设计简介

摘 要

本文主要介绍了R180柴油机曲轴工艺设计及其中两道工序的夹具设计。本文作者是在保证产品质量、提高生产率、降低成本、充分利用现有生产条件、保证工人具有良好而安全劳动条件的前提下进行设计的。在工艺设计中,作者结合实际进行理论设计,对曲轴传统生产工艺进行了改进,优化了工艺过程和工艺装备,使曲轴的生产加工更经济、合理。在夹具设计部分,作者在收集加工所用机床、刀具及辅助工具等有关资料后,对工件材料、结构特点、技术要求及工艺分析的基础上,按照夹具设计步骤设计出符合曲轴生产工艺及夹具制造要求的夹具。

关键词:柴油机 曲轴 工艺 夹具

Keywords : Diesel engine Crankshaft Technology Jig

目 录

摘要 1

摘要 1

Abstract 2

Abstract 2

0 引言 1

0 引言 1

1 R180柴油机曲轴工艺设计 3

1 R180柴油机曲轴工艺设计 3

1.1 分析零件图 3

1.1 分析零件图 3

1.2 确定生产类型 3

1.2 确定生产类型 3

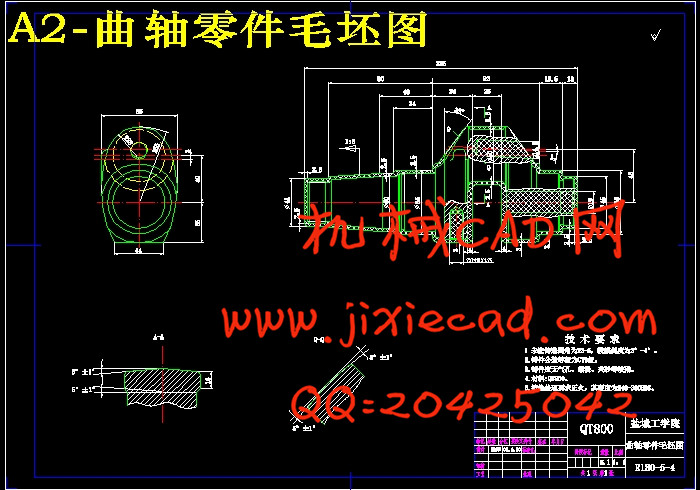

1.3 确定毛坯 3

1.3 确定毛坯 3

1.4 机械加工工艺过程设计 3

1.4 机械加工工艺过程设计 3

