设计简介

摘 要

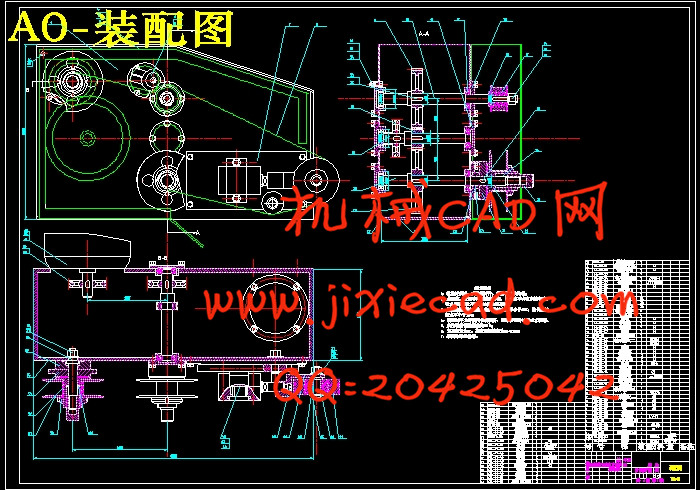

本设计是新型开式砂带磨削头架的设计,本次设计主要是用于轴颈外圆的精加工,

砂带磨削技术是一种先进的制造技术,是进行超精密加工的一种机械加工方法,近年来砂带磨削在机械磨削加工的应用也越来越广泛,而现今国内的轴颈研磨加工则还处于初级阶段。本文以砂带磨削原理为基础,阐述了轴颈研磨机磨头的设计过程和设计结果,并以AutoCAD、CAXA、ProE等计算机辅助设计软件为工具,对磨削头架进行设计建模分析。研磨机磨头总体采用开式砂带磨削磨头,针对轴颈外圆表面精度要求高及圆跳动精度高等特点,并考虑实际加工要求,设计出研磨效率高,操作方便,且安全可靠,能够满足高精度研磨的理想磨削头架。在机械制造技术飞速发展的今天,本次的毕业设计有着广阔的发展空间和前景。

关键词: 砂带磨削,轴颈研磨机磨头,AutoCAD

ABSTRACT

Belt Grinding is an advanced manufacture technology, it’s an mechanical workout way to super-accuracy processing. In recent years, the machinery of grinding axle journal has been used in mechanical grinding processing more and more, but nowadays,

The processing of grinding axle journal still located in primary stage, so the research of grinding axle journal technology is necessary to mechanical workout. This paper based on theory of Belt Grinding, it expounded the design process and design result of the wheel head of grinding axle journal machinery, and it recurred to the CAD software of AutoCAD、CAXA、ProE ,to analytical study of the wheel head of grinding axle journal machinery modeling .The wheel head adopted the open belt grinding head generally . To the high requirements of the axle journal surface quality and the circular runout precision, and considered the requirements of practical machining ,this paper worked out the wheel head of grinding axle journal machinery with high grinding efficiency, easy to operate and on the safe side, this wheel head can satisfied in high-precision grinding .Nowadays, the mechanical manufacture technology has boomed industry, this graduation design has wide develop space and prospect.

