设计简介

摘要

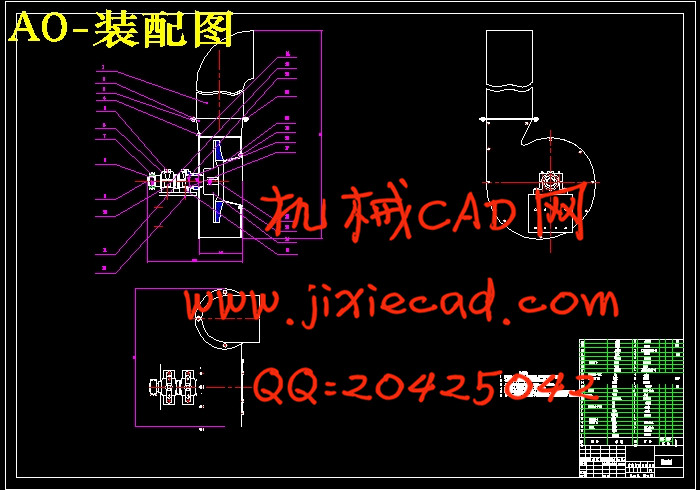

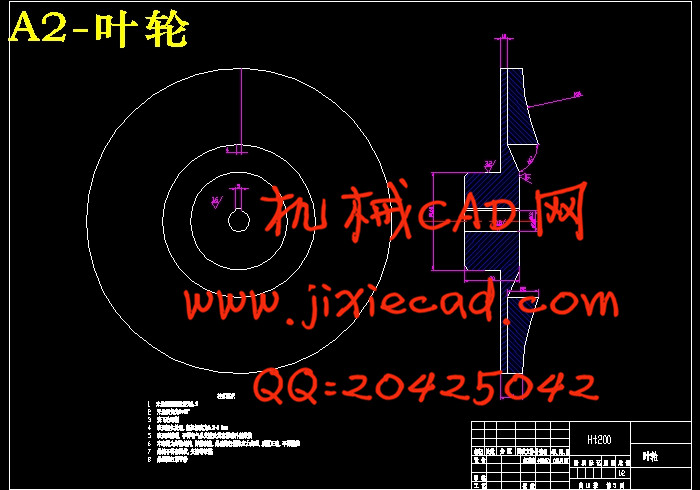

离心式通风机是树枝粉碎成型,饲料加工机械的主要传送方式,其性能对树枝的加工节能降耗意义重大。分析了离心式通风机的结构特点,设计出满足要求的离心式通风机。建立了离心通风机模型,利用ADAMS软件术对叶轮叶片排列形式的离心通风机进行动力学仿真分析,得到了与实际情况相近的结论。仿真结果表明,径向叶片对称交错排列叶轮的平衡性较好,其中交错排列叶片两端轴承承载情况相近,叶片稳定性好。风机是锤片式粉碎机的主要工作部件。利用Pro/E对锤片式粉碎机转子中的各零件进行三维建模、虚拟装配、模型分析和动态仿真。设计者可以充分利用Pro/E单一数据库管理技术,通过改变尺寸参数来方便地修改和更新零件,还可以直观地观察和分析转子的外形、零件间的相互位置关系和运动状态。关键词:振动;仿真;锤片式粉碎机;叶片;

Abstract

The centrifugal fan branches crushed shape, feed processing machinery transmission, has a great influence on economy energy sources in feed factory. In this paper the structural features of the hammers mill are analyzed. The statics and the vibration characteristic of its frame are investigated with the ADAMS software. A discrete model of hammers mill's rotor was set up. Mill's rotor arranged in different hammer forms was analyzed by way of dynamic simulation with virtual prototype technology. The result that is similar to facts was deduced. The conclusion indicated that the rotor with interlaced or symmetry-interlaced hammer form has better balance and the former is with good stability because of its equal load on each bearing. Rotor is an important assembly of hammers mill. This research utilized Pro/E to carry out three-dimensional modeling of the parts of hammer mill’s rotor, virtual assemble, model analysis, and motion emulation. Designers can modify the parts easily by changing size parameters, and also can observe forming, position relation of parts and motion state of the rotor.