1.5 选择加工设备与工艺装备 6

1.5 选择加工设备与工艺装备 6

1.6 确定工序尺寸 7

1.6 确定工序尺寸 7

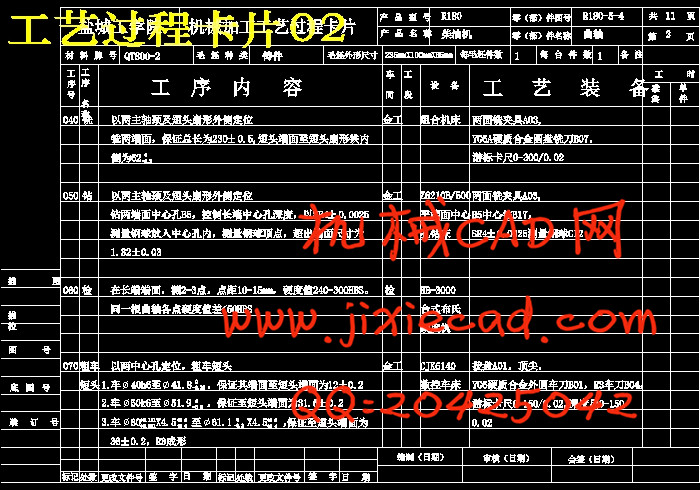

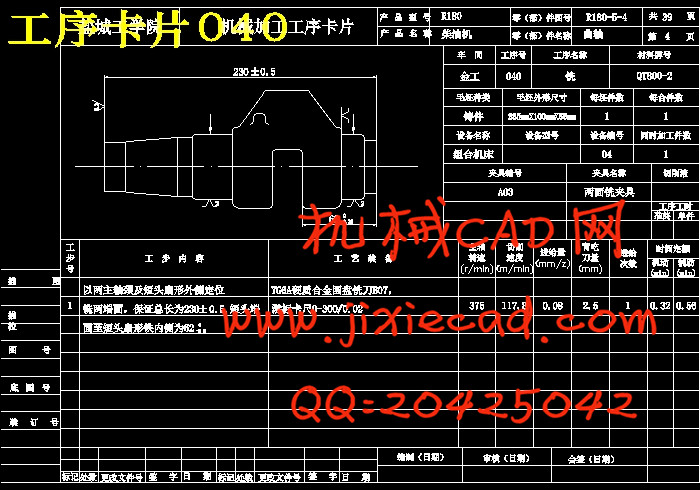

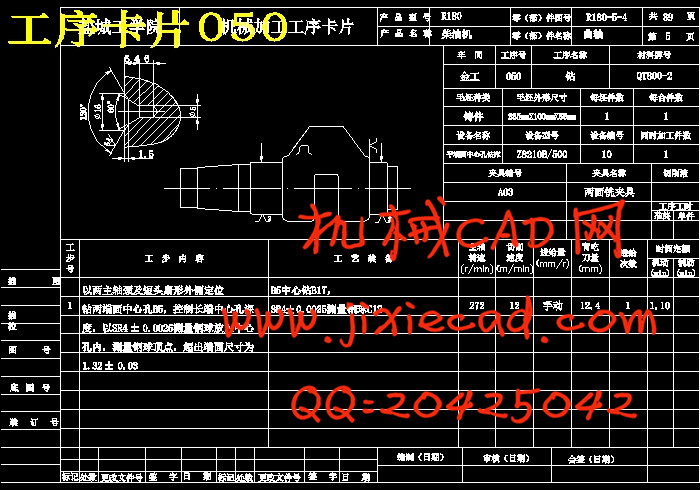

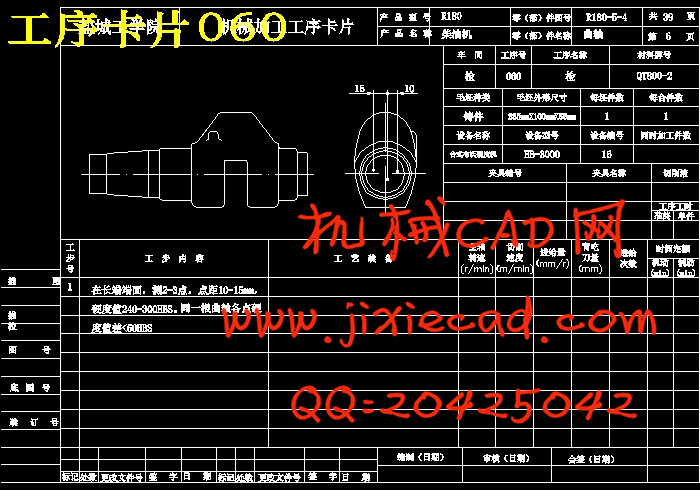

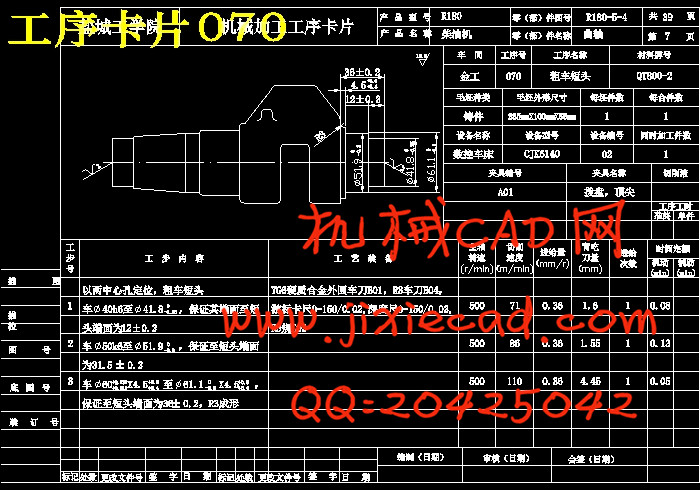

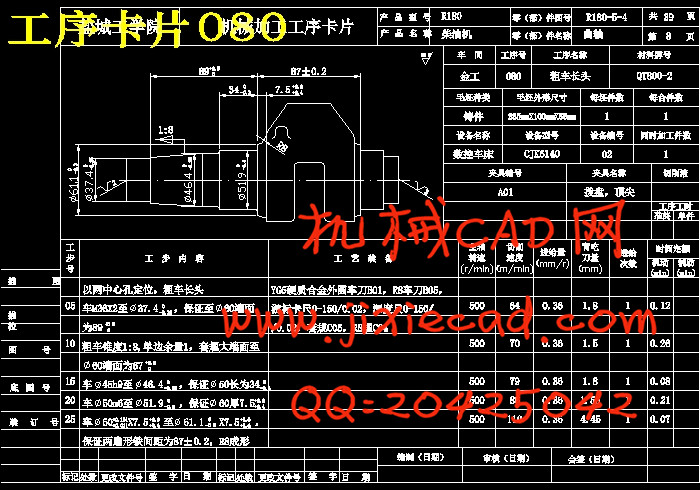

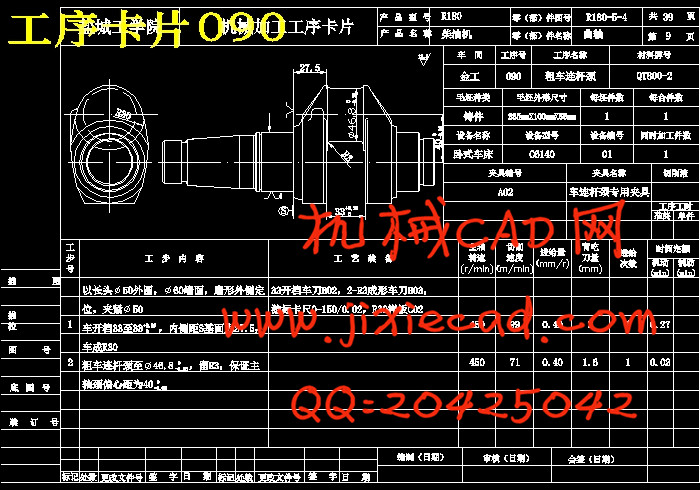

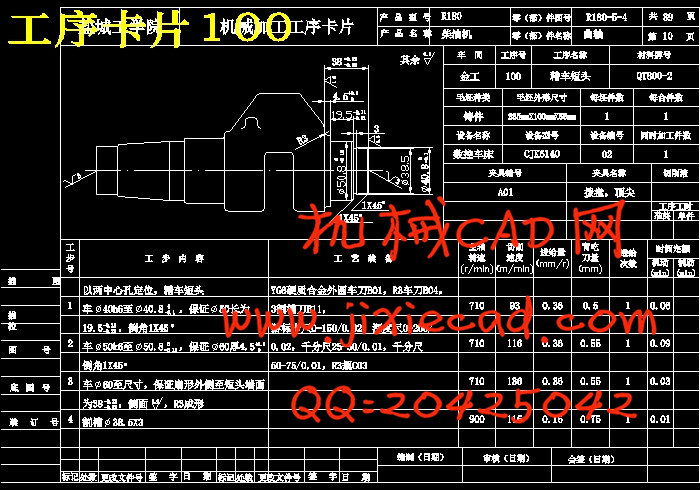

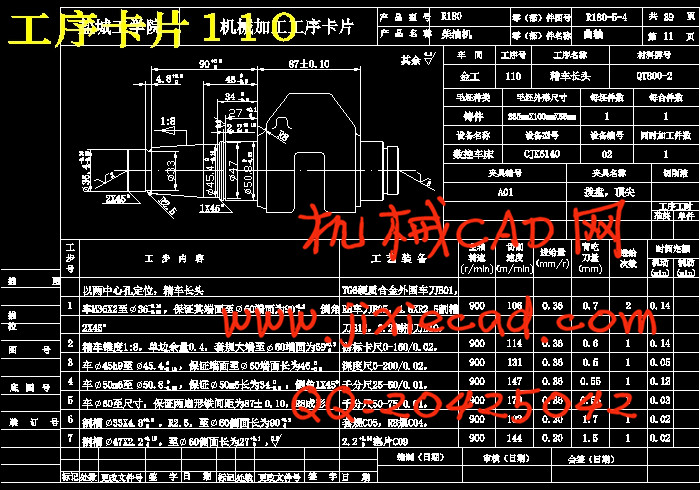

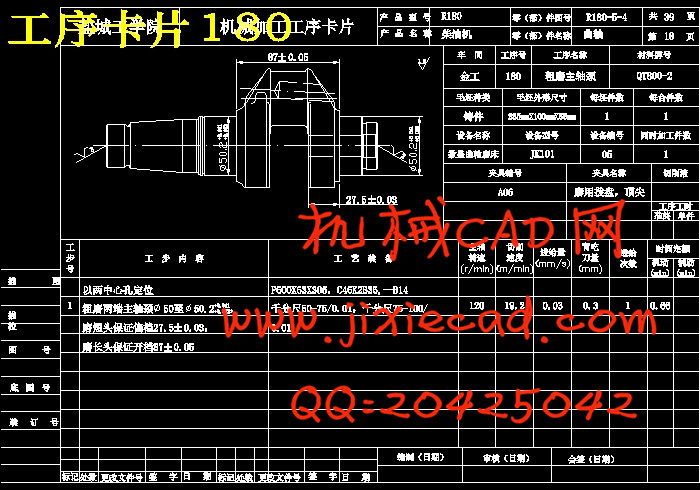

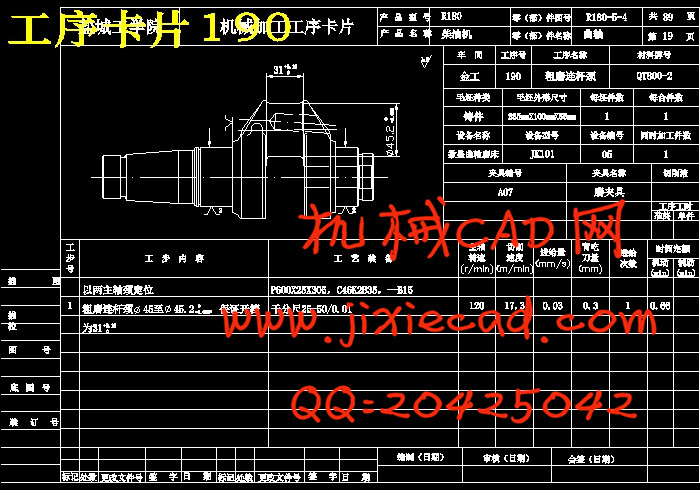

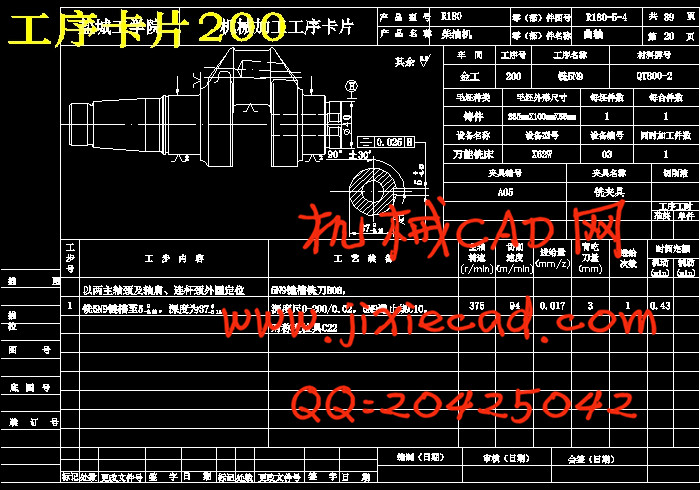

