设计简介

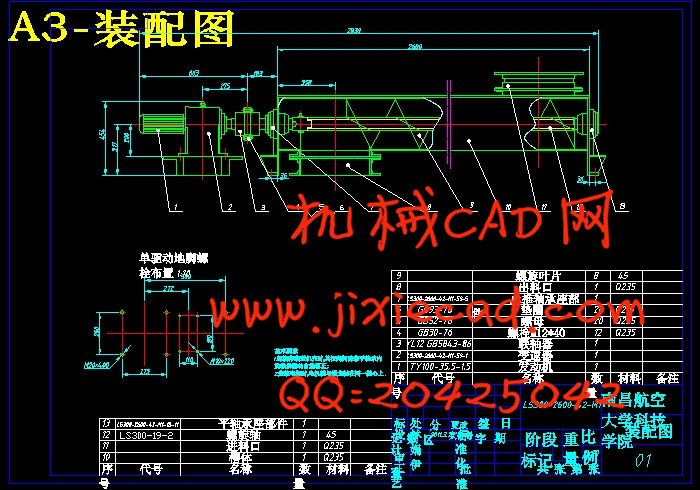

摘要:螺旋给料器是一种常用的没有挠性牵引构件的连续输送机械,是现代化生产不可缺少的重要机械设备之一。广泛应用于各行业,如建材、化工、电力、冶金、煤炭、粮食等行业。适用于水平和倾斜输送粉状、粒状和小块状物料。不适用于输送易变质的、粘性大的、易结块的物料。螺旋给料器由料槽、螺旋体、轴承及驱动装置组成。螺旋体由两端轴承和中间悬挂轴承支承,由驱动装置驱动。无级变速是指通过改变交流电频率来调节电机的转速,从而改变速度的快慢。而在调速的过程中,具有冲击小、平缓的进行换速,是一种理想的高效率、搞性能的调速手段。能够满足工程生产中的要求,还能够减轻工人的劳动强度,提高生产率,实现物料输送过程的机械化和自动化。

此次设计使用优化思想和方法,通过对给料器完整的设计计算使得输送量和效率得到较合理的匹配,输送性能和传输能力的主要参数分析和使用与改善在生产上的实用合理性。课题对螺旋给料器的设计研究的方法、理论分析结合起来,对整机进行全面的性能、参数的影响深入研究。根据选型要求,设计参数选择的原则和方法鉴定确定该机为LS型螺旋给料器。优化螺旋叶片,结合实际完成的工作目标经过计算后采用右旋弯曲母线螺旋面满面式叶片,确定最合理的填充系数即进料量、螺距大小等。采用变频调速器或调速电机,使螺旋给料器应用中提高劳动生产率、改善质量、提高设备自动化程度等。

关键词:无极变速 螺旋 给料器 变频器

Abstract: Screw feeder is a common continuous conveyor that has not flexible traction, it is one of the important and indispensable manchinery and equipment .Widely used in warious industries, such as building materials, chemicals, power, metallurgy, coal, grain etc. Apply to horizontal and inclined conveying powder, granular and small bulk materials. Does not apply to transport perishable, viscous, easy caking materials. Screw feeder make up of trough, spirocheres, bearings and drive components. Spirochete is supported of both ends of bearings and the middle suspension of bearings, divern by the dive. Continuously Variable Transmission is adjusted motor speed by changing the frequency of AC, thus changing the speed. In the speed of the process, with the impact of small, gentle to exchange rate, it is an ideal high-efficiency and high-performance speed control means. It can meet the engineering requirements of the production and can also ruduce workers labor intensity, improve productivity, to achieve material handling process mechanization and automation.

