设计简介

摘 要

变速箱(transmission)是汽车传动系统的主要组成之一。汽车的实际使用情况非常复杂,如起步、怠速停车、低速或高速行驶、加速、减速、爬坡和倒车等,这就要求汽车的驱动力和车速能在相当大的范围内变化,而目前广泛采用的活塞式发动机的输出转矩和转速变化范围较小。为了适应经常变化的行驶条件,同时使发动机在有利的工况下(功率较高、油耗较低)工作,在传动系统中设置了变速箱。本次设计的主要内容是汽车变速箱加工工艺及铣平面和钻孔夹具的设计,本文的研究重点在于通过对汽车变速箱的工艺性和力学性能分析,对加工工艺进行合理分析,选择确定合理的毛坯、加工方式、设计高效、省力的夹具,通过实践验证,最终加工出合格的汽车变速箱体。

关键词:变速箱,传动系统,加工工艺,工装夹具,

Abstract

Transmission (transmission) is one of the main components of automobile transmission. Actual use of the car is very complicated, such as start, stop idling, low speed or high speed, acceleration, deceleration, such as climbing and reverse, which requires vehicle drivers and vehicle speed in a large range of changes, and now widely used in piston engine output torque and low speed range. In order to adapt to constantly changing driving conditions, while the engine in the favorable conditions (higher power, lower fuel consumption) work, set the transmission in the transmission system. and the entering the giving amount of the lathe, cut depth .This topic abat the rotational speed of the main shaft and speed of cutting, the jig of this process, the cutter and measuring tool, a one hundred sheets of number of times still leaves and a one hundred sheets of length leaves, calculate basic time of this process , auxiliary time and service time of place of working finally.

Key word: Transmission, processing technology, fixture, positioning reference

目 录

摘要……………………………………………………………………………………………...3

绪论……………………………………………………………………………………………...4

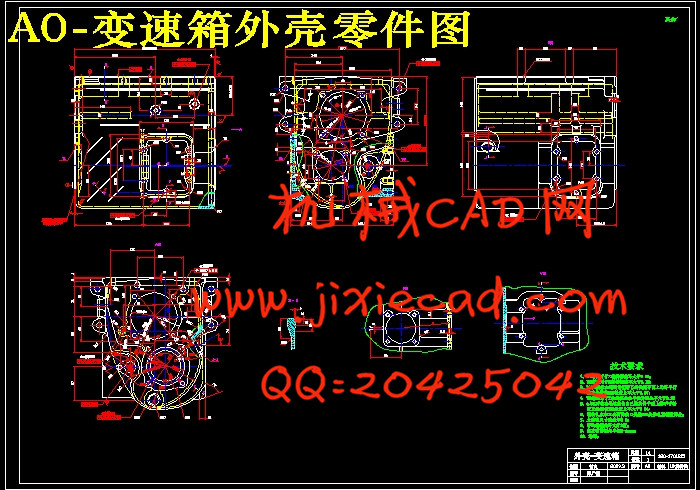

1、零件的分析……………………………………………………………..…………......5

1.1、零件的作用……………………………………………………………………………5

1.2、零件的技术要求…………………………………………………...............................5

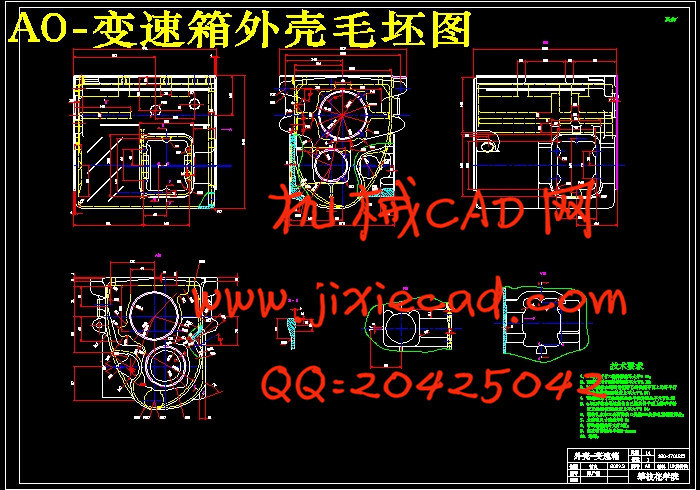

2、确定毛坯、画毛坯—零件合图………………………………..........................9

2.1、确定毛胚的制造形式及材料……………………………………........................9

2.2、机械加工余量、工序尺寸及毛坯尺寸的确定…………………..............9

2.3、选择加工设备及刀、夹、量具……………………………………..................14

3、夹具设计…………………………………………………………....................................14

3.1、定位基准的选择………………………………………………................................14

3.2、定位元件………………………………………………….. …….................................15

3.3、切削力及夹紧力的计算…………………………………. ………......................16

3.4加工工序设计...................................................................................................................8

