设计简介

摘 要

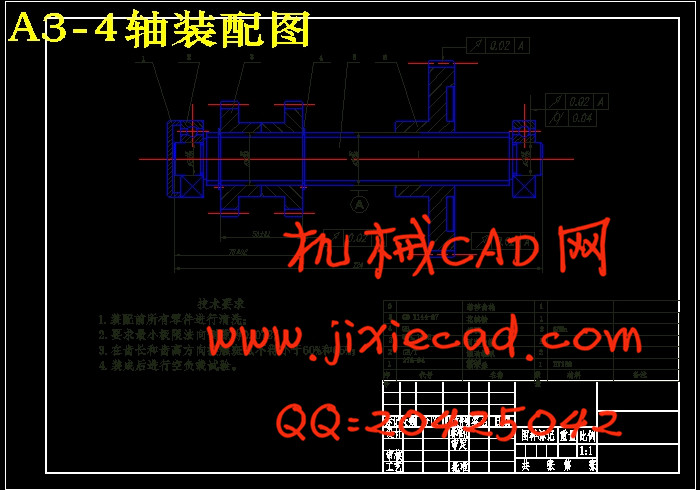

作为主要的车削加工机床,盘丝车床广泛的应用于机械加工行业中,本设计主要针对盘丝车床的床头箱进行设计,设计的内容主要有机床主要参数的确定,传动方案和传动系统图的拟定,对主要零件 进行了计算和验算,利用三维画图软件进行了零件的设计和处理。盘丝车床主轴箱设计,主要包括三方面的设计,即:根据设计题目所给定的机床用途、规格、主轴极限转速、转速数列公比或级数,确定其他有关运动参数,选定主轴各级转速值;通过分析比较,选择传动方案;拟定结构式或结构网,拟定转速图;确定齿轮齿数及带轮直径;绘制传动系统图。其次,根据机床类型和电动机功率,确定主轴及各传动件的计算转速,初定传动轴直径、齿轮模数,确定传动带型号及根数,摩擦片尺寸及数目;装配草图完成后要验算传动件(传动轴、主轴、齿轮、滚动轴承)的刚度、强度或寿命。最后,完成运动设计和动力设计后,要将主传动方案“结构化”,设计主轴变速箱装配图及零件图,侧重进行传动轴组件、主轴组件、变速机构、箱体、润滑与密封、传动轴及滑移齿轮零件的设计。

关键词:盘丝车床 床头箱 零件 传动

Abstract

As the main turning machine, plate wire lathe widely used in mechanical processing industry, this design is mainly for threading lathe headstock design, design of machine tool main parameters, transmission and drive system diagram design of the main parts, the calculation and checking, using three-dimensional drawing software for parts design and processing.Threading lathe spindle box design, mainly includes three aspects of the design, namely: according to the design topic given machine uses, specifications, spindle speed, speed ratio or series series, identify other related movement parameters, the selected spindle velocity value; through analysis and comparison, selection of transmission scheme; drawing structures or structural net, develop speed diagram; determining tooth number of gear and belt wheel diameter; diagram. Secondly, according to the type of machine and electric motor power, identification of the spindle and the transmission parts of the calculation speed, initial diameter of the transmission shaft, the gear modulus, confirm the transmission belt type and number, friction plate size and number; Assembly Sketches after checking transmission ( transmission shaft, shaft, gear, rolling bearing stiffness, ) intensity or life. Finally, complete the kinematic design and dynamic design, will main drive system of" structured", the design of spindle gear box assembly drawing and parts drawing, emphasizes on the transmission shaft component, main components, transmission mechanism, box, lubrication and seal, the transmission shaft and the slip gear parts design.

