设计简介

摘 要

本课题概要的介绍国内外机械制造行业的发展趋势,从而提出柴油机汽缸盖加工工艺研究的重要性。对影响汽缸盖机械加工质量的因素和主要对策的分析、研究,关键工序的加工进行分析,选择合适的刀具,选择合理定位基准和可靠定位基准以及设计可靠的夹紧来保证其加工质量和加工精度,提出相应的对策提高柴油机的良品率和满足客户的要求。同时粗铣顶底面、精镗缸套孔专用夹具和一套工艺规程的合理设计更使得加工工艺有所创新.

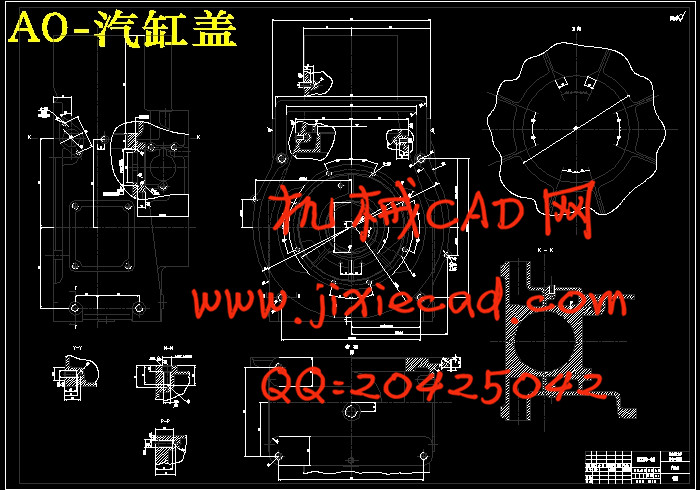

气缸盖是柴油机的重要零部件之一,属于典型的箱体类零件。他的结构比较复杂,其加工质量的好坏将直接影响到柴油机的整体性能。

通过对零件图的分析可知:气缸盖的底面、气道孔及底面座孔的技术要求加高,是重要的平面,因此需要精细加工。

由零件的年生产纲领可以确定该零件为大批量生产。毛坯采用HT20—40的铸铁由机器进行砂模铸造。

在查阅了一些相关的资料,并仔细地分析了大连柴油机厂的气缸盖加工工艺路线和其它一些同类产品的生产线状况后,才具体地制定了这次设计的工艺方案。实际的机械加工工序安排,遵循着:先主要、后次要,先粗后精,先面后孔等原则。

根据生产批量和生产实际情况,工序的安排采用了工序集中和工序分散相结合的办法,并且设计了一条自动化生产线DX33.当按工序集中原则组织过程时,还普遍的采用了自动化程度较高的高效机床和工艺装备。这样,大大地提高了生产率。

关键词: 柴油机; 加工工艺;夹具;

Abstract

Brief introduction of this topic at home and abroad and the development trend of machinery manufacturing industry, and then puts forward the engine block the importance of processing technology research. The influence of mechanical processing factors on the quality of the main countermeasures and analysis, research, the key working procedure of processing analysis, choose proper tool, select the reasonable positioning base and reliable position datum and the design of clamping reliable to ensure the process quality and machining precision, and put forward the corresponding countermeasures to improve the engine's rate and meet the demand of the customers. At the same time the bottom and fine rough milling boring cylinder liner hole special jig and a set of technical process the reasonable design of more make processing technology has innovation.

It is one of the important spare part of a diesel engine that the air cylinder is covered, belong to the typical case body type part. It relatively complicated structure, its the qualities of quality influence globality can diesel engine directly.

Can be confirmed this part as and produced in enormous quantities by producing the guiding principle annually of the part. Blank adopt HT go on sand mould's casting by machine by casting iron as much as 20-40.

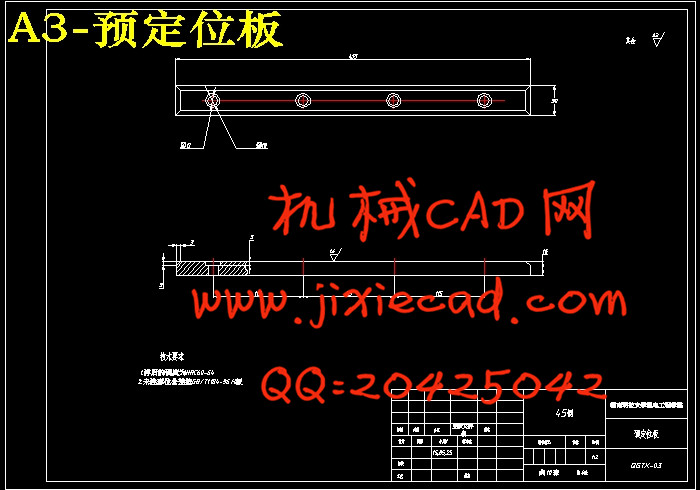

At the rough machining, choose about bottom surface who air cylinder stamp interact as the datum; At the finish machining, choose air cylinder that process leave datum on bottom surface. At bottom surface and eaches on the bottom surface sell and go on and make a reservation, namely" each sell at two" the type make a reservation.

