设计简介

摘 要

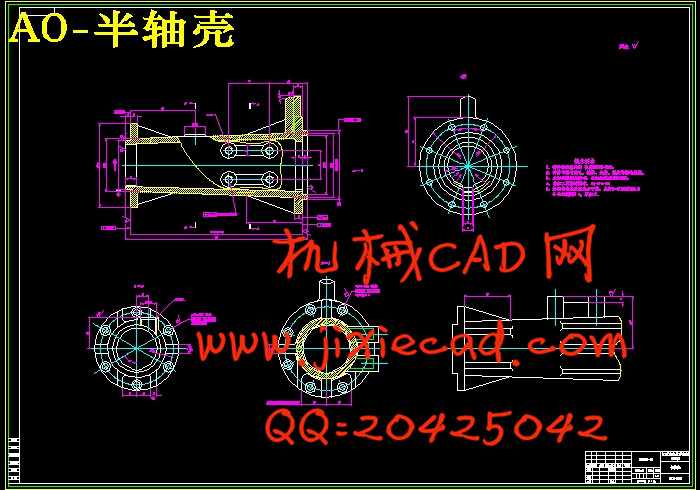

机床夹具是在金属切削加工中,用以准确地确定工件位置,并将其牢固地夹紧,以接受加工的工艺设备. 本着夹得快,夹得牢,夹得准的设计原则和在经济,高效的市场观念指导下进行本次 设计。 汽车半轴壳是汽车的重要部件之一。它既要承受车体和车载的全部质量,还要承受汽车在行驶过程中由于道路不平而引起的冲击力和扭矩,并要保证在行驶过程中不发生变形,而半轴在其内旋转自如。由拖拉机半轴壳零件图可知零件的基本结构和加工要求。该工件铸成后要达到图纸所示的加工要求要分三阶段完成,第一阶段需车削四个端面和两个外圆;车削后第二阶段铣削三个端面,其中两个是为了钻孔而做的前期工作,而有10度倾角要求的端面是零件结构的要求。完成前两阶段加工后再对两个端面钻通孔,各端面孔的位置要求为均布。据些分析设计铣床夹具。

关键词: 铣削 夹具 工件 定位 精度

Tractor rear axle shaft housing milling jig design

The engine bed jig is in the metal machining, with by accurately the definite work piece position, and its clamps reliably, accepts the processing the process unit. In line with clamps quickly, clamps the jail, clamps the accurate principle of design and in the economy, under the highly effective market idea instruction carries on this graduation project. The automobile rear axle shaft housing is one of automobile important parts.It already must withstand the complete quality which the chassis and the vehicle carry, but also must withstand the automobile in the travel process because the path does not put down the impulse and the torque which causes, and must guarantee does not have the distortion in the travel process, but the rear axle revolves in among them freely.May know the components by the tractor half axle sleeve detail drawing the basic structure and the processing request.After this work piece casts must achieve the blueprint shows the processing request must divide three stages to complete, the first stage needs the turning four end surfaces and two outer annuluses. After the turning the second stage milling three end surfaces, but has 10 degree inclination angle request end surface is the components structure request.After completes the first two stage processing to drill through the hole again to two end surfaces, various ends face position request is the even cloth.According to analysis design milling jig.

