设计简介

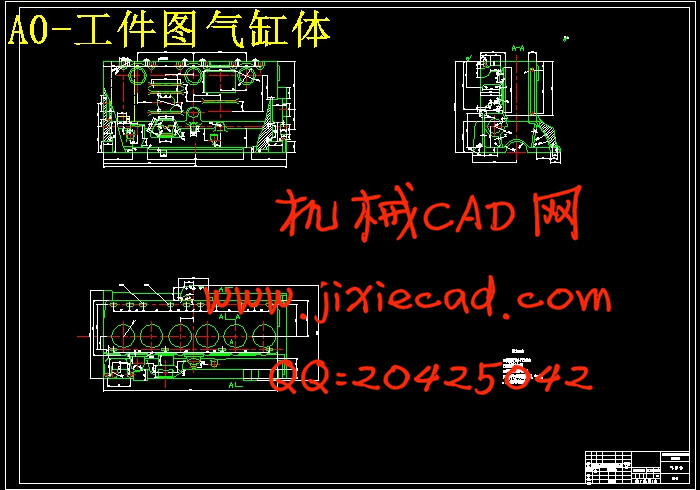

气缸体工艺及液压夹紧铣床夹具

摘要:机床夹具可根据其使用范围,分为通用夹具、专用夹具、组合夹具、通用可调夹具和成组夹具等类型。机床夹具还可按其所使用的机床和产生加紧力的动力源等进行分类。根据所使用的机床可将夹具分为车床夹具、铣床夹具、钻床夹具(钻模)、镗床夹具(镗模)、磨床夹具和齿轮机床夹具等,根据产生加紧力的动力源可将夹具分为手动夹具、气动夹具、液压夹具、电动夹具、电磁夹具和真空夹具等

现代机床夹具的发展方向主要表现为标准化、精密化、高效化和柔性化等四个方面。

机床夹具是机械加工工艺系统的一个重要组成部分。为保证工件某工序的加工要求,必须使工件在机床上相对刀具的切削或成形运动处于准确的相对位置。当用夹具装夹加工一批工件时,是通过夹具来实现这一要求的。而要实现这一要求,又必须满足三个条件:

(1)一批工件在夹具中占有正确的加工位置;

(2)夹具装夹在机床上的准确位置;

(3)刀具相对夹具的准确位置。这里涉及了三层关系:零件相 对夹具,夹具相对于机床,零件相对于机床。工件的最终精度是由零件相对于机床获得的。所以“定位”也涉及到

三层关系:工件在夹具上的定位,夹具相对于机床的定位,而工件相对于机床的定位是间接通过夹具来保证的。工件定位以后必须通过一定的装置产生夹紧力把工件固定,使工件保持在准确定位的位置上,否则,在加工过程中因受切削力,惯性力等力的作用而发生位置变化或引起振动,破坏了原来的准确定位,无法保证加工要求。这种产生夹紧力的装置便是夹紧装置。

关键字: 工艺 定位 夹紧力 精度

Cylinder block milling process and hydraulic clamping fixture

Summary

Fixture can be used in accordance with its scope, is divided into general-purpose fixtures, special fixtures, modular fixture, universal adjustable jig and fixture, such as the type of group. Fixture can also be used in accordance with its machine tools and power have stepped up the power source, such as classification. According to the machine tool can be used lathe fixture into fixtures, milling fixtures, drilling fixtures (Jig), Jig boring machine (boring mode), and gear grinding machine tool fixture fixture and so on, have stepped up force in accordance with the power source can be divided into fixture manual fixture, pneumatic fixtures, hydraulic fixtures, electrical fixtures, electromagnetic and vacuum fixture such as fixture

The development of modern machine tool fixture is mainly expressed in the direction of standardization, precision, and high-performance and flexible, and so on four aspects.

