设计简介

平面铣削自动夹具设计

摘 要

本论文主要阐述了液压夹具的设计,液压技术是机械设备中发展速度最快的技术之一。特别是近年可与微电子、计算机技术相结合、使液压技术进入了一个新的发展阶段。目前,已广泛应用在工业各领域。由于近年来微电子、计算机技术的发展,液压元器件制造技术的进一步提高,使液压技术不仅在作为一种基本的传统形式上占有重要地位而且以优良的静态、动态性能成为一种重要的控制手段。本文首先介绍液压系统工作原理,说明液压夹具的特点。然后分析工件加工工序和加工特点,确定夹具功能, 分析工件的定位和夹紧要求,确定定位方案和夹紧方案;分析工件的定位和夹紧要求,确定定位方案和夹紧方案;确定夹具结构,确定夹紧机构(液压夹紧)方案;分析液压系统工作过程,设计其功能;设计液压系统原理图;设计计算液压系统主要参数,即液压泵工作压力、流量,电动机功率,溢流阀、顺序阀等的调定压力值等。

关键词:液压系统,液压夹紧,液压缸,液压夹具

Automatic face milling fixture design

Abstract

This paper mainly expounds the design of hydraulic clamp, hydraulic technology is one of the fastest growing technology in mechanical equipment. Especially in recent years and microelectronics, computer technology combined, so that the hydraulic technology has entered a new stage of development. At present, has been widely used in various industrial fields. Due to the development of microelectronics, computer technology in recent years, hydraulic components manufacturing technology to further improve, so that the hydraulic technology not only plays an important role in as a basic form of traditional and good static and dynamic performance, has become an important means of control.This paper first introduces the working principle, hydraulic system, and explains the characteristics and advantages of hydraulic clamp. Then analysis the workpiece machining process and machining characteristics, determine the fixture function, analysis of positioning and clamping the workpiece requirements, determine the positioning and clamping scheme; analysis of positioning and clamping the workpiece requirements, determine the positioning and clamping scheme; determine the fixture structure, determine the clamping mechanism (hydraulic clamping) scheme; analysis of the hydraulic system of the working process, the design schematic diagram of hydraulic system; design; design and calculation of main parameters of hydraulic system, namely the pump working pressure, hydraulic flow, motor power, relief valve, sequence valve set pressure value.

Keywords: hydraulic system, hydraulic clamping, hydraulic cylinder, hydraulic fixture