It consults relevant materialses analyse diesel engine of Dalian the air cylinders of factory build route and similar the production lines of productses after the state processing technology carefully, Have made this technology scheme designed concretly . The real machining process is arranged, is following : It is neither first main, afterwards less important nor first after being thick precise, the hole waits for the principle after one first.

At production lot and reality of producing, the arrangements of process adopt in collecting and process disperse way that combine together process, Design one a piece of automatic production line DX 33s. When concentrate the principle on organizing the course according to the process, also relatively and technology equip high high-efficient lathes general adoption automatic degrees. So, have boosted productivity greatly .

Keywords: Engine Block; Processing technology; Jig; Factors

目 录

第一章 前言……………………………………………………………………… 5

第二章 零件的分析………………………………………………… 6

2.1 零件的作用及性能……………………………………………………………… 6

2.2 零件的生产纲领………………………………………………………………… 6

2.3 汽缸盖的主要技术条件分析…………………………………………………… 7

2.3.1 尺寸精度…………………………………………………………………… 7

2.3.2几何精度……………………………………………………………… 7

2.3.3位置精度…………………………………………………………………… 7

2.3.4 表面粗糙度………………………………………………………………… 7

第三章 工艺规程的制定…………………………………………………8

3.1 确定毛坯制造形式……………………………………………………………… 8

3.2 零件结构工艺分析……………………………………………………………… 8

3.2.1 零件图分析………………………………………………………………… 9

3.2.2结构工艺性分析………………………………………………………… 10

3.3 工艺路线的拟定……………………………………………………………… 10

3.3.1 基准的选择……………………………………………………………… 10

3.3.2加工方法的选择………………………………………………………… 11

2.3.3加工阶段的划分与工序路线的确定…………………………………… 11

3.4 加工余量的确定……………………………………………………………… 13

3.5 选择加工设备和工艺设备…………………………………………………… 17

3.6 主要工序定位方案…………………………………………………………… 18

3.7 影响柴油机汽缸盖主要工序的因素及主要对策…………………………… 19

3.7.1 设备精度的影响……………………………………………………………19

3.7.2 工艺系统的影响……………………………………………………………20

3.7.3 温度的影响………………………………………………………………21

3.8 主要工序单件机动工时的计算…………………………………………………24

3.9 基本工时的确定………………………………………………………………27

3.10 工艺装备的选择及工艺规程设计特点…………………………………………28

3.11 重点工序的分析……………………………………………………………29

第四章 夹具设计…………………………………………………………………30

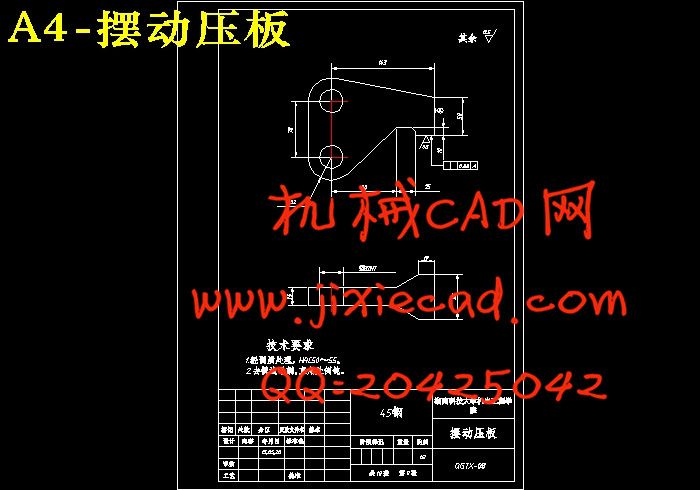

4.1 粗铣汽缸盖顶底端面夹具设计…………………………………………………30

4.2 夹具液压系统的设计……………………………………………………………33

4.3 液压缸的选用计算………………………………………………………………35

4.4 液压系统的控制及动力源………………………………………………………37

第五章 结论…………………………………………………………………………… 38

参考文献………………………………………………………………………………… 39

致谢……………………………………………………………………………………… 40

本课题概要的介绍国内外机械制造行业的发展趋势,从而提出柴油机汽缸盖加工工艺研究的重要性。对影响汽缸盖机械加工质量的因素和主要对策的分析、研究,关键工序的加工进行分析,选择合适的刀具,选择合理定位基准和可靠定位基准以及设计可靠的夹紧来保证其加工质量和加工精度,提出相应的对策提高柴油机的良品率和满足客户的要求。同时粗铣顶底面、精镗缸套孔专用夹具和一套工艺规程的合理设计更使得加工工艺有所创新.

