设计简介

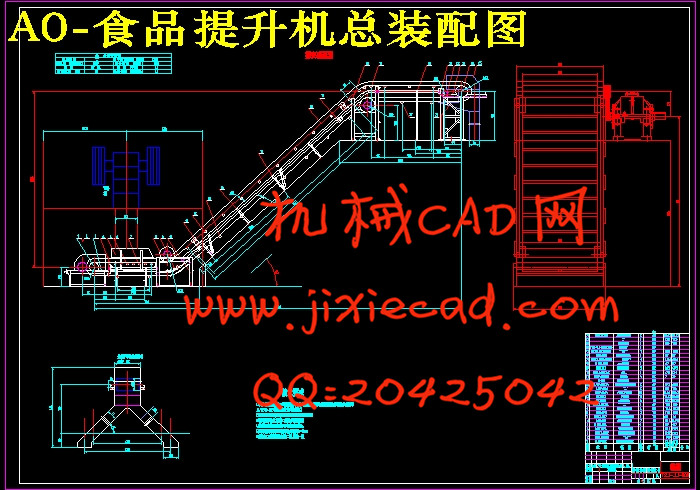

摘 要:本设计为一种新型食品包装自动输送线的专用设备食品提升机的设计。利用异型输送带的盛料和输送作用,结合常用带式提升机的输送原理,实现产品水平提升、输送的功能。该机设计输送精度高、运行平稳、制造成本低、实用性强、自动化程度高,极大地提高了工作效率。据此设计可用于不同承载对象的其它类食品提升机,降低机器设计难度,具有广泛的应用前景。

关键词:减速器;改向滚筒;改向压轮;托辊

Abstract: A new type of special equipment for food packaging automatic transportation line – elevator is designed in this paper. Special-shaped belt hoist realized the function of lifting and transporting prod-ucts by using special-shaped conveyor belt to load and transport materials,combined with the conveying prin-ciple of common belt hoist.This device had the advantages of high precision,smooth operation,low manufac-turing cost,high practicability,high automation and it will improve the efficiency greatly.This design can be used for the other types of food hoist carrying different load-bearing objects, and lower the difficulty of designing machine. So, it has a wide range of applications.

Key words:Reduction gear; Changes to the drum; Pressure roller; Supporting roller