目 录

平面铣削自动夹具设计 I摘 要 I

Abstract II

目 录 III

1.1 液压系统工作原理 5

1.2 液压系统的优缺点 5

1.3液压夹具的特点和优势 6

第2章 夹具结构设计 8

2.1 分析加工工序和加工特点,确定夹具功能 8

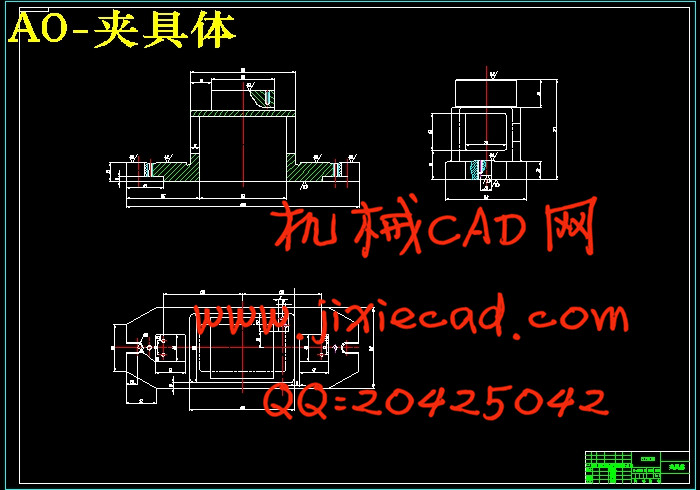

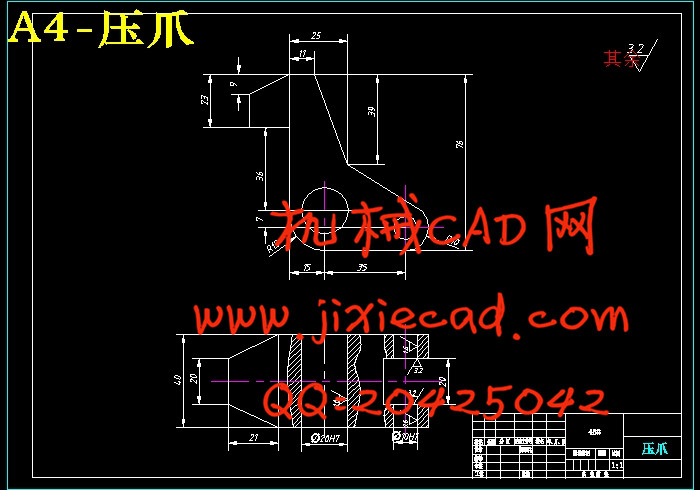

2.2确定夹具结构,确定夹紧机构(液压夹紧)方案 10

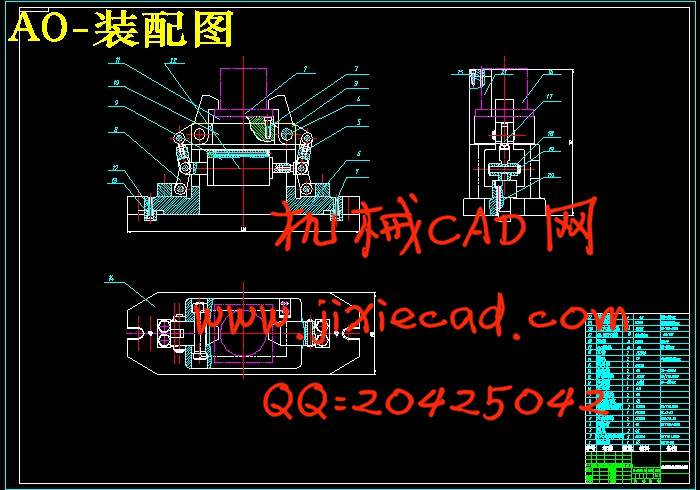

2.3设计夹具装配图 12

2.5 对刀块设计与选用 13

第3章 液压夹紧系统设计 14

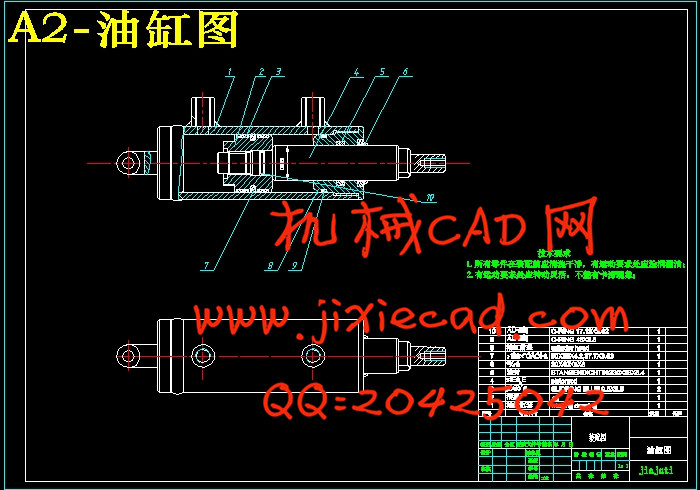

3.2液压缸设计 16

3.2.1液压缸设计计算 16

3.2.2液压缸工作压力设定 16

3.2.3确定系统工作压力 16

3.2.4确定液压缸的尺寸 17