Key words: Milling jig work piece pointing accuracy

目录

1绪论 1

1.1前 言 1

1.2 课题总体任务概述 1

2 工件的加工工艺分析 4

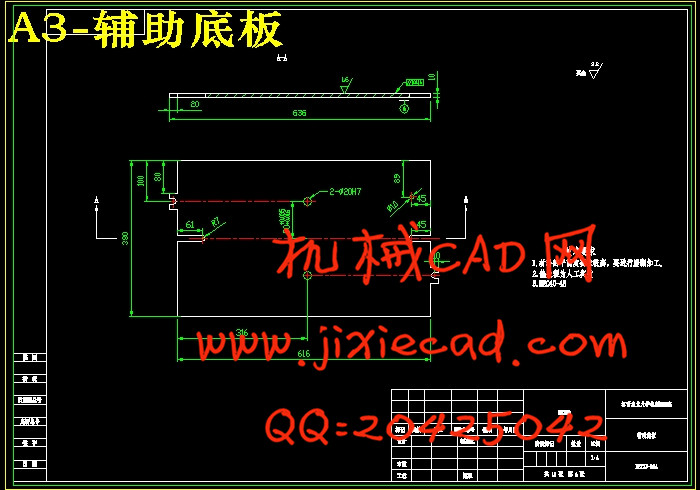

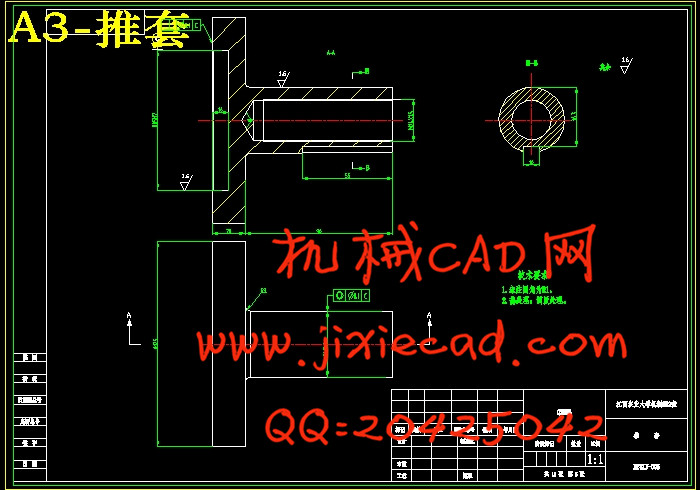

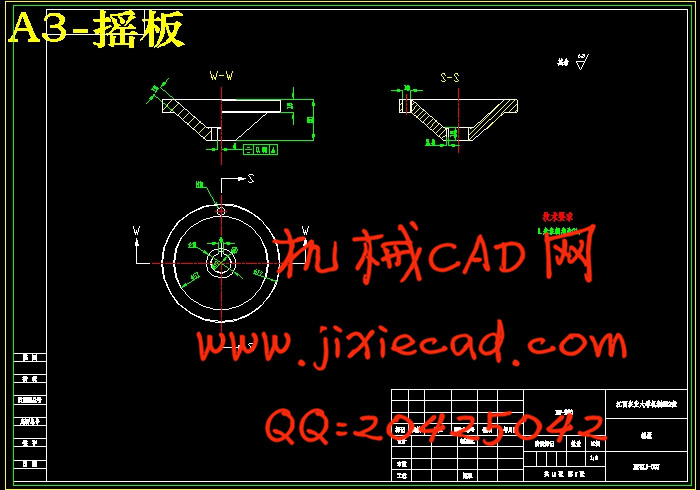

3.夹具的结构设计 5

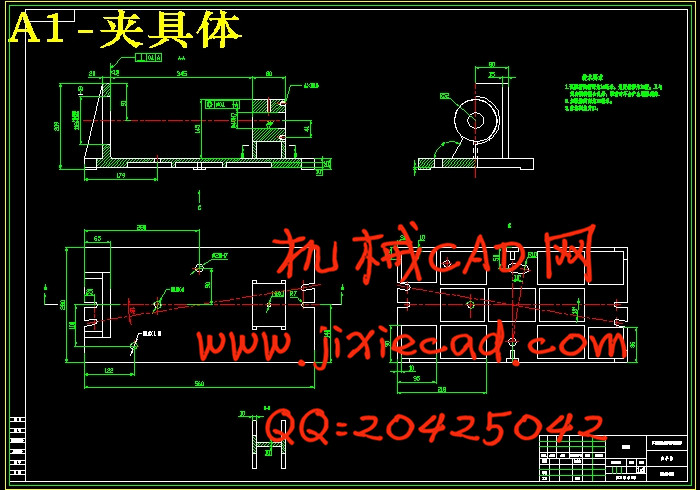

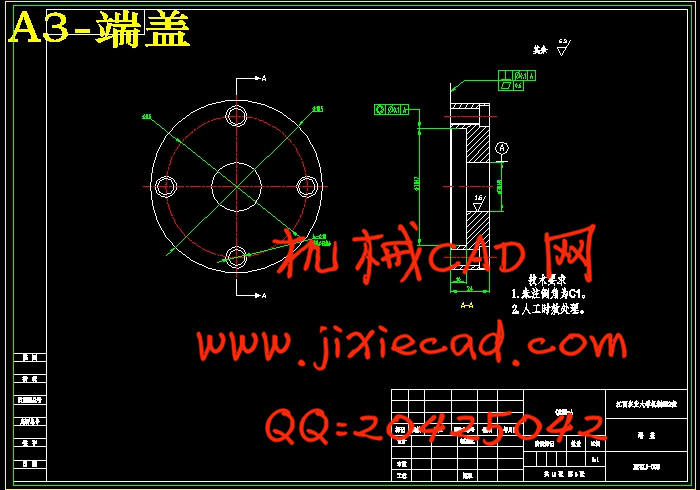

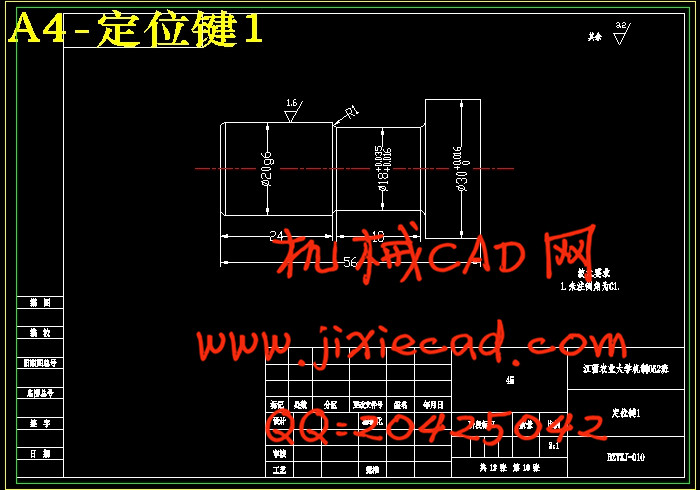

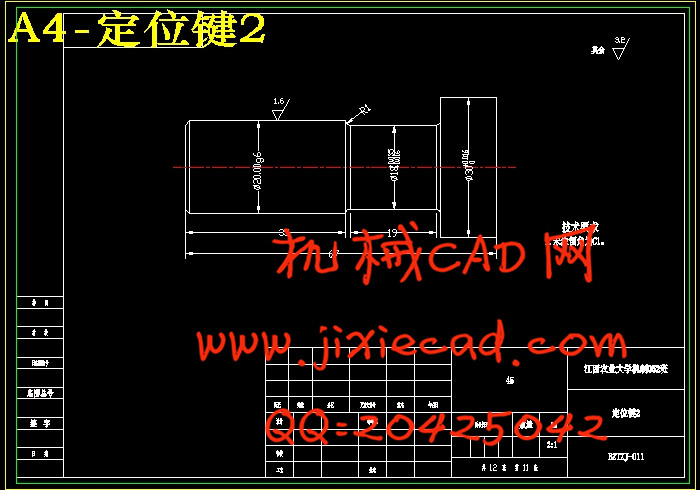

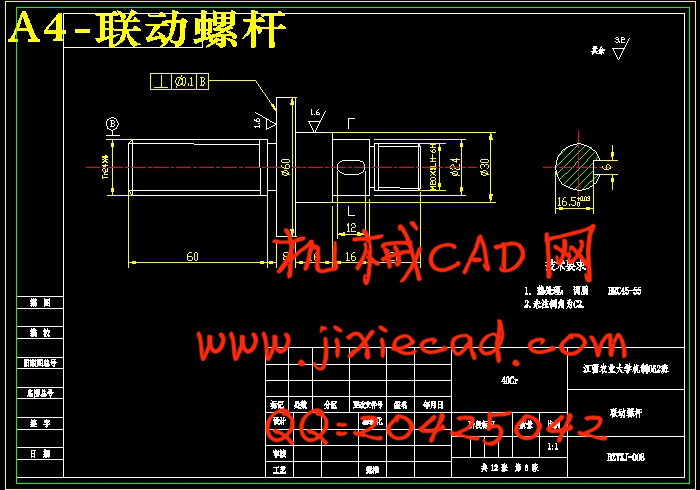

3.1定位方案选择及定位元件设计 5

3.2定位误差分析 7

3.3夹具对定方案的确定 8

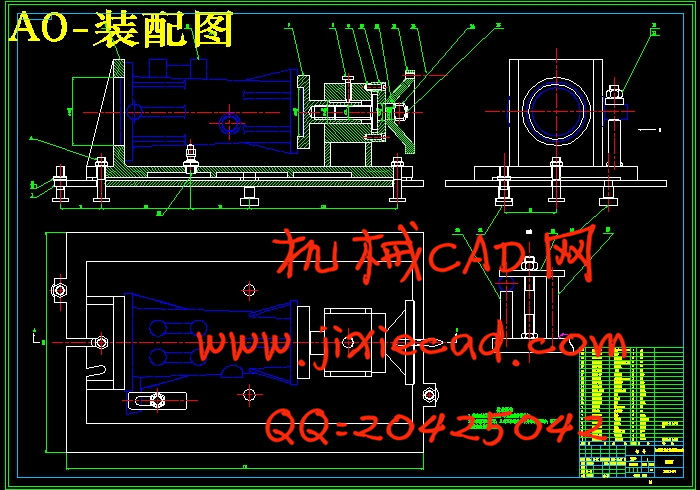

4.绘制夹具总图(见图纸) 9

4.1铣削力的计算 9

4.1.1圆盘铣刀…………………………………………………………………………….9

4.1.2粗齿锥柄立铣刀…………………………………………………………………...10

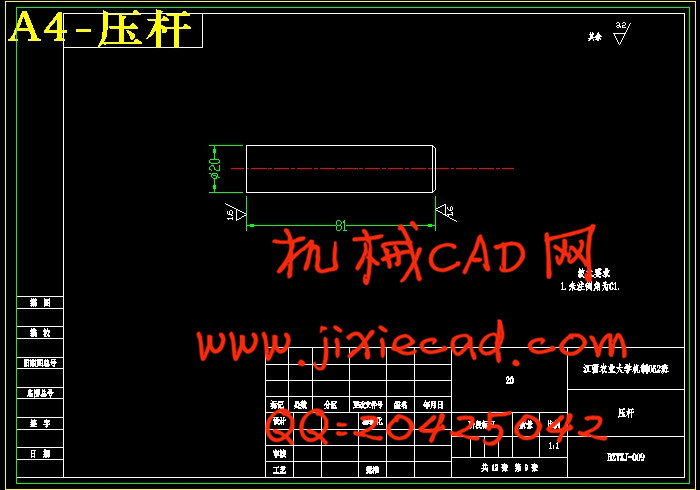

4.2夹紧力的计算 10

5. 确定夹具的主要尺寸,公差及技术要求 12

5.1 夹具总图上应标尺寸,公差 12

5.2 夹具总图应标注的技术条件 12

6.总结 13

7.参考文献 14

8.致谢 15

机床夹具是在金属切削加工中,用以准确地确定工件位置,并将其牢固地夹紧,以接受加工的工艺设备. 本着夹得快,夹得牢,夹得准的设计原则和在经济,高效的市场观念指导下进行本次 设计。 汽车半轴壳是汽车的重要部件之一。它既要承受车体和车载的全部质量,还要承受汽车在行驶过程中由于道路不平而引起的冲击力和扭矩,并要保证在行驶过程中不发生变形,而半轴在其内旋转自如。由拖拉机半轴壳零件图可知零件的基本结构和加工要求。该工件铸成后要达到图纸所示的加工要求要分三阶段完成,第一阶段需车削四个端面和两个外圆;车削后第二阶段铣削三个端面,其中两个是为了钻孔而做的前期工作,而有10度倾角要求的端面是零件结构的要求。完成前两阶段加工后再对两个端面钻通孔,各端面孔的位置要求为均布。据些分析设计铣床夹具。

