设计简介

摘要

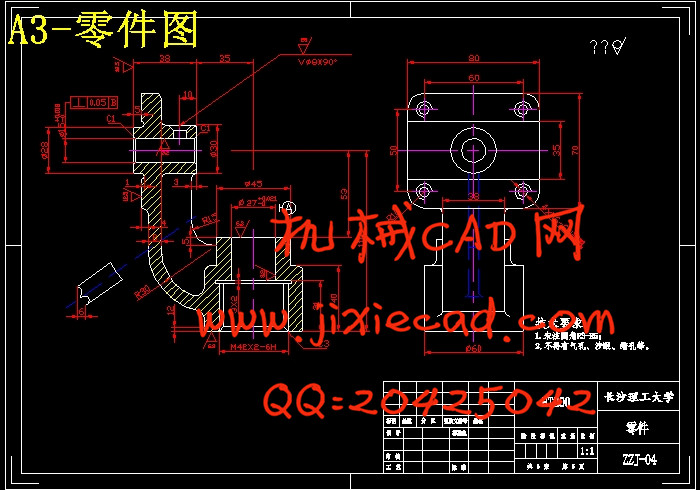

轴支架是重要零件,其制造精度直接影响到齿轮运动的质量。本课题是对轴

支架的加工工艺规程及选择某道工序对其夹具加以设计。在工艺规程设计中工作

包括了零件的工艺分析与毛坯的设计,工艺路线的拟定,工艺计算和工艺文件的

编制。

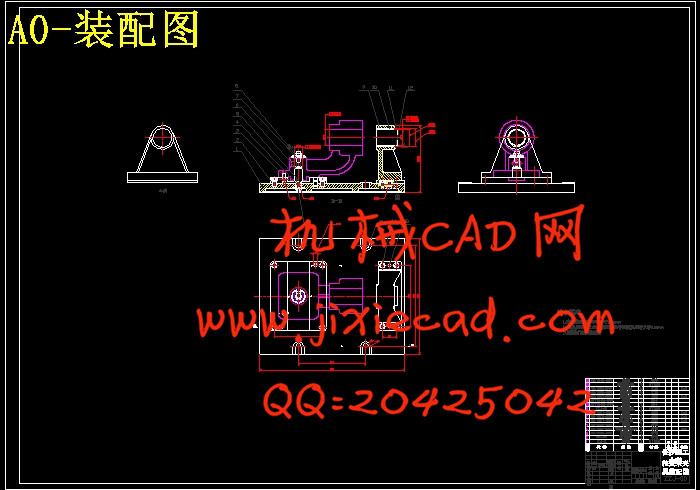

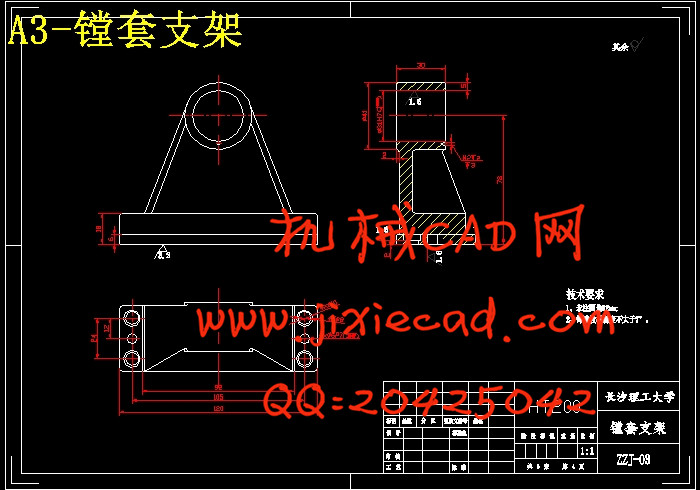

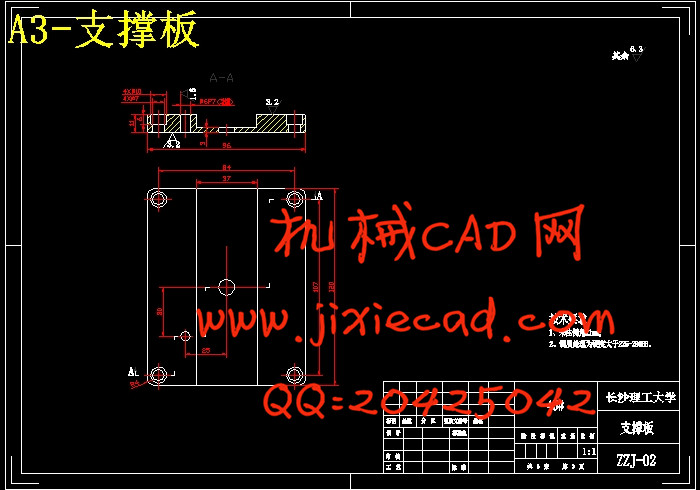

夹具设计是整个设计过程中的难点和重点部分。本课题的夹具设计时围绕精

镗孔进行的。采用一面两孔方式定位,这种定位方式夹具结构简单,定位稳定可

靠。夹紧采用螺母压紧。通过定位方式和夹具零件的分析和选择最后绘制了夹具

装配图及主要零件图。

关键词:轴支架;工艺规程;夹具设计

Shaft stents is the a important part, the manufacturing precision of shaft stents

directly affects the parts quality .This topic is for shaft stents 's processing technology

and select a process to designed the fixture .In process planning ,including the rough

parts of the process analysis and design. The preparation process route, process

calculation and process documentation.

Fixture design is for fine boring the spindle holes. Way with two holes side

positioning .This positioning made fixture simple ,positioning stable and

reliable .Clamping screw clamping mechanism .Screw clamp is simple in structure,

easy to manufacture, good for Self-locking, reliable clamping. Determine the

positioning approach and the analysis of selected parts of the fixture, and finally draw

the fixture assembly diagram and major parts diagram.

Key words: Shaft Stents; Processing Design; Fixture Design

目录

1 绪论............................................................................................................................................... 1

1.1 课题背景............................................................................................................................ 1

1.1.1 轴支架概述............................................................................................................. 1

1.1.2 工艺设计的现状及发展趋势................................................................................. 3

1.1.3 夹具的现状及发展趋势......................................................................................... 3

1.2 本设计的内容及目的........................................................................................................ 4

2 轴支架的加工工艺规程设计....................................................................................................... 6

2.1 轴支架的工艺分析及生产类型确定................................................................................ 6

2.1.1 轴支架的工艺分析................................................................................................. 6

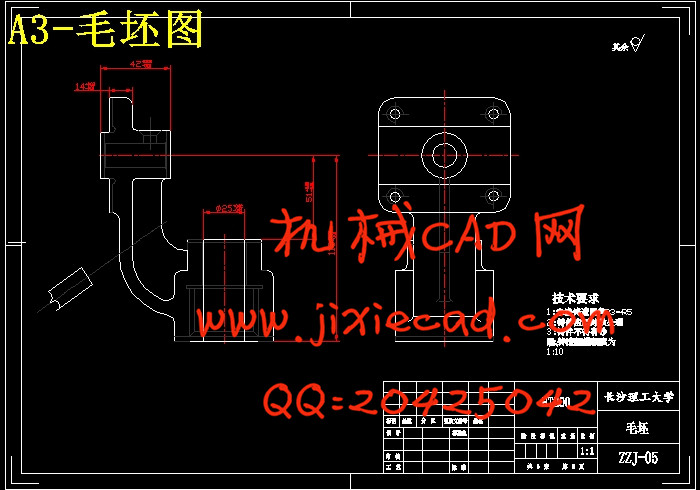

2.2 确定毛坯的制造类型........................................................................................................ 6

