设计简介

机械加工工艺流程设计能力是从事机械制造专业的科研、工程技术人员必须具备的基本素质之一。机械加工工艺流程设计作为高等工科院校教学的基本科目,在实践中占有极其重要的地位,工艺流程设计在加深对专业课程基本理论的理解和加强对解决工程实际问题的能力培养方面所发挥的作用是显而易见的。

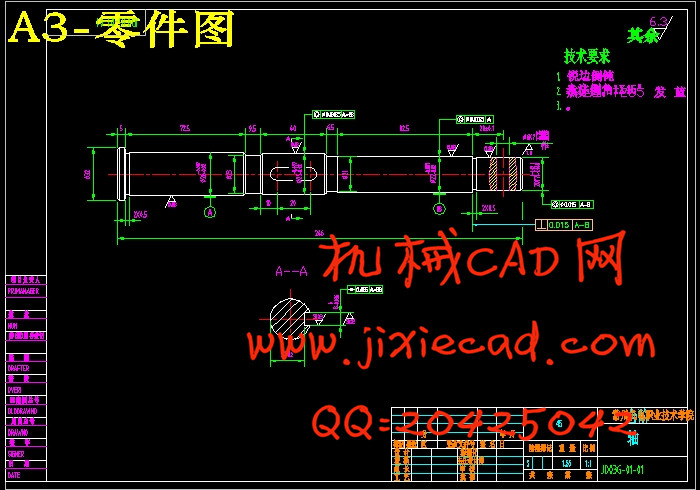

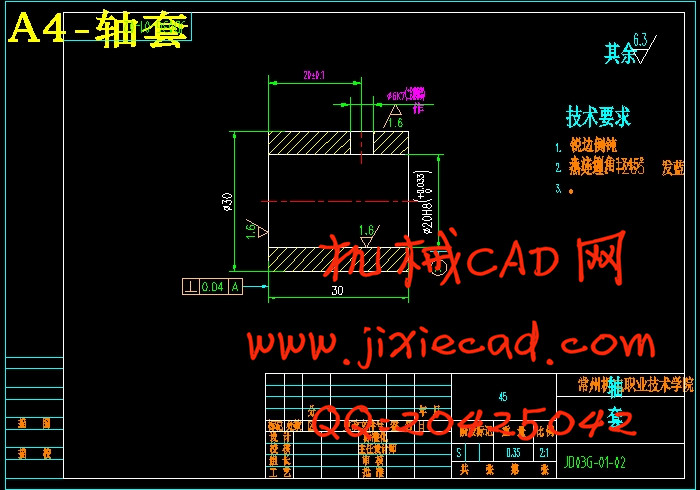

本设计是台阶轴的加工工艺流程设计,其结构虽然规则,但是精度要求比较高,所以工艺要求比较复杂。需要粗车、精车、铣车、磨销,其中精车是加工关键。车床加工工艺是以机械制造中的工艺基本理论为基础,结合车床的特点,综合运用多方面的知识解决车床加工过程中面临的工艺问题。

工艺流程是保证机械产品高质量、低成本的一种重要的工艺依据,工艺流程设计在机械加工中就显得更为突出,因此中小型零件加工的流程设计常被选作毕业设计的主要内容之一。

关键词:传动轴,工艺流程,粗车

Abstract:

The ability of machine-finishing process design is one of the basic abilities which the machinery manufacture specialized scientific researcher, engineers and technicians are engaged in must be have.The machine-finishing process design as a basical subject that all the higher engineering course colleges and universities teaching took,holding the extremely important position in the practice.The machine-finishing process design has a significantly function which is deepening on the specialized curriculum elementary theory understanding and strengthening the ability to solve the function that the project actual problem.

This design is drive shaft's machine-finishing process design, it’s structure is rule, but the accuracy requirement is quite high.needing rough turning, Finish turning,milling, grinding, and rough turning is the key. Finish processing machinery is in the process based on the basic theory, combining the characteristics of Lathe, comprehensive use of various aspects of knowledge to solve Lathe in the process of facing the problem.

The machine-finishing process design is an important craft basis that guarantee high grade, low cost machine-finishing. The process design appears more prominent in the machine-finishing,therefore middle and small scale components machine-finishing process design is selected frequently to do graduation project.

