设计简介

摘 要

曲轴是发动机中承受冲击载荷、传递动力的重要零件,在发动机五大件中最难以保证加工质量。其材料是由碳素结构钢或球墨铸铁制成的,由于曲轴工作条件恶劣,因此对曲轴材质以及毛坯加工技术、精度、表面粗糙度、热处理和表面强化、动平衡等要求都十分严格。如果其中任何一个环节质量没有得到保证,则可严重影响曲轴的使用寿命和整机的可靠性。曲轴有两个重要部位:轴径,拐径,(还有其他)。轴径被安装在缸体上,拐径与连杆大头孔连接,连杆小头孔与汽缸活塞连接,是一个典型的曲柄滑块机构。发动机工作过程就是,活塞经过混合压缩气的燃爆,推动活塞做直线运动,并通过连杆将力传给曲轴,由曲轴将直线运动转变为旋转运动。曲轴的旋转是发动机的动力源。世界汽车工业发达国家对曲轴的加工十分重视,并不断改进曲轴加工工艺。

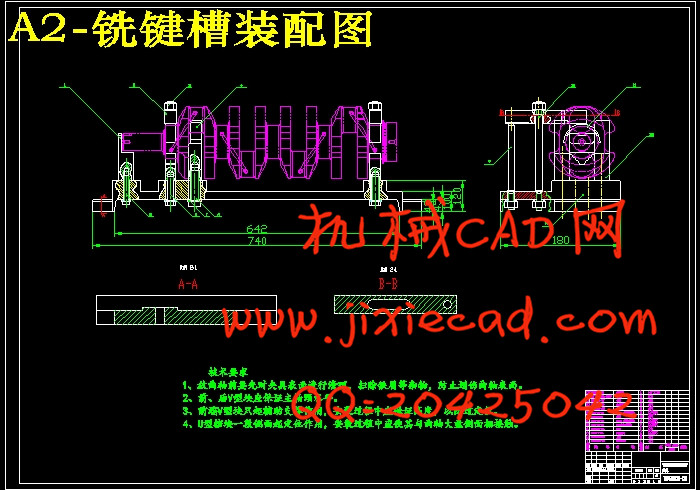

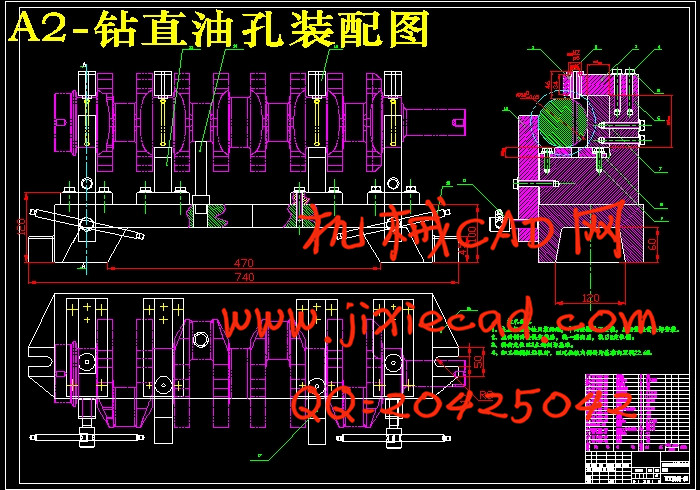

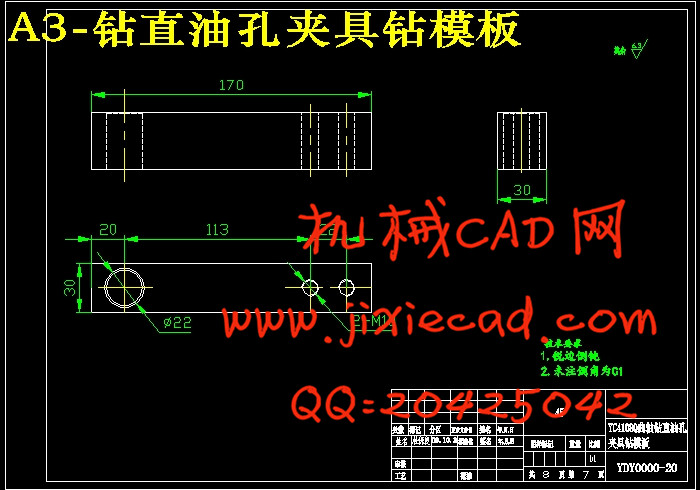

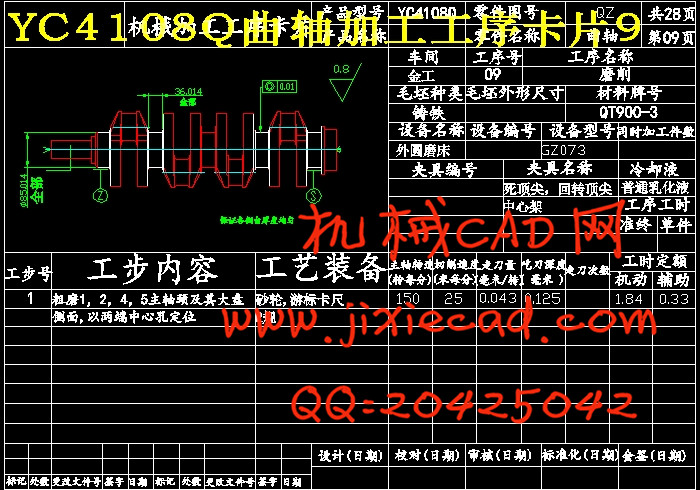