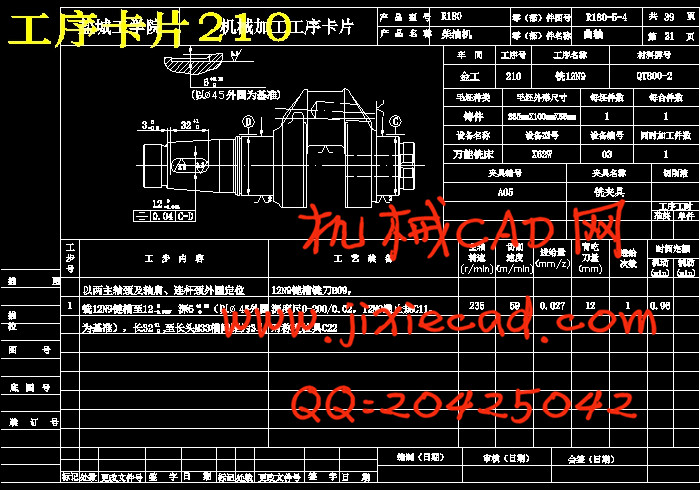

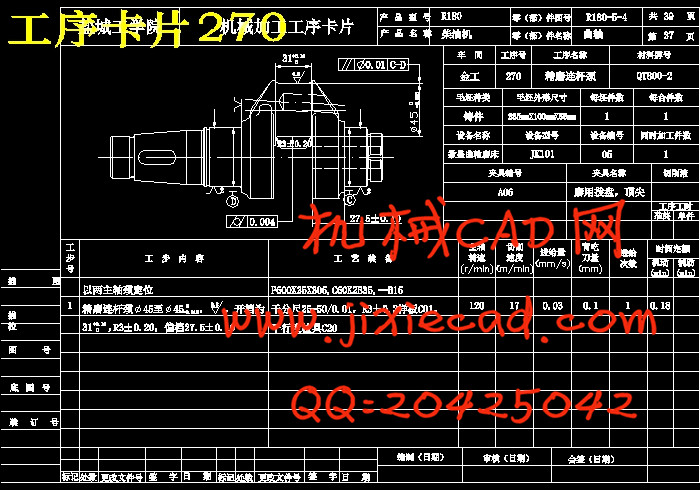

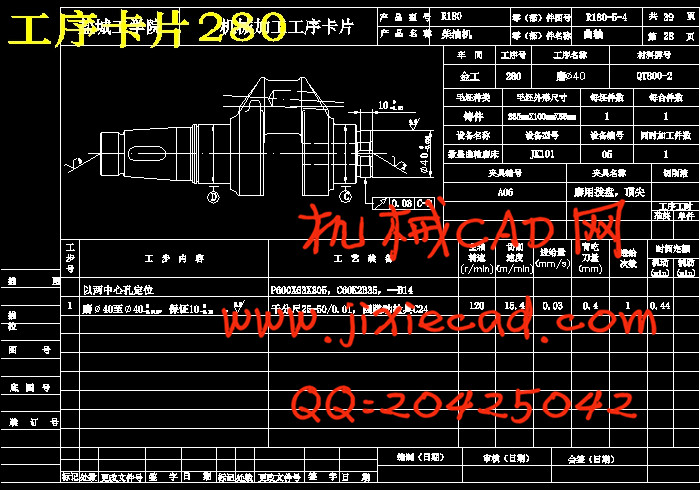

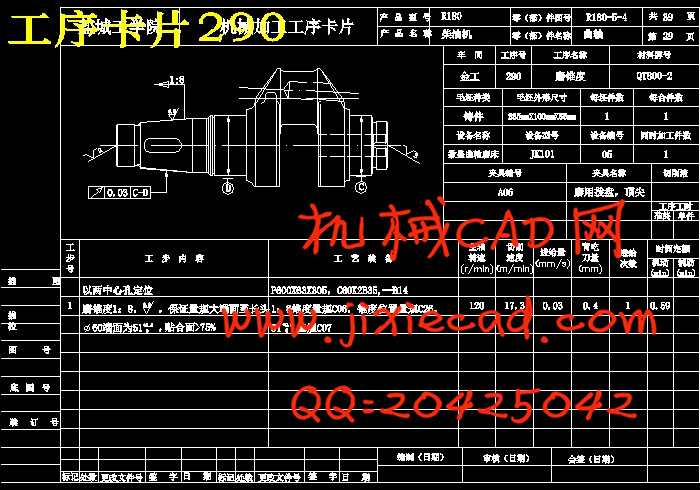

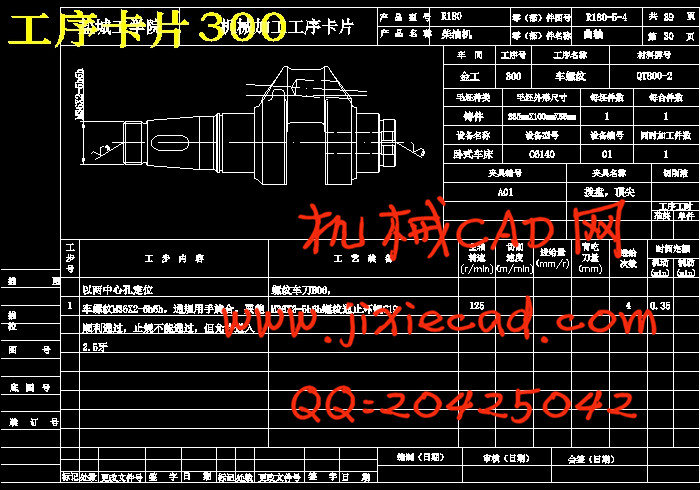

1.7 确定切削用量及时间定额 9

1.7 确定切削用量及时间定额 9

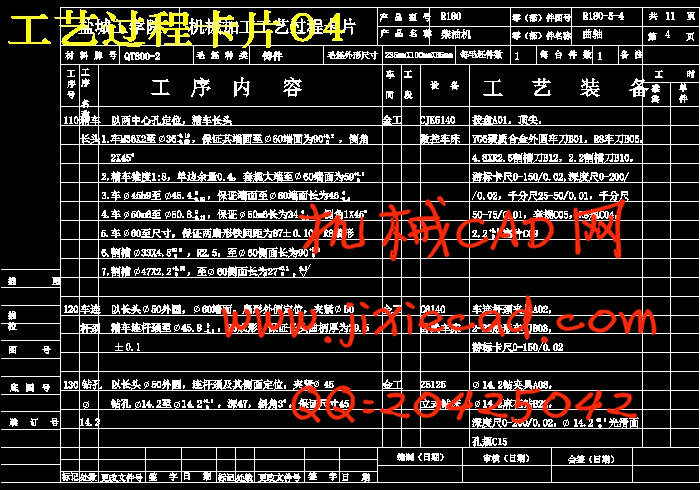

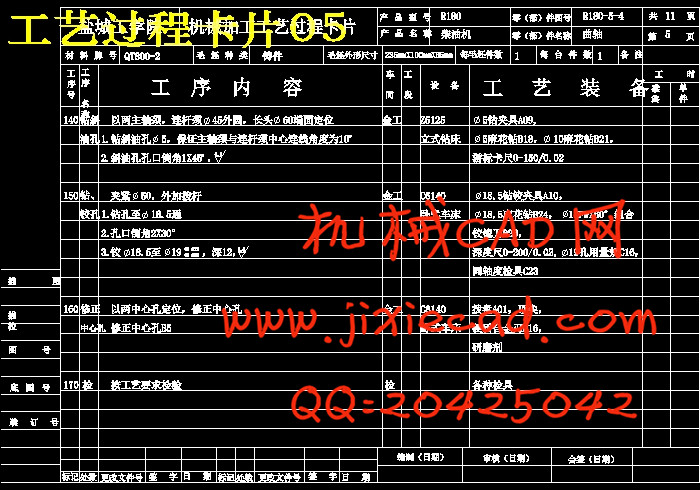

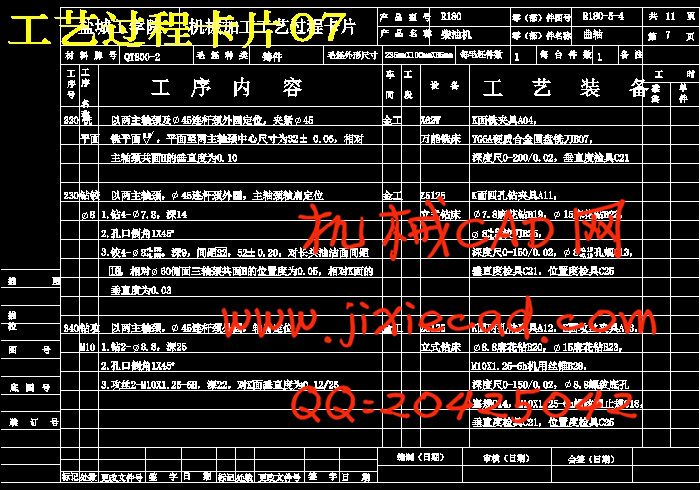

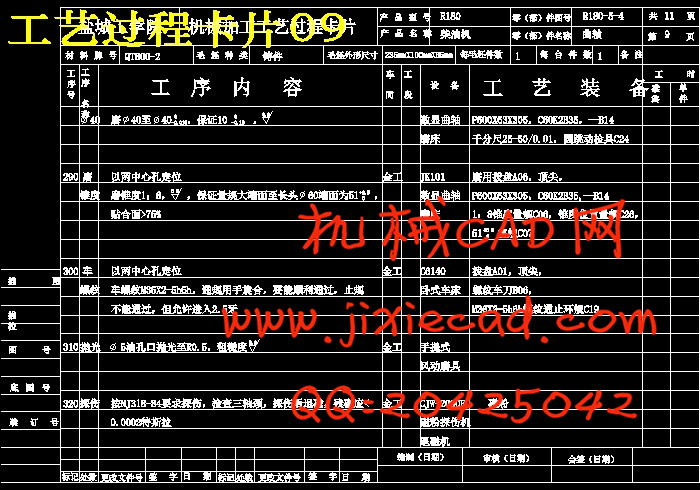

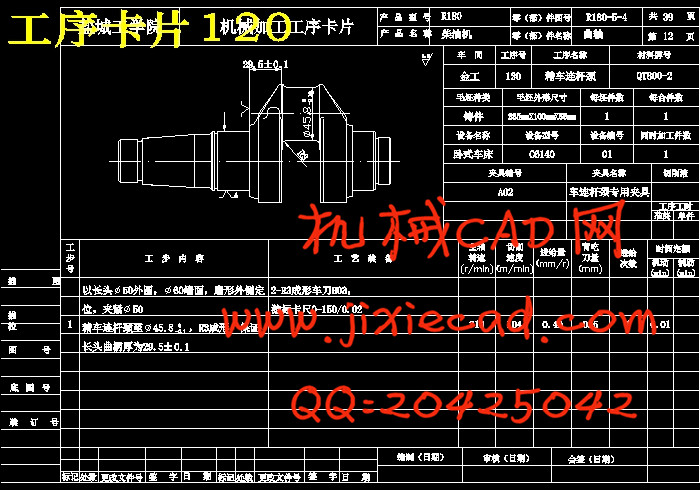

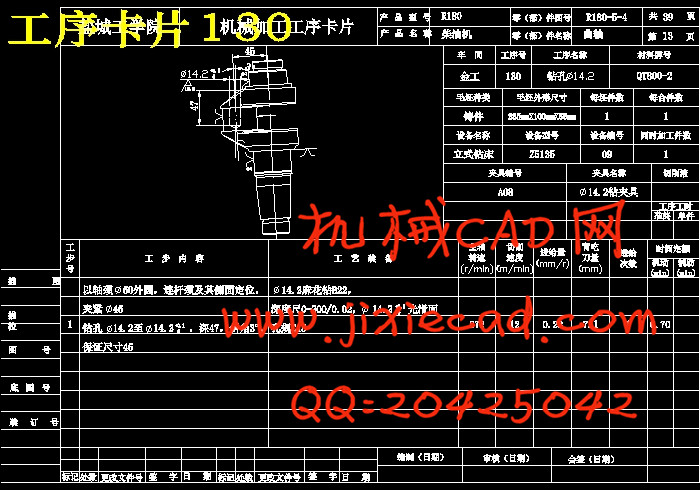

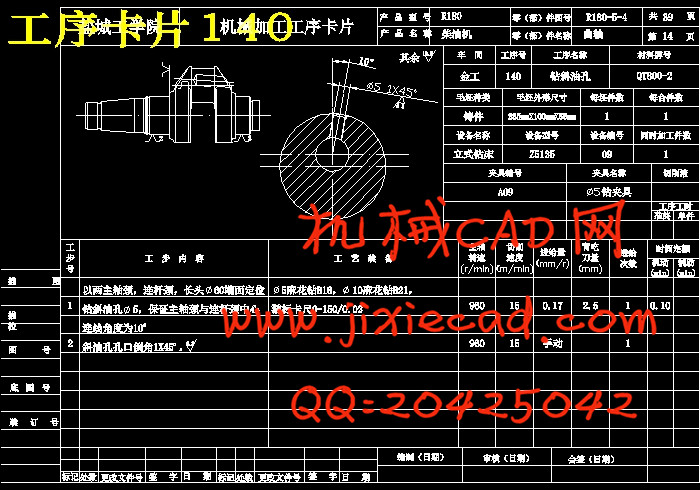

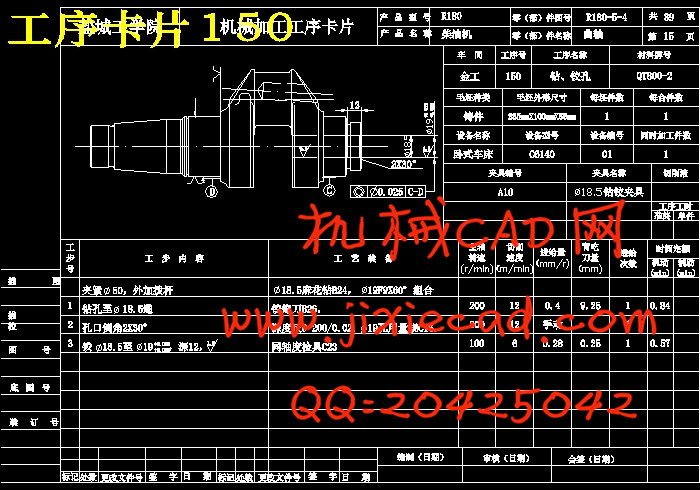