Keywords: Belt Grinding; wheel head of grinding axle journal machinery; AutoCAD

,目 录

中文摘要 Ⅰ

ABSTRACT Ⅱ

1绪论 1

1.1 国内外研究现状 1

1.1.1砂带磨削的发展 1

1.1.2新型开式砂带振动磨削机的发展现状及应用 2

1.1.3外圆精密砂带磨削头架的研究现状 4

1.2 研究内容 4

2 总体方案的分析 5

2.1砂带磨削的金属切除率 5

2.2砂带磨削与砂轮磨削在机械加工中的比较 5

2.2.1加工机理 5

2.2.2磨削特点的比较 5

2.3新型开式磨削的基本原理 6

2.4外圆砂带磨削 7

2.5本课题最终选择方案 8

3 新型开式砂带磨削头架组件设计 9

3.1头架结构的尺寸及几何关系 9

3.1.1磨削头架电机的选用及砂带磨削驱动功率的计算 9

31.2驱动轮直径(D1)的确定 10

3.2磨削头架主要结构件的设计 10

3.2.1接触轮的参数设计 10

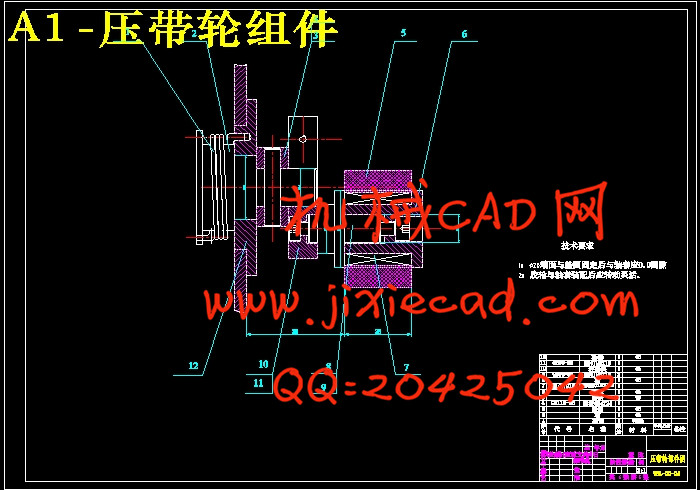

3.2.2张紧力与驱动轮结构参数的设计 12

3.2.3砂带张紧力的设计计算 13

4 磨削头头架功能部件的设计 15

4.1砂带张紧快换操纵机构的选择 15

4.2砂带调偏机构及砂带横向振动装置 15

4.2.1砂带调偏机构 15

4.2.2砂带横向振动装置 16

5 主要零、部件的设计与校 17

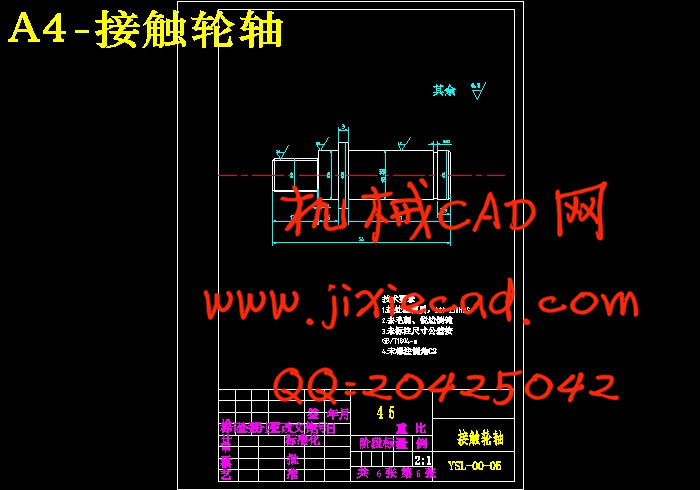

5.1接触轮主轴的结构设计和强度校核 17

5.1.1选择轴的材料 17

5.1.2轴的结构设计 18

5.1.3轴的强度校核计算 19

6 结论 24

7 结束语 25

参考文献 26

本设计是新型开式砂带磨削头架的设计,本次设计主要是用于轴颈外圆的精加工,

砂带磨削技术是一种先进的制造技术,是进行超精密加工的一种机械加工方法,近年来砂带磨削在机械磨削加工的应用也越来越广泛,而现今国内的轴颈研磨加工则还处于初级阶段。本文以砂带磨削原理为基础,阐述了轴颈研磨机磨头的设计过程和设计结果,并以AutoCAD、CAXA、ProE等计算机辅助设计软件为工具,对磨削头架进行设计建模分析。研磨机磨头总体采用开式砂带磨削磨头,针对轴颈外圆表面精度要求高及圆跳动精度高等特点,并考虑实际加工要求,设计出研磨效率高,操作方便,且安全可靠,能够满足高精度研磨的理想磨削头架。在机械制造技术飞速发展的今天,本次的毕业设计有着广阔的发展空间和前景。

关键词: 砂带磨削,轴颈研磨机磨头,AutoCAD

ABSTRACT

Belt Grinding is an advanced manufacture technology, it’s an mechanical workout way to super-accuracy processing. In recent years, the machinery of grinding axle journal has been used in mechanical grinding processing more and more, but nowadays,

The processing of grinding axle journal still located in primary stage, so the research of grinding axle journal technology is necessary to mechanical workout. This paper based on theory of Belt Grinding, it expounded the design process and design result of the wheel head of grinding axle journal machinery, and it recurred to the CAD software of AutoCAD、CAXA、ProE ,to analytical study of the wheel head of grinding axle journal machinery modeling .The wheel head adopted the open belt grinding head generally . To the high requirements of the axle journal surface quality and the circular runout precision, and considered the requirements of practical machining ,this paper worked out the wheel head of grinding axle journal machinery with high grinding efficiency, easy to operate and on the safe side, this wheel head can satisfied in high-precision grinding .Nowadays, the mechanical manufacture technology has boomed industry, this graduation design has wide develop space and prospect.

Keywords: Belt Grinding; wheel head of grinding axle journal machinery; AutoCAD

,目 录

中文摘要 Ⅰ

ABSTRACT Ⅱ

1绪论 1

1.1 国内外研究现状 1

1.1.1砂带磨削的发展 1

1.1.2新型开式砂带振动磨削机的发展现状及应用 2

1.1.3外圆精密砂带磨削头架的研究现状 4

1.2 研究内容 4

2 总体方案的分析 5

2.1砂带磨削的金属切除率 5

2.2砂带磨削与砂轮磨削在机械加工中的比较 5

2.2.1加工机理 5

2.2.2磨削特点的比较 5

2.3新型开式磨削的基本原理 6

2.4外圆砂带磨削 7

2.5本课题最终选择方案 8

3 新型开式砂带磨削头架组件设计 9

3.1头架结构的尺寸及几何关系 9

3.1.1磨削头架电机的选用及砂带磨削驱动功率的计算 9

31.2驱动轮直径(D1)的确定 10

3.2磨削头架主要结构件的设计 10

3.2.1接触轮的参数设计 10

3.2.2张紧力与驱动轮结构参数的设计 12

3.2.3砂带张紧力的设计计算 13

4 磨削头头架功能部件的设计 15

4.1砂带张紧快换操纵机构的选择 15

4.2砂带调偏机构及砂带横向振动装置 15

4.2.1砂带调偏机构 15

4.2.2砂带横向振动装置 16

5 主要零、部件的设计与校 17

5.1接触轮主轴的结构设计和强度校核 17

5.1.1选择轴的材料 17

5.1.2轴的结构设计 18

5.1.3轴的强度校核计算 19

6 结论 24

7 结束语 25

参考文献 26