设计简介

摘 要

在学完了大学四年的机械设计制造及其自动化的所以课程以后对机械这个行业有了更深入的认识。当下机械制造工艺日新月异,加工方式越来越简便,数控加工中心逐渐代替了大量传统机床的位置,快捷、高效、高精度、经济性好。3D打印机的出现也正冲击着这个行业。

着眼于现状,传统机床仍将在中国制造业中持续数十年。作为这个专业的一名学生,从基础出发,从传统工艺出发做出这篇毕业设计对于今后在这个领域的发展也不可否认其有着重大意义。

我所设计的是磨齿机涡轮下圆盘的制造工艺及其所用到的专用夹具的设计,综合运用了《机械制造技术基础》、《工程材料与成型技术基础》、《机床夹具设计》以及制图课程。专用夹具的设计可减少装夹时间、提高生产效率、降低劳动强度。这次设计促进我综合运用大学四年里所学的理论知识,是一次知识的升华。融入实习期间的在工厂实践经验,提高分析和解决工艺问题、工艺规程和专用夹具设计的能力,以及运用有关手册、图表资料,为今后所从事的行业打基础、做铺垫。

关键词:机械加工工艺;机床夹具。

ABSTRACT

Finished studying at the university of four years of mechanical design and manufacturing and its automation so after course of mechanical have a deeper understanding of the industry. Rapid progress in the mechanical manufacturing process, processing way more and more convenient, CNC machining center gradually take the place of a lot of traditional machine tool, shortcut, high efficiency, high accuracy and good economy. The appearance of 3 d printers are also impact on the industry.

Focus on the present situation, the traditional machine tool will still last for decades in China's manufacturing industry. As a student of this major, starting from the foundation, embarks from the traditional process to make the graduation design for the future development in this field and there's no denying it has important significance.

Traditional mechanical manufacturing technology including turning, milling, planing, grinding, process arrangement, cutting parameter, cutting tool parameters and so on a series of factors affect the parts quality and production efficiency are the predecessors' experience accumulated gradually. I design the manufacturing process of ball valve bonnet and drilling of special fixture used in the design, the integrated use of <mechanical manufacturing technology foundation>, <engineering material and the molding technology foundation>, journal of machine tool fixture design and cartography curriculum. The design of special fixture can reduce clamping time and improve production efficiency, reduce labor intensity. This design to promote my comprehensive use the theoretical knowledge they learned at the university of four years, is a sublimation of knowledge. Into the internship experience in factory, analyze and solve process problems, the ability of process planning and special fixture design, and use the relevant manuals, charts, data. Also exercise the query literature on how to quickly and efficiently. In the industry for the future is in groundwork.

Keywords:machining process;machine tool fixture

3.2.6 夹具体设计 37

3.2.7 绘制夹具体图 38

第四章 结论 39

在学完了大学四年的机械设计制造及其自动化的所以课程以后对机械这个行业有了更深入的认识。当下机械制造工艺日新月异,加工方式越来越简便,数控加工中心逐渐代替了大量传统机床的位置,快捷、高效、高精度、经济性好。3D打印机的出现也正冲击着这个行业。

着眼于现状,传统机床仍将在中国制造业中持续数十年。作为这个专业的一名学生,从基础出发,从传统工艺出发做出这篇毕业设计对于今后在这个领域的发展也不可否认其有着重大意义。

我所设计的是磨齿机涡轮下圆盘的制造工艺及其所用到的专用夹具的设计,综合运用了《机械制造技术基础》、《工程材料与成型技术基础》、《机床夹具设计》以及制图课程。专用夹具的设计可减少装夹时间、提高生产效率、降低劳动强度。这次设计促进我综合运用大学四年里所学的理论知识,是一次知识的升华。融入实习期间的在工厂实践经验,提高分析和解决工艺问题、工艺规程和专用夹具设计的能力,以及运用有关手册、图表资料,为今后所从事的行业打基础、做铺垫。

关键词:机械加工工艺;机床夹具。

ABSTRACT

Finished studying at the university of four years of mechanical design and manufacturing and its automation so after course of mechanical have a deeper understanding of the industry. Rapid progress in the mechanical manufacturing process, processing way more and more convenient, CNC machining center gradually take the place of a lot of traditional machine tool, shortcut, high efficiency, high accuracy and good economy. The appearance of 3 d printers are also impact on the industry.

Focus on the present situation, the traditional machine tool will still last for decades in China's manufacturing industry. As a student of this major, starting from the foundation, embarks from the traditional process to make the graduation design for the future development in this field and there's no denying it has important significance.

