设计简介

数控技术的水平高低和机床的数控化率是衡量一个国家工业发展水平的重要标志。目前我国机床的数控化率还不到5%,无论从数控技术水平和机床的数控化率都大大落后于西方发达国家。加快发展我国的机床改造业,具有重要的现实意义和使用价值。

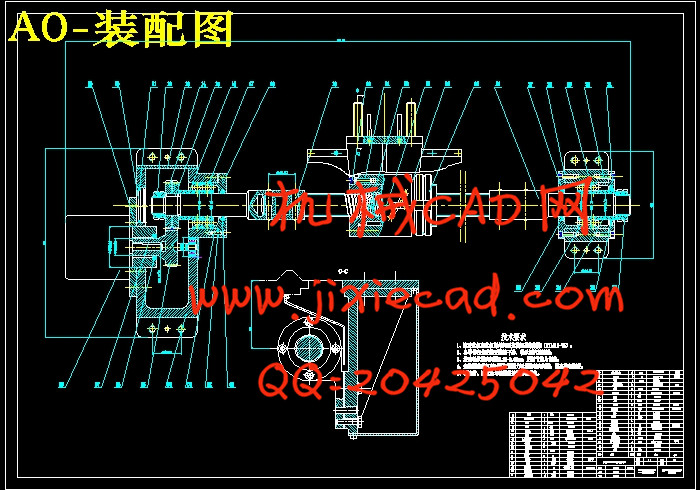

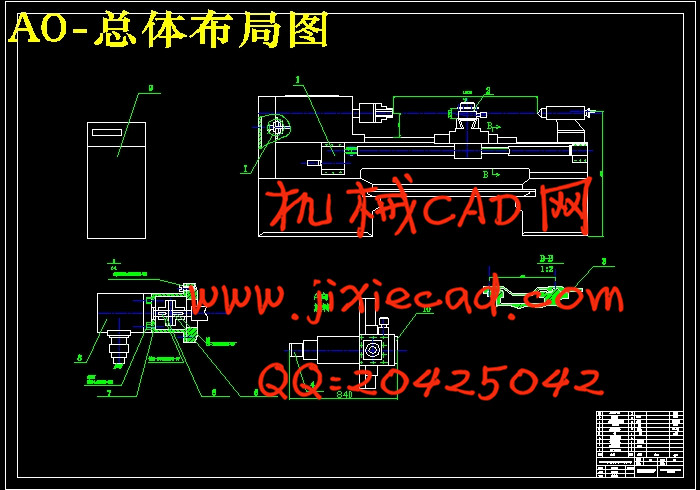

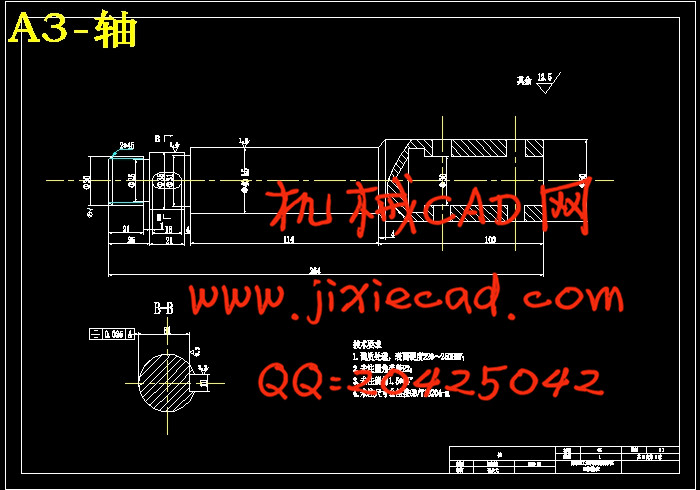

本文主要是采用微机数控技术对最大加工直径为400mm的普通卧式车床进行改造。首先对普通卧式车床的改造任务和功能需求进行了认真分析,其次设计出总体改造方案,包括主传动系统、进给系统、回转刀架及微机控制系统的方案设计,最后经过对切削力的计算、滚珠丝杠副、齿轮副及步进电机的选型,给出了纵向进给系统的详细设计。

关键词 数控 改造 车床 纵向进给

Abstract

Level of numerical control technology and CNC machine tool is a measure of the rate of a national industrial development an important indicator of the level. CNC machine tools in China is less than the rate of 5%, CNC technology in terms of the level and rate of NC machine tools are lagging far behind developed countries in the West. Speed up the transformation of the development of China's machine tool industry, has important practical significance and value.

This paper mainly using computer numerical control technology to alter the ordinary horizontal lathe whose maximum machining diameter is 400mm.

first of all, horizontal lathe for ordinary tasks and functions of the transformation of a careful analysis of needs,Second, the design of the overall reform program, including the main drive system, feed system, rotary tool holder and the program of microcomputer control system design, after the final calculation of cutting force, ball screw, gear and stepper motor selection, vertical feed is given for the detailed design.