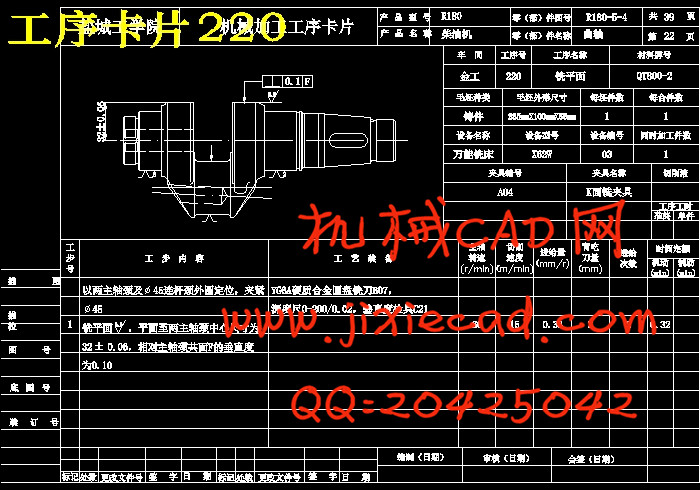

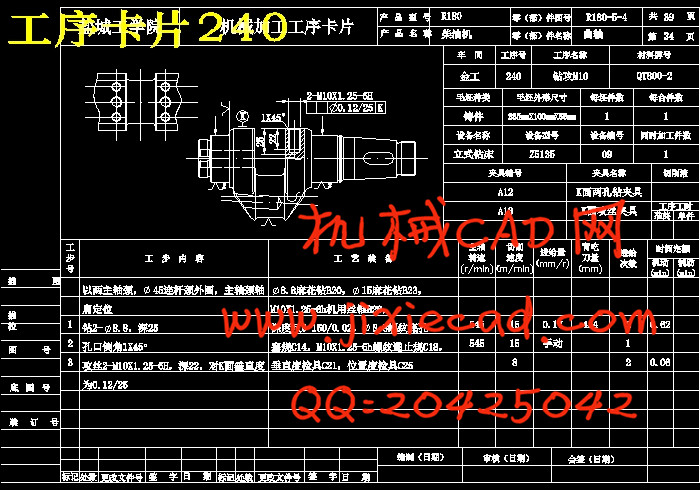

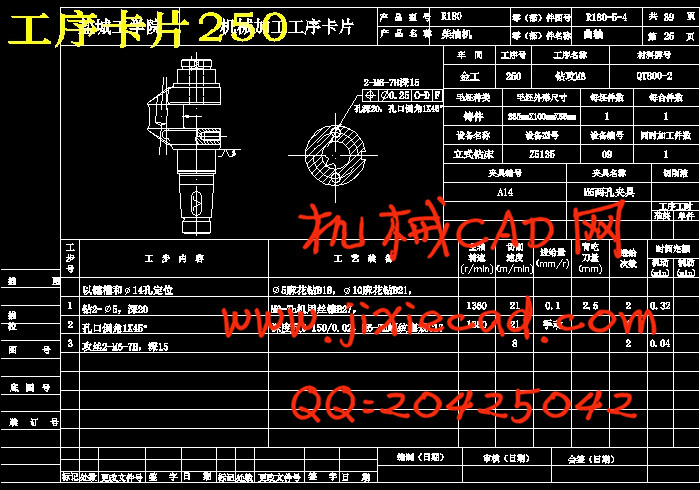

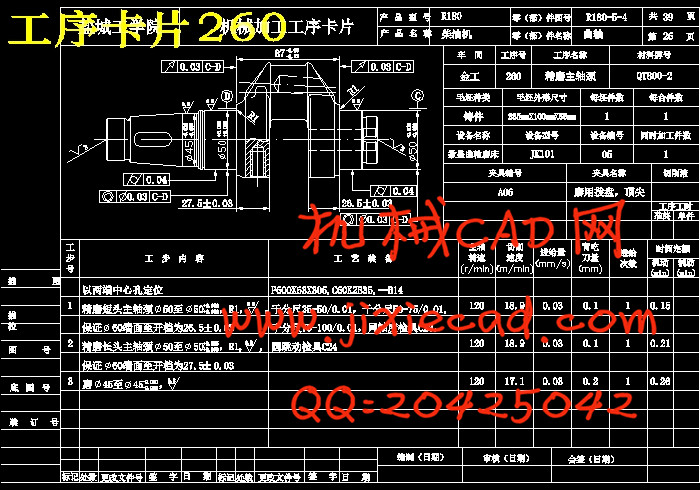

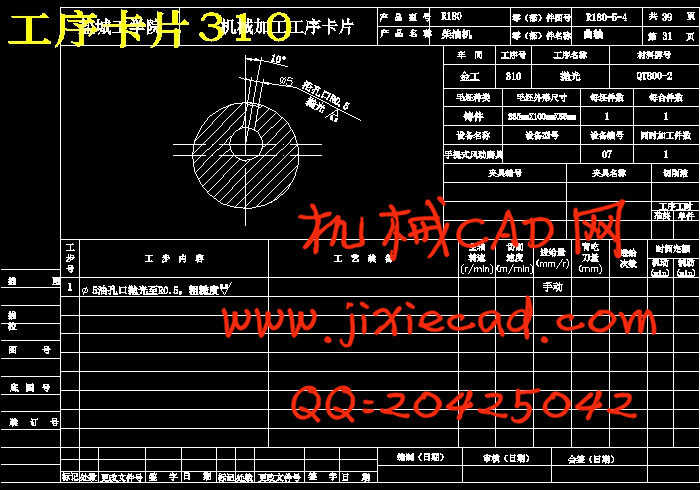

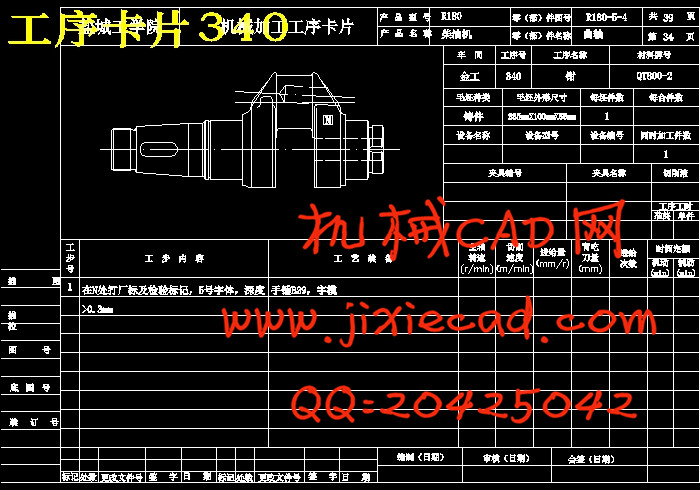

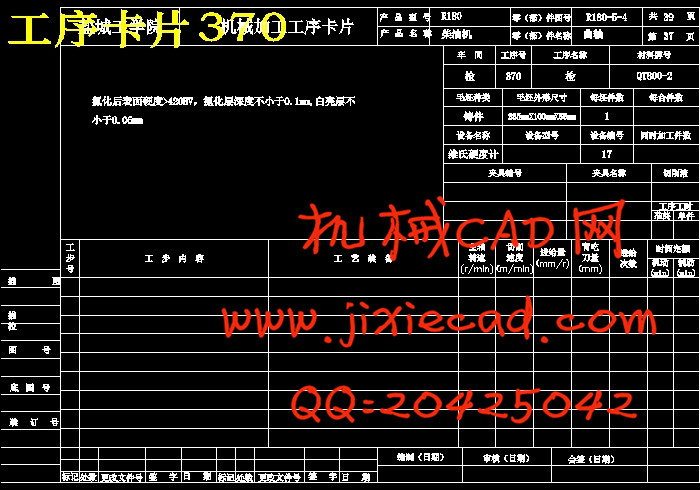

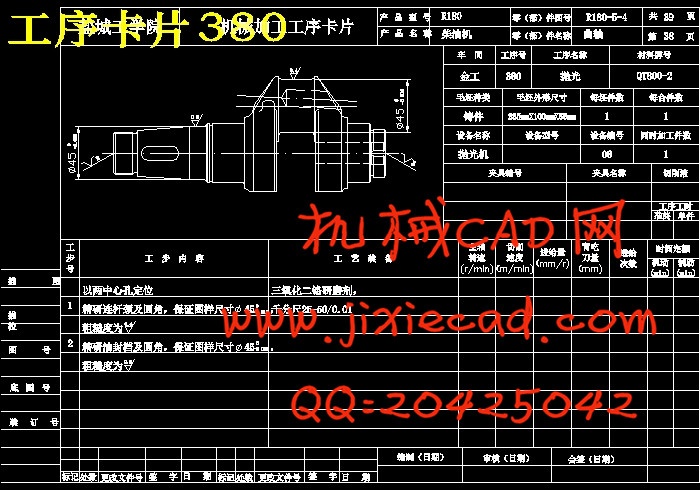

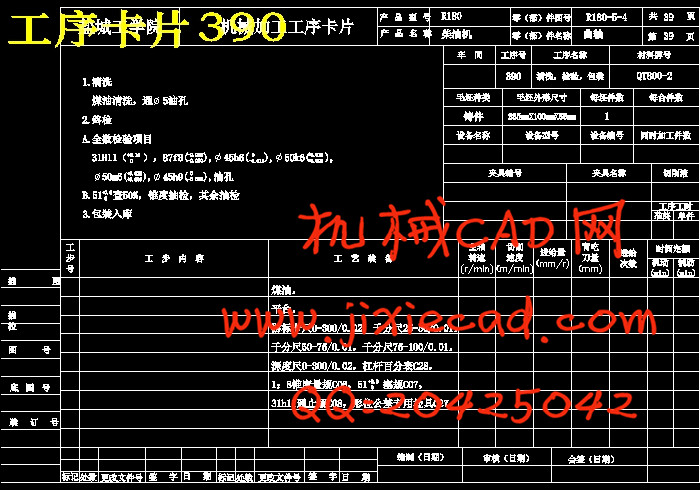

1.8 填写工艺规程卡 15

1.8 填写工艺规程卡 15

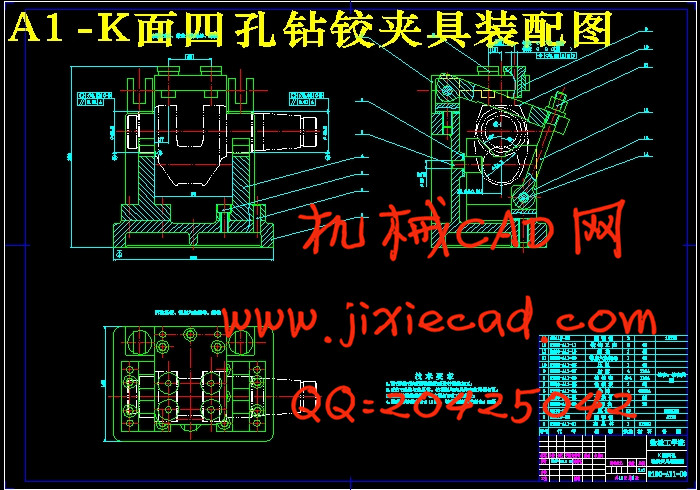

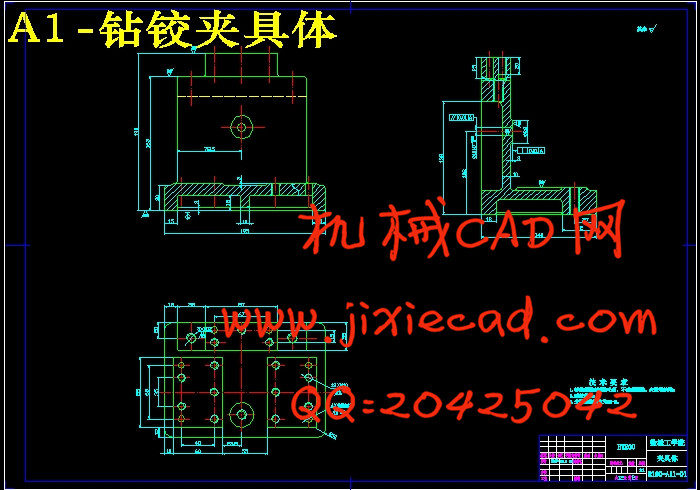

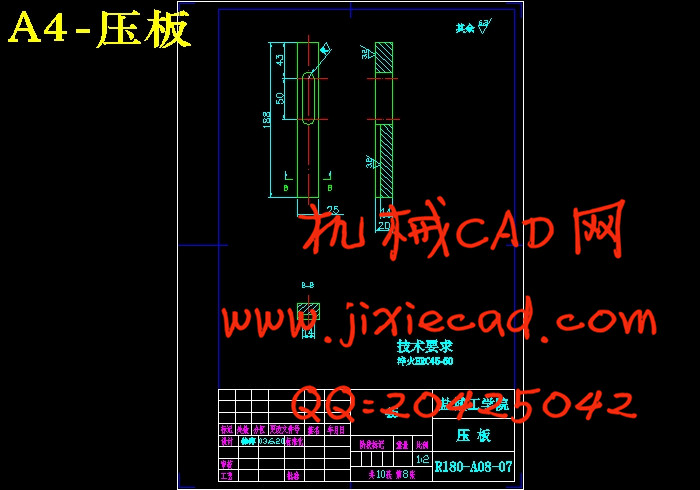

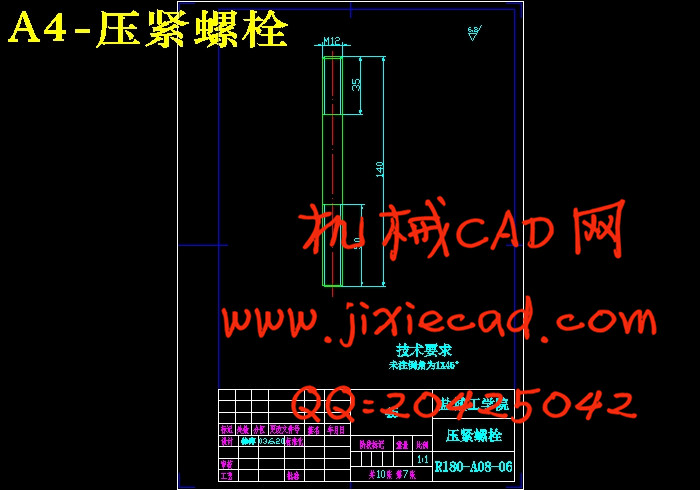