Traditional mechanical manufacturing technology including turning, milling, planing, grinding, process arrangement, cutting parameter, cutting tool parameters and so on a series of factors affect the parts quality and production efficiency are the predecessors' experience accumulated gradually. I design the manufacturing process of ball valve bonnet and drilling of special fixture used in the design, the integrated use of <mechanical manufacturing technology foundation>, <engineering material and the molding technology foundation>, journal of machine tool fixture design and cartography curriculum. The design of special fixture can reduce clamping time and improve production efficiency, reduce labor intensity. This design to promote my comprehensive use the theoretical knowledge they learned at the university of four years, is a sublimation of knowledge. Into the internship experience in factory, analyze and solve process problems, the ability of process planning and special fixture design, and use the relevant manuals, charts, data. Also exercise the query literature on how to quickly and efficiently. In the industry for the future is in groundwork.

Keywords:machining process;machine tool fixture

目 录

第一章 前言 1

第二章 机械加工工艺规程制订 2

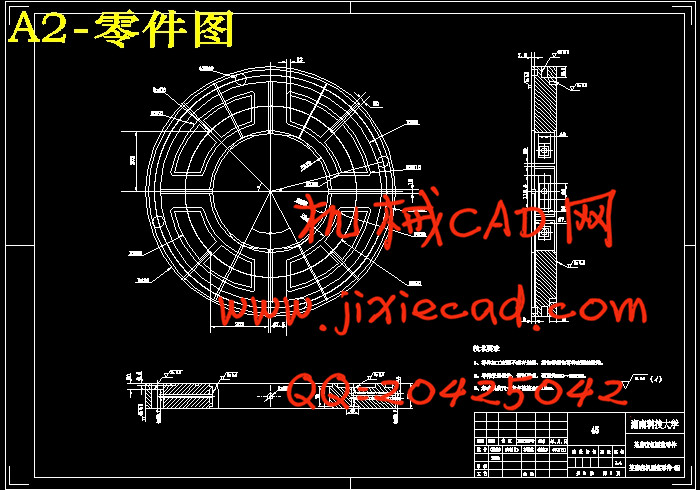

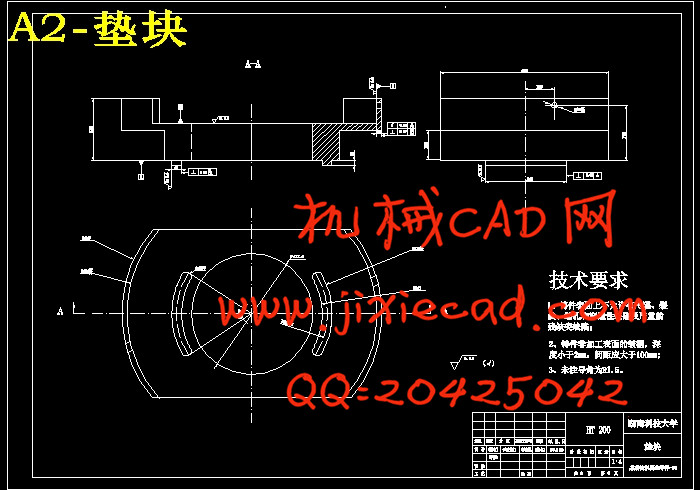

2.1零件的工艺分析 2

2.1.1 零件的功用、结构及特点 2

2.1.2 主要加工表面及其要求 4

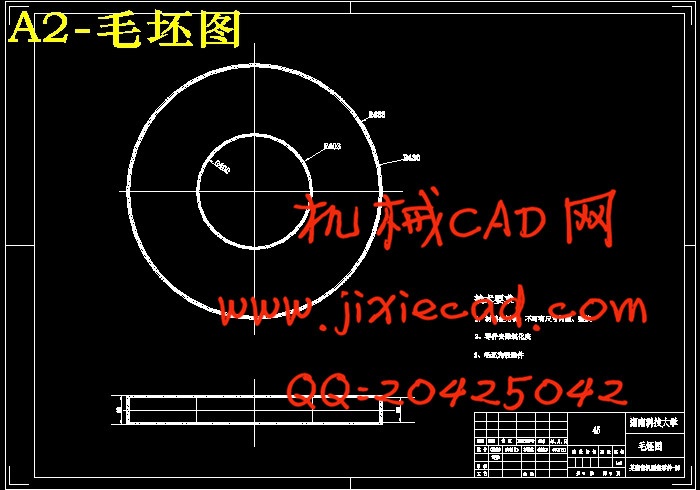

2.2 毛坯的选择 5

2.2.1 确定毛坯的类型、制造方法和尺寸及其公差 5

2.2.2 确定毛坯的技术要求 5

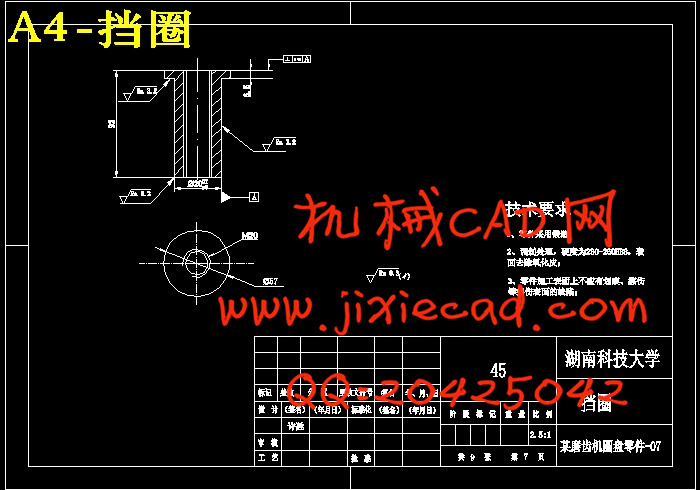

2.2.3 绘制零件-毛坯合图 5

2.3 基准的选择 6

2.4 拟订机械加工工艺路线 8

2.4.1 确定各表面的加工方法 8

2.4.2 拟定加工艺路线 9

2.4.3 工艺路线方案的分析与比较 10

2.5 确定机械加工余量、工序尺寸及公差 10

2.6 选择机床及工艺装备 12

2.6.1 选择机床 12

2.6.2 选择刀具 13

2.6.3 选择夹具 13

2.6.4 选择量具 13

2.7 确定切削用量及基本工时 14

第三章 夹具设计 29

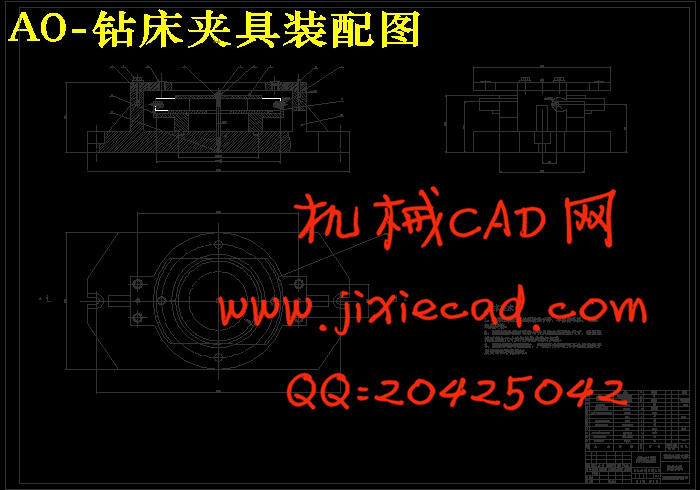

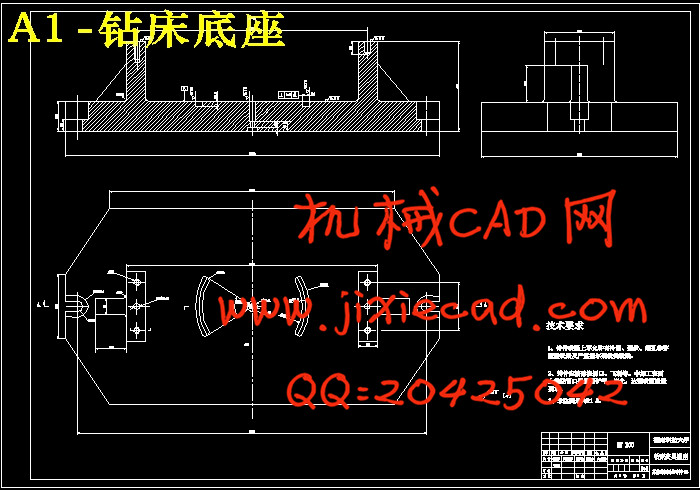

3.1钻床钻孔夹具设计 29