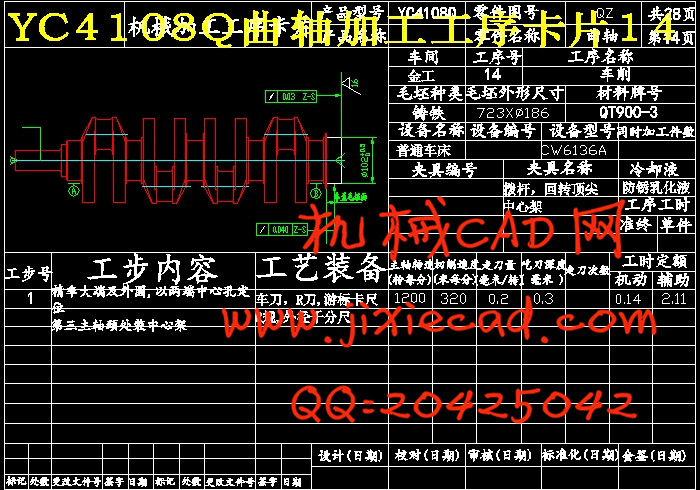

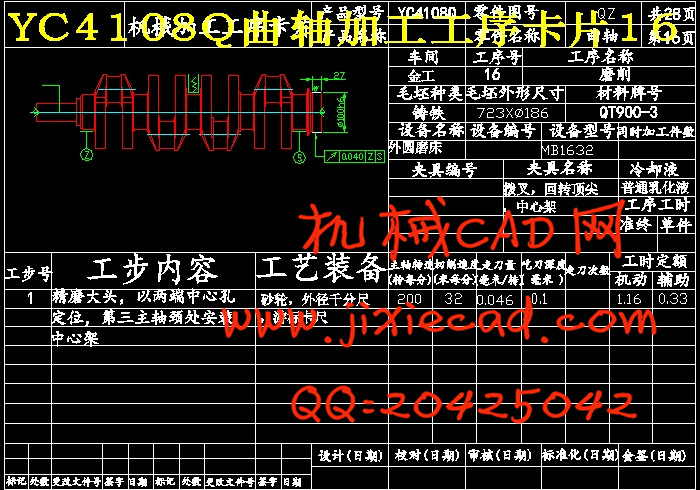

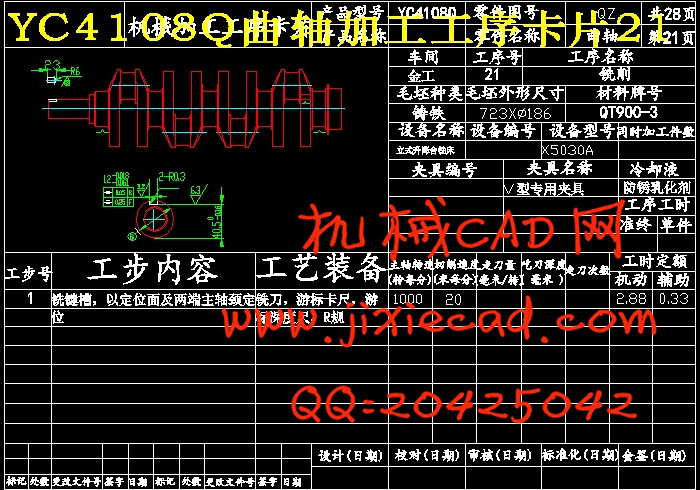

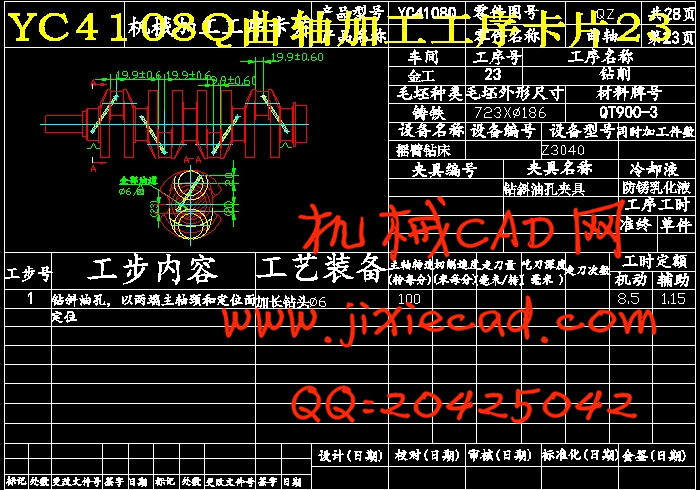

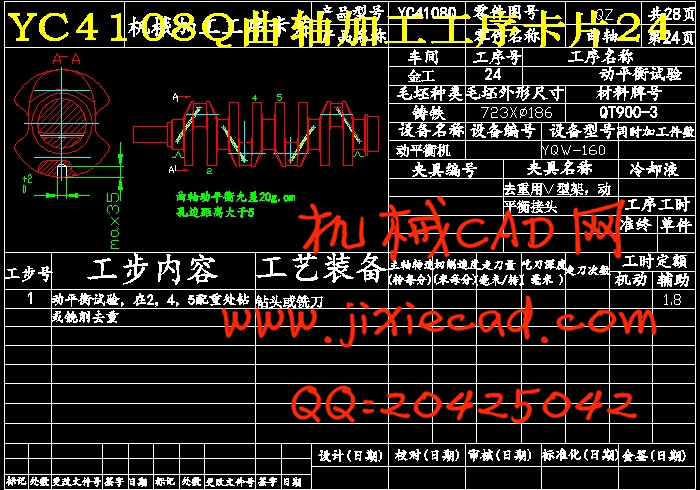

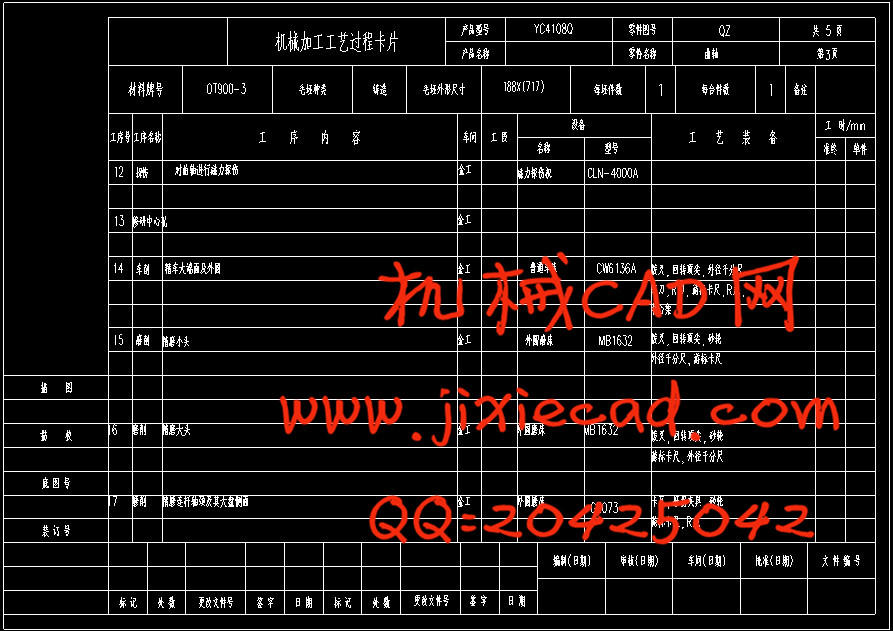