Keywords : drive shaft,technical process,rough turning

目录

1前 言 1

2 零件分析 2

§2.1 计算生产纲领,确定生产类型 2

§2.2轴类零件的作用、分类及技术要求 2

§2.3工艺分析 5

3 工艺流程设计 7

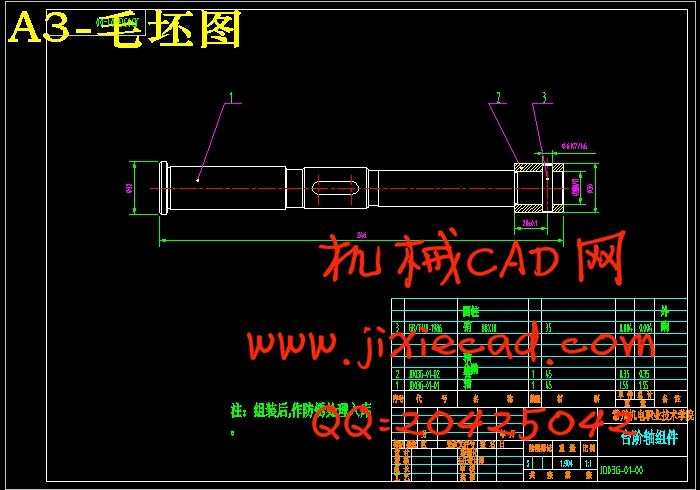

§3.1确定毛坯制造形式及尺寸 7

§3.2基准的选择 7

§3.2.1 粗基准的选择 7

§3.2.2 精基准的选择 7

§3.3主要工序加工方法 8

§3.4工艺流程的拟定 9

4 工序设计 13

§4.1选择加工设备和工艺设备 13

§4.1.1 选择机床 13

§4.1.2 选择夹具 13

§4.1.3 选择刀具 13

§4.1.4 选择量具 15

§4.2确定工序尺寸 15

结 论 16

致 谢 17

参考文献 18

本设计是台阶轴的加工工艺流程设计,其结构虽然规则,但是精度要求比较高,所以工艺要求比较复杂。需要粗车、精车、铣车、磨销,其中精车是加工关键。车床加工工艺是以机械制造中的工艺基本理论为基础,结合车床的特点,综合运用多方面的知识解决车床加工过程中面临的工艺问题。

工艺流程是保证机械产品高质量、低成本的一种重要的工艺依据,工艺流程设计在机械加工中就显得更为突出,因此中小型零件加工的流程设计常被选作毕业设计的主要内容之一。

关键词:传动轴,工艺流程,粗车

Abstract:

The ability of machine-finishing process design is one of the basic abilities which the machinery manufacture specialized scientific researcher, engineers and technicians are engaged in must be have.The machine-finishing process design as a basical subject that all the higher engineering course colleges and universities teaching took,holding the extremely important position in the practice.The machine-finishing process design has a significantly function which is deepening on the specialized curriculum elementary theory understanding and strengthening the ability to solve the function that the project actual problem.

This design is drive shaft's machine-finishing process design, it’s structure is rule, but the accuracy requirement is quite high.needing rough turning, Finish turning,milling, grinding, and rough turning is the key. Finish processing machinery is in the process based on the basic theory, combining the characteristics of Lathe, comprehensive use of various aspects of knowledge to solve Lathe in the process of facing the problem.

The machine-finishing process design is an important craft basis that guarantee high grade, low cost machine-finishing. The process design appears more prominent in the machine-finishing,therefore middle and small scale components machine-finishing process design is selected frequently to do graduation project.

Keywords : drive shaft,technical process,rough turning

目录

1前 言 1

2 零件分析 2

§2.1 计算生产纲领,确定生产类型 2

§2.2轴类零件的作用、分类及技术要求 2

§2.3工艺分析 5

3 工艺流程设计 7

§3.1确定毛坯制造形式及尺寸 7

§3.2基准的选择 7

§3.2.1 粗基准的选择 7

§3.2.2 精基准的选择 7

§3.3主要工序加工方法 8

§3.4工艺流程的拟定 9

4 工序设计 13

§4.1选择加工设备和工艺设备 13

§4.1.1 选择机床 13

§4.1.2 选择夹具 13

§4.1.3 选择刀具 13

§4.1.4 选择量具 15

§4.2确定工序尺寸 15

结 论 16

致 谢 17

参考文献 18