设计简介

CA6140车床齿轮加工工艺与夹具设计

摘要 制造业是一个国家经济发展的重要支柱,其发展水平标志着该国家的经济实力、科技水平、生活水准和国防实力。而制造业的生产能力主要取决于制造装备——机床的先进程度。

进给变速系统设计是Φ1500㎜毛坯专用车床研制课题的一部分。车床进给系统由进给变速箱,溜板箱等组成。根据任务书要求,车床主轴的转速分为两个区,高速区和低速区。高速区转速介于60 r/min-160r/min;低速区速度的介于6 r/min-16r/min。从电机1450 r/min的转速,降到6r/min的转速,减速比达到1:241。与主轴相匹配的进给量变化范围较大。这是本设计难点之一。设计者采用从主轴箱第三轴采取主轴转速信息,通过进给箱和溜板箱变速,得与车床所需相匹配的进给量,从而解决了这个问题。

本着“经济,实用”的设计原则,本设计根据精车和粗车的不同要求,设计了两种不同的进给量。对各部分的设计及选用进行了详细的计算和论证,机构简单,布局紧凑,节约了材料,降低了成本,利于安装和维修,完成了设计任务。

关键词 专用车床 齿轮毛坯 变速系统 设计

Design on processing of gear for CA6140 lath with the main process equipment

Abstract

The manufacturing industry is a national economic development major pillar, its level of development symbolizes this national economic potentiality, the technical level, the level of living and the national defense strength. But manufacturing industry productivity is mainly decided by the manufacture equipment -- engine bed's advanced degree.

This design isΦ1500㎜ the gear blank special-purpose lathe to feed speed change system design. The lathe to feed system module by to feed gear box, the apron and so on is composed. According to the project description request, the lathe main axle's rotational speed divides into two areas, high speed area and low speed area. The high speed area rotational speed is situated between 60--160r/min; The low speed area speed is situated between 6--16r/min. From the electrical machinery 1450 r/min rotational speeds, fall to the 6r/min rotational speed, the reduction gear ratio achieve 1:241. To feed quantity range of variation which matches with the main axle is big. This is one of this design difficulties. The designer root uses from the headstock adopts the cutting velocity, through the gear box speed change, to feed quantity which must match with the lathe, thus has solved this problem.

In line with “economy, practical” the principle of design, this design basis lathe finishing and the roughing various requirement, has designed two kind of different to feed quantities. And selected to various part of designs has carried on the detailed computation and the proof, the organization simplifies, the layout was compact, the frugal material, reduced the cost.