在曲轴零件的加工工艺过程中轴与轴中心线之间要有位置要求, 以毛坯轴两端定位先加工两中心孔,以两端中心孔定位再粗、精加工各轴的表面,然后以粗、精后的两轴径定位,采用专用夹具加工直油孔和铣键槽最后粗、精磨各轴。

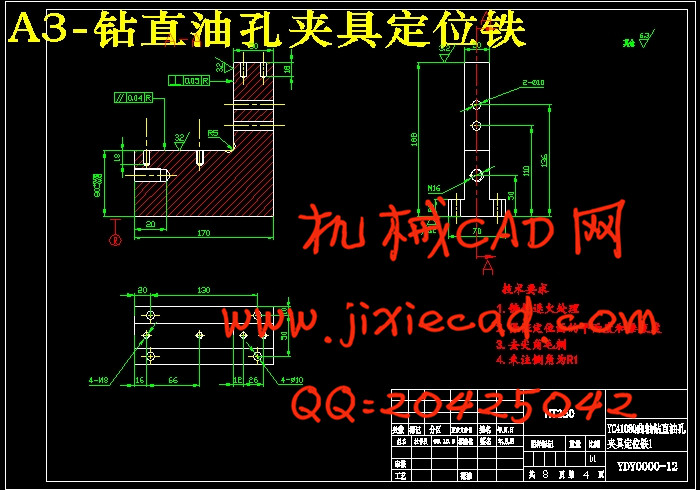

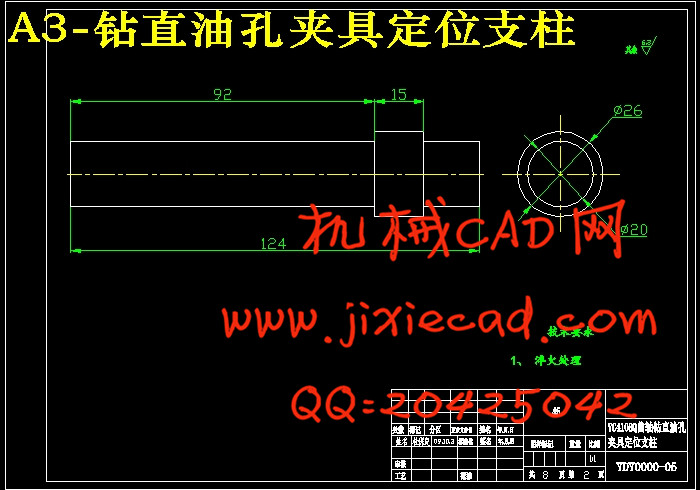

在夹具的设计过程中,主要以V形块和支承板来定位,靠直压板和螺母来夹紧,钻直油孔时应采用长型快换钻套,铣键槽时采用立式铣床,曲轴小头处应安装一个对刀块,夹具设计要方便、简单。