Fixture system, the machining process is an important part. In order to ensure a process of workpiece processing the request must be made on the workpiece in the machine tool relative movement of the cutting or forming in a precise relative position. When processing a number of workpiece clamping fixture, the fixture is required to achieve this. To achieve this requirement, it must meet three conditions:

(1) a number of fixture holds the workpiece in the correct location of the processing;

(2) clamping fixture in the exact location of the machine;

(3) an accurate tool fixture relative position. The relationship between the three involved here: the relative fixture components, fixture relative to machine tools, machine tool parts in relation to. The ultimate accuracy of the workpiece is compared with the machine tool parts obtained. Therefore, the "positioning" also involves

Three relations: on the workpiece in the fixture positioning, machine tool fixture relative to the positioning of the workpiece relative to the positioning of machine tools is indirect through the fixture to be guaranteed. After the workpiece positioning device must have a certain amount of clamping force to the workpiece fixed to the workpiece to maintain the accurate position location, otherwise, in the process due to the cutting force, inertial force and the occurrence of force caused by vibration or changes in location undermine the accuracy of the original position, can not guarantee that the processing requirements. Such devices have a clamping force is the clamping device.

Keywords Technology Positioning Clamping force Accuracy.

目录

1 引言 4

2设计任务书 5

2.1对机床夹具的基本要求 5

2.2夹具设计的工作步骤 5

3 机床夹具设计原理 6

3.1 夹具 7

3.1.1机床夹具的概念 7

3.1.2机床夹具的分类 7

3.1.3机床夹具的组成 7

3.2定位基准 7

3.3工件在夹具中的定位 8

3.3.1六点定位原理 8

3.3.2支承点与定位元件 9

3.3.3完全定位与不完全定位 10

3.3.4欠定位与过定位 10

3.4组合夹具和随行夹具 11

3.4.1组合夹具 11

3.4.2随行夹具 11

3.5夹具定位误差分析计算 11

4零件的工艺分析 11

4.1平面度分析 12

4.2 表面粗糙度 12

5毛坯的制造形式 12

6铣削方式的选择 12

6.1端面铣 12

6.2周边铣削 13

6.3 端面铣削和周边铣削的比较 13

6.4端面铣削时的顺铣与逆铣 14

6.5对称铣削 14

6.6非对称铣削 14

7 刀具的选择 15

7.1基本要求 15

7.1.1硬度 15

7.1.2韧性和强度 15

7.1.3铣刀切削部分的材料的要求 15

7.2常用材料 15

7.2.1高速工具钢(高速钢和锋钢等) 16

7.2.2硬质合金 16

8铣削用量 17

8.1每齿进给量的选择 17

8.2铣削速度的选择 18

8.3切削液 18

8.4.切削液的种类 19

8.5 切削液的选用 19

8.6选择测量方法 19

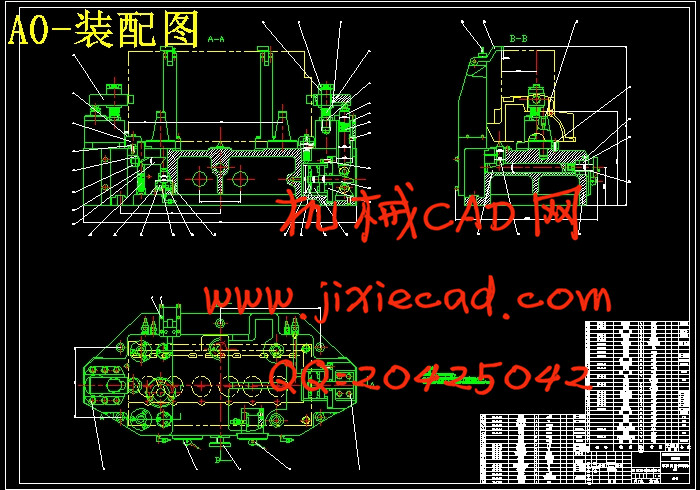

9夹具设计 20

9.1 基面的选择 20

9.2 加工方案的设计 20

9.3 加工设备的选择 21

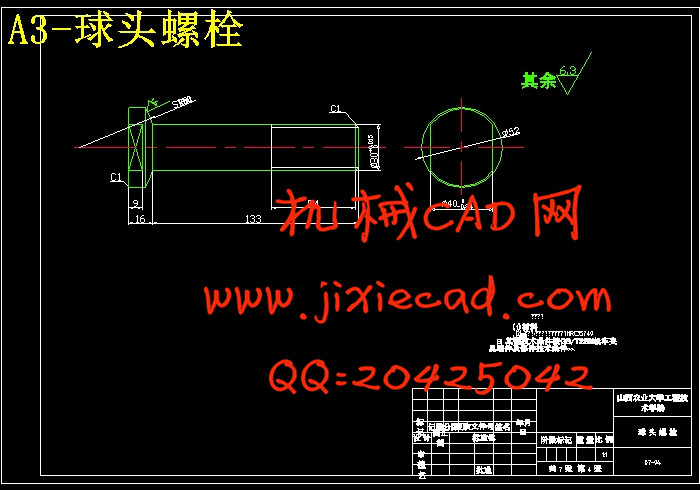

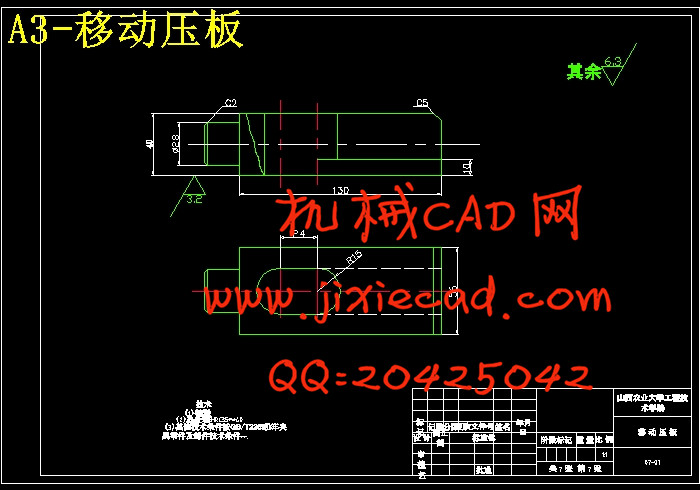

9.4 主轴转速,切削力及夹紧力的计算: 21

9.5 定位误差的分析 24

9.6 使用说明书 24

10结 论 25

11 标准化审核报告 26

11.1产品图样的审查 26

11.2 产品技术文件的审查 26

11.3 标准件的使用情况 26

11.4审查结论 27

致 谢 28

参考文献 29

摘要:机床夹具可根据其使用范围,分为通用夹具、专用夹具、组合夹具、通用可调夹具和成组夹具等类型。机床夹具还可按其所使用的机床和产生加紧力的动力源等进行分类。根据所使用的机床可将夹具分为车床夹具、铣床夹具、钻床夹具(钻模)、镗床夹具(镗模)、磨床夹具和齿轮机床夹具等,根据产生加紧力的动力源可将夹具分为手动夹具、气动夹具、液压夹具、电动夹具、电磁夹具和真空夹具等

现代机床夹具的发展方向主要表现为标准化、精密化、高效化和柔性化等四个方面。

机床夹具是机械加工工艺系统的一个重要组成部分。为保证工件某工序的加工要求,必须使工件在机床上相对刀具的切削或成形运动处于准确的相对位置。当用夹具装夹加工一批工件时,是通过夹具来实现这一要求的。而要实现这一要求,又必须满足三个条件:

(1)一批工件在夹具中占有正确的加工位置;

(2)夹具装夹在机床上的准确位置;

(3)刀具相对夹具的准确位置。这里涉及了三层关系:零件相 对夹具,夹具相对于机床,零件相对于机床。工件的最终精度是由零件相对于机床获得的。所以“定位”也涉及到

三层关系:工件在夹具上的定位,夹具相对于机床的定位,而工件相对于机床的定位是间接通过夹具来保证的。工件定位以后必须通过一定的装置产生夹紧力把工件固定,使工件保持在准确定位的位置上,否则,在加工过程中因受切削力,惯性力等力的作用而发生位置变化或引起振动,破坏了原来的准确定位,无法保证加工要求。这种产生夹紧力的装置便是夹紧装置。

