设计简介

摘 要

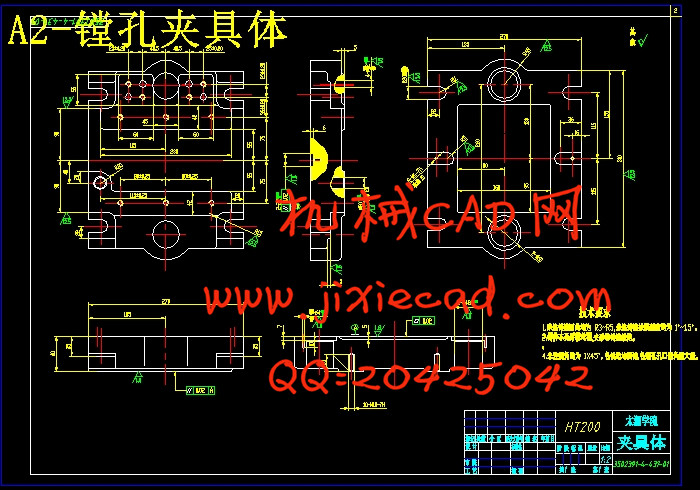

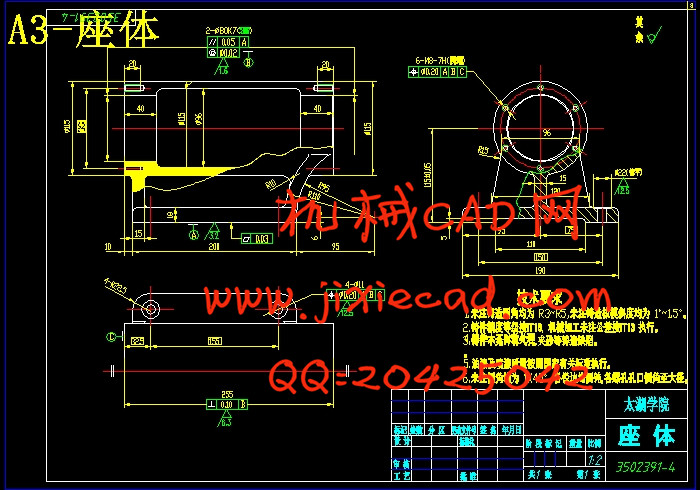

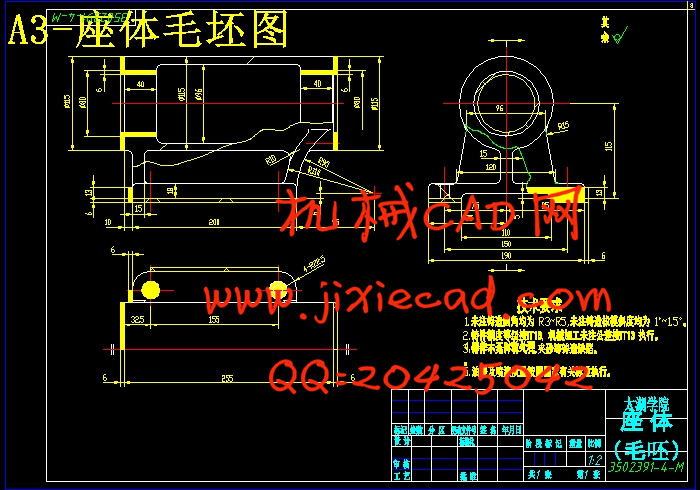

铣刀头座体是铣床加工的重要组成元件之一,它的制造工艺对铣削加工的尺寸精度有显著的影响。本课题的目的是对铣床的铣刀头座体的机械制造工艺及夹具设计。在第一部分的制造工艺设计中,主要的工作是铣刀头座体的毛坯件的铸造,加工工艺路线的设定,机件的工艺查阅和计算,编制主要的工艺文件。铣刀头座体的夹具设计是这次课题的重要的部分,也是本次课题的难点分,夹具的设计主要是铣刀头的定位和夹紧。主要会影响加工元件的尺寸精度和位置精度。在本次课题中主要采用的是不完全定位方式,这种通用的定位方式的夹具的结构比较简单,并且有良好的定位的稳定性。夹紧机构主要采用螺旋式,这种结构的构成比较简单,自锁性能好,可靠性能高。在确定夹紧方式后绘出主要的零件图和装配图。