2.3 基准的选择........................................................................................................................ 7

2.3.1 粗基准的选择......................................................................................................... 7

2.3.2 精基准的选择......................................................................................................... 7

2.4 零件表面加工方法的确定................................................................................................ 8

2.5 工艺路线的制定与分析.................................................................................................... 8

2.5.1 工艺路线的拟定..................................................................................................... 8

2.5.2 工艺方案的分析与确定....................................................................................... 10

2.6 机械加工余量、毛坯工序尺寸的确定.......................................................................... 11

2.7 确定切削用量及基本工时.............................................................................................. 12

3 轴支架专用夹具设计................................................................................................................. 33

3.1 夹具设计的原则和要求.................................................................................................. 33

3.1.1 夹具设计的要求................................................................................................... 33

3.1.2 六点定位原则....................................................................................................... 34

3.2 夹具设计.......................................................................................................................... 34

3.2.1 确定定位方案....................................................................................................... 34

3.2.2 设计夹紧机构....................................................................................................... 35

3.2.3 切削力及夹紧力的计算....................................................................................... 35

3.2.4 定位误差分析....................................................................................................... 36

3.2.5 确定夹具总体结构和尺寸................................................................................... 37

4 总结............................................................................................................................................. 40

参考文献......................................................................................................................................... 42

致谢................................................................................................................................................. 43

