设计简介

斯太尔转向节铣钻组合机床总体设计及电气控制部分设计

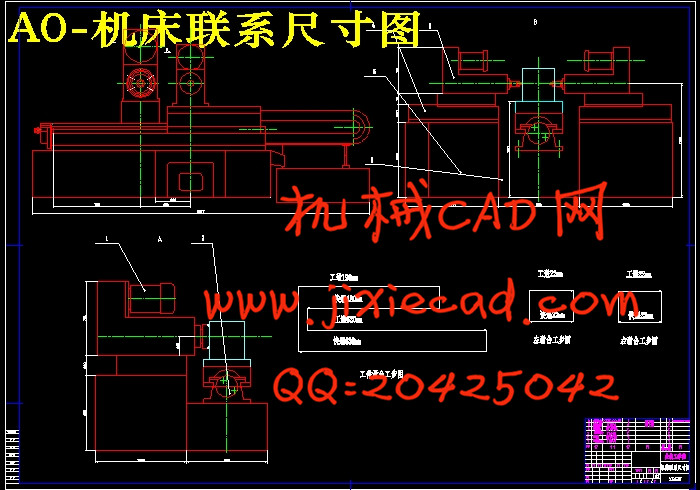

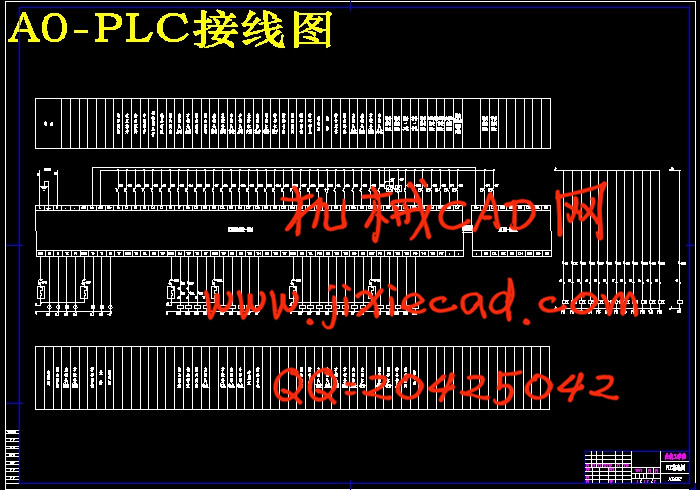

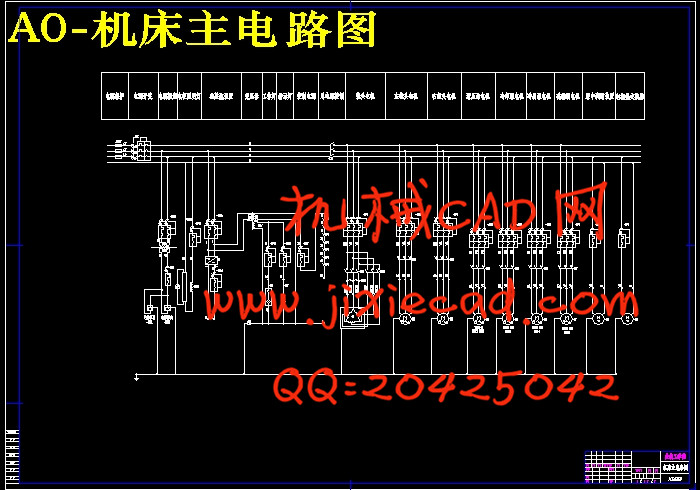

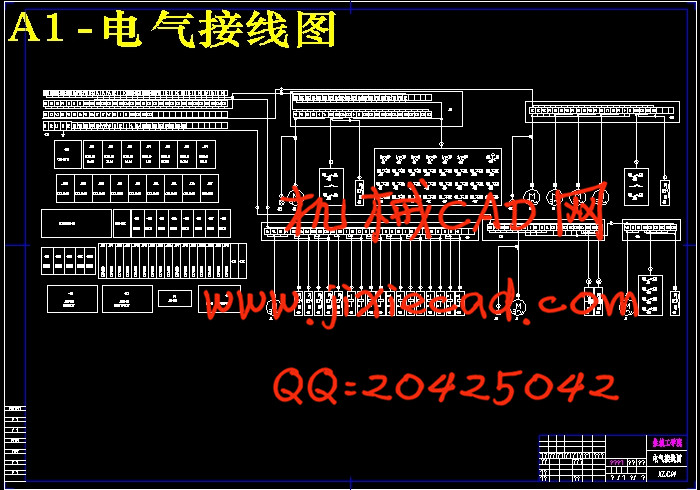

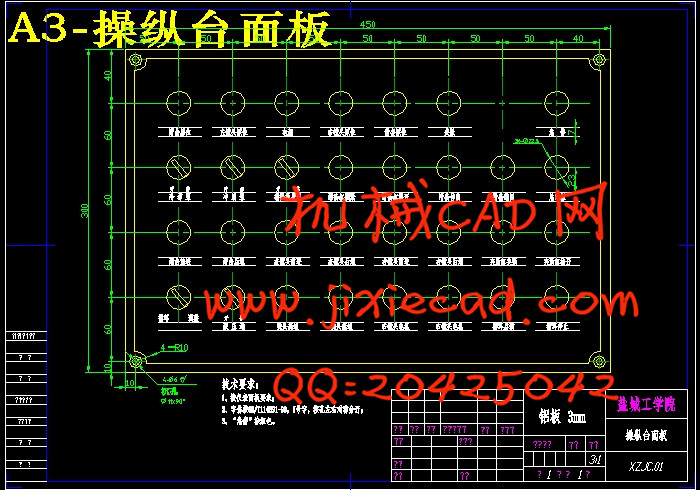

摘 要:本课题为斯太尔转向节铣钻组合机床的总体及电气控制部分设计。设计的主要内容为,确定机床总体结构方案;绘制出机床联系尺寸总图;确定加工工序,夹紧方式,选用刀具,切削用量,切削速度,铣削动力头,左右镗削动力头,动力头滑台,工件滑台。根据机床的总体电气控制要求,完成机床主电路的设计,绘制控制系统的主电路图,并进行操纵台面板的设计。选定三菱FX2N80MR-001型号的PLC,并使用了FX2N-16EX输入端子专用扩展模块。绘制出了输入/输出端子接线图。编写PLC控制程序,完成对机床的动力头和夹具的调整和整机循环的控制。完成工件滑台和左右镗削动力滑台的快进,工进,快退的控制程序的编写。并进行PLC程序的仿真测试,保证所编程序的正确性。

关键词:斯太尔;组合机床;PLC;电气控制

The design of the Modular Machine for Steyr Knuckle to Milling and Drilling and The electrical control system

Abstract: This topic is the design of the modular machine for steyr knuckle to milling and drilling and the electrical control system . The main content of the design is determining the overall structure of machine tools , drawing the "General Plan of the machine", determining the processing operations, clamping method, the choice of cutting tools, cutting parameters, cutting speed, milling power head, boring power head, power head slider and the work-piece slider. According to the overall requirements of the electrical control of the machine, I complete the design of machine tool’s main circuit, draw the main schematic control system, design the console panel, select the model of PLC Mitsubishi FX2N80MR-001, and use the FX2N-16EX specific extension module input. Also I draw out the input/output terminal wiring diagram, write the PLC control program to complete the adjustment of the power head for machine tools, the fixture and the machine control loop. And I complete the control procedures for the preparation of the work-piece slider and the boring power slider's fast forward, working forward and rewind. At last I test the PLC program to guarantee it's correctness.

Key word: steyr; modular machine; PLC ; electrical control system.

目 录

1 前言 1

1.1 课题的来源 1

1.2 国内外现状及发展趋势 1

1.3 设计的思路及解决的主要问题 2

2 机床总体方案设计..................................................... 4

2.1 工艺方案的拟订 4

2.2 机床联系尺寸总图 10

3 机床的电气控制部分设计 12

3.1 机床的控制要求 12

3.2 机床控制方案的确定................................................ 13

3.3 机床主电路的设计 14

3.4 PLC控制部分硬件的设计 15