关键词:曲轴;加工工艺;专用夹具;中心孔;对刀块

Abstract

曲轴是发动机中承受冲击载荷、传递动力的重要零件,在发动机五大件中最难以保证加工质量。其材料是由碳素结构钢或球墨铸铁制成的,由于曲轴工作条件恶劣,因此对曲轴材质以及毛坯加工技术、精度、表面粗糙度、热处理和表面强化、动平衡等要求都十分严格。如果其中任何一个环节质量没有得到保证,则可严重影响曲轴的使用寿命和整机的可靠性。曲轴有两个重要部位:轴径,拐径,(还有其他)。轴径被安装在缸体上,拐径与连杆大头孔连接,连杆小头孔与汽缸活塞连接,是一个典型的曲柄滑块机构。发动机工作过程就是,活塞经过混合压缩气的燃爆,推动活塞做直线运动,并通过连杆将力传给曲轴,由曲轴将直线运动转变为旋转运动。曲轴的旋转是发动机的动力源。世界汽车工业发达国家对曲轴的加工十分重视,并不断改进曲轴加工工艺。

在曲轴零件的加工工艺过程中轴与轴中心线之间要有位置要求, 以毛坯轴两端定位先加工两中心孔,以两端中心孔定位再粗、精加工各轴的表面,然后以粗、精后的两轴径定位,采用专用夹具加工直油孔和铣键槽最后粗、精磨各轴。

在夹具的设计过程中,主要以V形块和支承板来定位,靠直压板和螺母来夹紧,钻直油孔时应采用长型快换钻套,铣键槽时采用立式铣床,曲轴小头处应安装一个对刀块,夹具设计要方便、简单。

关键词:曲轴;加工工艺;专用夹具;中心孔;对刀块

Abstract

Engine crankshaft is subject to impact load, transmission power of the important parts, the five pieces in the engine are the most difficult to ensure quality processing. Its material is from the carbon structure which made of steel or ductile iron, as a result of the poor working conditions, the crankshaft and the rough material processing technology, precision, surface roughness, heat treatment and surface hardening, dynamic balancing requirements are very stringent. If any of these are not a part of quality assurance that can be seriously affected the life of the crankshaft and machine reliability. There are two important parts of the crankshaft: shaft diameter, Po Drive, (and others). Shaft has been installed in the cylinder block, the Po Drive and connecting rod big hole, connecting rod and cylinder head piston connecting hole, is a typical slider-crank mechanism. Engine working process is that the Pistons after the blasting compressed gas mixture to promote the piston to do linear motion and force through the connecting rod to the crankshaft will be from the crankshaft to linear motion into rotary movement. The rotation of the crankshaft is the engine power source. The world automobile industry in developed countries are attach great importance to improve the processing crankshaft and crankshaft processing technology.

In crankshaft machining process between the central axis, with the axis center line of the location of the requirements have to be rough-axis positioning processing at both ends of the two central hole to center hole location on both ends and then rough, finishing the surface of

the shaft, and then to crude, refined of the two shaft after positioning, the use of dedicated processing fixture straight hole and the final rough keyway milling, grinding of the shaft.

In the fixture design process, mainly V-shaped block and bearing plates to locate by direct plate and nut to clamp, drill hole should be directly used for drilling long set of fast, used vertical milling keyway milling, crankshaft head should be installed on a knife block, fixture design should be convenient and simple.

Key words: crankshaft; processing technology; dedicated fixture; central hole; the knife block

目 录

摘 要 I

Abstract II

1 绪 论 1

2 零件分析 2

2.1 零件的作用 2

2.2 零件的技术要求分析 2

2.3 零件的结构及其工艺性分析 2

2.4 零件的加工面的分析 3

3 机械加工工艺过程设计 5

3.1 定义 5

3.2 机械加工工艺过程的组成 5

3.3 工艺规程的作用 5

3.4 工艺规程的设计原则 5

3.5 计算生产纲领,确定生产类型 5

3.6 确定毛坯的制造形式 6

3.7 基准的选择 7

3.8 材料及热处理 8

3.9 分析并制订工艺路线 8

3.10 机械加工余量、工序尺寸及毛坯尺寸的确定 10

3.11 确定切削用量及基本工时 13

4 夹具设计 17

4.1 打直油孔夹具设计 17

4.2 铣键槽夹具设计 25

5 加工方案的技术经济分析 30

5.1工艺方案比较 30

5.2 技术经济指标 31

5.3应用举例 31

结 论 34

致 谢 35

参考文献 36

附录 37