3.1.1定位方案及定位元件的选择和设计 29

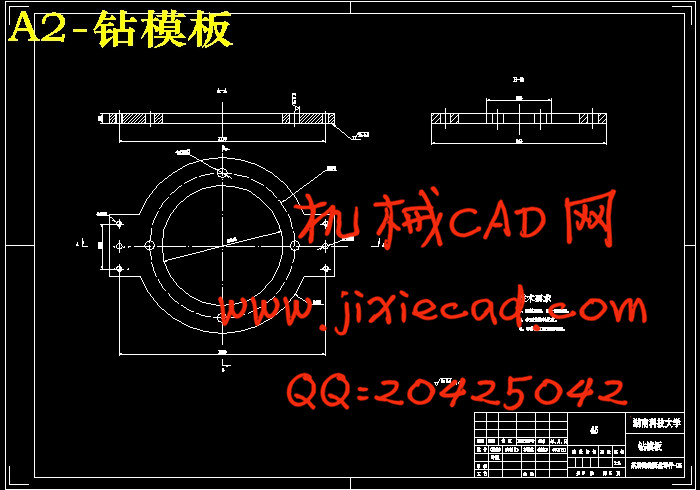

3.1.2导向方案及导向元件的选择和设计 30

3.1.3 夹紧装置设计 31

3.1.4夹具体设计 32

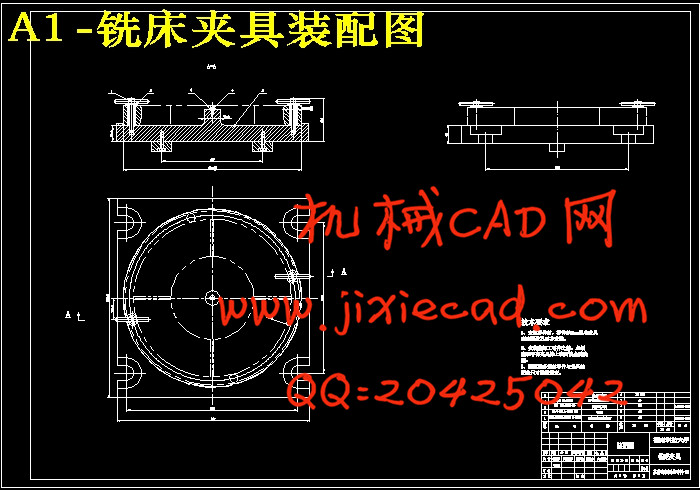

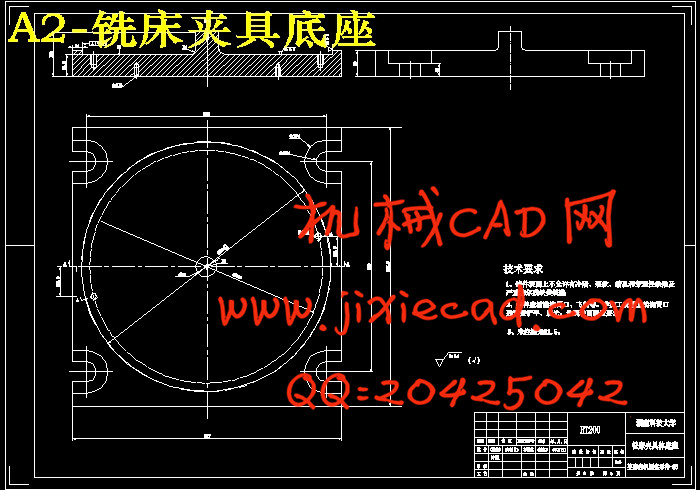

3.2铣床夹具设计 33

3.2.1 确定定位方案 33

3.2.2 计算定位误差 34

3.2.3 确定导引方案 35

3.2.4 确定夹紧方案 35

3.2.5 夹紧力及误差计算 36

第一章 前言 1

第二章 机械加工工艺规程制订 2

2.1零件的工艺分析 2

2.1.1 零件的功用、结构及特点 2

2.1.2 主要加工表面及其要求 4

2.2 毛坯的选择 5

2.2.1 确定毛坯的类型、制造方法和尺寸及其公差 5

2.2.2 确定毛坯的技术要求 5

2.2.3 绘制零件-毛坯合图 5

2.3 基准的选择 6

2.4 拟订机械加工工艺路线 8

2.4.1 确定各表面的加工方法 8

2.4.2 拟定加工艺路线 9

2.4.3 工艺路线方案的分析与比较 10

2.5 确定机械加工余量、工序尺寸及公差 10

2.6 选择机床及工艺装备 12

2.6.1 选择机床 12

2.6.2 选择刀具 13

2.6.3 选择夹具 13

2.6.4 选择量具 13

2.7 确定切削用量及基本工时 14

第三章 夹具设计 29

3.1钻床钻孔夹具设计 29

3.1.1定位方案及定位元件的选择和设计 29

3.1.2导向方案及导向元件的选择和设计 30

3.1.3 夹紧装置设计 31

3.1.4夹具体设计 32

3.2铣床夹具设计 33

3.2.1 确定定位方案 33

3.2.2 计算定位误差 34

3.2.3 确定导引方案 35

3.2.4 确定夹紧方案 35

3.2.5 夹紧力及误差计算 36

3.2.6 夹具体设计 37

3.2.7 绘制夹具体图 38

第四章 结论 39