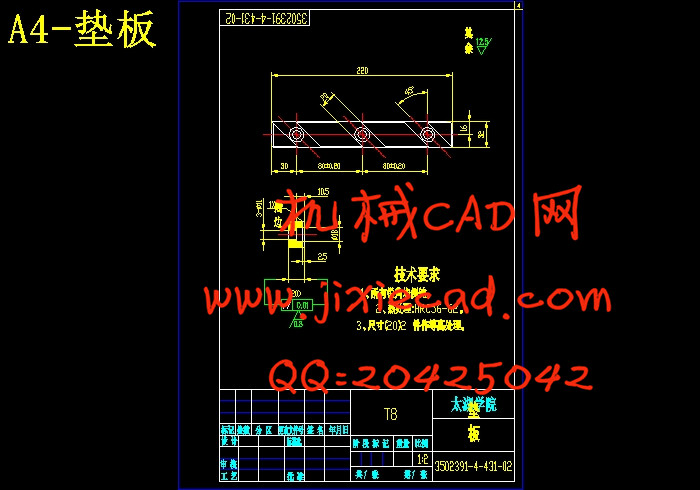

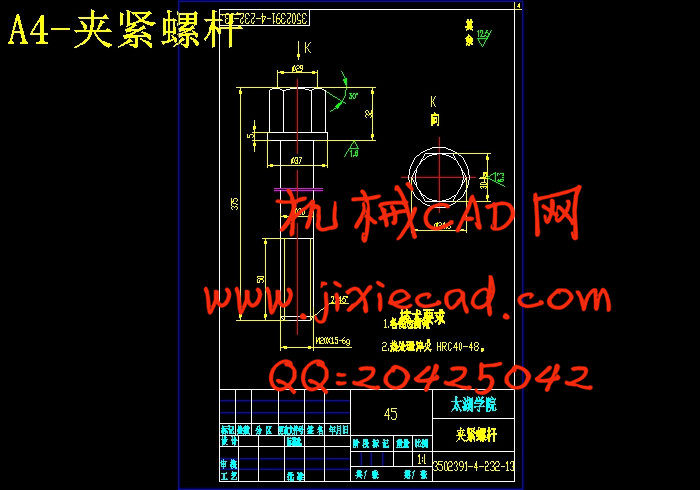

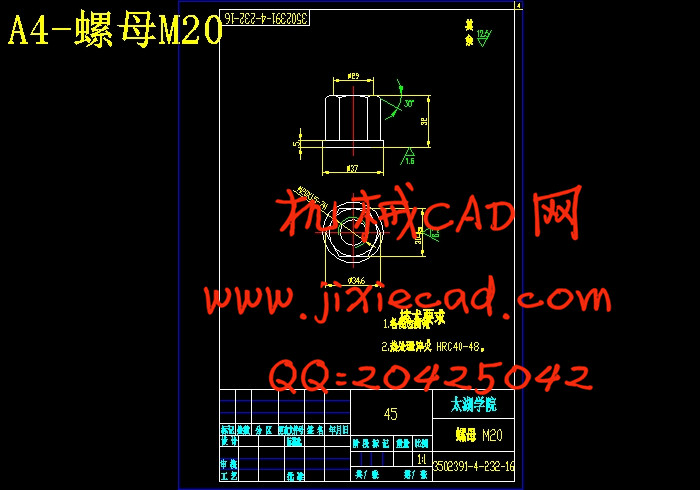

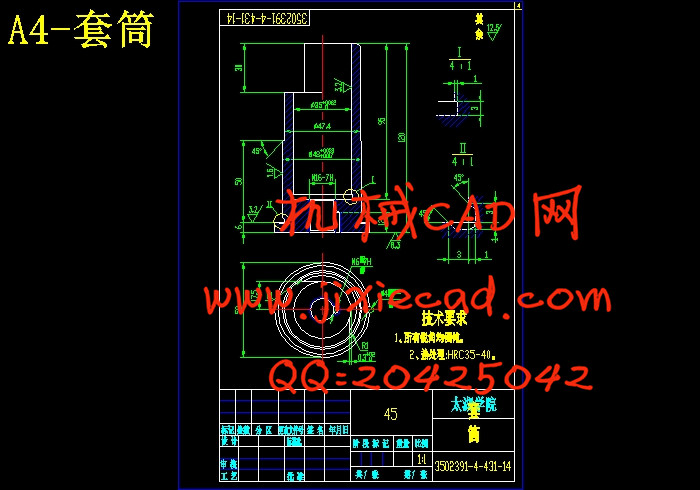

关键词:铣床;铣刀头座体;制造工艺;夹具设计

ABSTRACT

Milling cutter head base is an integral component of milling manufacturing process and has a significant impact on the dimensional accuracy of milling . The purpose of this project is generally milling cutter head base mechanical manufacturing process and fixture design. In the first part of the manufacturing process design, the main work is casting of milling cutter head base , machining and line set, mechanical inspection and calculation process, the preparation of the main process documents.

The Fixture Block of milling cutter head base is an important part of this project and also is a part of this difficult subject, mainly milling fixture design is clamping and positioning. these will affect the processing of the dimensional accuracy and position accuracy of main components. The issue is used three holes of the positioning in one surface . the positioning of such a general way the fixture structure is relatively simple and has good positioning stability. Clamping institutions are mainly spiral , the composition of this structure is relatively simple, self-locking performance, high reliability. drawing three-dimensional and assembly drawings.

Key words: milling machine; milling cutter head base; manufacturing processes;fixture design

目 录

摘要................................................................................................................................................III

ABSTRACT...................................................................................................................................IV

目录.................................................................................................................................................V

1 绪论.............................................................................................................................................1

1.1 课题背景.............................................................................................................................1

1.1.1铣刀头座体的概述.........................................................................................................1

1.1.2铣刀头的现状和发展趋势.............................................................................................1

1.1.3铣刀的分类.....................................................................................................................1

1.1.4铣刀的结构和构成.........................................................................................................2