Key words: Vibration;Simulate;centrifugal ;Pro/E;rotor;3D modeling

目 录

摘要 1

Abstract 2

1.1 课题的目的和意义 3

1.2 国内风机机发展概况 3

1.3国外风机发展概况 3

1.4 风机的发展趋势 4

2 风机的设计 6

2.1 传动方案的选择 6

2.2.传动的主要结构和计算 7

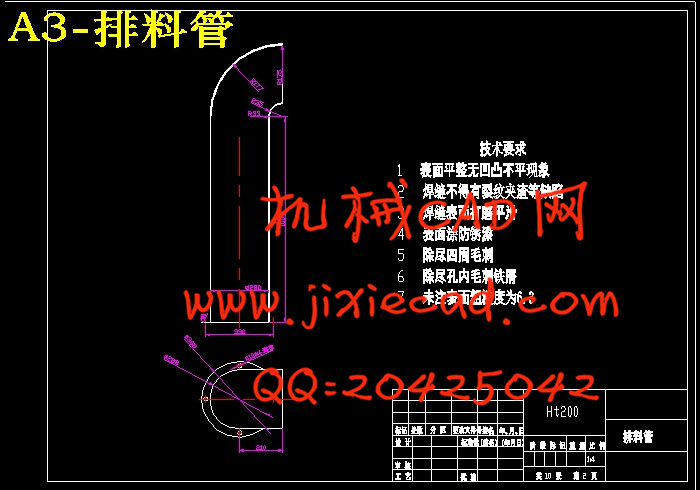

2.2.1排料管的尺寸确定 7

2.2.2 电机计算和选择 9

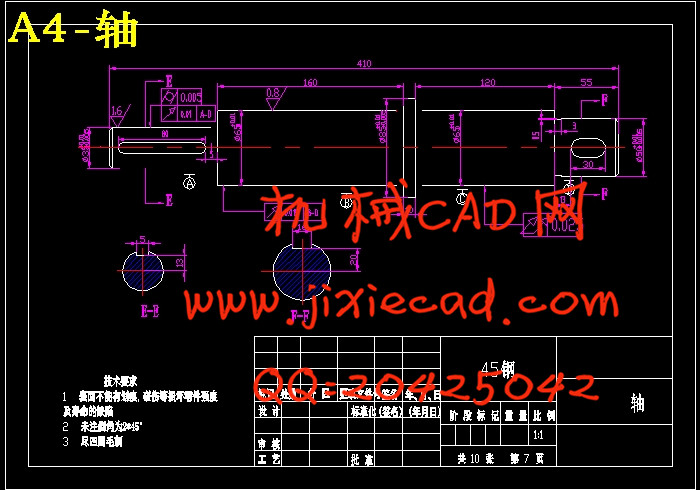

2.2.3. 轴尺寸计算 11

