设计简介

摘 要

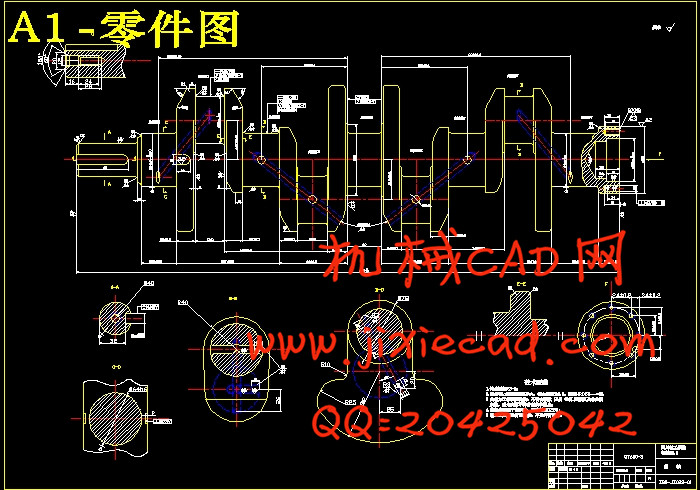

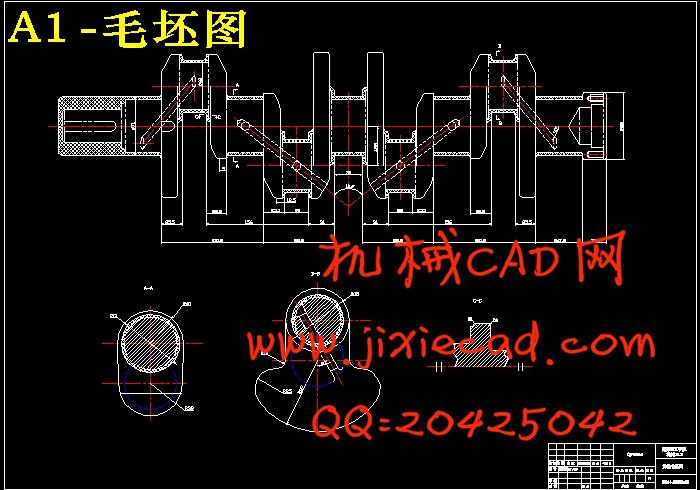

在这次 设计中,进行了曲轴的测绘及根据实物模型了解曲轴的外型和曲轴斜油孔的位置结构。本设计为四缸柴油机曲轴工艺工装设计:绘制曲轴零件图、确定加工方法、制定加工工艺、编制加工工序卡、曲轴斜油孔加工的工装设计。

曲轴由轴颈和轴柄构成。

曲轴是受冲击载荷、传递动力的重要零件,在五大件中最难以保证加工质量。由于曲轴工作条件恶劣,因此对曲轴材质以及毛坯加工技术、精度、表面粗糙度、热处理和表面强化、动平衡等要求都十分严格。如果其中任何一个环节质量没有得到保证,则可严重影响曲轴的使用寿命和整机的可靠性。

曲轴材质有球墨铸铁和钢两类。由于球墨铸铁的切削性能良好,可获得较理想的结构形状,并且和钢质曲轴一样可以进行各种热处理和表面强化处理来提高曲轴的抗疲劳强度、硬度和耐磨性。球墨铸铁曲轴成本只有调质钢曲轴成本的1/3左右,所以球墨铸铁曲轴在国内外得到了广泛应用。

关键词:曲轴 斜油孔 工装设计 可靠 疲劳强度 球墨铸铁

ABSTRACT

In this graduation project, has carried on the crank mapping and the basis working model understands the crank the outlook and the tune axle tilt oil hole position structure.This design is four cylinder diesel engine crank craft work clothes design: Plan crank detail drawing, determination processing method, formulation processing craft, establishment processing travel chart, tune axle tilt oil hole processing work clothes design.

The crank constitutes by the journal and the axis handle.

The crank is in the engine withstands the impact load, the transmission power important components, guarantees the processing quality most with difficulty in the engine five big-ticket items.Because the crank working condition is bad, therefore to the crank material quality as well as the semifinished materials processing technology, the precision, the surface roughness, the heat treatment and the surface strengthens, requests and so on transient equilibrium extremely is all strict.If any link quality has not obtained the guarantee, then may affect the crank seriously the service life and the complete machine reliability.

The crank material quality has the modular cast iron and the steel two kinds.Because the modular cast iron cutting value is good, may obtain the ideal structure shape, and may carry on each kind of heat treatment and superficial strengthening processing equally with the steel crank enhances the crank the anti-fatigue strength, degree of hardness and the resistance to wear.Modular cast iron crank cost only then about quenched and tempered steel crank cost 1/3, therefore the modular cast iron crank in domestic and foreign obtained the widespread application.

Key word: Cranks Slanting oil holes Work clothes designs Reliability Fatigue strength Modular cast irons.