1.1.5夹具的现状及发展趋势.................................................................................................2

1.2 本设计的内容及目的..........................................................................................................3

2 铣刀头座体的机械加工工艺规程设计.....................................................................................5

2.1 铣刀头座体的工艺分析及生产类型确定..........................................................................5

2.1.1 铣刀头座体的工艺分析...............................................................................................5

2.1.2 铣刀头座体的生产类型...............................................................................................6

2.2 确定毛坯的制造类型..........................................................................................................6

2.3 基准的选择..........................................................................................................................6

2.3.1 粗基准的选择...............................................................................................................6

2.3.2 精基准的选择...............................................................................................................7

2.4 零件表面加工方法的确定..................................................................................................7

2.5 工艺路线的制定与分析......................................................................................................7

2.5.1 工艺路线的拟定...........................................................................................................7

2.5.2 工艺方案的分析与确定...............................................................................................8

2.6 机械加工余量、毛坯工序尺寸的确定............................................................................10

2.6.1 孔的加工余量.............................................................................................................10

2.6.2 平面的加工余量.........................................................................................................10

2.6.3 切削用量及工时的计算.............................................................................................11

3 铣刀头座体专用夹具设计.......................................................................................................23

3.1 夹具设计的原则和要求....................................................................................................23

3.1.1 夹具设计的要求.........................................................................................................23

3.1.2 六点定位原则.............................................................................................................23