关键词: 铣削 夹具 工件 定位 精度

Tractor rear axle shaft housing milling jig design

The engine bed jig is in the metal machining, with by accurately the definite work piece position, and its clamps reliably, accepts the processing the process unit. In line with clamps quickly, clamps the jail, clamps the accurate principle of design and in the economy, under the highly effective market idea instruction carries on this graduation project. The automobile rear axle shaft housing is one of automobile important parts.It already must withstand the complete quality which the chassis and the vehicle carry, but also must withstand the automobile in the travel process because the path does not put down the impulse and the torque which causes, and must guarantee does not have the distortion in the travel process, but the rear axle revolves in among them freely.May know the components by the tractor half axle sleeve detail drawing the basic structure and the processing request.After this work piece casts must achieve the blueprint shows the processing request must divide three stages to complete, the first stage needs the turning four end surfaces and two outer annuluses. After the turning the second stage milling three end surfaces, but has 10 degree inclination angle request end surface is the components structure request.After completes the first two stage processing to drill through the hole again to two end surfaces, various ends face position request is the even cloth.According to analysis design milling jig.

Key words: Milling jig work piece pointing accuracy

目录

1绪论 1

1.1前 言 1

1.2 课题总体任务概述 1

2 工件的加工工艺分析 4

3.夹具的结构设计 5

3.1定位方案选择及定位元件设计 5

3.2定位误差分析 7

3.3夹具对定方案的确定 8

4.绘制夹具总图(见图纸) 9

4.1铣削力的计算 9

4.1.1圆盘铣刀…………………………………………………………………………….9

4.1.2粗齿锥柄立铣刀…………………………………………………………………...10

4.2夹紧力的计算 10

5. 确定夹具的主要尺寸,公差及技术要求 12

5.1 夹具总图上应标尺寸,公差 12

5.2 夹具总图应标注的技术条件 12

6.总结 13

7.参考文献 14

8.致谢 15