目 录

中文摘要 Ⅰ在这次 设计中,进行了曲轴的测绘及根据实物模型了解曲轴的外型和曲轴斜油孔的位置结构。本设计为四缸柴油机曲轴工艺工装设计:绘制曲轴零件图、确定加工方法、制定加工工艺、编制加工工序卡、曲轴斜油孔加工的工装设计。

曲轴由轴颈和轴柄构成。

曲轴是受冲击载荷、传递动力的重要零件,在五大件中最难以保证加工质量。由于曲轴工作条件恶劣,因此对曲轴材质以及毛坯加工技术、精度、表面粗糙度、热处理和表面强化、动平衡等要求都十分严格。如果其中任何一个环节质量没有得到保证,则可严重影响曲轴的使用寿命和整机的可靠性。

曲轴材质有球墨铸铁和钢两类。由于球墨铸铁的切削性能良好,可获得较理想的结构形状,并且和钢质曲轴一样可以进行各种热处理和表面强化处理来提高曲轴的抗疲劳强度、硬度和耐磨性。球墨铸铁曲轴成本只有调质钢曲轴成本的1/3左右,所以球墨铸铁曲轴在国内外得到了广泛应用。

关键词:曲轴 斜油孔 工装设计 可靠 疲劳强度 球墨铸铁

ABSTRACT

In this graduation project, has carried on the crank mapping and the basis working model understands the crank the outlook and the tune axle tilt oil hole position structure.This design is four cylinder diesel engine crank craft work clothes design: Plan crank detail drawing, determination processing method, formulation processing craft, establishment processing travel chart, tune axle tilt oil hole processing work clothes design.

The crank constitutes by the journal and the axis handle.

The crank is in the engine withstands the impact load, the transmission power important components, guarantees the processing quality most with difficulty in the engine five big-ticket items.Because the crank working condition is bad, therefore to the crank material quality as well as the semifinished materials processing technology, the precision, the surface roughness, the heat treatment and the surface strengthens, requests and so on transient equilibrium extremely is all strict.If any link quality has not obtained the guarantee, then may affect the crank seriously the service life and the complete machine reliability.

The crank material quality has the modular cast iron and the steel two kinds.Because the modular cast iron cutting value is good, may obtain the ideal structure shape, and may carry on each kind of heat treatment and superficial strengthening processing equally with the steel crank enhances the crank the anti-fatigue strength, degree of hardness and the resistance to wear.Modular cast iron crank cost only then about quenched and tempered steel crank cost 1/3, therefore the modular cast iron crank in domestic and foreign obtained the widespread application.

Key word: Cranks Slanting oil holes Work clothes designs Reliability Fatigue strength Modular cast irons.

目 录

英文摘要 .............Ⅱ

第1章 设计的相关知识...........................................................................................1

1.1 毕业设计的目的、要求和内容 1

1.1.1 毕业设计的目的 1

1.1.2 毕业设计的基本要求及主要内容 1

1.2 毕业设计的步骤 2

1.2.1机械加工工艺规程设计 2

第二章 零件的分析 3

2.1 零件的作用及分析 3

2.2 曲轴的制造技术及工艺进展 ....3

2.2.1 曲轴的毛坯制造技术......................................................................................................3

2.2.2 机械加工技术..................................................................................................................4

2.2.3 热处理和表面强化处理技术..........................................................................................4

第三章 零件的工艺路线及加工工艺.................................................................................5

3.1拟定工艺路线应注意的事项...............................................................................................5

3.2 零件的工艺路线..................................................................................................................6

3.2.1 基准的选择.......................................................................................................................6

3.2.2 曲轴工艺路线内容...........................................................................................................6

3.2.3 零件加工工序内容...........................................................................................................7

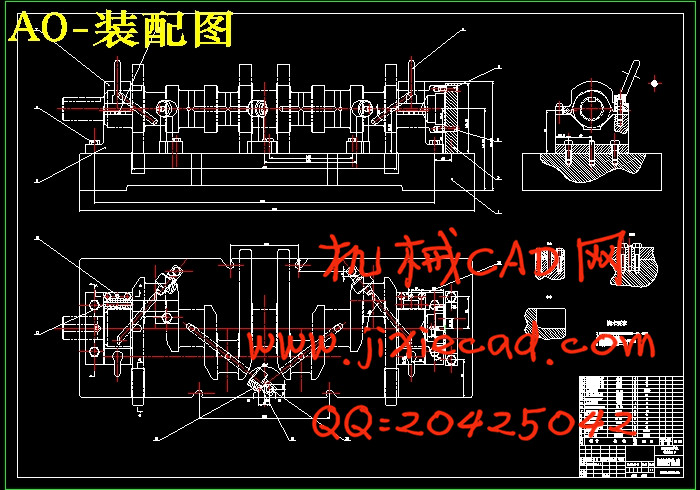

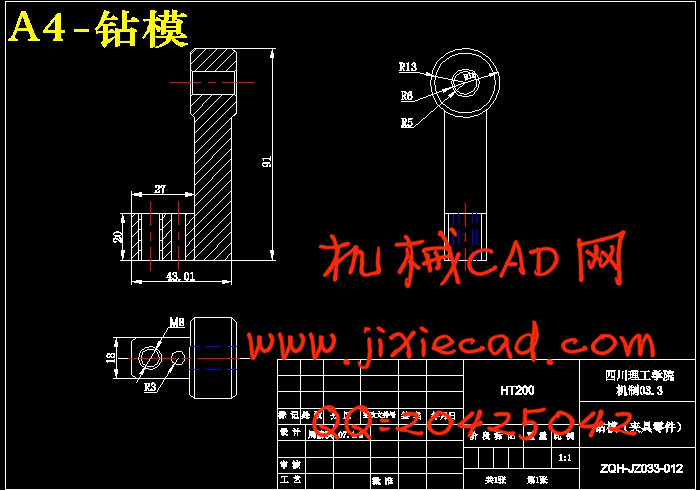

第四章 专用夹具设计及撰写说明.......................................................................................35

4.1 专用夹具设计......................................................................................................................35

4.1.1 设计说明..........................................................................................................................35

4.1.2 夹具设计分析..................................................................................................................35

4.2 撰写说明书应注意的事项..................................................................................................36

第五章 结 论............................................................................................................................37

参考文献........................................................................................................................38

致 谢..........................................................................................................................39