The design uses ideas and methods of optimization, through the feeder allows the complete design and calculation of transmission capacity and efficiency of a more reasonable match, transmission performance and transmission capacity of the main parameters of the analysis and use in the production and improvement of practical rationality. Subject to the design research methods of screw conveyor, theoretical analysis combined the performance of the machine to conduct a comprehensive, parameters of in-depth study. According to model selection, design parameters to determine the principles and methods of identification of aircraft for the LS-type screw conveyor. Optimization of spiral blades, combined with the actual completion of work objectives through the calculated use of R-bend helical sounded style blade, to determine the most reasonable fill factor that is feeding quantity, pitch size. With frequency converter or motor, so screw conveyor applications to improve productivity, improve quality, increase the degree of automation equipment.

Keyword: Infinitely variable Spiral Feeder Inverter

目录

1. 引言………………………………………………………(1)

2. 螺旋给料器概述

2.1 螺旋给料器的基本结构………………………………………………(2)

2.2 螺旋给料器的类型……………………………………………………(3)

2.2.1 水平螺旋给料器………………………………………………………(3)

2.2.2 倾斜螺旋给料器………………………………………………………(3)

2.2.3 垂直螺旋给料器………………………………………………………(4)

2.3 螺旋给料器的特点……………………………………………………(4)

2.4 螺旋给料器的研究现状………………………………………………(4)

2.5 螺旋给料器的发展趋势………………………………………………(5)

3. 螺旋给料器工作原理及主要构件的设计和选用

3.1 水平螺旋给料器的工作原理…………………………………………(6)

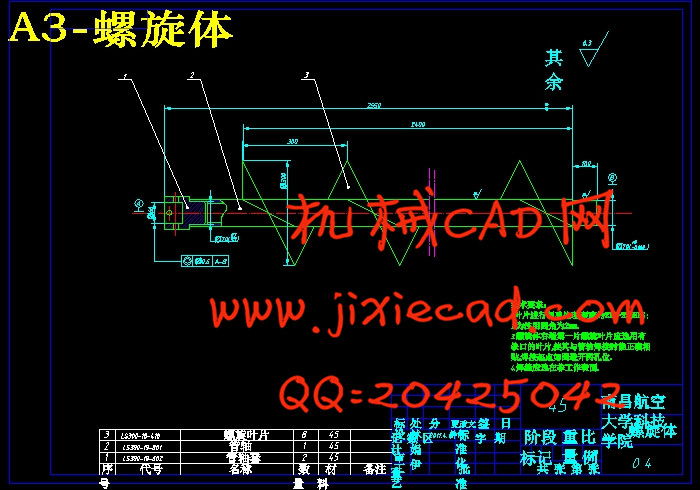

3.2. 螺旋体…………………………………………………………………(7)

3.2.1 螺旋叶片………………………………………………………………(7)

3.2.2 螺旋轴 ………………………………………………………………(11)

3.2.3 轴承 …………………………………………………………………(12)

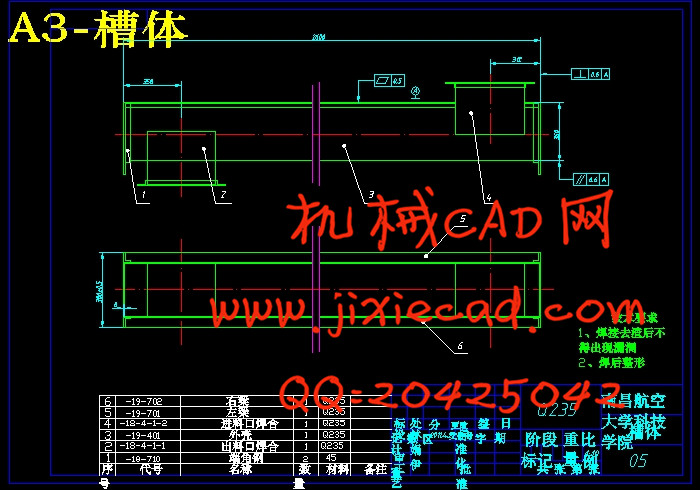

3.2.4 机槽 …………………………………………………………………(13)

3.2.5 驱动装置 ……………………………………………………………(17)