轴支架是重要零件,其制造精度直接影响到齿轮运动的质量。本课题是对轴

支架的加工工艺规程及选择某道工序对其夹具加以设计。在工艺规程设计中工作

包括了零件的工艺分析与毛坯的设计,工艺路线的拟定,工艺计算和工艺文件的

编制。

夹具设计是整个设计过程中的难点和重点部分。本课题的夹具设计时围绕精

镗孔进行的。采用一面两孔方式定位,这种定位方式夹具结构简单,定位稳定可

靠。夹紧采用螺母压紧。通过定位方式和夹具零件的分析和选择最后绘制了夹具

装配图及主要零件图。

关键词:轴支架;工艺规程;夹具设计

Shaft stents is the a important part, the manufacturing precision of shaft stents

directly affects the parts quality .This topic is for shaft stents 's processing technology

and select a process to designed the fixture .In process planning ,including the rough

parts of the process analysis and design. The preparation process route, process

calculation and process documentation.

Fixture design is for fine boring the spindle holes. Way with two holes side

positioning .This positioning made fixture simple ,positioning stable and

reliable .Clamping screw clamping mechanism .Screw clamp is simple in structure,

easy to manufacture, good for Self-locking, reliable clamping. Determine the

positioning approach and the analysis of selected parts of the fixture, and finally draw

the fixture assembly diagram and major parts diagram.

Key words: Shaft Stents; Processing Design; Fixture Design

目录

1 绪论............................................................................................................................................... 1

1.1 课题背景............................................................................................................................ 1

1.1.1 轴支架概述............................................................................................................. 1

1.1.2 工艺设计的现状及发展趋势................................................................................. 3

1.1.3 夹具的现状及发展趋势......................................................................................... 3

1.2 本设计的内容及目的........................................................................................................ 4

2 轴支架的加工工艺规程设计....................................................................................................... 6

2.1 轴支架的工艺分析及生产类型确定................................................................................ 6

2.1.1 轴支架的工艺分析................................................................................................. 6

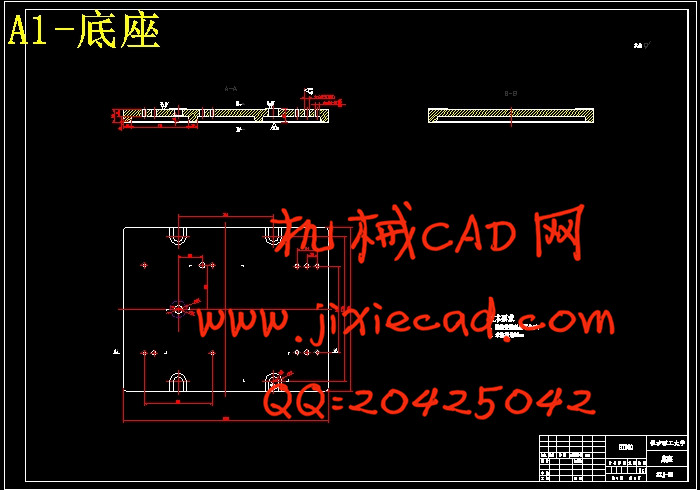

2.2 确定毛坯的制造类型........................................................................................................ 6

2.3 基准的选择........................................................................................................................ 7

2.3.1 粗基准的选择......................................................................................................... 7

2.3.2 精基准的选择......................................................................................................... 7

2.4 零件表面加工方法的确定................................................................................................ 8

2.5 工艺路线的制定与分析.................................................................................................... 8

2.5.1 工艺路线的拟定..................................................................................................... 8

2.5.2 工艺方案的分析与确定....................................................................................... 10

2.6 机械加工余量、毛坯工序尺寸的确定.......................................................................... 11

2.7 确定切削用量及基本工时.............................................................................................. 12

3 轴支架专用夹具设计................................................................................................................. 33

3.1 夹具设计的原则和要求.................................................................................................. 33

3.1.1 夹具设计的要求................................................................................................... 33

3.1.2 六点定位原则....................................................................................................... 34

3.2 夹具设计.......................................................................................................................... 34

3.2.1 确定定位方案....................................................................................................... 34

3.2.2 设计夹紧机构....................................................................................................... 35

3.2.3 切削力及夹紧力的计算....................................................................................... 35

3.2.4 定位误差分析....................................................................................................... 36

3.2.5 确定夹具总体结构和尺寸................................................................................... 37

4 总结............................................................................................................................................. 40

参考文献......................................................................................................................................... 42

致谢................................................................................................................................................. 43