目 录

摘要………………………………………………………………………………1

关键词 …………………………………………………………………………………1

1 前言………………………………………………………………………1

2提升机设计原理和方案……………………………………………………8

2.1提升机的设计原理………………………………………………………8

2.1设计要求和方案…………………………………………………………8

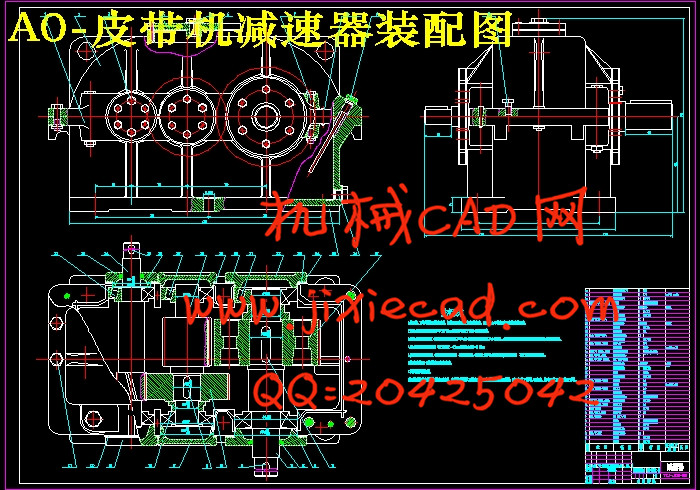

3减速器结构的计算…………………………………………………………10

3.1电动机的选择…………………………………………………………10

3.2计算传动装置的总传动比和分配各级传动比…………………………11

3.3传动装置的运动和动力参数……………………………………………11

3.4 V带的设计………………………………………………………………12

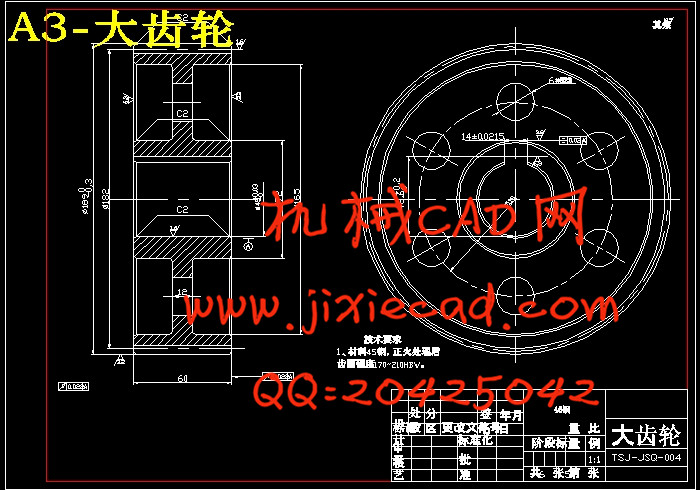

3.5齿轮传动的设计计算及核算……………………………………………14

3.6低速级减速齿轮设计(斜齿圆柱齿轮)…………………………………17

4部件选型设计…………………………………………………………19

4.1槽轮机构………………………………………………………………20

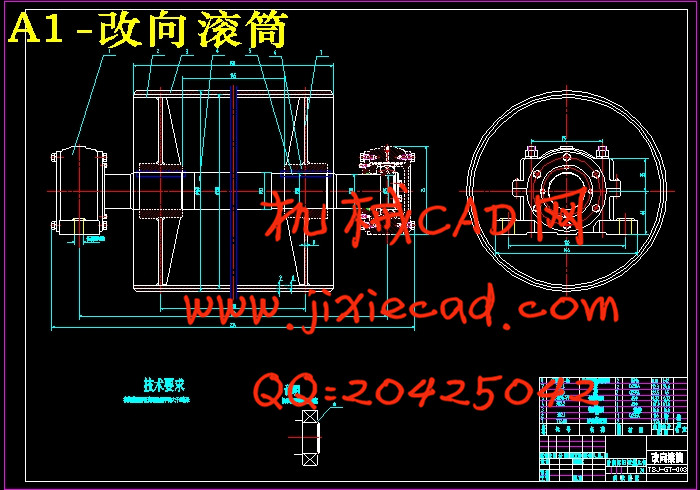

4.2 改向滚筒的设计……………………………………………………21

4.3改向压轮的设计…………………………………………………………24

4.4 托辊的设计………………………………………………………………28

5食品提升机的安装和操作维护……………………………………………31

6 结论…………………………………………………………………………33

参考文献………………………………………………………………………34

致谢……………………………………………………………………………35

关键词:减速器;改向滚筒;改向压轮;托辊

Abstract: A new type of special equipment for food packaging automatic transportation line – elevator is designed in this paper. Special-shaped belt hoist realized the function of lifting and transporting prod-ucts by using special-shaped conveyor belt to load and transport materials,combined with the conveying prin-ciple of common belt hoist.This device had the advantages of high precision,smooth operation,low manufac-turing cost,high practicability,high automation and it will improve the efficiency greatly.This design can be used for the other types of food hoist carrying different load-bearing objects, and lower the difficulty of designing machine. So, it has a wide range of applications.

Key words:Reduction gear; Changes to the drum; Pressure roller; Supporting roller

目 录

摘要………………………………………………………………………………1

关键词 …………………………………………………………………………………1

1 前言………………………………………………………………………1

2提升机设计原理和方案……………………………………………………8

2.1提升机的设计原理………………………………………………………8

2.1设计要求和方案…………………………………………………………8

3减速器结构的计算…………………………………………………………10

3.1电动机的选择…………………………………………………………10

3.2计算传动装置的总传动比和分配各级传动比…………………………11

3.3传动装置的运动和动力参数……………………………………………11

3.4 V带的设计………………………………………………………………12

3.5齿轮传动的设计计算及核算……………………………………………14

3.6低速级减速齿轮设计(斜齿圆柱齿轮)…………………………………17

4部件选型设计…………………………………………………………19

4.1槽轮机构………………………………………………………………20

4.2 改向滚筒的设计……………………………………………………21

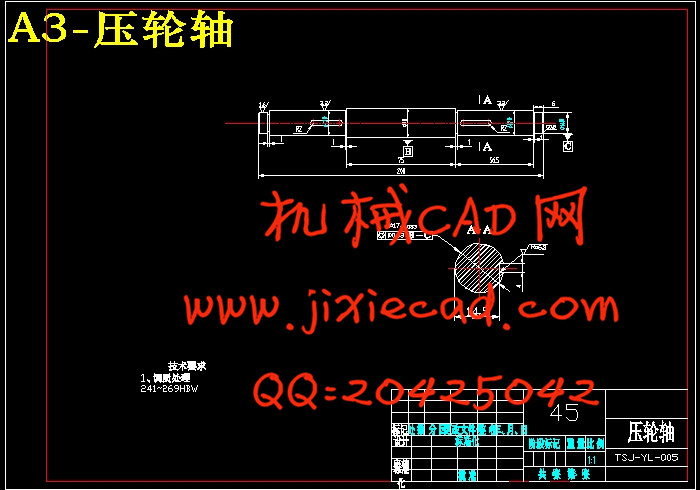

4.3改向压轮的设计…………………………………………………………24

4.4 托辊的设计………………………………………………………………28

5食品提升机的安装和操作维护……………………………………………31

6 结论…………………………………………………………………………33

参考文献………………………………………………………………………34

致谢……………………………………………………………………………35