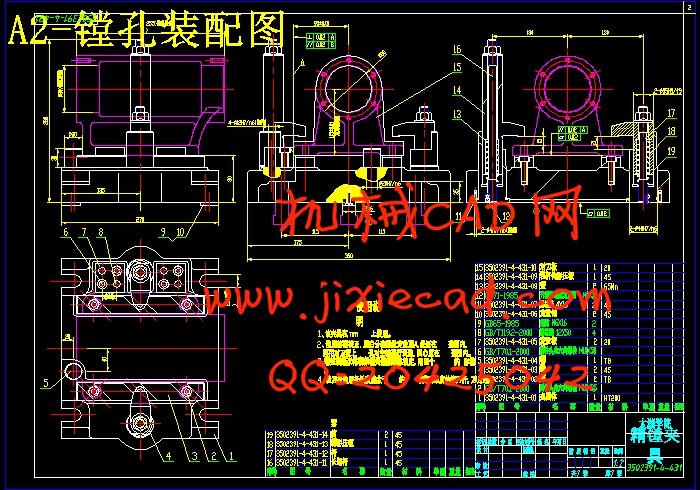

3.2 镗夹具的设计..................................................................................................................24

3.2.1 确定定位方案.............................................................................................................24

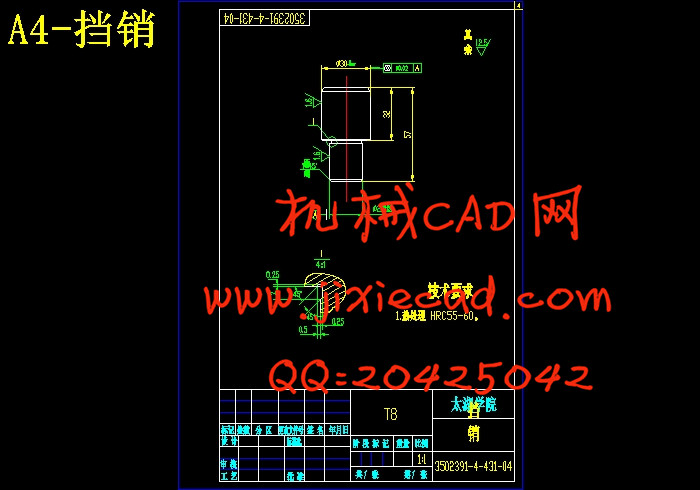

3.2.2 设计夹紧机构.............................................................................................................24

ABSTRACT...................................................................................................................................IV

目录.................................................................................................................................................V

1 绪论.............................................................................................................................................1

1.1 课题背景.............................................................................................................................1

1.1.1铣刀头座体的概述.........................................................................................................1

1.1.2铣刀头的现状和发展趋势.............................................................................................1

1.1.3铣刀的分类.....................................................................................................................1

1.1.4铣刀的结构和构成.........................................................................................................2

1.1.5夹具的现状及发展趋势.................................................................................................2

1.2 本设计的内容及目的..........................................................................................................3

2 铣刀头座体的机械加工工艺规程设计.....................................................................................5

2.1 铣刀头座体的工艺分析及生产类型确定..........................................................................5

2.1.1 铣刀头座体的工艺分析...............................................................................................5

2.1.2 铣刀头座体的生产类型...............................................................................................6

2.2 确定毛坯的制造类型..........................................................................................................6

2.3 基准的选择..........................................................................................................................6

2.3.1 粗基准的选择...............................................................................................................6

2.3.2 精基准的选择...............................................................................................................7

2.4 零件表面加工方法的确定..................................................................................................7

2.5 工艺路线的制定与分析......................................................................................................7

2.5.1 工艺路线的拟定...........................................................................................................7

2.5.2 工艺方案的分析与确定...............................................................................................8

2.6 机械加工余量、毛坯工序尺寸的确定............................................................................10

2.6.1 孔的加工余量.............................................................................................................10

2.6.2 平面的加工余量.........................................................................................................10

2.6.3 切削用量及工时的计算.............................................................................................11

3 铣刀头座体专用夹具设计.......................................................................................................23

3.1 夹具设计的原则和要求....................................................................................................23

3.1.1 夹具设计的要求.........................................................................................................23

3.1.2 六点定位原则.............................................................................................................23

3.2 镗夹具的设计..................................................................................................................24

3.2.1 确定定位方案.............................................................................................................24

3.2.2 设计夹紧机构.............................................................................................................24

3.2.3 夹紧力的计算.............................................................................................................25

3.3.4 确定镗夹具总体结构和尺寸.....................................................................................25

3.3.5 使用说明.....................................................................................................................26

