设计简介

摘要

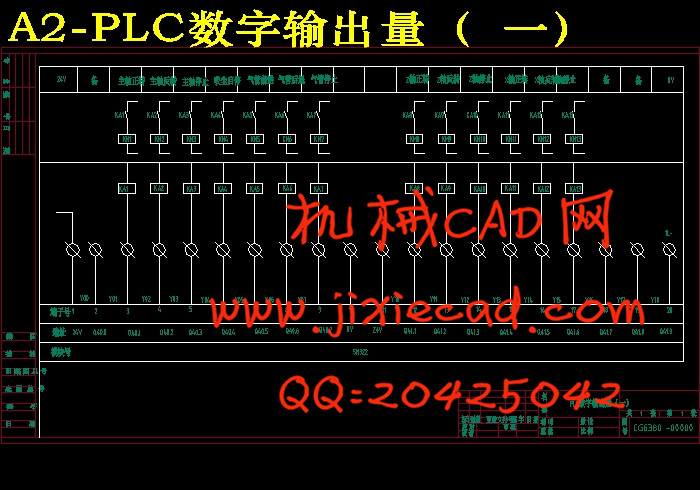

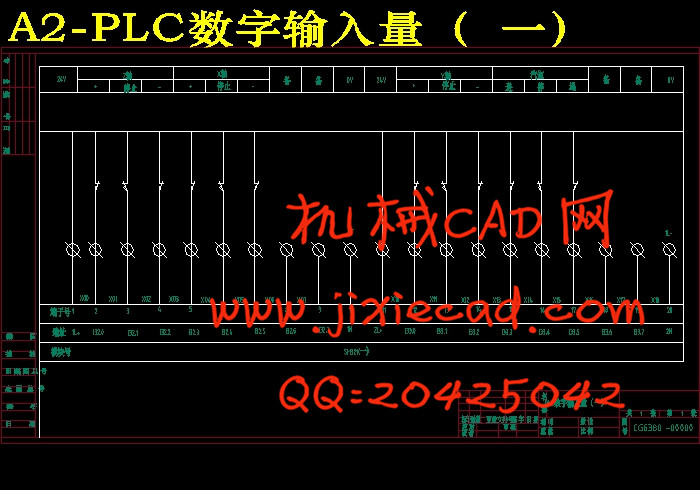

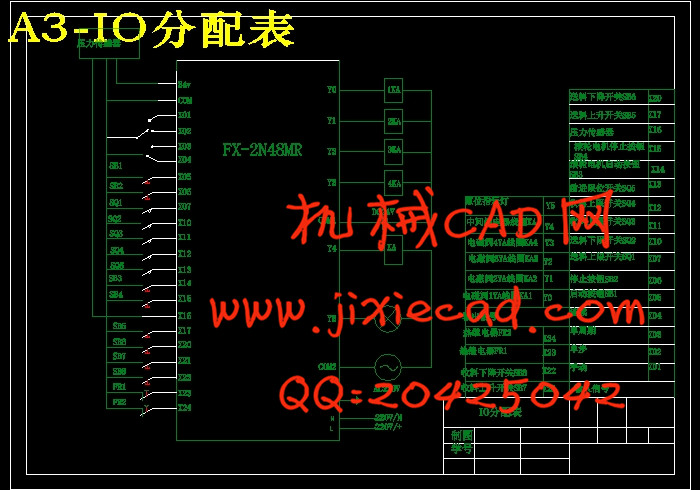

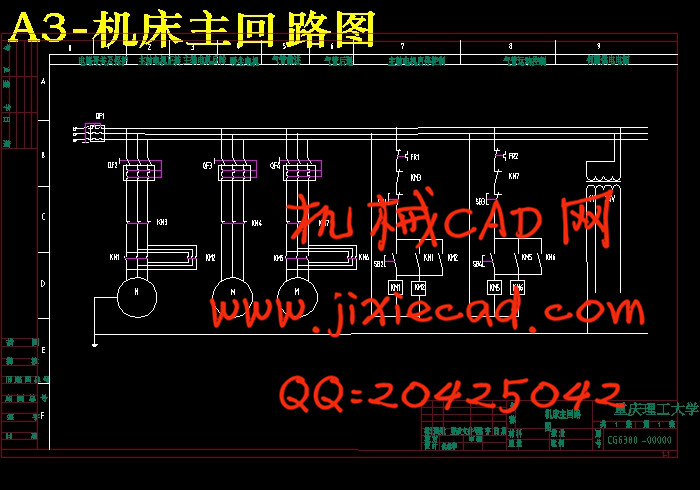

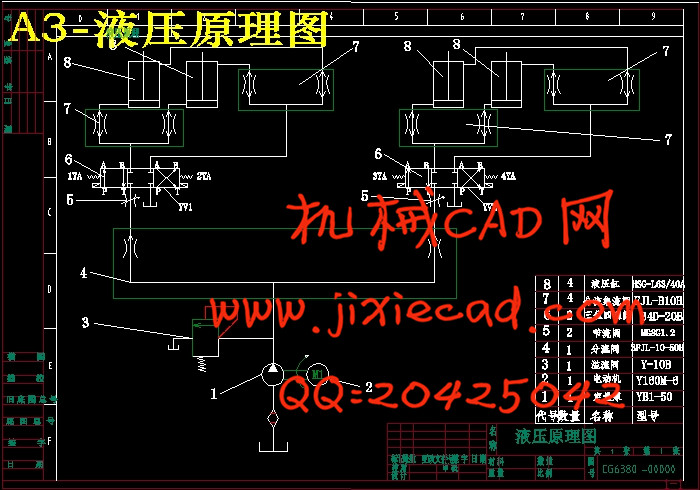

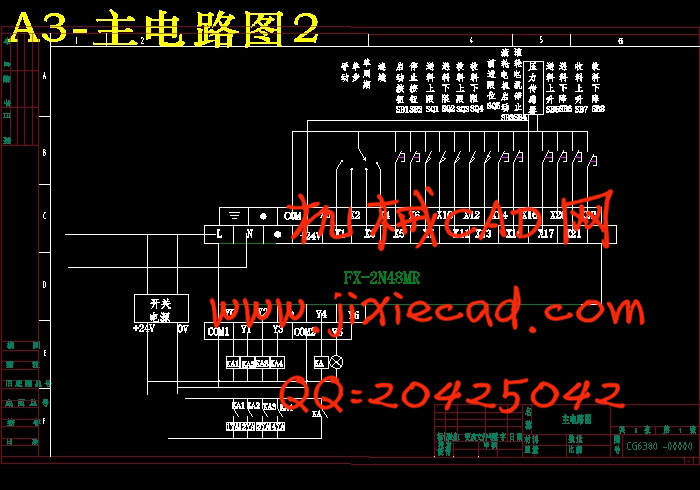

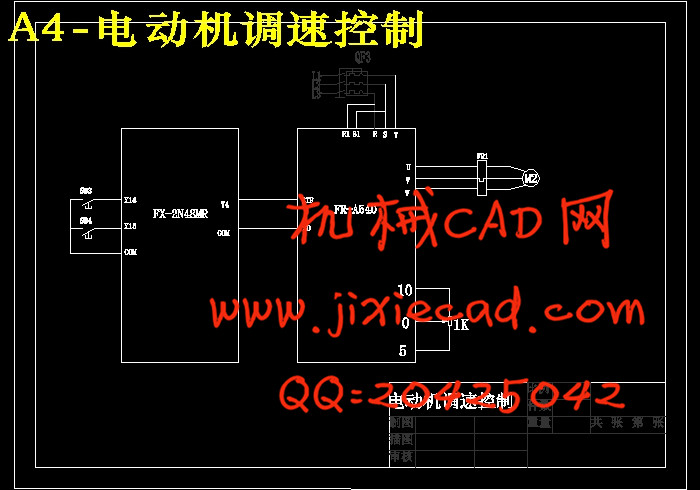

本文介绍了无心外圆磨床的上下料系统控制的原理和特点,主要是通过PLC控制液压系统实现对工件上料和收料的控制。先根据的已知条件计算并选择液压系统各个元件,如液压泵、电磁阀、流量控制阀等,再设计连接液压回路,形成液压的传动系统。由液压系统的不同控制控制方式、如手动控制和自动控制,选择合适的PLC,编写程序,绘制电气接线图,并在运行过程中不断的调整和优化。而且在整个过程中会有变频器对电机的调速和传感器的检测,这些也有赖于PLC的控制,总之,最后由PLC程序控制液压系统形成一个统一的控制系统整体,达到控制液压系统完成特定的工作行程的目的。

关键词:PLC 液压系统 变频器 Abstract

本文介绍了无心外圆磨床的上下料系统控制的原理和特点,主要是通过PLC控制液压系统实现对工件上料和收料的控制。先根据的已知条件计算并选择液压系统各个元件,如液压泵、电磁阀、流量控制阀等,再设计连接液压回路,形成液压的传动系统。由液压系统的不同控制控制方式、如手动控制和自动控制,选择合适的PLC,编写程序,绘制电气接线图,并在运行过程中不断的调整和优化。而且在整个过程中会有变频器对电机的调速和传感器的检测,这些也有赖于PLC的控制,总之,最后由PLC程序控制液压系统形成一个统一的控制系统整体,达到控制液压系统完成特定的工作行程的目的。

关键词:PLC 液压系统 变频器 Abstract

This article describes the centerles cylindrical grinding machine loading and unloading system control principles and characteristics,Mainly through PLC control hydraulic system to achieve the workpiece feeding and rewinding controlled.First calculated according to the known conditions and select the individual components of hydraulic systems,Such as pumps, solenoid valves, flow control valve,Redesign of the hydraulic circuit connected to form a hydraulic drive system.Controlled by the hydraulic system of different control methods, such as manual control and automatic control,Select the appropriate PLC, programming,drawing electrical wiring diagram,And running continuously during the adjustment and optimization.But in the process will be the drive speed of the motor and sensor detection,These also depends on control of the PLC,In short, the last by the PLC program control hydraulic system to form a unified control system as a whole,To control the hydraulic system to accomplish specific tasks travel purposes.

Key Words: PLC Hydraulic System Inverter