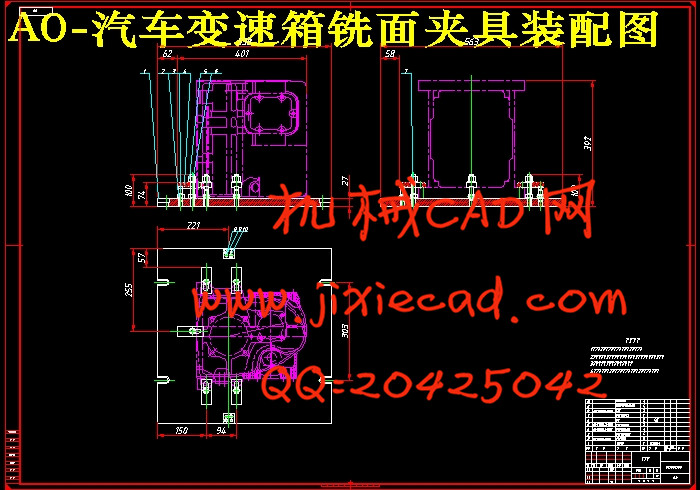

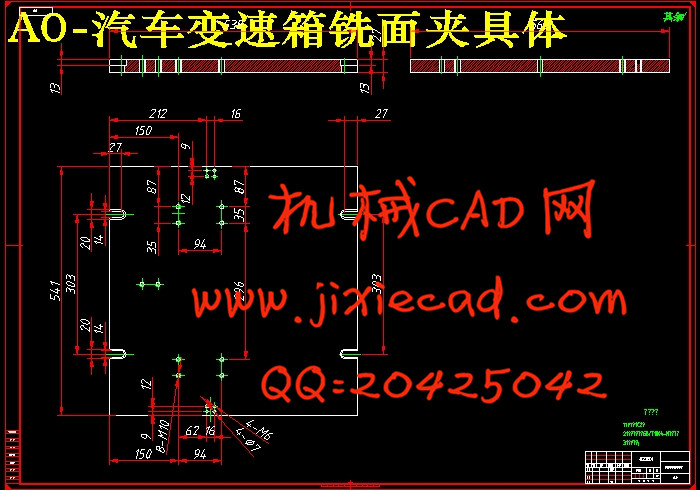

4、铣面夹具设计.................................................................................................................8

4.1定位基准的选择..............................................................................................................8

4.2切削力的计算与夹紧力分析……………………………………….....................31

4.3定位误差的分析………………………………………................................................33

4.4夹具设计简要操作说明………………………………………................................33

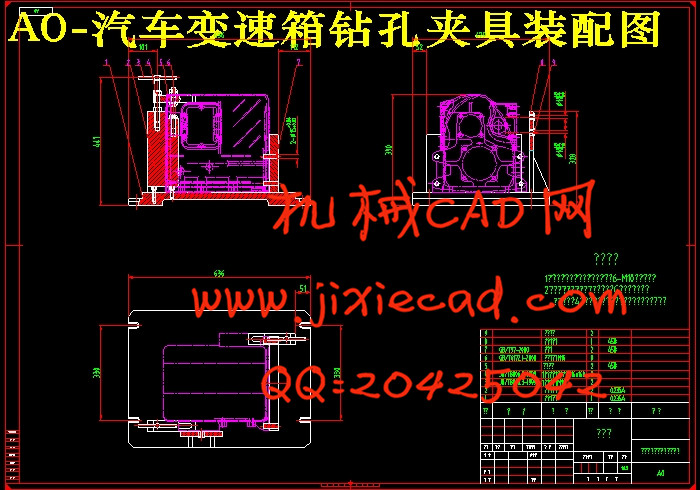

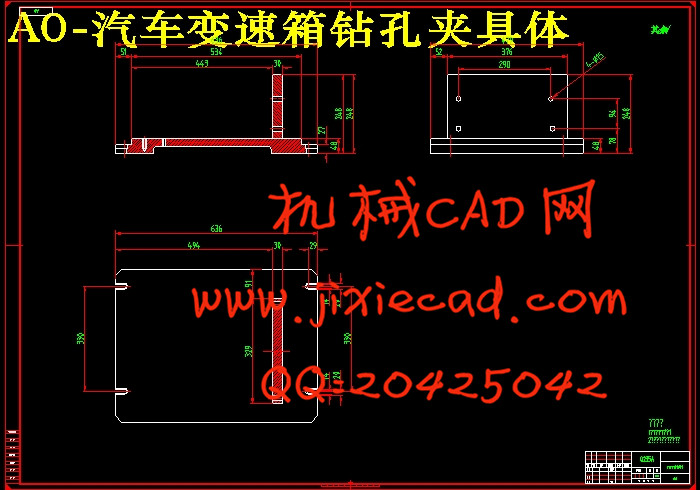

5、钻孔夹具设计………………………………………...................................................33

5.1定位基准的选择……………………………………….............................................33

5.2定位元件的设计……………………………………….............................................33

5.3 切削力及夹紧力的计算………………………………………............................33

5.4 钻、衬套及钻模板的设计……………………………………….......................33

5.5 夹具定位误差分析……………………………………….......................................33

小结…………………………………………………………………………………………....38

致谢………………………………………………………………………………………........39

参考文献………………………………………………………………………………….....40