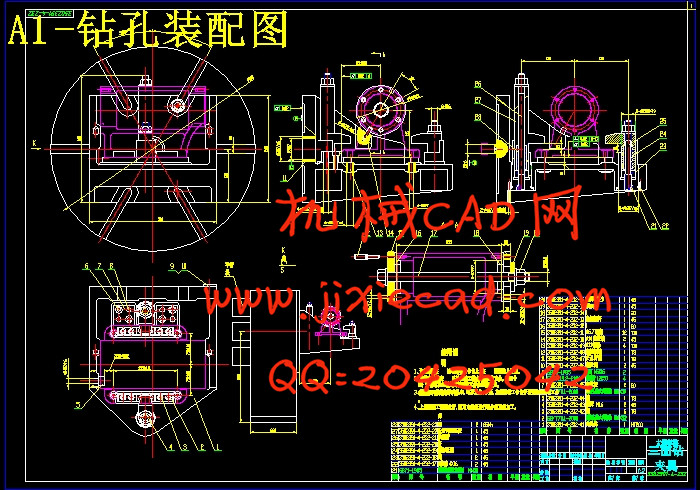

3.3 钻孔夹具的设计................................................................................................................27

3.3.1 定位基准的选择.........................................................................................................27

3.3.2 切削力和夹紧力的计算.............................................................................................27

3.3.3 定位误差分析.............................................................................................................27

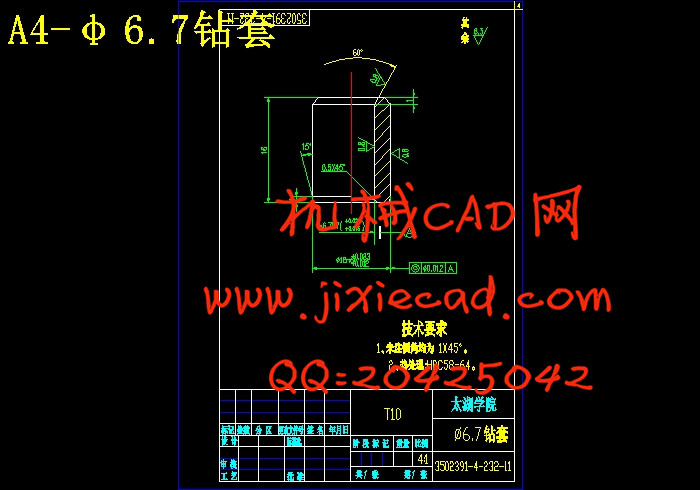

3.3.4 确定定位方案.............................................................................................................28

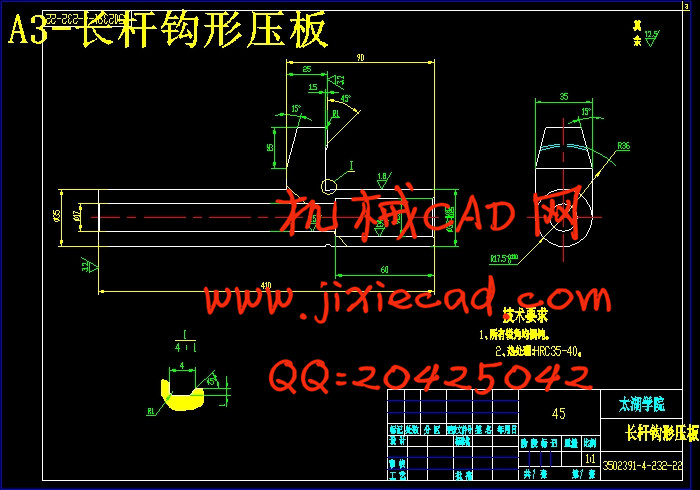

3.3.5 设计夹紧机构.............................................................................................................28

3.3.6 确定钻夹具总体结构和尺寸.....................................................................................28

3.3.7 使用说明.....................................................................................................................29

4 结论与展望...............................................................................................................................31

4.1 结论....................................................................................................................................31

4.2 不足之处与展望................................................................................................................31

致谢...............................................................................................................................................32

参考文献.......................................................................................................................................33