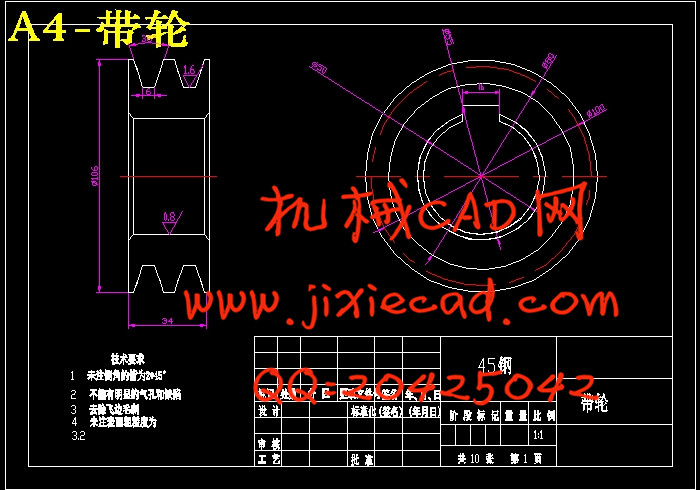

2.2.4 带轮的设计计算 12

2.2.5叶轮的设计计算 15

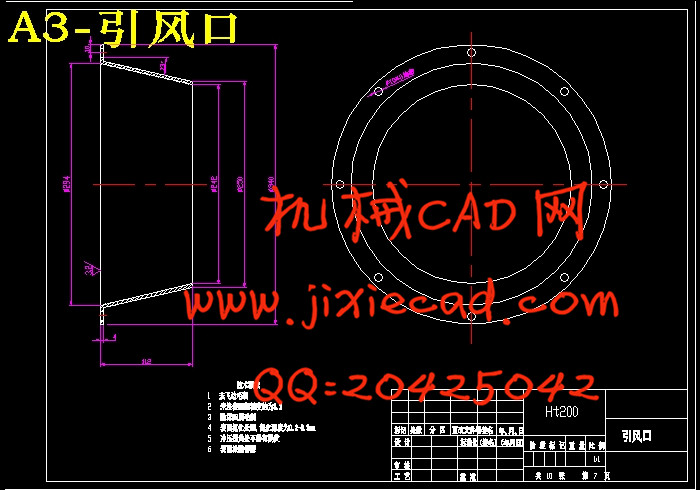

2.2.6 引风口设计 18

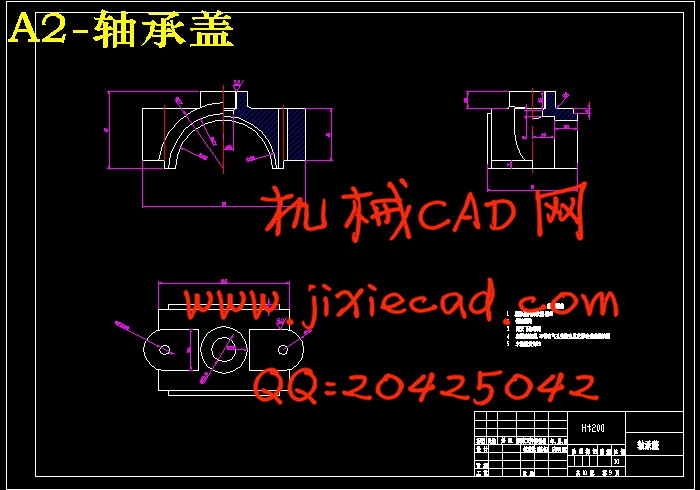

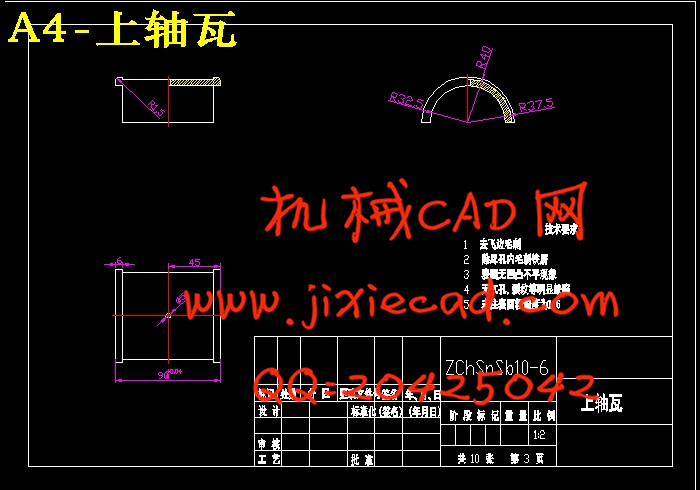

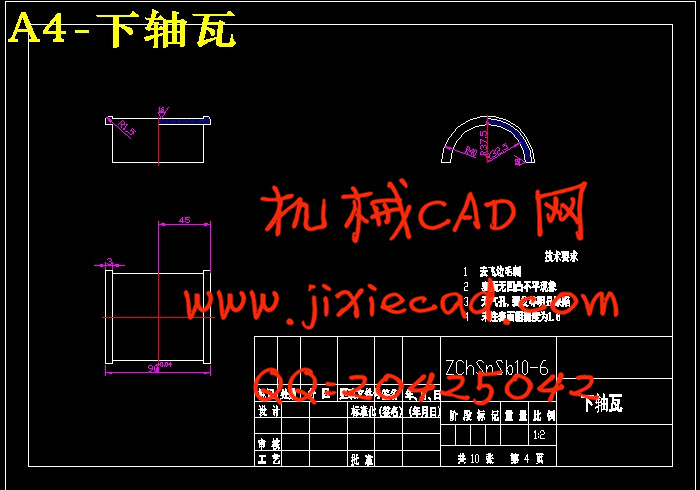

2.2.7轴承座的选择 19

3 强度校核 20

3.1轴的强度校核 20

3.2键的选择及校核计算 24

总结 25

参考文献 26

致 谢 27