4. 水平给料器工作过程分析

4.1 物料的运动分析和叶片的设计…………………………………………(19)

5. 总体设计计算

5.1 被输送物料的名称及特性 …………………………………………(27)

5.2 选型要求 ……………………………………………………………(27)

5.3 螺旋给料器的设计计算 ……………………………………………(27)

5.3.1 确定螺旋直径 D ……………………………………………………(30)

5.3.2 确定螺旋转速 n ……………………………………………………(30)

6. 总体尺寸设计

6.1 LS 螺旋给料器的外形及尺寸 ……………………………………(31)

6.2 附件尺寸 ……………………………………………………………(31)

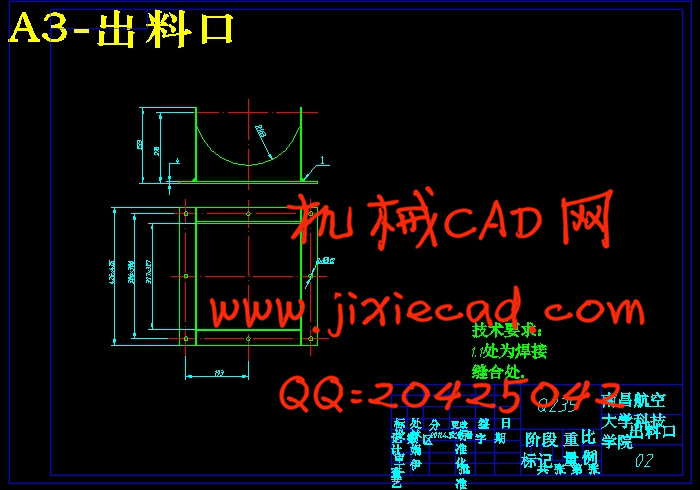

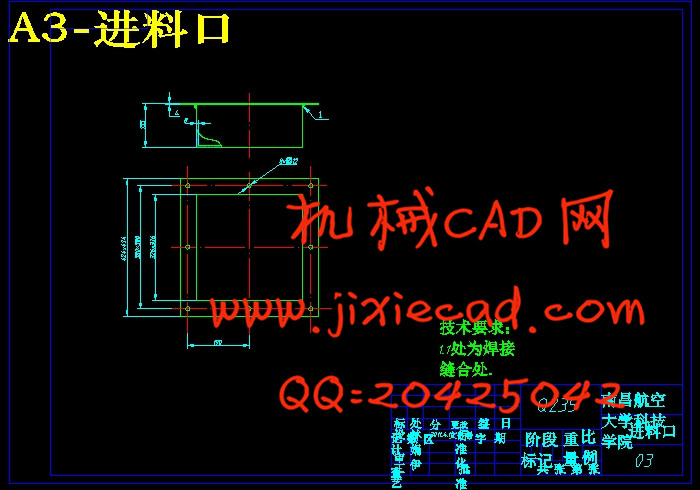

6.2.1 进出料口 ……………………………………………………………(31)

7. 无级变速器

7.1 变频调速器 …………………………………………………………(33)

7.1.1 变频调速器的基本原则 ……………………………………………(34)

7.1.2 变频调速器的工作原理 ……………………………………………(35)

7.2 变频调速器的选型 …………………………………………………(37)

7.2.1 变频调速器的选用原则 …………………………………………

此次设计使用优化思想和方法,通过对给料器完整的设计计算使得输送量和效率得到较合理的匹配,输送性能和传输能力的主要参数分析和使用与改善在生产上的实用合理性。课题对螺旋给料器的设计研究的方法、理论分析结合起来,对整机进行全面的性能、参数的影响深入研究。根据选型要求,设计参数选择的原则和方法鉴定确定该机为LS型螺旋给料器。优化螺旋叶片,结合实际完成的工作目标经过计算后采用右旋弯曲母线螺旋面满面式叶片,确定最合理的填充系数即进料量、螺距大小等。采用变频调速器或调速电机,使螺旋给料器应用中提高劳动生产率、改善质量、提高设备自动化程度等。