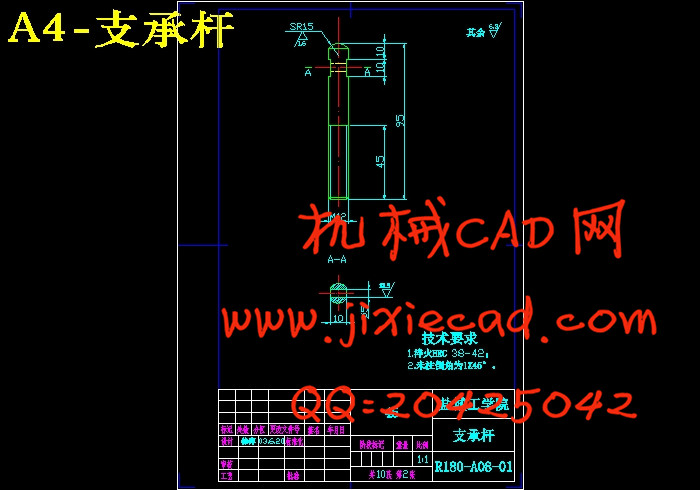

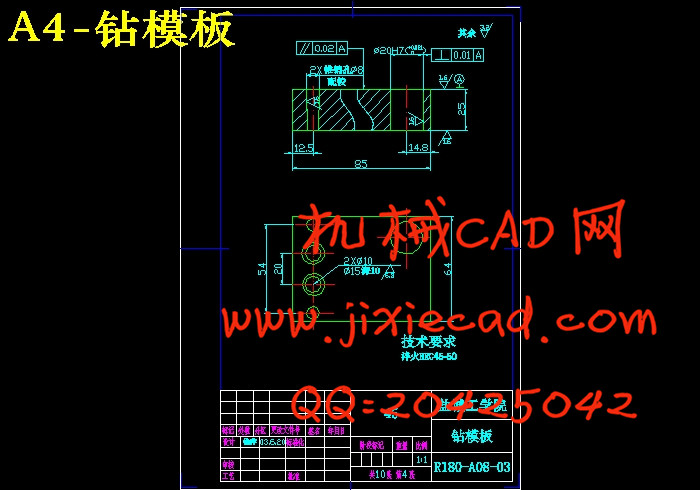

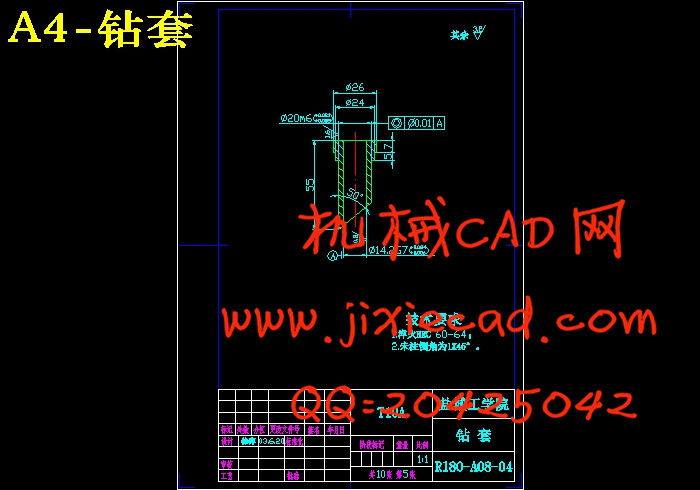

2 R180柴油机曲轴第一套夹具设计 16

2 R180柴油机曲轴第一套夹具设计 16

2.1 明确设计任务、收集分析原始资料 16

2.1 明确设计任务、收集分析原始资料 16

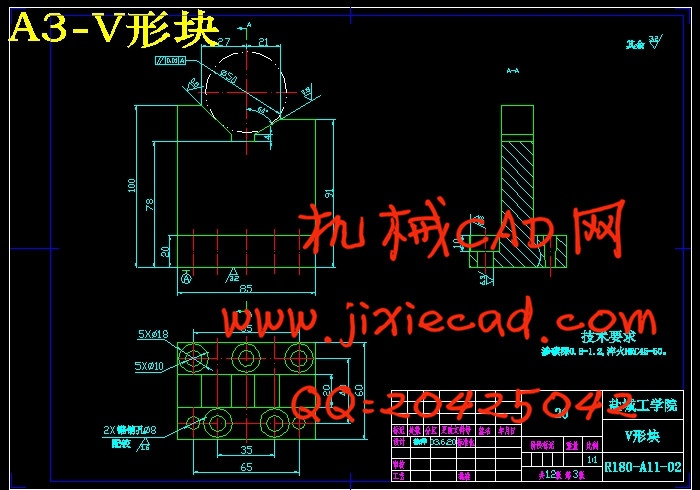

2.2 确定夹具的结构方案 17

2.2 确定夹具的结构方案 17

2.3 绘制夹具结构草图 19

2.3 绘制夹具结构草图 19

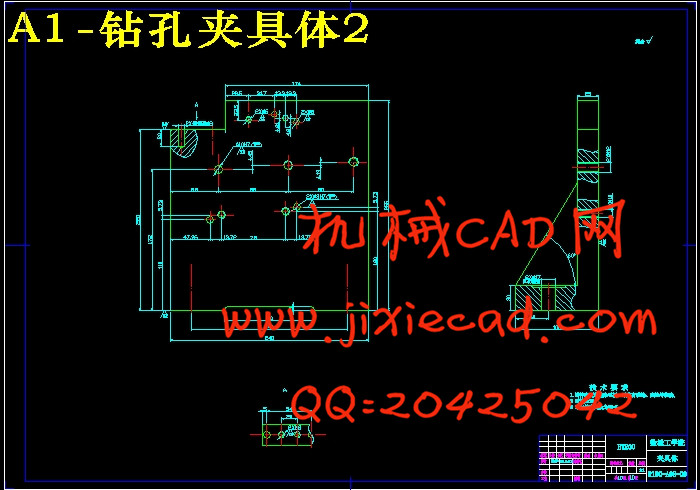

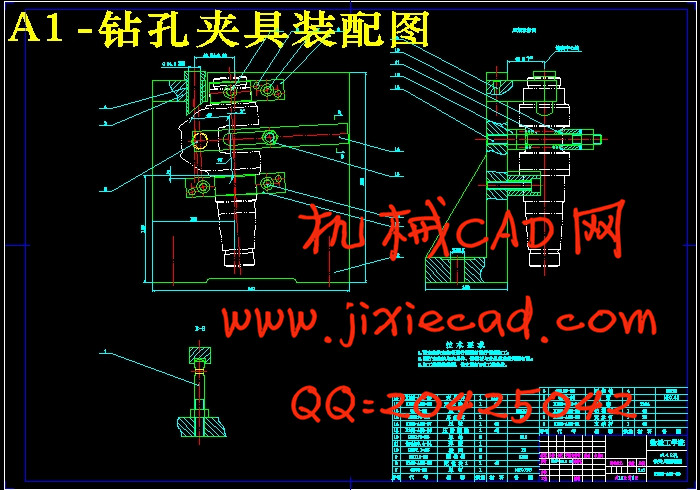

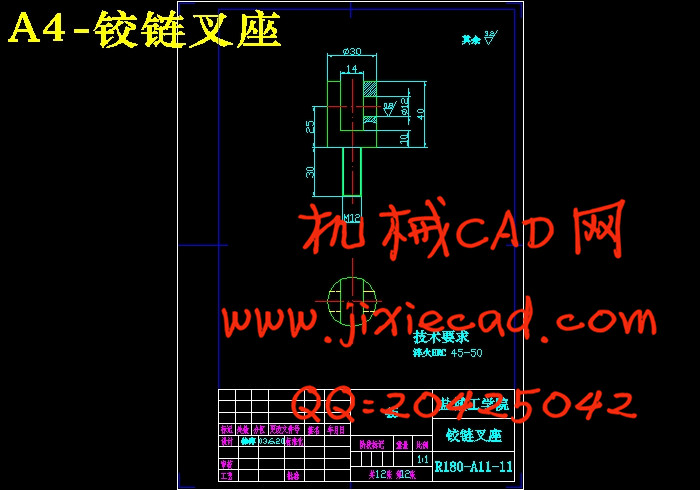

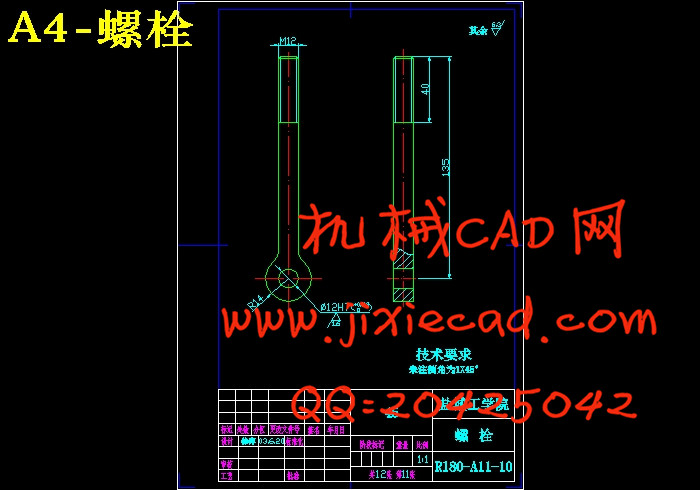

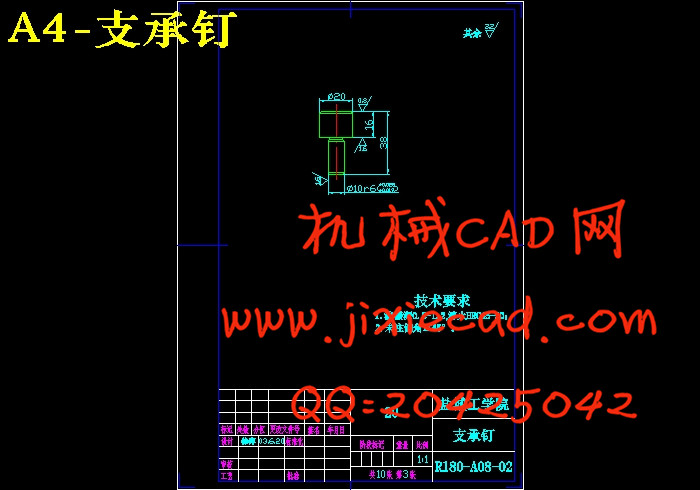

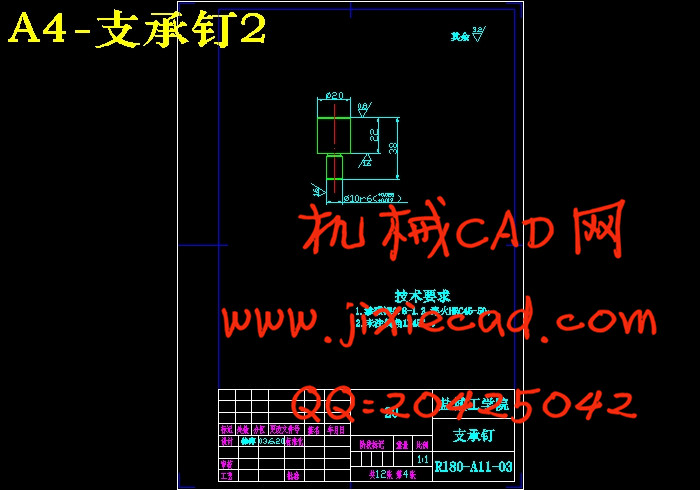