Keywords Special-purpose lathe Wheel Blank Speed Change Design

目 录

1. 引言 1

2. 课题背景 1

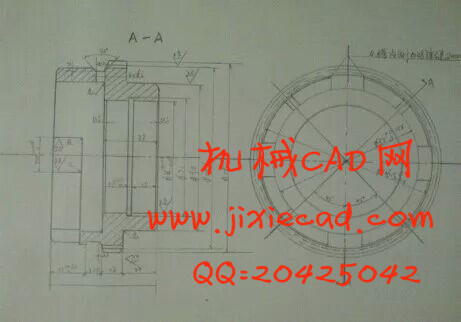

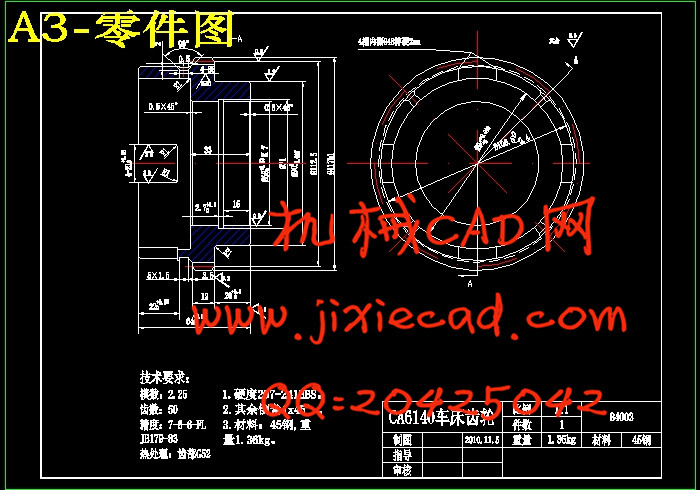

3. 车床齿轮特点 4

4. 齿轮加工机床和齿轮加工方法 5

5. 零件加工工艺设计 6

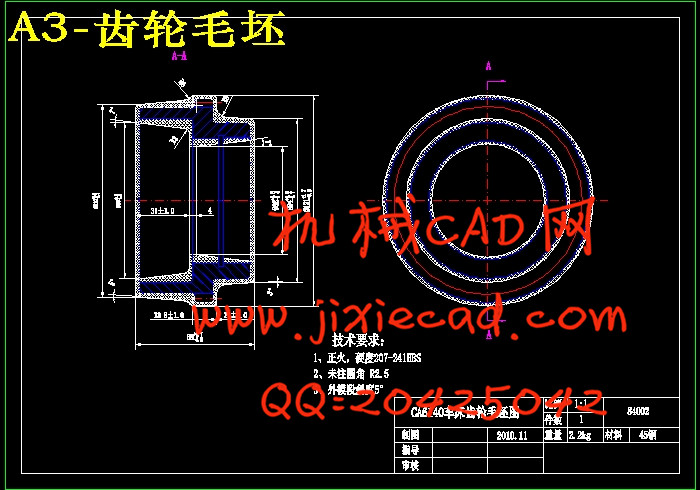

5.1 选择毛坯的尺寸 6

5.1.1 审查零件的工艺性 6

5.1.2 主要技术要求 6

5.1.3 加工表面的尺寸及要求 6

5.1.4 零件的材料 7

5.2 选择毛坯的形状、尺寸、公差. 7

5.3 定位基准的选择 7

5.4 零件表面加工方法的选择 8

5.5 制订工艺路线 8

5.6 确定工序机械加工余量、工序尺寸及公差 13

5.7 选择机床设备及工艺装备, 16

6. 填写工艺文件 16

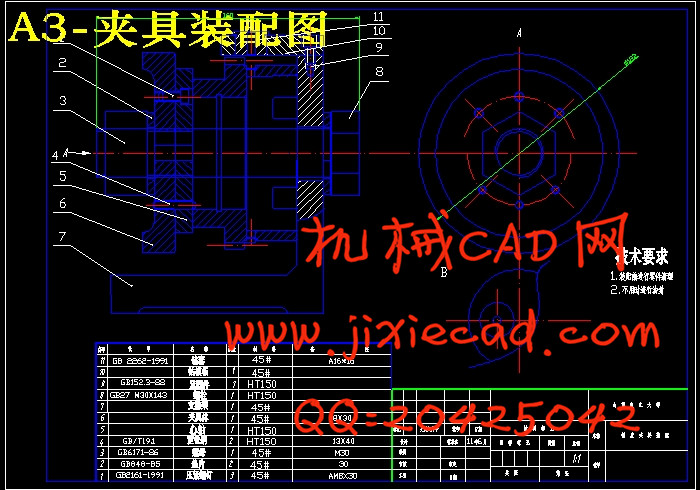

6.1 设计任务 16

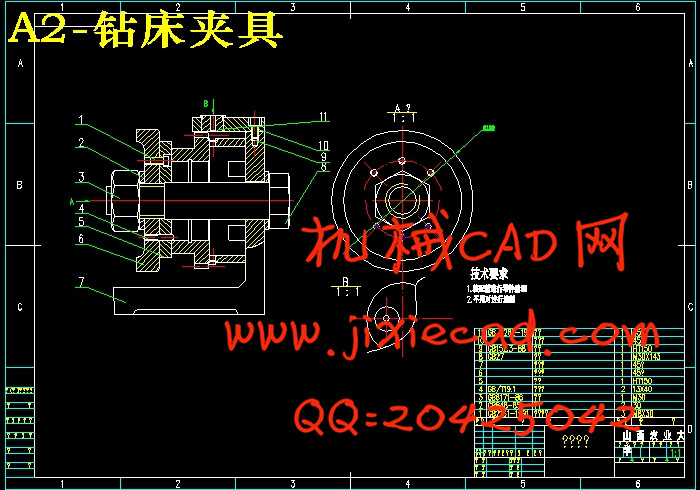

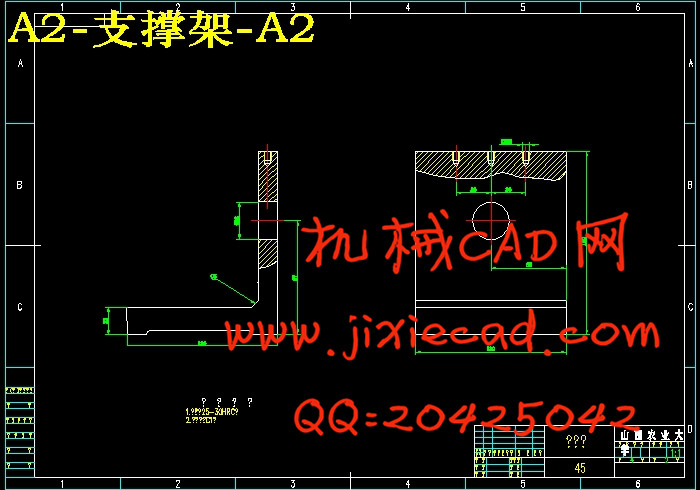

6.2 确定定位方案、选择定位元件 16

6.3 夹紧机构的选择与设计 17

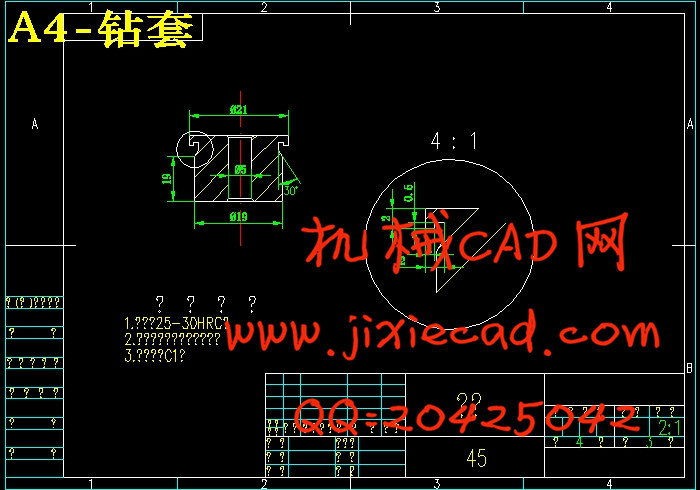

6.4 对刀装置的选择 17

6.5 夹具在机床上的定位与夹紧 17

结论 18

参考文献 19

致谢 20

摘要 制造业是一个国家经济发展的重要支柱,其发展水平标志着该国家的经济实力、科技水平、生活水准和国防实力。而制造业的生产能力主要取决于制造装备——机床的先进程度。

进给变速系统设计是Φ1500㎜毛坯专用车床研制课题的一部分。车床进给系统由进给变速箱,溜板箱等组成。根据任务书要求,车床主轴的转速分为两个区,高速区和低速区。高速区转速介于60 r/min-160r/min;低速区速度的介于6 r/min-16r/min。从电机1450 r/min的转速,降到6r/min的转速,减速比达到1:241。与主轴相匹配的进给量变化范围较大。这是本设计难点之一。设计者采用从主轴箱第三轴采取主轴转速信息,通过进给箱和溜板箱变速,得与车床所需相匹配的进给量,从而解决了这个问题。

本着“经济,实用”的设计原则,本设计根据精车和粗车的不同要求,设计了两种不同的进给量。对各部分的设计及选用进行了详细的计算和论证,机构简单,布局紧凑,节约了材料,降低了成本,利于安装和维修,完成了设计任务。

关键词 专用车床 齿轮毛坯 变速系统 设计

Design on processing of gear for CA6140 lath with the main process equipment

Abstract

The manufacturing industry is a national economic development major pillar, its level of development symbolizes this national economic potentiality, the technical level, the level of living and the national defense strength. But manufacturing industry productivity is mainly decided by the manufacture equipment -- engine bed's advanced degree.