关键词:无极变速 螺旋 给料器 变频器

Abstract: Screw feeder is a common continuous conveyor that has not flexible traction, it is one of the important and indispensable manchinery and equipment .Widely used in warious industries, such as building materials, chemicals, power, metallurgy, coal, grain etc. Apply to horizontal and inclined conveying powder, granular and small bulk materials. Does not apply to transport perishable, viscous, easy caking materials. Screw feeder make up of trough, spirocheres, bearings and drive components. Spirochete is supported of both ends of bearings and the middle suspension of bearings, divern by the dive. Continuously Variable Transmission is adjusted motor speed by changing the frequency of AC, thus changing the speed. In the speed of the process, with the impact of small, gentle to exchange rate, it is an ideal high-efficiency and high-performance speed control means. It can meet the engineering requirements of the production and can also ruduce workers labor intensity, improve productivity, to achieve material handling process mechanization and automation.

The design uses ideas and methods of optimization, through the feeder allows the complete design and calculation of transmission capacity and efficiency of a more reasonable match, transmission performance and transmission capacity of the main parameters of the analysis and use in the production and improvement of practical rationality. Subject to the design research methods of screw conveyor, theoretical analysis combined the performance of the machine to conduct a comprehensive, parameters of in-depth study. According to model selection, design parameters to determine the principles and methods of identification of aircraft for the LS-type screw conveyor. Optimization of spiral blades, combined with the actual completion of work objectives through the calculated use of R-bend helical sounded style blade, to determine the most reasonable fill factor that is feeding quantity, pitch size. With frequency converter or motor, so screw conveyor applications to improve productivity, improve quality, increase the degree of automation equipment.

Keyword: Infinitely variable Spiral Feeder Inverter

目录

1. 引言………………………………………………………(1)

2. 螺旋给料器概述

2.1 螺旋给料器的基本结构………………………………………………(2)

2.2 螺旋给料器的类型……………………………………………………(3)

2.2.1 水平螺旋给料器………………………………………………………(3)

2.2.2 倾斜螺旋给料器………………………………………………………(3)

2.2.3 垂直螺旋给料器………………………………………………………(4)

2.3 螺旋给料器的特点……………………………………………………(4)

2.4 螺旋给料器的研究现状………………………………………………(4)

2.5 螺旋给料器的发展趋势………………………………………………(5)

3. 螺旋给料器工作原理及主要构件的设计和选用

3.1 水平螺旋给料器的工作原理…………………………………………(6)

3.2. 螺旋体…………………………………………………………………(7)

3.2.1 螺旋叶片………………………………………………………………(7)

3.2.2 螺旋轴 ………………………………………………………………(11)

3.2.3 轴承 …………………………………………………………………(12)

3.2.4 机槽 …………………………………………………………………(13)

3.2.5 驱动装置 ……………………………………………………………(17)

4. 水平给料器工作过程分析

4.1 物料的运动分析和叶片的设计…………………………………………(19)

5. 总体设计计算

5.1 被输送物料的名称及特性 …………………………………………(27)

5.2 选型要求 ……………………………………………………………(27)

5.3 螺旋给料器的设计计算 ……………………………………………(27)

5.3.1 确定螺旋直径 D ……………………………………………………(30)

5.3.2 确定螺旋转速 n ……………………………………………………(30)

6. 总体尺寸设计

6.1 LS 螺旋给料器的外形及尺寸 ……………………………………(31)

6.2 附件尺寸 ……………………………………………………………(31)

6.2.1 进出料口 ……………………………………………………………(31)

7. 无级变速器

7.1 变频调速器 …………………………………………………………(33)

7.1.1 变频调速器的基本原则 ……………………………………………(34)

7.1.2 变频调速器的工作原理 ……………………………………………(35)

7.2 变频调速器的选型 …………………………………………………(37)

7.2.1 变频调速器的选用原则 …………………………………………