Keywords Numerical control Transformation lathe Vertical feeding system

目 录

1 绪论 1

1.1 国内外数控机床的发展现状 1

1.2 数控系统的发展趋势 2

1.3 普通机床数控改造的意义 3

1.4 本文的设计任务 3

2 C6140普通车床数控改造的总体方案设计 5

2.1 C6140普通车床介绍 5

2.2 总体方案的确定 6

2.3 机械系统的改造设计方案 8

3 纵向进给系统的详细设计与计算 13

3.1 脉冲当量的确定 13

3.2 切削力的计算 13

3.3 滚珠丝杠螺母副的设计及计算 14

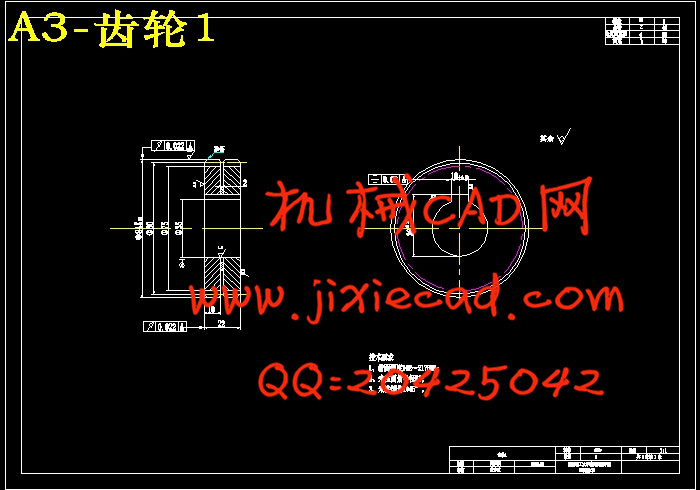

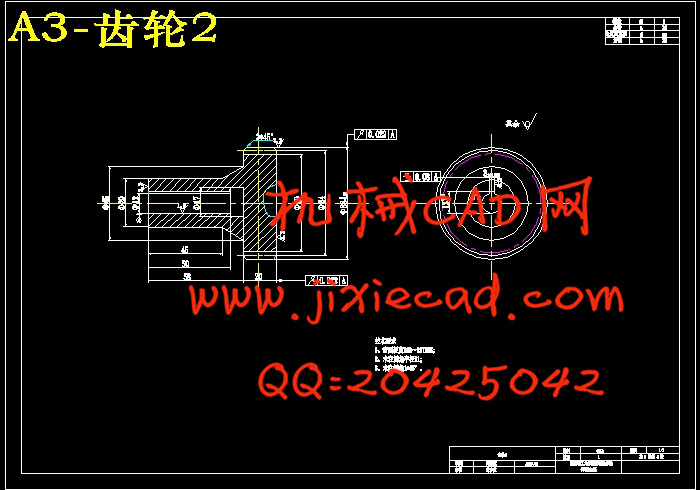

3.4 齿轮传动的计算 18

3.5 步进电动机的选择 19

4 传动间隙的调整与预紧及导轨的设计 22

4.1 滚珠丝杠副轴向间隙的调整与预紧 22

4.2 进给系统传动齿轮间隙的消除 23

4.3 数控改造C6140车床导轨设计 24

5 数控系统硬件电路设计和软件设计 28

5.1 数控系统基本硬件组成 28

5.2 单板机控制系统的设计 28

5.3 软件设计 31

结束语 33

致 谢 34

参 考 文 献 35

本文主要是采用微机数控技术对最大加工直径为400mm的普通卧式车床进行改造。首先对普通卧式车床的改造任务和功能需求进行了认真分析,其次设计出总体改造方案,包括主传动系统、进给系统、回转刀架及微机控制系统的方案设计,最后经过对切削力的计算、滚珠丝杠副、齿轮副及步进电机的选型,给出了纵向进给系统的详细设计。

关键词 数控 改造 车床 纵向进给

Abstract

Level of numerical control technology and CNC machine tool is a measure of the rate of a national industrial development an important indicator of the level. CNC machine tools in China is less than the rate of 5%, CNC technology in terms of the level and rate of NC machine tools are lagging far behind developed countries in the West. Speed up the transformation of the development of China's machine tool industry, has important practical significance and value.

This paper mainly using computer numerical control technology to alter the ordinary horizontal lathe whose maximum machining diameter is 400mm.

first of all, horizontal lathe for ordinary tasks and functions of the transformation of a careful analysis of needs,Second, the design of the overall reform program, including the main drive system, feed system, rotary tool holder and the program of microcomputer control system design, after the final calculation of cutting force, ball screw, gear and stepper motor selection, vertical feed is given for the detailed design.

Keywords Numerical control Transformation lathe Vertical feeding system

目 录

1 绪论 1

1.1 国内外数控机床的发展现状 1

1.2 数控系统的发展趋势 2

1.3 普通机床数控改造的意义 3

1.4 本文的设计任务 3

2 C6140普通车床数控改造的总体方案设计 5

2.1 C6140普通车床介绍 5

2.2 总体方案的确定 6

2.3 机械系统的改造设计方案 8

3 纵向进给系统的详细设计与计算 13

3.1 脉冲当量的确定 13

3.2 切削力的计算 13

3.3 滚珠丝杠螺母副的设计及计算 14

3.4 齿轮传动的计算 18

3.5 步进电动机的选择 19

4 传动间隙的调整与预紧及导轨的设计 22

4.1 滚珠丝杠副轴向间隙的调整与预紧 22

4.2 进给系统传动齿轮间隙的消除 23

4.3 数控改造C6140车床导轨设计 24

5 数控系统硬件电路设计和软件设计 28

5.1 数控系统基本硬件组成 28

5.2 单板机控制系统的设计 28

5.3 软件设计 31

结束语 33

致 谢 34

参 考 文 献 35