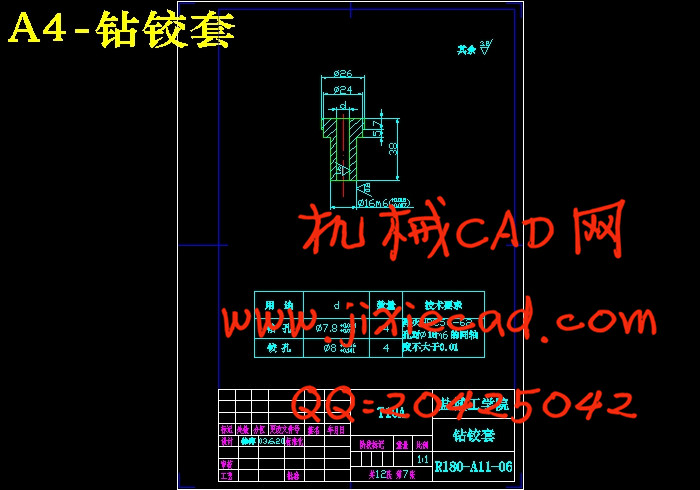

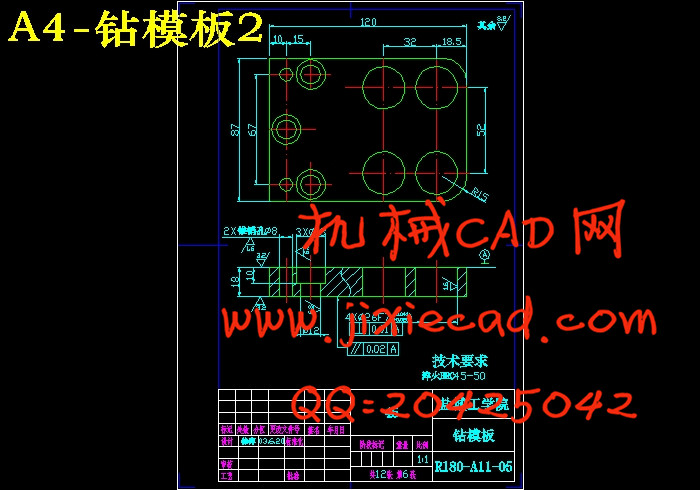

3 R180柴油机曲轴第二套夹具设计 21

3 R180柴油机曲轴第二套夹具设计 21

3.1 明确设计任务、收集分析原始资料 21

3.1 明确设计任务、收集分析原始资料 21

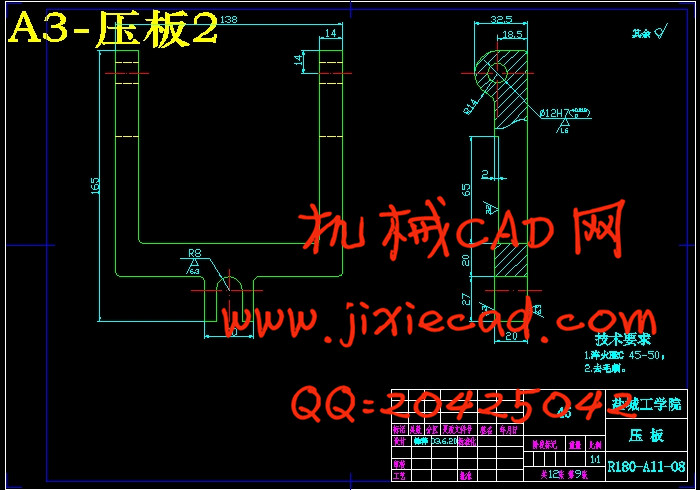

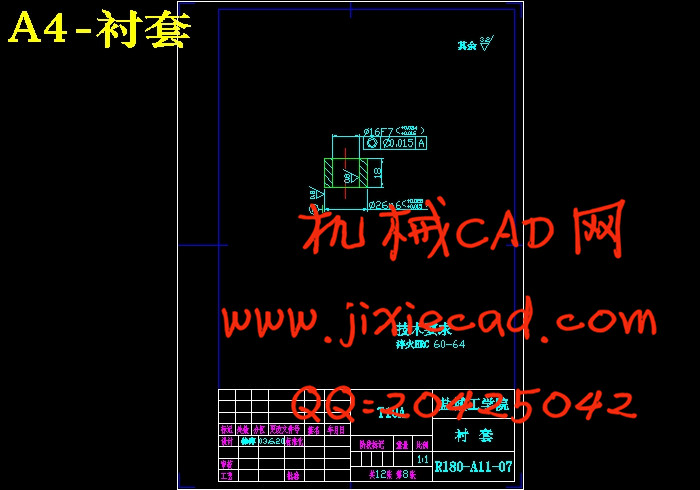

3.2 确定夹具的结构方案 22

3.2 确定夹具的结构方案 22

3.3 夹具定位误差分析 22

3.3 夹具定位误差分析 22

3.4 拟订夹具总装图的尺寸、公差与配合及技术要求 22

3.4 拟订夹具总装图的尺寸、公差与配合及技术要求 22

3.5 绘制夹具总装图 23

3.5 绘制夹具总装图 23

4 结论 24

4 结论 24

致谢 25

致谢 25

参考文献 26

参考文献 26

附件清单 27

附件清单 27

