设计简介

摘 要

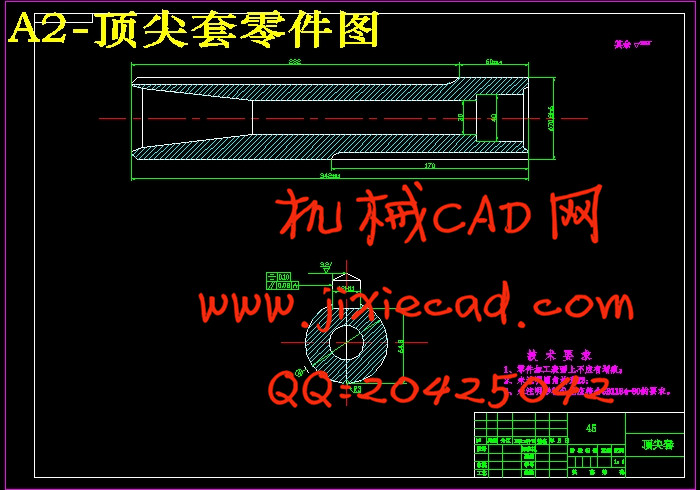

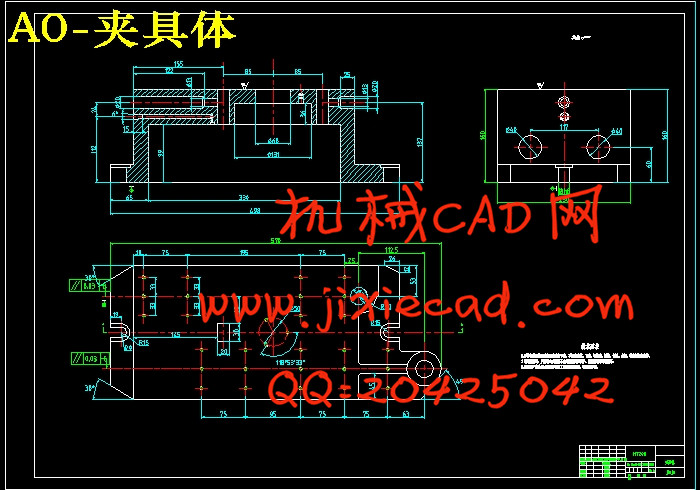

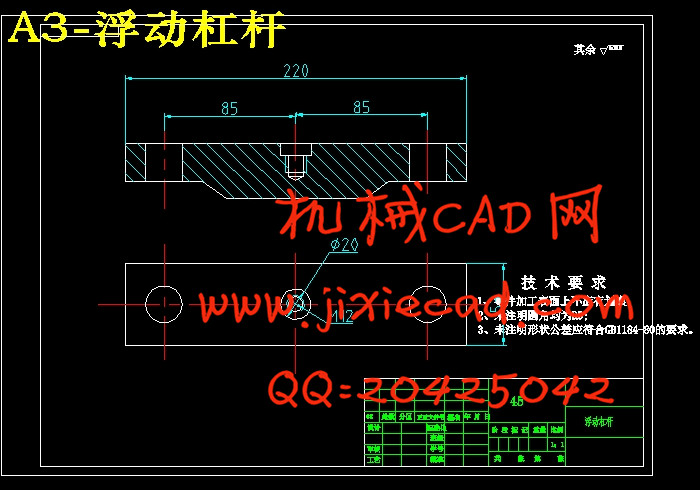

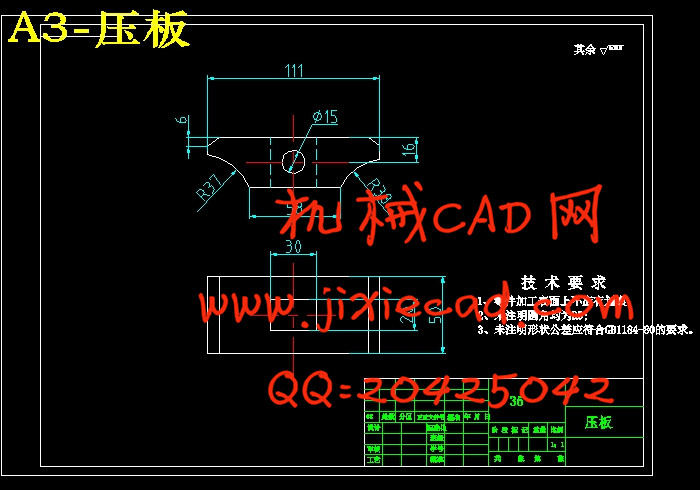

顶尖套零件加工工艺及钻床夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。关键词:工艺,工序,切削用量,夹紧,定位,误差

Abstract

Parts and fittings drilling fixture design process includes parts machining process design, process design, and special fixture design three parts. In the process of designing the parts to be the first analysis to understand the parts of the process re-design the structure of the blank, and select the machining datum good parts, the design process route parts; then the part of each step of the process to calculate the size of a key is to determine the technical equipment and cutting the amount of each process; then dedicated fixture design, select the design of the various components of the fixture, such as positioning elements, clamping elements, guiding element, clamp connections and machine parts and other components; positioning error generated when calculating the fixture, analytical rationality and inadequacies fixture structure and attention to improving the design in the future.Keywords: technology, processes, cutting the amount of clamping, positioning error

目 录

摘 要 2

Abstract 2

1 序言 4

2 零件的分析 4

2.1零件的作用 4

2.2零件的工艺分析 5

3 机械加工工艺规程制定 5

3.1 确定毛坯的制造形式 5

3.2 选择定位基准 5

3.3 选择加工方法 5

3.4 制定工艺路线 6

3.5 确定加工余量及毛坯尺寸 6

3.6 工序设计 7

3.7 确定加工用量及基本时间 9

4夹具的设计 18

4.1设计步骤 18

4.2设计要点 19

4.3初定夹具结构方案 20

4.4铣床尾座顶尖套双槽夹具设计 21

4.4.1零件本工序的加工要求分析 21

4.4.2拟订定位方案 21

4.4.3定位误差计算 21

总结 23

参 考 文 献 24

致谢 25