设计简介

摘 要

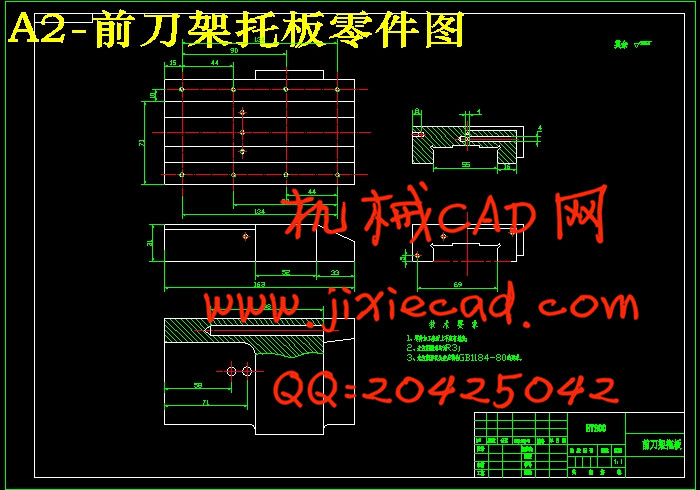

本课题来源于车床前刀架拖板零件的生产制造。本课题要求对车床前刀架拖板零件进行合理的工艺规程设计,包括零件每一道工序的选用设备、切削刀具、切削用量、定位方式等,并要求绘出工序图。另外要求对车床前刀架拖板工艺规程设计及翻转式钻摸进行夹具设计。其目的是把所学的机械制造工艺,金属切削原理及工艺装备设计基础知识与计算机辅助设计方法结合起来,加强理论知识并锻炼实践和动手的能力。为培养学生独立的分析问题和解决问题的能力打下良好的基础。

在课题的研究设计阶段,针对该零件的结构特点,制定加工工艺;深入理解了夹具的相关知识,结合零件的结构特点选择需要的夹具元件,设计出夹具的整体结构

关键词:工件定位 夹具设计 CAD

Abstract

This subject comes from the front turret lathe carriage parts manufacturing. The requirements on the knife carriage parts process planning reasonable lathe, selection of equipment, including parts of every process of the cutting tool, cutting, positioning, and drawing process. In addition to the front tool lathe carriage process design and fixture design of rotary drilling touch. The purpose is to make the manufacturing process of the mechanical, metal cutting principle and process equipment design basic knowledge and method of computer aided design combine to strengthen the theoretical knowledge and practical ability and training. A good foundation for the ability of independent analysis and problem solving problems the students lay.

The research topics in the design phase, according to the structure characteristics of the parts, make the process; understand the relevant knowledge of fixture, with parts of the structural features of fixture components need, design the overall structure of the fixture

Keywords: positioning of the workpiece and fixture design CAD

本课题来源于车床前刀架拖板零件的生产制造。本课题要求对车床前刀架拖板零件进行合理的工艺规程设计,包括零件每一道工序的选用设备、切削刀具、切削用量、定位方式等,并要求绘出工序图。另外要求对车床前刀架拖板工艺规程设计及翻转式钻摸进行夹具设计。其目的是把所学的机械制造工艺,金属切削原理及工艺装备设计基础知识与计算机辅助设计方法结合起来,加强理论知识并锻炼实践和动手的能力。为培养学生独立的分析问题和解决问题的能力打下良好的基础。

在课题的研究设计阶段,针对该零件的结构特点,制定加工工艺;深入理解了夹具的相关知识,结合零件的结构特点选择需要的夹具元件,设计出夹具的整体结构

关键词:工件定位 夹具设计 CAD

Abstract

This subject comes from the front turret lathe carriage parts manufacturing. The requirements on the knife carriage parts process planning reasonable lathe, selection of equipment, including parts of every process of the cutting tool, cutting, positioning, and drawing process. In addition to the front tool lathe carriage process design and fixture design of rotary drilling touch. The purpose is to make the manufacturing process of the mechanical, metal cutting principle and process equipment design basic knowledge and method of computer aided design combine to strengthen the theoretical knowledge and practical ability and training. A good foundation for the ability of independent analysis and problem solving problems the students lay.

The research topics in the design phase, according to the structure characteristics of the parts, make the process; understand the relevant knowledge of fixture, with parts of the structural features of fixture components need, design the overall structure of the fixture