本文主要介绍了R180柴油机曲轴工艺设计及其中两道工序的夹具设计。本文作者是在保证产品质量、提高生产率、降低成本、充分利用现有生产条件、保证工人具有良好而安全劳动条件的前提下进行设计的。在工艺设计中,作者结合实际进行理论设计,对曲轴传统生产工艺进行了改进,优化了工艺过程和工艺装备,使曲轴的生产加工更经济、合理。在夹具设计部分,作者在收集加工所用机床、刀具及辅助工具等有关资料后,对工件材料、结构特点、技术要求及工艺分析的基础上,按照夹具设计步骤设计出符合曲轴生产工艺及夹具制造要求的夹具。

关键词:柴油机 曲轴 工艺 夹具

Abstract

This text introduce R180 diesel engine crankshaft technological design and two of them jig of process design mainly. The author of this text is guaranteeing product quality, boost productivity, lower costs, utilize existing working condition, guaranteeing worker to have good work prerequisite of terms to design . In technological design, the author combine carrying on theory design, improve the traditional production technology of the crankshaft actually, optimize craft course and craft equip, enable economy rational even more of production and processing of the crankshaft. Designing in the jig , the author collect the relevant materials, such as lathe, cutter and handling tool,etc. At the foundation of the analyse of work piece material, specification requirement and craft, and make jig of request according to jig measure design and cankshaft production technology and jig.Keywords : Diesel engine Crankshaft Technology Jig

目 录