Key Words: Threading lathe, headstock, transmission ,parts

目 录

摘 要 3Abstract 4

目 录 5

第1章 绪论 7

第2章 主要技术参数、传动方案和传动系统图的拟定 8

2.1 拟定技术参数 8

2.1 细化技术参数 9

2.1.1.确定极限转速 9

2.1.2确定公比 9

2.1.3.求出主轴转速级数Z 9

2.1.4确定结构网或结构式 9

2.1.5绘制转速图 9

第3章 主要设计零件的计算和验算 11

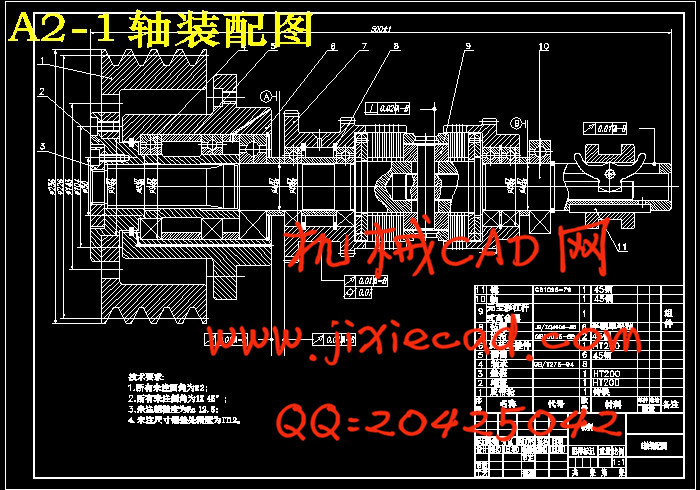

3.1传动系统的I轴及轴上零件设计 11

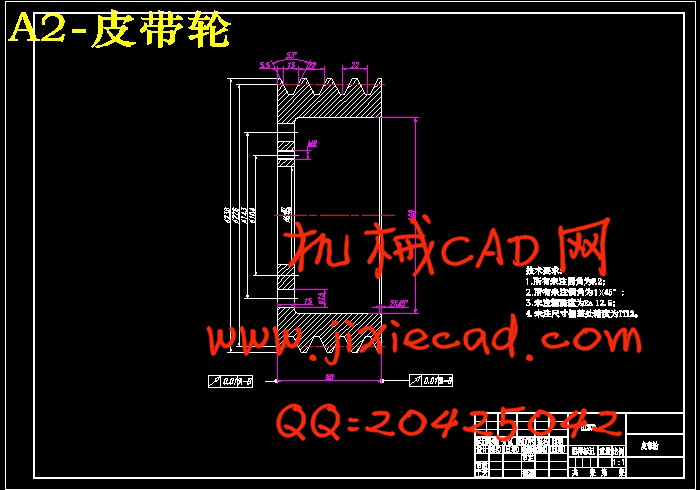

3.1.1普通V带传动的计算 11

3.1.2多片式摩擦离合器的计算 13

3.2.3齿轮的验算 15

3.1.4传动轴的验算 17

3.1.5轴承疲劳强度校核 18

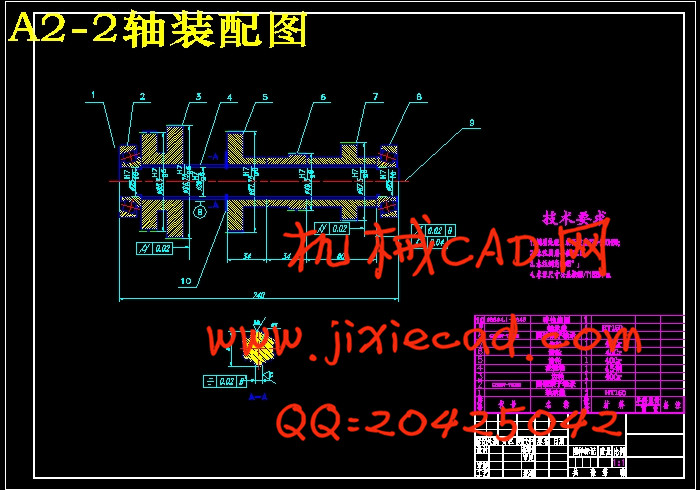

3.2 传动系统的Ⅱ轴及轴上零件设计 19

3.2.1齿轮的验算 19

3.2.2传动轴的验算 22

3.2.3轴组件的刚度验算 23

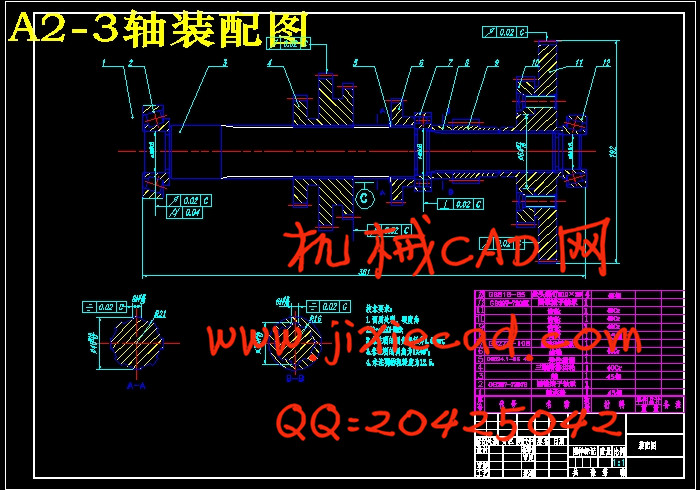

3.3 传动系统的Ⅲ轴及轴上零件设计 24

3.3.1齿轮的验算 24

3.3.2 传动轴的验算 27

3.3.3 轴组件的刚度验算 29

3.4传动系统的Ⅳ轴及轴上零件设计 30

3.4.1齿轮的验算 30

3.4.2传动轴的验算 33

3.4.3轴组件的刚度验算 34

3.5. 传动系统的Ⅴ轴及轴上零件设计 36

3.5.1齿轮的验算 36

3.5.2传动轴的验算 38

3.5.3轴组件的刚度验算 40

第4章 床头箱的箱体设计 41

总 结 44

致 谢 45

参考资料 46