气缸盖是柴油机的重要零部件之一,属于典型的箱体类零件。他的结构比较复杂,其加工质量的好坏将直接影响到柴油机的整体性能。

通过对零件图的分析可知:气缸盖的底面、气道孔及底面座孔的技术要求加高,是重要的平面,因此需要精细加工。

由零件的年生产纲领可以确定该零件为大批量生产。毛坯采用HT20—40的铸铁由机器进行砂模铸造。

在查阅了一些相关的资料,并仔细地分析了大连柴油机厂的气缸盖加工工艺路线和其它一些同类产品的生产线状况后,才具体地制定了这次设计的工艺方案。实际的机械加工工序安排,遵循着:先主要、后次要,先粗后精,先面后孔等原则。

根据生产批量和生产实际情况,工序的安排采用了工序集中和工序分散相结合的办法,并且设计了一条自动化生产线DX33.当按工序集中原则组织过程时,还普遍的采用了自动化程度较高的高效机床和工艺装备。这样,大大地提高了生产率。

关键词: 柴油机; 加工工艺;夹具;

Abstract

Brief introduction of this topic at home and abroad and the development trend of machinery manufacturing industry, and then puts forward the engine block the importance of processing technology research. The influence of mechanical processing factors on the quality of the main countermeasures and analysis, research, the key working procedure of processing analysis, choose proper tool, select the reasonable positioning base and reliable position datum and the design of clamping reliable to ensure the process quality and machining precision, and put forward the corresponding countermeasures to improve the engine's rate and meet the demand of the customers. At the same time the bottom and fine rough milling boring cylinder liner hole special jig and a set of technical process the reasonable design of more make processing technology has innovation.

It is one of the important spare part of a diesel engine that the air cylinder is covered, belong to the typical case body type part. It relatively complicated structure, its the qualities of quality influence globality can diesel engine directly.

Can be confirmed this part as and produced in enormous quantities by producing the guiding principle annually of the part. Blank adopt HT go on sand mould's casting by machine by casting iron as much as 20-40.

At the rough machining, choose about bottom surface who air cylinder stamp interact as the datum; At the finish machining, choose air cylinder that process leave datum on bottom surface. At bottom surface and eaches on the bottom surface sell and go on and make a reservation, namely" each sell at two" the type make a reservation.

It consults relevant materialses analyse diesel engine of Dalian the air cylinders of factory build route and similar the production lines of productses after the state processing technology carefully, Have made this technology scheme designed concretly . The real machining process is arranged, is following : It is neither first main, afterwards less important nor first after being thick precise, the hole waits for the principle after one first.

At production lot and reality of producing, the arrangements of process adopt in collecting and process disperse way that combine together process, Design one a piece of automatic production line DX 33s. When concentrate the principle on organizing the course according to the process, also relatively and technology equip high high-efficient lathes general adoption automatic degrees. So, have boosted productivity greatly .

Keywords: Engine Block; Processing technology; Jig; Factors

目 录

第一章 前言……………………………………………………………………… 5

第二章 零件的分析………………………………………………… 6

2.1 零件的作用及性能……………………………………………………………… 6

2.2 零件的生产纲领………………………………………………………………… 6

2.3 汽缸盖的主要技术条件分析…………………………………………………… 7

2.3.1 尺寸精度…………………………………………………………………… 7

2.3.2几何精度……………………………………………………………… 7

2.3.3位置精度…………………………………………………………………… 7

2.3.4 表面粗糙度………………………………………………………………… 7

第三章 工艺规程的制定…………………………………………………8

3.1 确定毛坯制造形式……………………………………………………………… 8

3.2 零件结构工艺分析……………………………………………………………… 8

3.2.1 零件图分析………………………………………………………………… 9

3.2.2结构工艺性分析………………………………………………………… 10

3.3 工艺路线的拟定……………………………………………………………… 10

3.3.1 基准的选择……………………………………………………………… 10

3.3.2加工方法的选择………………………………………………………… 11

2.3.3加工阶段的划分与工序路线的确定…………………………………… 11

3.4 加工余量的确定……………………………………………………………… 13

3.5 选择加工设备和工艺设备…………………………………………………… 17

3.6 主要工序定位方案…………………………………………………………… 18

3.7 影响柴油机汽缸盖主要工序的因素及主要对策…………………………… 19

3.7.1 设备精度的影响……………………………………………………………19

3.7.2 工艺系统的影响……………………………………………………………20

3.7.3 温度的影响………………………………………………………………21

3.8 主要工序单件机动工时的计算…………………………………………………24

3.9 基本工时的确定………………………………………………………………27

3.10 工艺装备的选择及工艺规程设计特点…………………………………………28

3.11 重点工序的分析……………………………………………………………29

第四章 夹具设计…………………………………………………………………30

4.1 粗铣汽缸盖顶底端面夹具设计…………………………………………………30

4.2 夹具液压系统的设计……………………………………………………………33

4.3 液压缸的选用计算………………………………………………………………35

4.4 液压系统的控制及动力源………………………………………………………37

第五章 结论…………………………………………………………………………… 38

参考文献………………………………………………………………………………… 39

致谢……………………………………………………………………………………… 40