Keywords: positioning of the workpiece and fixture design CAD

目 录

前 言 1

第一章 车床前刀架拖板零件分析 3

1.1 拖板零件分析 3

1.2毛坯的设计 4

1.3 车床前刀架拖板零件的特点 4

第二章 前刀架拖板的机械加工工艺规程 5

2.1前刀架拖板的加工方法的选择 5

2.2前刀架拖板零件的机械加工工艺规程 5

2.2.1工艺规程的作用 5

2.2.2生产类型的确定 6

2.3前刀架拖板零件加工工艺过程的设计 6

2.3.1定位基准的选择 6

2.3.2加工顺序的安排 6

2.3.3前刀架拖板加工工艺过程的确定 7

2.4工序设计 7

2.4.1工时定额的计算 7

2.4.2机床的选择 7

2.4.3工艺装备的选择 8

2.4.4加工余量及工序尺寸的确定 8

2.4.5具体工序计算 8

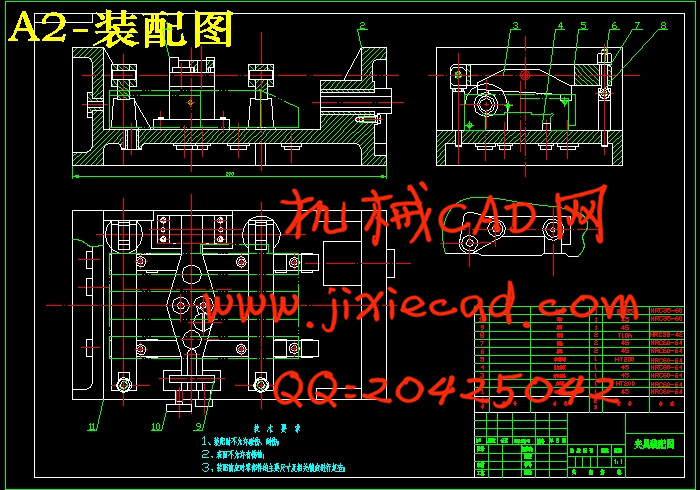

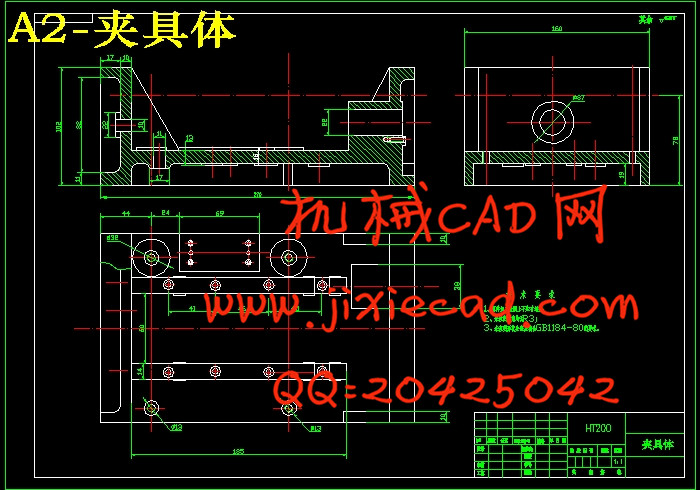

第三章 前刀架拖板翻转式钻模夹具设计 17

3.1夹具的设计要求 17

3.2定位方案和定位元件 17

3.3定位误差分析 18

3.3.1 定位误差的计算 19

3.3.2 夹紧力计算 20

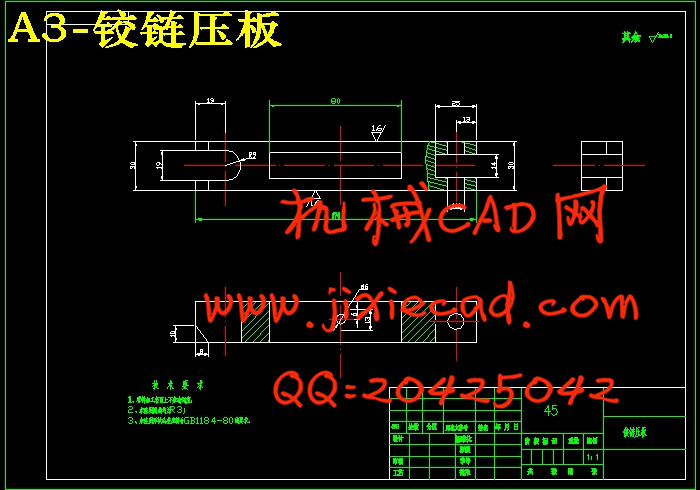

3.3.3 夹紧机构的设计 21

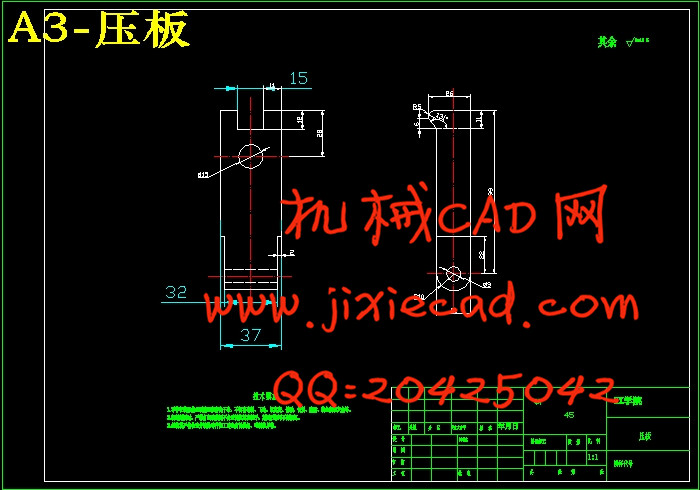

3.4 钻套、衬套、钻模板设计与选用 22

3.5 确定夹具体结构尺寸和总体结构 24

3.6 夹具设计及操作的简要说明 25

结论 26

致谢 27

参考文献 28