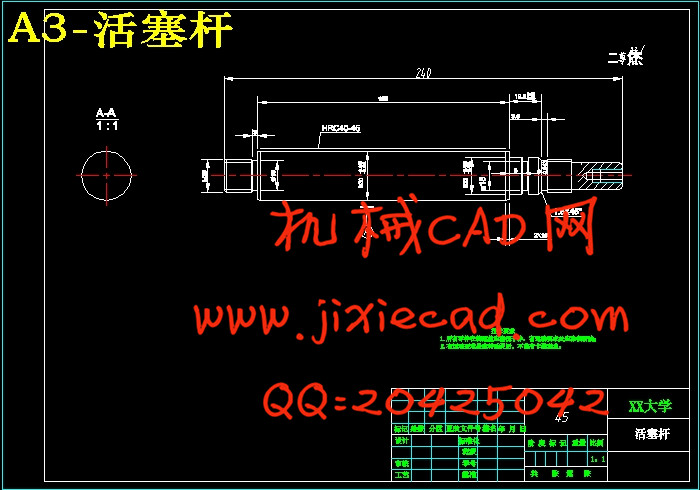

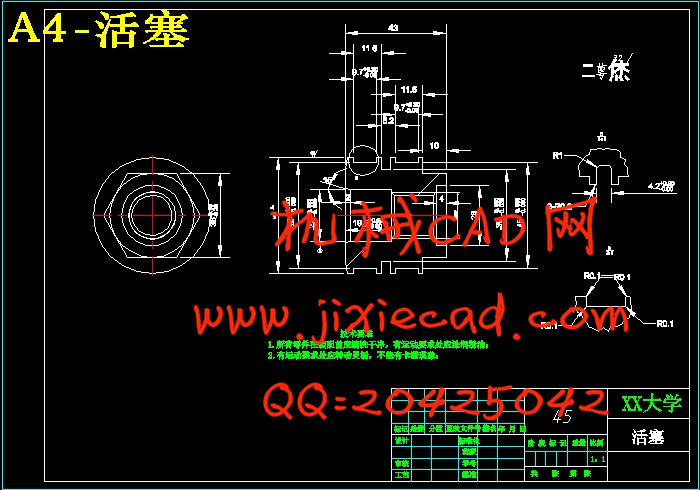

3.3 活塞的设计 19

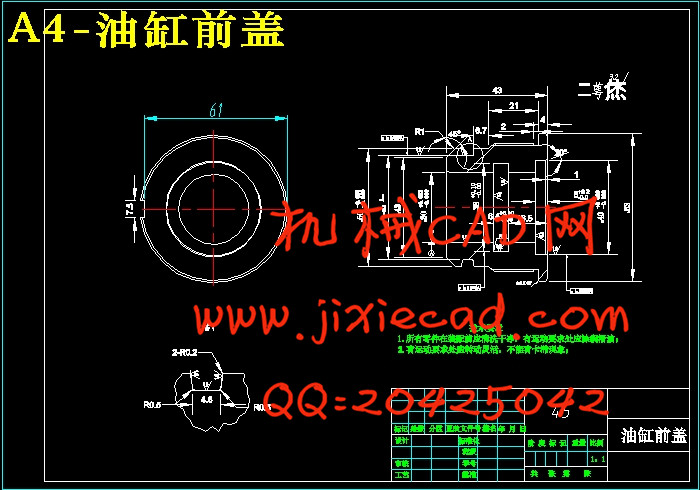

3.4液压缸缸盖设计 20

3.5 导向套的设计与计算 21

3.6 端盖和缸底的设计与计算 23

3.7 缸体长度的确定 24

3.8液压系统方案设计 24

3.8.1确定液压泵类型及调速方式 24

3.8.2选用执行原件 24

3.8.3换向回路和压力回路的选择 24

3.8.4组成液压系统绘原理图 24

3.8.5 负载图与速度图的绘制 25

第4章 液压元件的选择 26

4.1液压泵的选择 26

4.2电动机的选择 26

4.3 阀类元件及辅助元件 27

4.4油箱的容积计算 27

第5章 液压系统性能的运算 29

5.1 压力损失和调定压力的确定 29

5.2 油液温升的计算 30

结论和展望 32

参考文献 33

致谢 34