关键字: 工艺 定位 夹紧力 精度

Cylinder block milling process and hydraulic clamping fixture

Summary

Fixture can be used in accordance with its scope, is divided into general-purpose fixtures, special fixtures, modular fixture, universal adjustable jig and fixture, such as the type of group. Fixture can also be used in accordance with its machine tools and power have stepped up the power source, such as classification. According to the machine tool can be used lathe fixture into fixtures, milling fixtures, drilling fixtures (Jig), Jig boring machine (boring mode), and gear grinding machine tool fixture fixture and so on, have stepped up force in accordance with the power source can be divided into fixture manual fixture, pneumatic fixtures, hydraulic fixtures, electrical fixtures, electromagnetic and vacuum fixture such as fixture

The development of modern machine tool fixture is mainly expressed in the direction of standardization, precision, and high-performance and flexible, and so on four aspects.

Fixture system, the machining process is an important part. In order to ensure a process of workpiece processing the request must be made on the workpiece in the machine tool relative movement of the cutting or forming in a precise relative position. When processing a number of workpiece clamping fixture, the fixture is required to achieve this. To achieve this requirement, it must meet three conditions:

(1) a number of fixture holds the workpiece in the correct location of the processing;

(2) clamping fixture in the exact location of the machine;

(3) an accurate tool fixture relative position. The relationship between the three involved here: the relative fixture components, fixture relative to machine tools, machine tool parts in relation to. The ultimate accuracy of the workpiece is compared with the machine tool parts obtained. Therefore, the "positioning" also involves

Three relations: on the workpiece in the fixture positioning, machine tool fixture relative to the positioning of the workpiece relative to the positioning of machine tools is indirect through the fixture to be guaranteed. After the workpiece positioning device must have a certain amount of clamping force to the workpiece fixed to the workpiece to maintain the accurate position location, otherwise, in the process due to the cutting force, inertial force and the occurrence of force caused by vibration or changes in location undermine the accuracy of the original position, can not guarantee that the processing requirements. Such devices have a clamping force is the clamping device.

Keywords Technology Positioning Clamping force Accuracy.

目录

1 引言 4

2设计任务书 5

2.1对机床夹具的基本要求 5

2.2夹具设计的工作步骤 5

3 机床夹具设计原理 6

3.1 夹具 7

3.1.1机床夹具的概念 7

3.1.2机床夹具的分类 7

3.1.3机床夹具的组成 7

3.2定位基准 7

3.3工件在夹具中的定位 8

3.3.1六点定位原理 8

3.3.2支承点与定位元件 9

3.3.3完全定位与不完全定位 10

3.3.4欠定位与过定位 10

3.4组合夹具和随行夹具 11

3.4.1组合夹具 11

3.4.2随行夹具 11

3.5夹具定位误差分析计算 11

4零件的工艺分析 11

4.1平面度分析 12

4.2 表面粗糙度 12

5毛坯的制造形式 12

6铣削方式的选择 12

6.1端面铣 12

6.2周边铣削 13

6.3 端面铣削和周边铣削的比较 13

6.4端面铣削时的顺铣与逆铣 14

6.5对称铣削 14

6.6非对称铣削 14

7 刀具的选择 15

7.1基本要求 15

7.1.1硬度 15

7.1.2韧性和强度 15

7.1.3铣刀切削部分的材料的要求 15

7.2常用材料 15

7.2.1高速工具钢(高速钢和锋钢等) 16

7.2.2硬质合金 16

8铣削用量 17

8.1每齿进给量的选择 17

8.2铣削速度的选择 18

8.3切削液 18

8.4.切削液的种类 19

8.5 切削液的选用 19

8.6选择测量方法 19

9夹具设计 20

9.1 基面的选择 20

9.2 加工方案的设计 20

9.3 加工设备的选择 21

9.4 主轴转速,切削力及夹紧力的计算: 21

9.5 定位误差的分析 24

9.6 使用说明书 24

10结 论 25

11 标准化审核报告 26

11.1产品图样的审查 26

11.2 产品技术文件的审查 26

11.3 标准件的使用情况 26

11.4审查结论 27

致 谢 28

参考文献 29