设计简介

摘 要

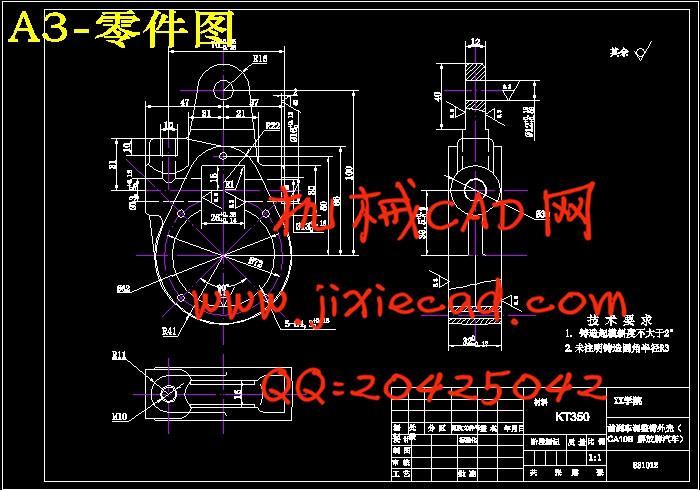

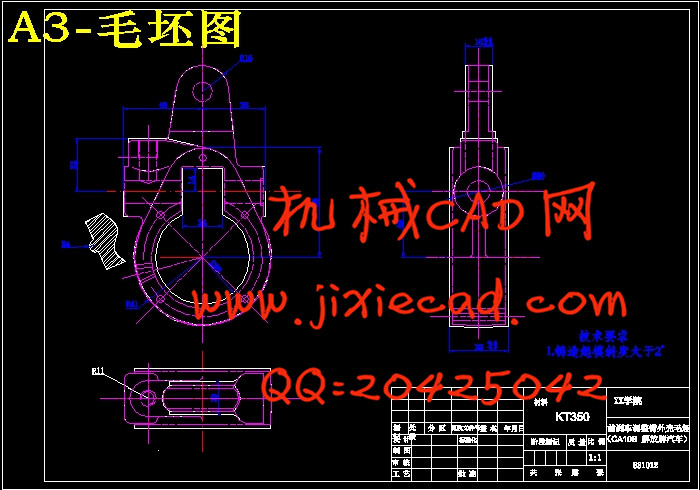

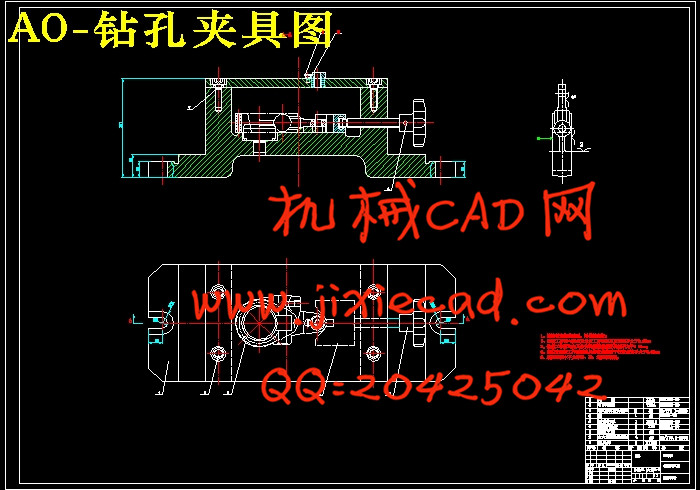

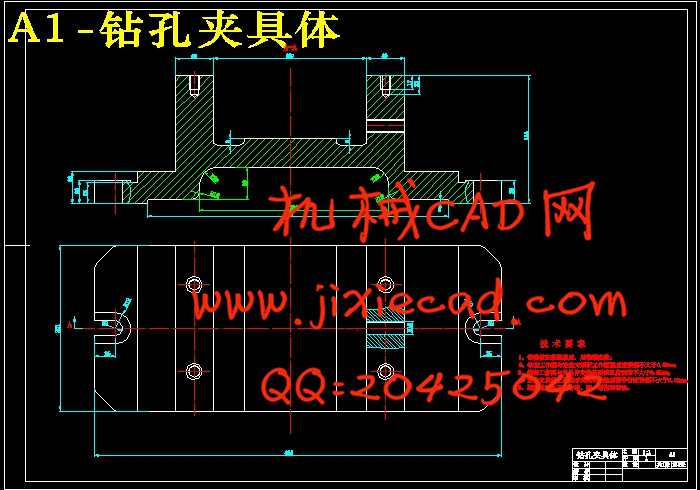

本文是对前刹车调整臂外壳零件加工应用及加工的工艺性分析,主要包括对零件图的分析、毛坯的选择、零件的装夹、工艺路线的制订、刀具的选择、切削用量的确定、加工工艺文件的填写。选择正确的加工方法,设计合理的加工工艺过程。此外还对零件设计了专用夹具.机床夹具的种类很多,其中,使用范围最广的通用夹具,规格尺寸多已标准化,并且有专业的工厂进行生产。而广泛用于批量生产,专为某工件加工工序服务的专用夹具,则需要各制造厂根据工件加工工艺自行设计制造。本论文夹具设计的主要内容是设计钻孔夹具。

关键词:前刹车调整臂外壳,加工工艺,加工方法,工艺文件,夹具

Abstract

This article is on the camshaft adjusting fork parts processing application and processing technology and analysis, including the spare parts diagram analysis, the choice of blank, parts of the clamping, the craft route making, tool selection, the determination of cutting conditions, processing documents. Choose the correct processing method, the rational design of machining process. In addition to the camshaft adjusting fork parts of the two process designing special fixture.Machine tool fixture of many kinds, among them, the most widely used common fixture, size specifications have been standardized, and a professional production plant. While widely used in batch production, designed for a certain workpiece processing services for the fixture, it needs each factory according to workpiece machining technology to design and manufacture. In this paper, fixture design are the main contents of design jig boring machine and milling fixture, the design of a test fixture.

Key Words:Adjust the fork,Processing technology, processing method, process documentation, fixture

目 录

摘 要 IAbstract II

目 录 1

第1章 绪论 3

1.1前言 3

1.1.1设计的课题 4

1.1.2课题的意义和目的 4

1.2课题研究范围 4

1.3 国内外的发展概况 5

1.4 设计课题的指导思想 6

1.5 本课题应解决的主要问题 6

第2章 工艺规程设计 6

2.1零件的工艺分析 6

2.1.1零件的作用 6

2.1.2 零件的工艺分析 6

2.1.3前刹车调整臂外壳的选材 7

2.2基面的选择 8

2.3制订工艺路线 8

2.4 确定切削用量及基本工时 15

第3章 钻孔夹具设计 25

3.1概述 25

3.2方案设计 25

3.3定位基准的选择 25

3.4切削力和夹紧力的计算 25

3 .5 定位误差分析 26

3.6 导向装置设计 26

3.7夹具设计及操作说明 27

总 结 28

致 谢 29

参 考 文 献 30