3.5 PLC控制部分软件的设计 19

3.6 操作面板的设计.................................................... 20

4 结论 21

参考文献 22

致 谢 23

摘 要:本课题为斯太尔转向节铣钻组合机床的总体及电气控制部分设计。设计的主要内容为,确定机床总体结构方案;绘制出机床联系尺寸总图;确定加工工序,夹紧方式,选用刀具,切削用量,切削速度,铣削动力头,左右镗削动力头,动力头滑台,工件滑台。根据机床的总体电气控制要求,完成机床主电路的设计,绘制控制系统的主电路图,并进行操纵台面板的设计。选定三菱FX2N80MR-001型号的PLC,并使用了FX2N-16EX输入端子专用扩展模块。绘制出了输入/输出端子接线图。编写PLC控制程序,完成对机床的动力头和夹具的调整和整机循环的控制。完成工件滑台和左右镗削动力滑台的快进,工进,快退的控制程序的编写。并进行PLC程序的仿真测试,保证所编程序的正确性。

关键词:斯太尔;组合机床;PLC;电气控制

The design of the Modular Machine for Steyr Knuckle to Milling and Drilling and The electrical control system

Abstract: This topic is the design of the modular machine for steyr knuckle to milling and drilling and the electrical control system . The main content of the design is determining the overall structure of machine tools , drawing the "General Plan of the machine", determining the processing operations, clamping method, the choice of cutting tools, cutting parameters, cutting speed, milling power head, boring power head, power head slider and the work-piece slider. According to the overall requirements of the electrical control of the machine, I complete the design of machine tool’s main circuit, draw the main schematic control system, design the console panel, select the model of PLC Mitsubishi FX2N80MR-001, and use the FX2N-16EX specific extension module input. Also I draw out the input/output terminal wiring diagram, write the PLC control program to complete the adjustment of the power head for machine tools, the fixture and the machine control loop. And I complete the control procedures for the preparation of the work-piece slider and the boring power slider's fast forward, working forward and rewind. At last I test the PLC program to guarantee it's correctness.

Key word: steyr; modular machine; PLC ; electrical control system.

目 录

1 前言 1

1.1 课题的来源 1

1.2 国内外现状及发展趋势 1

1.3 设计的思路及解决的主要问题 2

2 机床总体方案设计..................................................... 4

2.1 工艺方案的拟订 4

2.2 机床联系尺寸总图 10

3 机床的电气控制部分设计 12

3.1 机床的控制要求 12

3.2 机床控制方案的确定................................................ 13

3.3 机床主电路的设计 14

3.4 PLC控制部分硬件的设计 15

3.5 PLC控制部分软件的设计 19

3.6 操作面板的设计.................................................... 20

4 结论 21

参考文献 22

致 谢 23