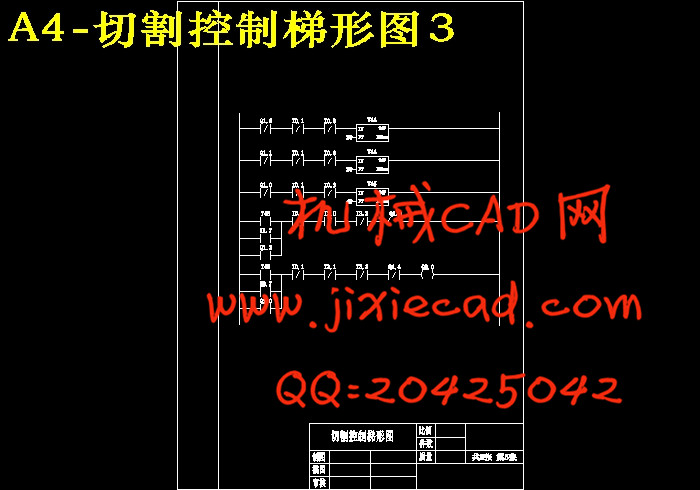

5.5 铸坯火焰自动切割系统PLC控制程序设计 23

结束语 32

致谢 33

参考文献 34

附录 35

附录1 I/O硬件接线图 35

附录2 西门子PLC CPU226 I/O分配表 36

关键词 可编程控制器 连铸火焰切割机 定尺系统

Abstract

The system structure of cast slab flame cutting machine is briefly introduced in this paper, and PLC control technology is applied to solve the scale accuracy on continuous casting production line, besides cutting quality control and other key technologies are analyzed. The features of the system are as follows: reliable measurement system of scale, saving time of billet subsection, steady and unlagged synchronous running between the flame cutting machine and casting blank, the accuracy of rapid return to the grass root and application of the programmable logic controller as control unit for a new type of flame cutting machine control system. Siemens S7-200 is chosen as the programmable logic controller in this paper and makes design of hardware and software. PLC is control unit of flame cutting machine, with which the operator send signals to the control system. In addition, it would also collect the signals of flame cutting machine’s and other types of switches, as well as the work status, etc..The practice has proved that the design of the cast slab flame cutting system based on Siemens PLC software and hardware flame to be a successful, with simple structure, good performance which lay a solid foundation for the future development of a similar system.

Keywords Programmable logic controller Cast slab flame cutting machine Fixed scale system

目 录

1 引言 1

1.1 设计的目的、意义、以及应达到的技术要求 1

1.2 国内外的发展状况及存在的问题 2

1.3 设计时应注意的问题 4

2 系统分析 5

2.1 铸坯火焰自动切割系统总体结构分析 5

2.2 电控系统分析 7

3 低压电气选择 8

3.1 磁阀的选型 8

3.2 接触器的选型 9

3.3 按钮的选型 10

3.4 转换开关的选型 11

3.3 接近开关的选型 11

4 基于西门子PLC铸坯火焰自动切割系统硬件设计 13

4.1 铸坯火焰切割系统PLC选择与设计 13

4.2 红外定尺技术简介 16

4.3 铸坯火焰自动切割系统PLC I/O接线图设计 17

4.4 铸坯火焰自动切割系统电气原理图设计 17

5 铸坯火焰自动切割系统软件设计 19

5.1 铸坯火焰自动切割系统控制要求 19

5.2 所用指令介绍 19

5.3 铸坯火焰自动切割系统PLC I/O地址分配 21

5.4 铸坯火焰自动切割系统控制流程图设计 21

5.5 铸坯火焰自动切割系统PLC控制程序设计 23

结束语 32

致谢 33

参考文献 34

附录 35

附录1 I/O硬件接线图 35

附录2 西门子PLC CPU226 I/O分配表 36