This design isΦ1500㎜ the gear blank special-purpose lathe to feed speed change system design. The lathe to feed system module by to feed gear box, the apron and so on is composed. According to the project description request, the lathe main axle's rotational speed divides into two areas, high speed area and low speed area. The high speed area rotational speed is situated between 60--160r/min; The low speed area speed is situated between 6--16r/min. From the electrical machinery 1450 r/min rotational speeds, fall to the 6r/min rotational speed, the reduction gear ratio achieve 1:241. To feed quantity range of variation which matches with the main axle is big. This is one of this design difficulties. The designer root uses from the headstock adopts the cutting velocity, through the gear box speed change, to feed quantity which must match with the lathe, thus has solved this problem.

In line with “economy, practical” the principle of design, this design basis lathe finishing and the roughing various requirement, has designed two kind of different to feed quantities. And selected to various part of designs has carried on the detailed computation and the proof, the organization simplifies, the layout was compact, the frugal material, reduced the cost.

Keywords Special-purpose lathe Wheel Blank Speed Change Design

目 录

1. 引言 1

2. 课题背景 1

3. 车床齿轮特点 4

4. 齿轮加工机床和齿轮加工方法 5

5. 零件加工工艺设计 6

5.1 选择毛坯的尺寸 6

5.1.1 审查零件的工艺性 6

5.1.2 主要技术要求 6

5.1.3 加工表面的尺寸及要求 6

5.1.4 零件的材料 7

5.2 选择毛坯的形状、尺寸、公差. 7

5.3 定位基准的选择 7

5.4 零件表面加工方法的选择 8

5.5 制订工艺路线 8

5.6 确定工序机械加工余量、工序尺寸及公差 13

5.7 选择机床设备及工艺装备, 16

6. 填写工艺文件 16

6.1 设计任务 16

6.2 确定定位方案、选择定位元件 16

6.3 夹紧机构的选择与设计 17

6.4 对刀装置的选择 17

6.5 夹具在机床上的定位与夹紧 17

结论 18

参考文献 19

致谢 20